Shaft milling key slot fixture

A technology for milling keyways and fixtures, applied in clamping, milling machine equipment, manufacturing tools, etc., can solve the problems of time-consuming and laborious operation, reduce work efficiency, inconvenience, etc., and achieve high clamping stability, high positioning accuracy, reliability and accuracy The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

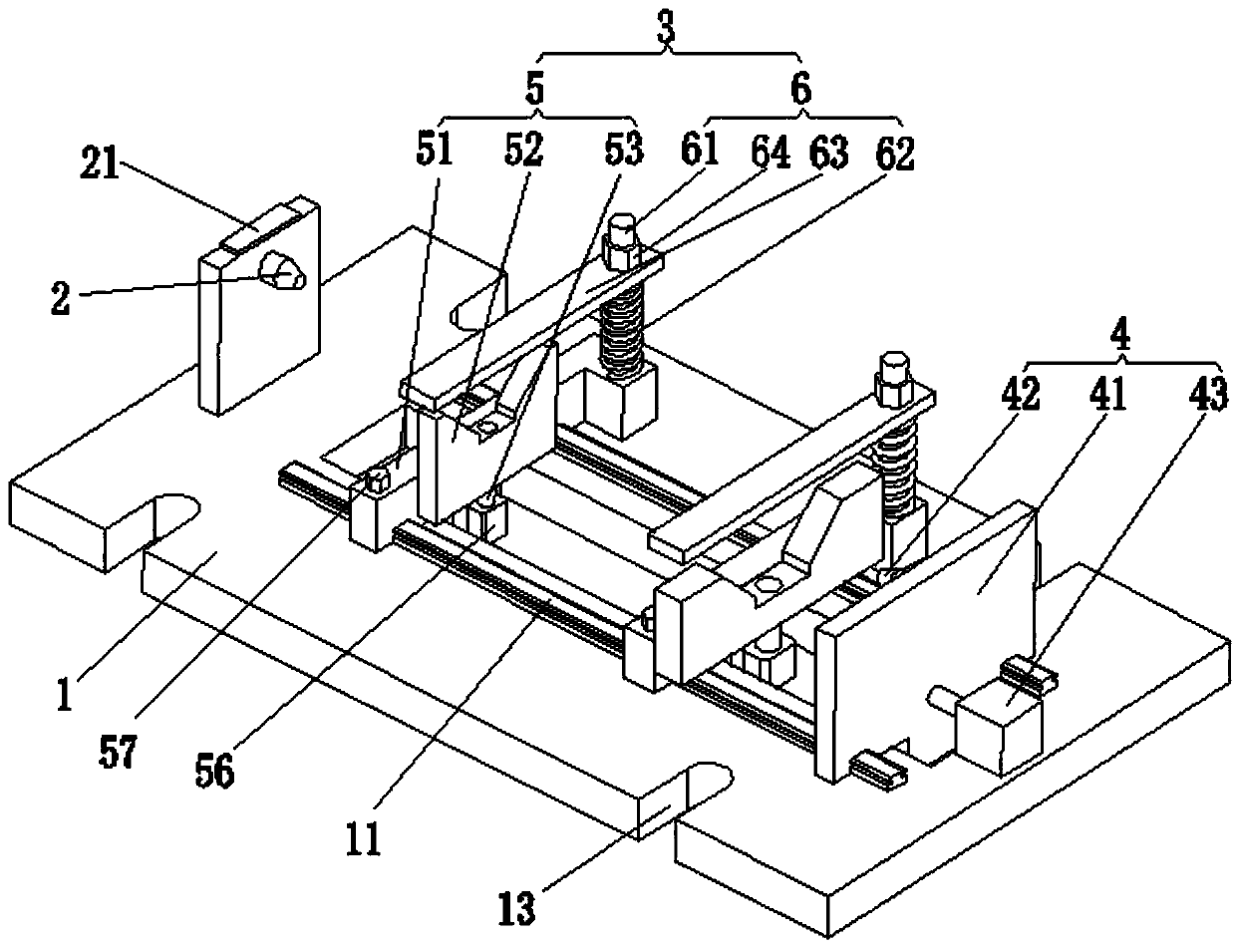

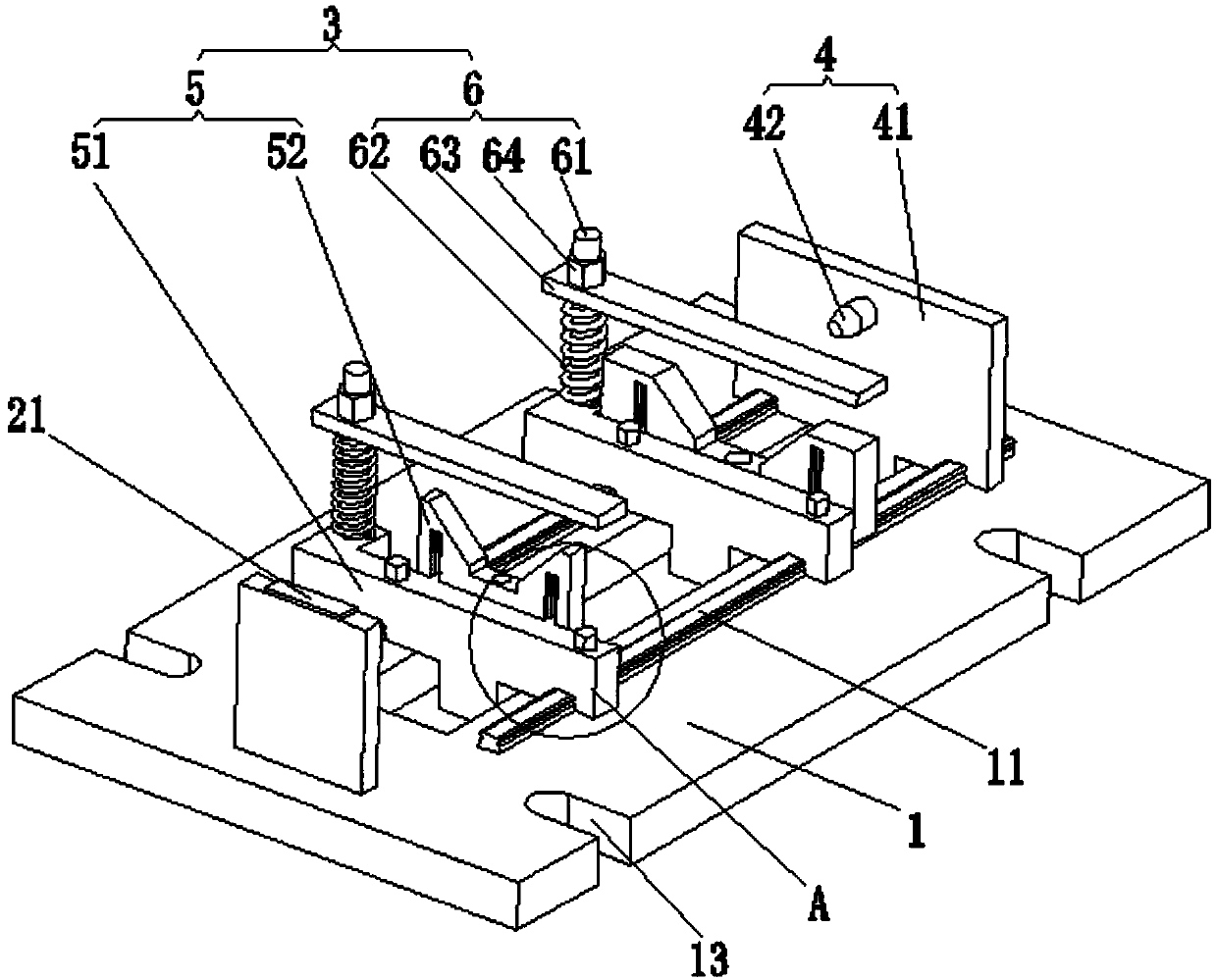

