MVR technology-based machining emulsified wastewater treatment method

A treatment method, emulsified wastewater technology, applied in the direction of heating water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of large usage, complicated cleaning process, and heavy cleaning workload, and achieve Reduce the trouble of secondary treatment, simplify the anaerobic treatment device, and reduce the effect of investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

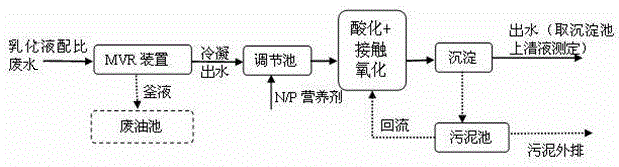

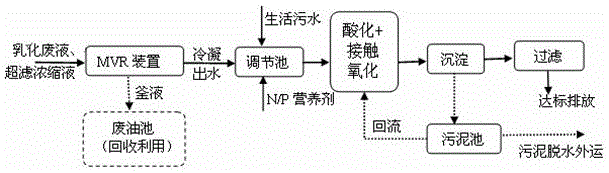

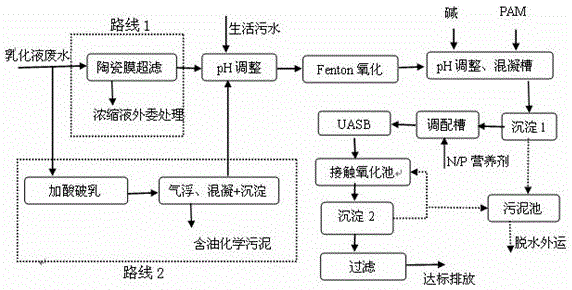

[0030] Such as figure 1 Shown, the present invention is based on the machining emulsified wastewater treatment method of MVR technology, specifically comprises the following steps:

[0031] The first step is to use MVR technology (steam mechanical recompression technology) to realize the oil-water separation of the emulsified waste liquid. The water content of the separated waste oil can be controlled within 10%, and the condensed water generated by evaporation enters the regulating tank for biochemical treatment;

[0032] The second step is biochemical nutrient deployment, that is, adding N, P and other necessary supplementary nutrients to the tank for subsequent biological treatment, so that subsequent biological treatment (anaerobic and aerobic) can be realized;

[0033] The third step, hydrolytic acidification + contact oxidation treatment

[0034] Hydrolytic acidification treatment is to convert the refractory organic matter in the original wastewater into dissolved org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com