Part machining method for automatically obtaining dimensional tolerance

A dimensional tolerance and parts processing technology, applied in the field of parts processing that automatically obtains dimensional tolerances, can solve problems that affect the quality and efficiency of parts, search, input errors, time-consuming search processes, etc., to improve efficiency and quality, and meet engineering quality Requirements, the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The present invention avoids the problem of manual intervention in the existing three-dimensional model tolerance information labeling, conducts secondary development based on the UG environment, and establishes a suitable Tolerance classification of 3D dimensioning, and a part processing method for automatically obtaining dimensional tolerances.

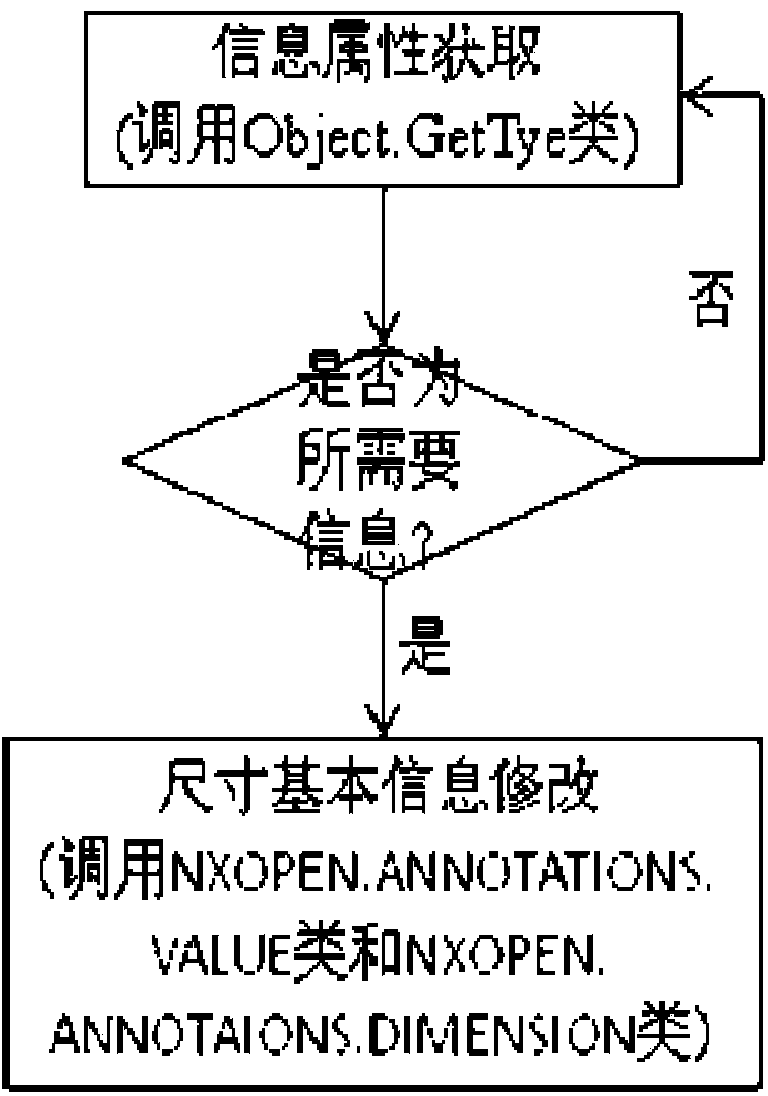

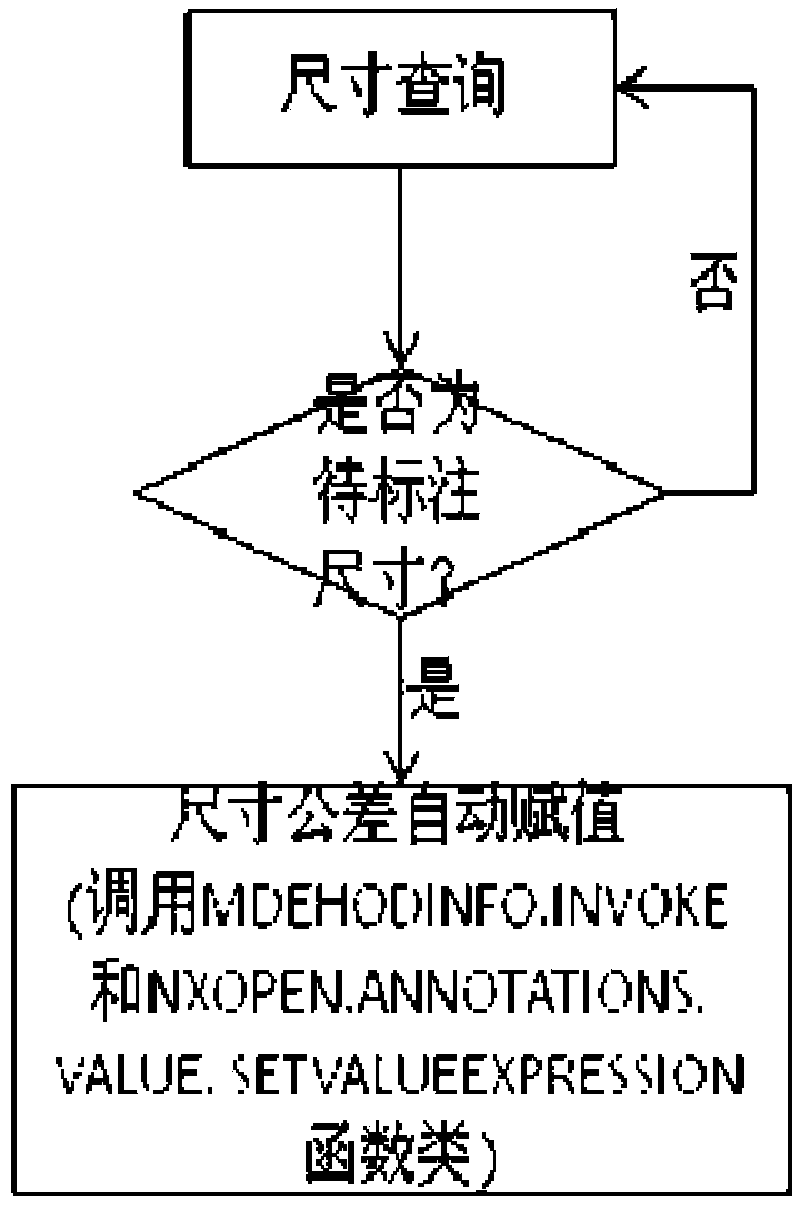

[0029] In the embodiment of the present invention, the part processing method for automatically obtaining dimensional tolerances, the method flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0030] Step 1. Establish the model of the processed part in the UG environment;

[0031] In the embodiment of the present invention, based on the UG NX7.5 platform, the Microsoft Visual Studio 2008 programming framework is applied, and the UG NX7.5 software is redevelope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com