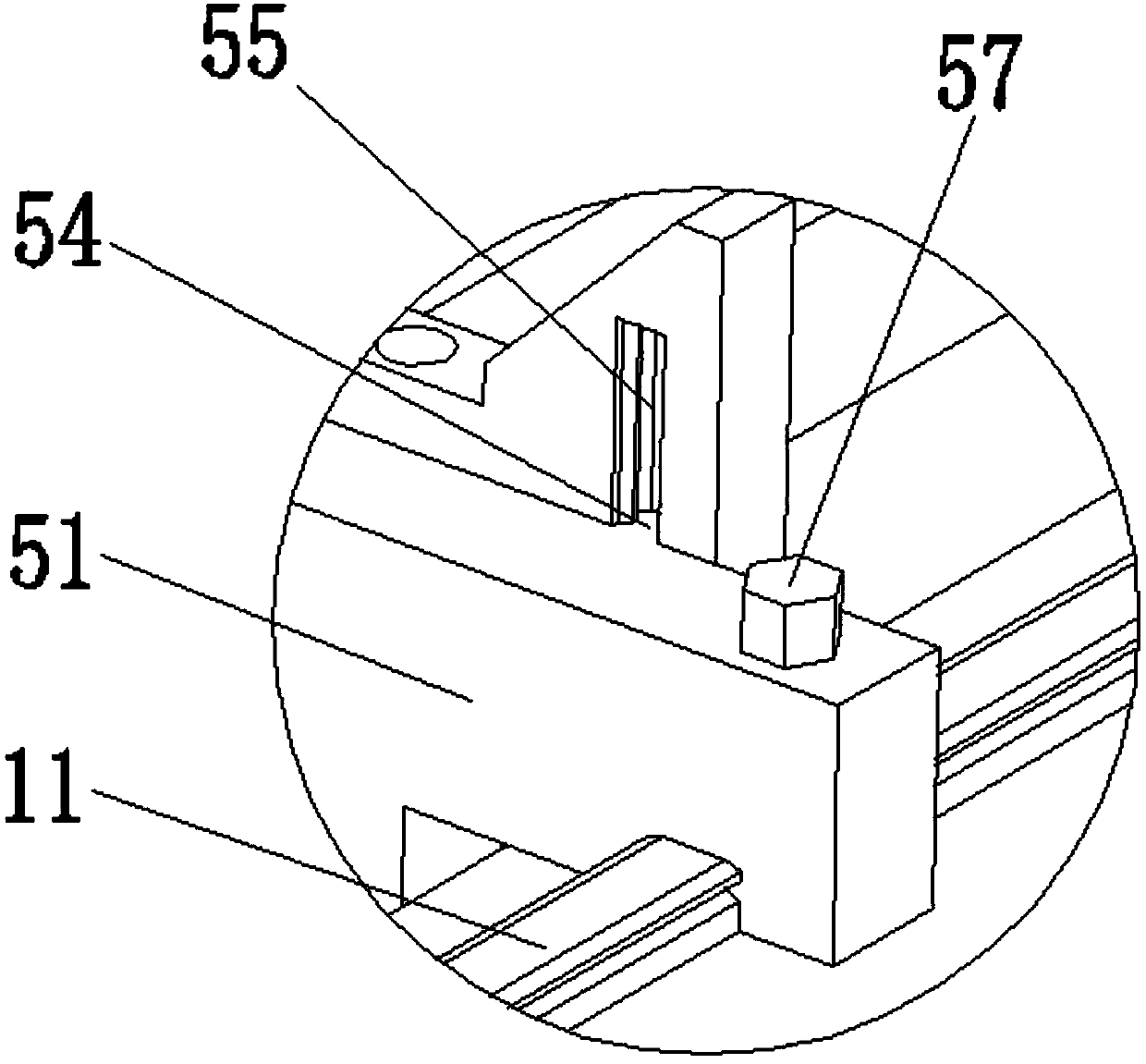

[0017] A jig for machining key grooves of a rotating shaft according to the present invention, as attached Figure 1-3 As shown, it includes a bottom plate 1, a static thimble 2 sequentially arranged on the bottom plate 1 in the axial direction, two V-shaped positioning mechanisms 3 and a moving thimble assembly 4; the four corners of the bottom plate 1 are respectively provided with installation grooves 13; The lower end of the static thimble 2 is fixedly connected to the bottom plate 1 by screws; the moving thimble assembly 4 includes a support base 41, a moving thimble 42 and a driving device 43; the support base 41 is slidably connected to the connection base plate 1, so The driving device 43 controls the support seat 41 to drive the thimble 42 to move axially; the front ends of the static thimble 2 and the moving thimble 42 are all in the shape of a flat cone, and their axis lines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com