Pile gripper for offshore piling

A technology of pile holding device and steel pile, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of insufficient piling safety, low piling efficiency, large size and weight, etc., so as to improve equipment safety and avoid repeated The effect of adjusting and reducing the weight of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

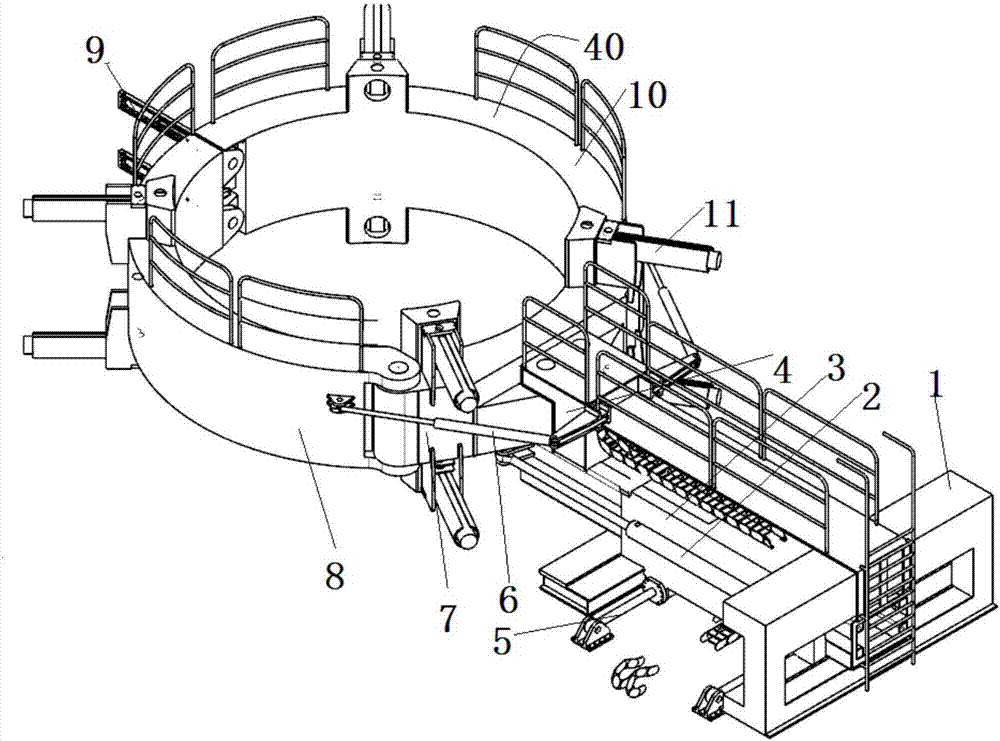

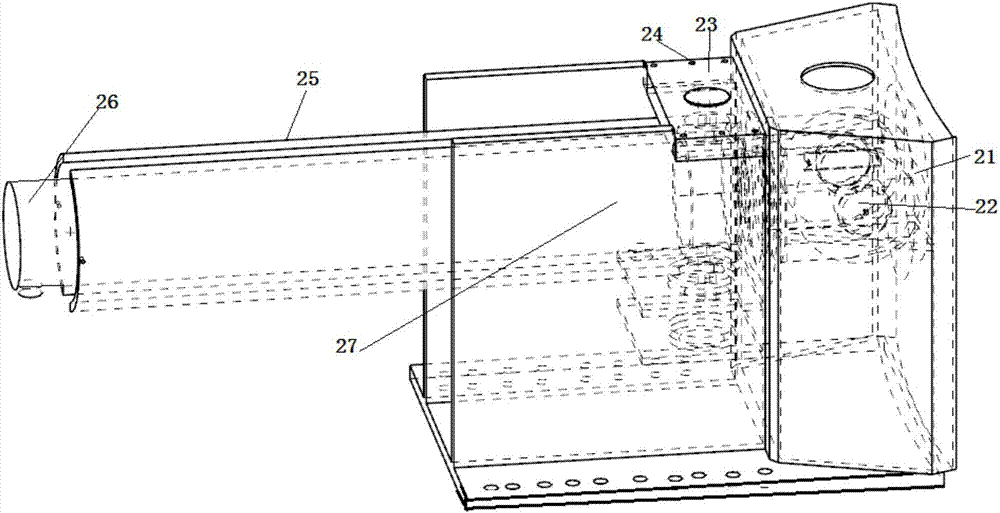

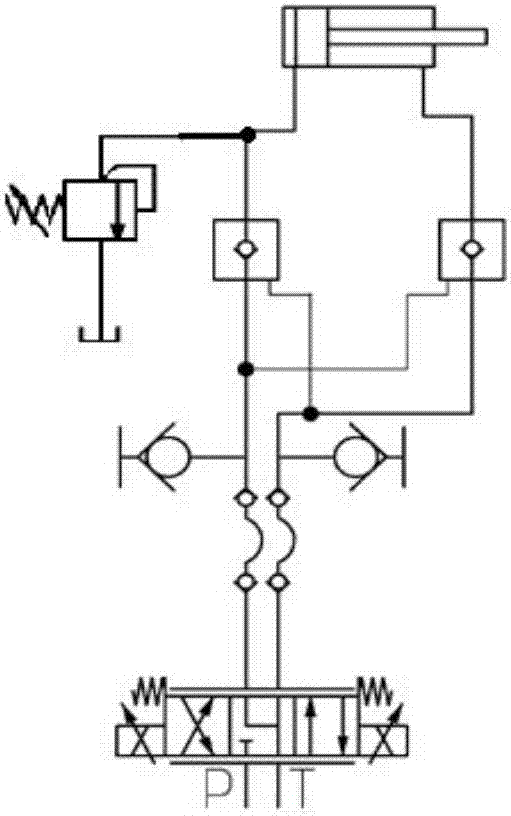

[0033] Such as Figure 1 to Figure 9 , The offshore pile driving device of the present invention is composed of three parts: a pile device mechanism system, a hydraulic system, and an electrical system.

[0034] Such as figure 1As shown, the pile holding mechanism system mainly includes: large base 1, main push cylinder 2, sliding seat 3, beam 4, side push cylinder 5, opening and closing cylinder 6, ring base 7, left ring 8, locking mechanism 9, right ring 10, holding pile clamping mechanism 11. The large base 1 is installed on the deck 13. The large base 1 is divided into two parts, the front and the rear. On the slide rail in the base, the chute in the sliding seat 3 is installed with the crossbeam 4, the side thrust cylinder 5 is installed on the mounting seat between the deck 13 and the sliding seat 3, and the main thrust cylinder 2 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com