Multi-axis glass cutting control platform and glass automatic cutting control system

A technology for glass cutting and control platform, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high labor intensity of workers, large weight deviation of glass blocks, increased glass loss, etc., to improve glass cutting quality, Improve glass cutting efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

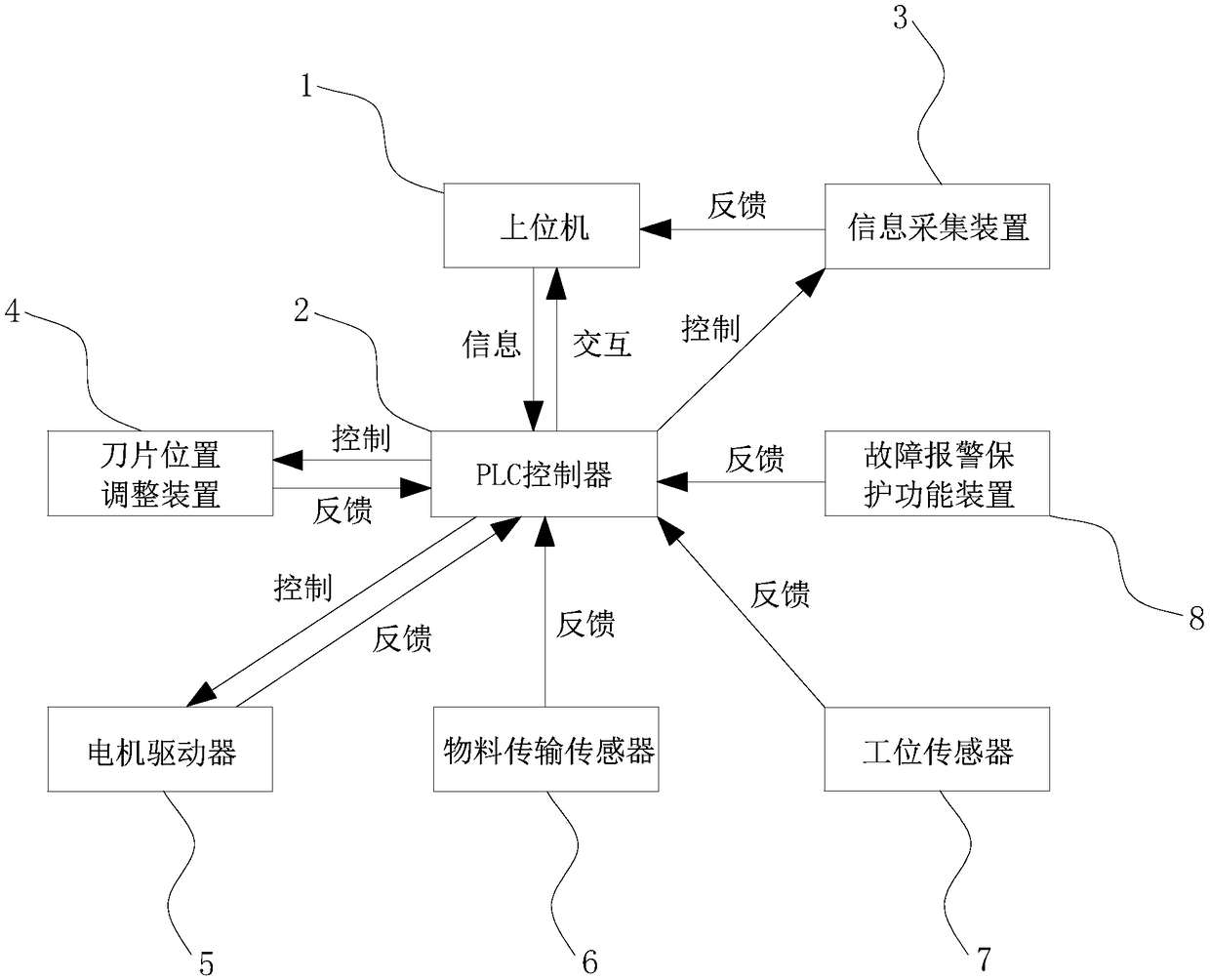

[0031] Such as figure 1 As shown, the multi-axis glass cutting control platform of the present invention includes a host computer 1, a PLC controller 2, an information collection device 3, a blade position adjustment device 4, a motor driver 5, a material transmission sensor 6, a station sensor 7 and fault alarm protection Functional device 8.

[0032] The host computer 1, PLC controller 2, information collection device 3, blade position adjustment device 4, motor driver 5, material transmission sensor 6, station sensor 7 and fault alarm protection function device 8 are all connected to an external power supply.

[0033] The upper computer 1 adopts a computer, its output end is electrically connected to the PLC controller 2 through the RS485 / 232 interface, and the input end is electrically connected to the information collection device 3; wherein, the upper computer 1 is used to run the software operation interface and image acquisition data Processing, the upper computer 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com