Heating supply system hydraulic equilibrium model prediction control method and system

A model predictive control and heating system technology, applied in heating systems, heating methods, household heating, etc., can solve problems such as low efficiency and high technical requirements for operating personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

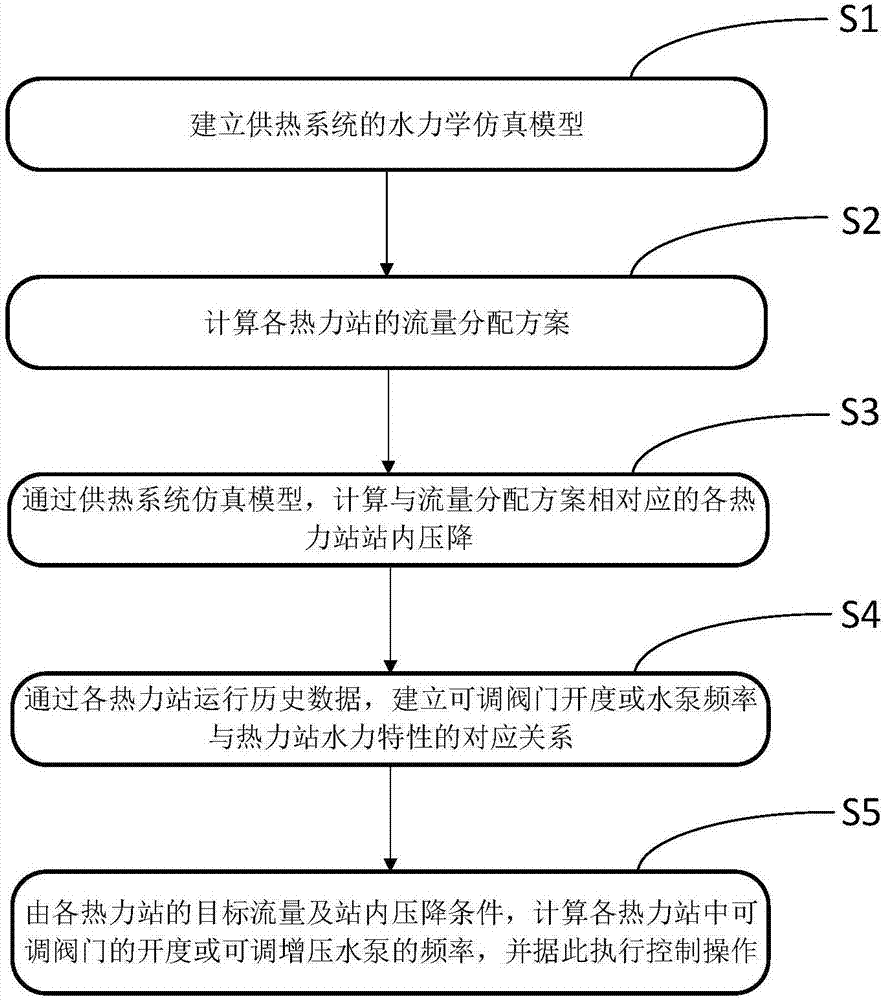

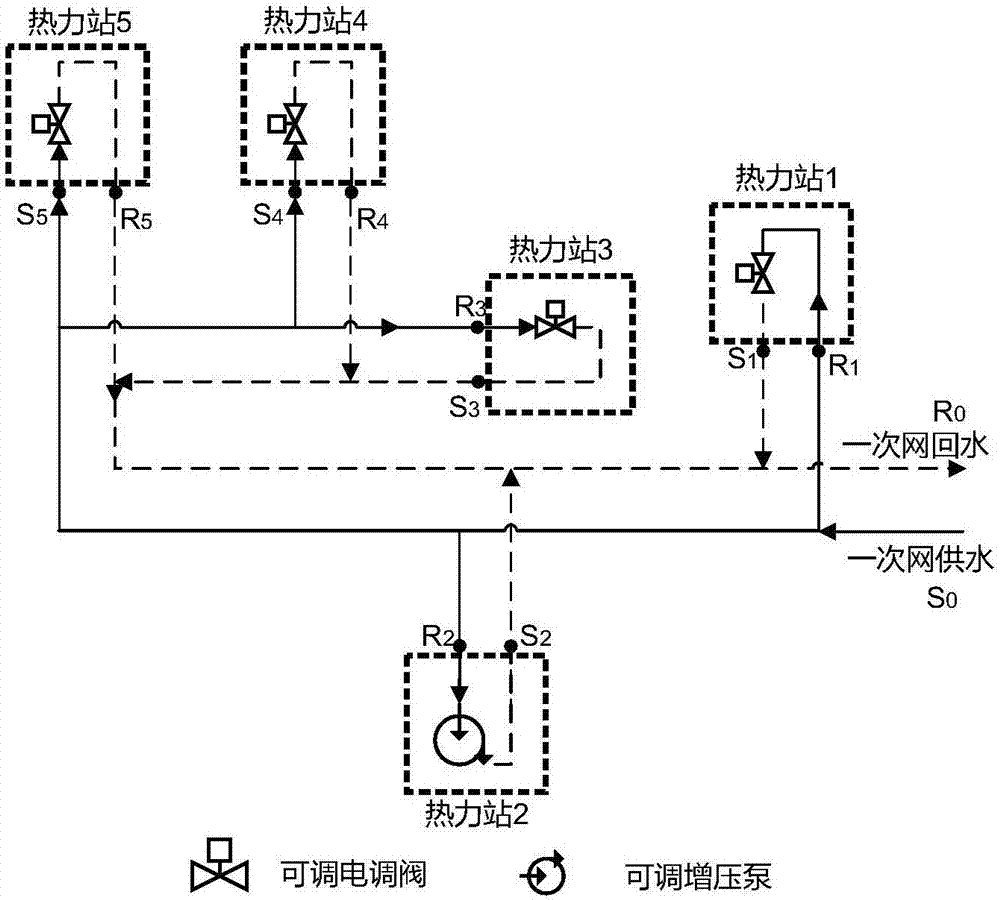

[0091] combine figure 1 and figure 2 , the model predictive control method of the hydraulic balance adjustment of the heating system of the present invention, specifically comprises the following steps:

[0092] Step S1, establishing a hydraulic simulation model of the heating system;

[0093] Step S2, calculating the flow distribution scheme of each thermal station;

[0094] Step S3, through the simulation model of the heating system, calculate the pressure drop in each heating station corresponding to the flow distribution scheme;

[0095] Step S4, establish the corresponding relationship between the adjustable valve opening or water pump frequency and the hydraulic characteristics of the thermal station through the operation history data of each thermal station; and

