Batch-type flexible printing device

An intermittent, flexographic printing technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as waste, tediousness, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

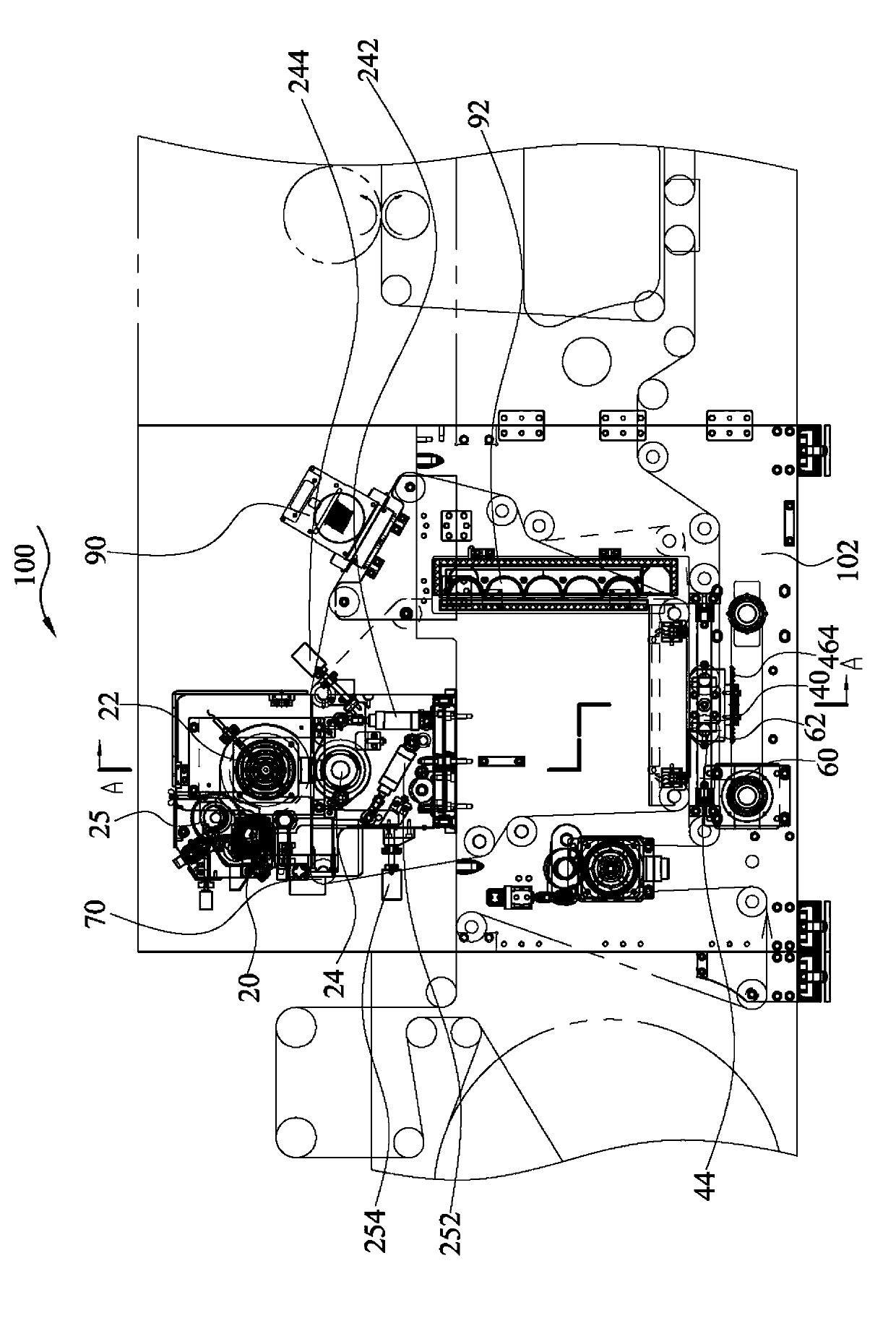

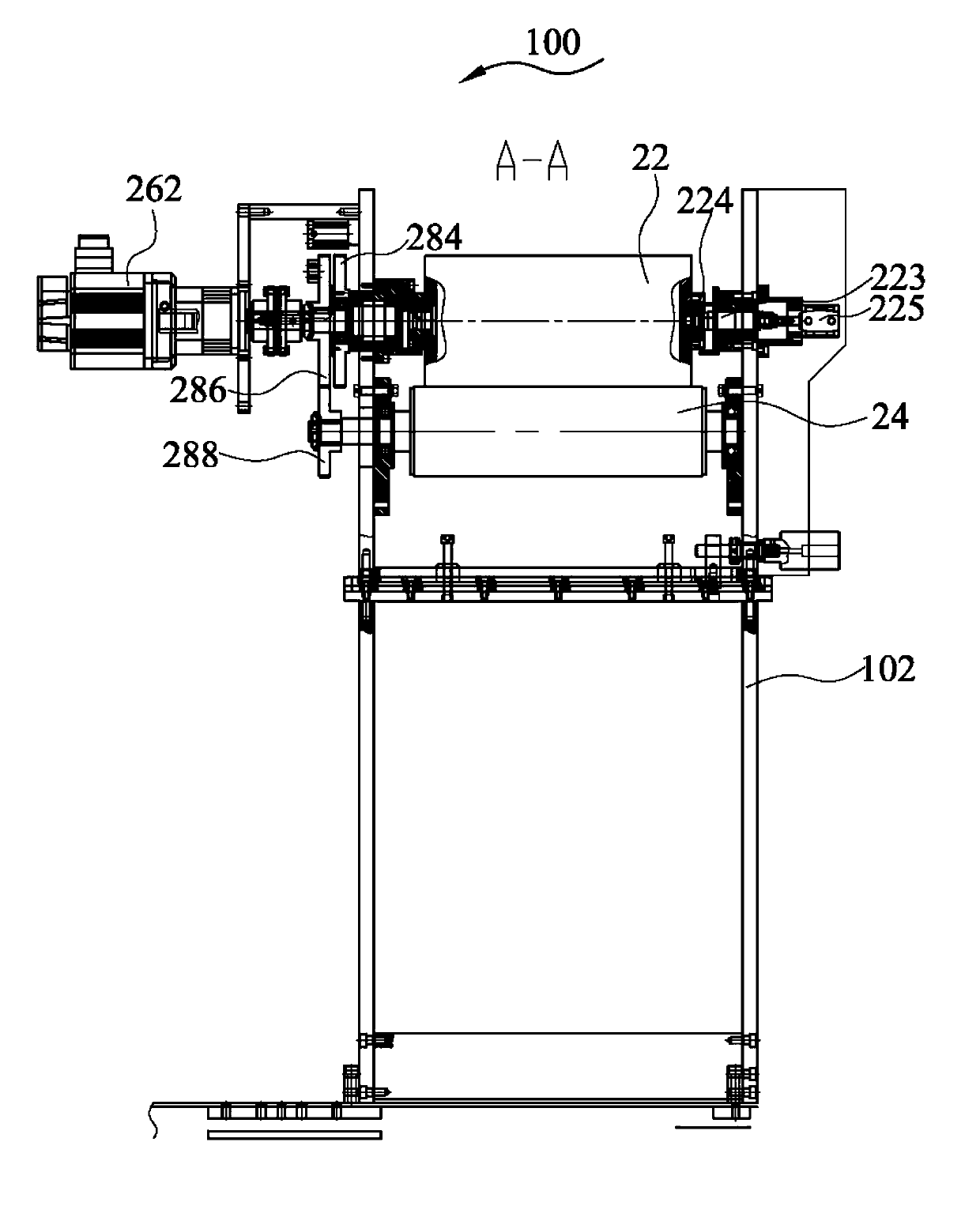

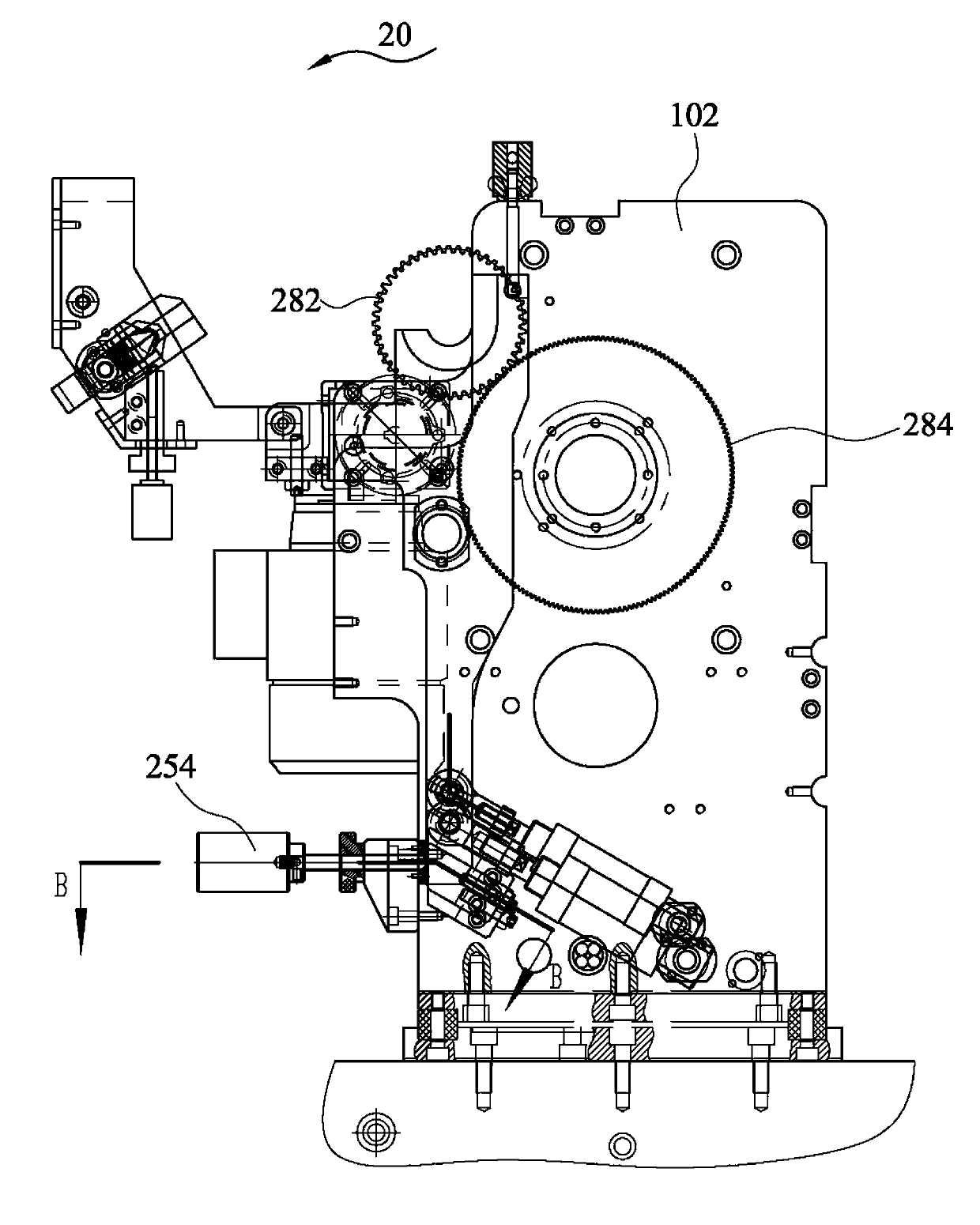

[0023] Such as Figure 1 to Figure 6 As shown, the intermittent flexo printing equipment 100 according to an embodiment of the present invention includes: a frame 102 and an intermittent flexo printing unit 20 arranged on the frame 102 .

[0024] The substrates of the intermittent flexo printing equipment 100 in this embodiment are fed through the feeding device arranged at the front station, and are received at the same time through the receiving device arranged at the rear station. The feeding device transports the substrate to the intermittent flexo printing equipment 100 of this embodiment for printing through the intermittent flexo printing unit 20 .

[0025] The intermittent flexo printing unit 20 of this embodiment includes: a printing plate roller 22 and a printing roller 24 that cooperate with each other to print, and a flexo printing power element that provides driving power, and is connected with the flexo printing power element and driven by the flexo printing powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com