Construction method of anchorage anchoring system

An anchoring system and construction method technology, applied in bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems of increased flexibility of anchorage brackets, increased cumulative deformation, and cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An anchorage system construction method, including the following steps:

[0044] (1) Step 1. Construction of sunk well cover:

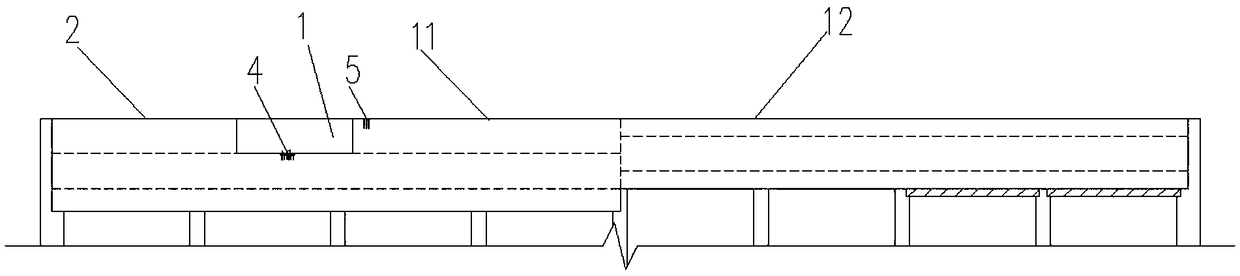

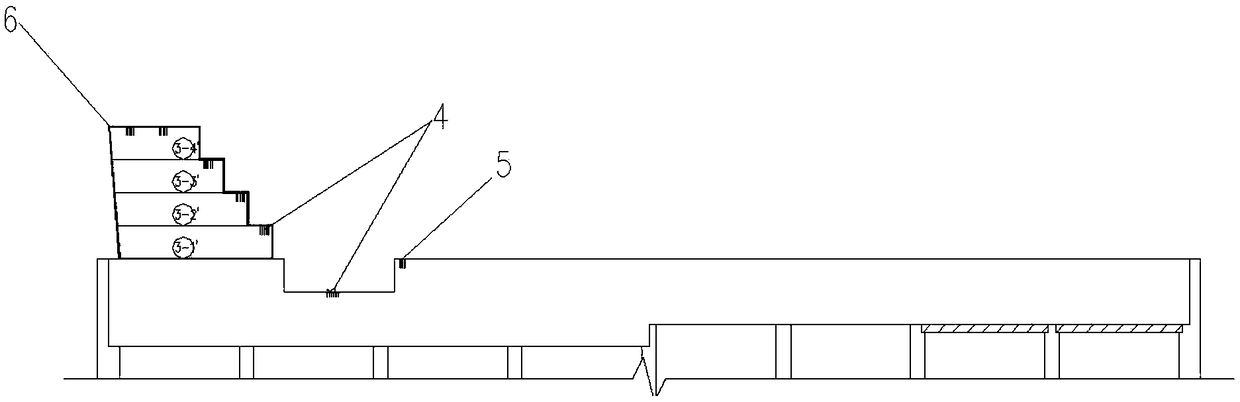

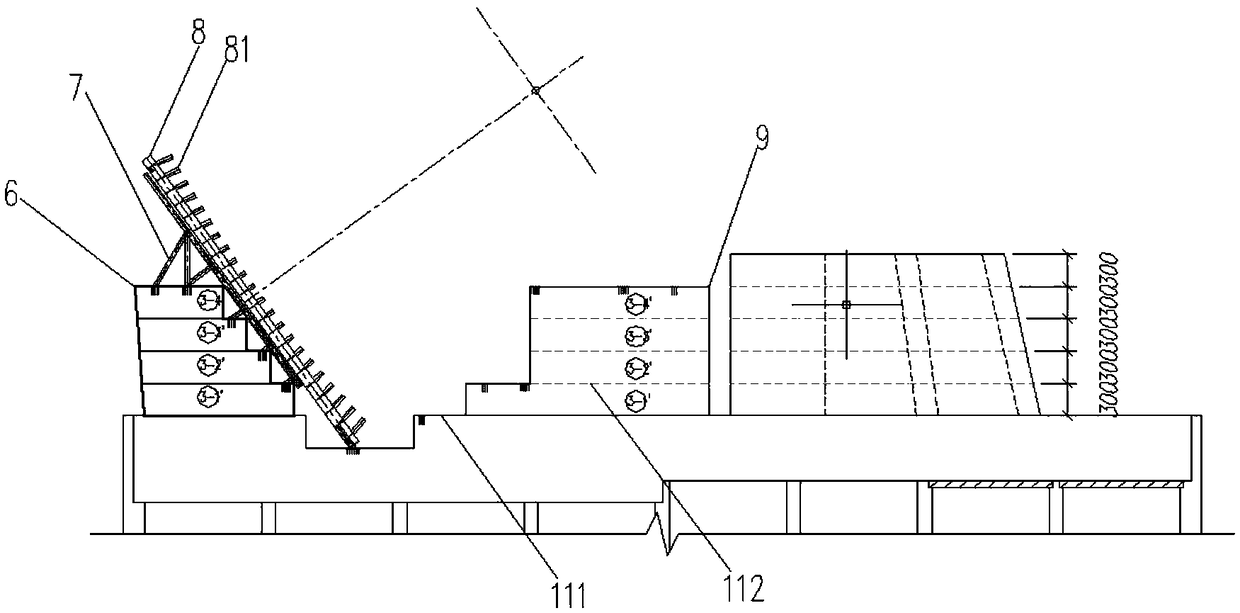

[0045] 1) Pouring the caisson well cover, reserve the anchor beam bracket installation position 1 above the poured manhole cover, such as figure 1 As shown, after the caisson cover is poured, the two sides of the anchor beam support installation site 1 are the anchor beam support step area 2 and the anchor support step area 11 respectively, and the anchor support step area 11 is divided into the middle anchor support area 111 and the step area 112 of the anchor rod bracket on the front anchor surface, such as figure 1 , 3, 4; the reserved anchor beam bracket installation site 1 distinguishes different areas after the manhole cover is poured, so as to form a hybrid support system in the later construction; in this embodiment, the method of pouring the caisson manhole cover is a technology in the art The common knowledge and common methods of personne...

Embodiment 2

[0096] Based on the above embodiment 1, as figure 1 As shown, in the first step, the caisson manhole cover is constructed, and the caisson manhole cover is poured in blocks and layers. According to the requirements of temperature control, the manhole cover is poured in blocks and layers, which can prevent the manhole cover from cracking. In this embodiment, other undescribed contents are the same as the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0098] Based on the above embodiment 1, as Figure 5-9 As shown, the anchor block concrete layer 3 has the same height except for the last layer. The height of each layer customized according to the concrete pouring template is the same. Therefore, the construction height of each layer of the anchor block concrete layer 3 is the same, and there is no need to adjust each time, which is convenient for construction. In general, the height of each floor of the customized concrete pouring formwork is 3m. In this embodiment, other undescribed contents are the same as the foregoing embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com