[0096] Step S5, calculate the opening of the adjustable valve or the frequency of the adjustable booster pump in each thermal station based on the target flow rate of each thermal station and the pressure ...

Embodiment 2

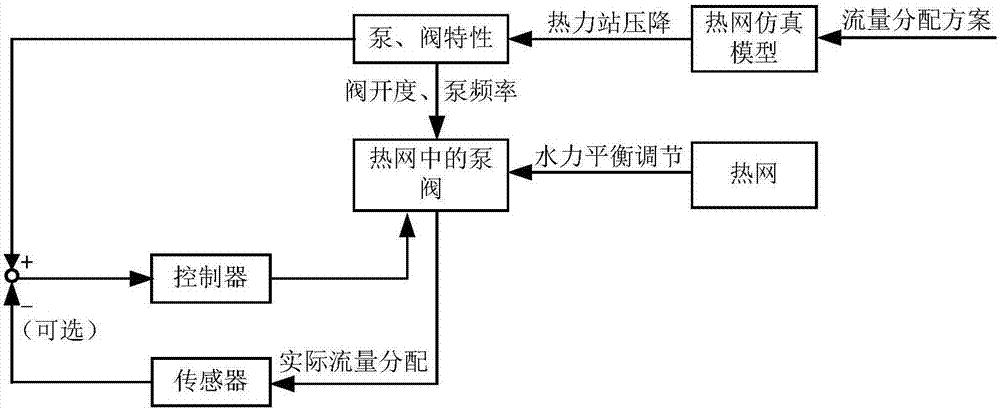

[0196] On the basis of Embodiment 1, Embodiment 2 provides a hydraulic balance control system for a heating system, including:

[0197] The model building module is used to establish the hydraulic simulation model of the heating system;

[0198] The flow distribution calculation module calculates the flow distribution scheme of each thermal station;

[0199] The pressure drop calculation module in the thermal station calculates the pressure drop in each thermal station corresponding to the flow distribution scheme through the simulation model of the heating system.

[0200]The hydraulic balance control system of the heating system also includes: a valve opening operating characteristic model and a water pump operating characteristic model building module, and through the valve opening operating characteristic model and the water pump operating characteristic model, the adjustment characteristic curve of the valve or water pump is obtained, namely According to the current flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com