Dual-medium carbonate rock pore-crack dual-network model construction method

A pore network model, carbonate rock technology, applied in 3D modeling, suspension and porous material analysis, image data processing, etc. Mechanism understanding and data support, the effect of improving calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

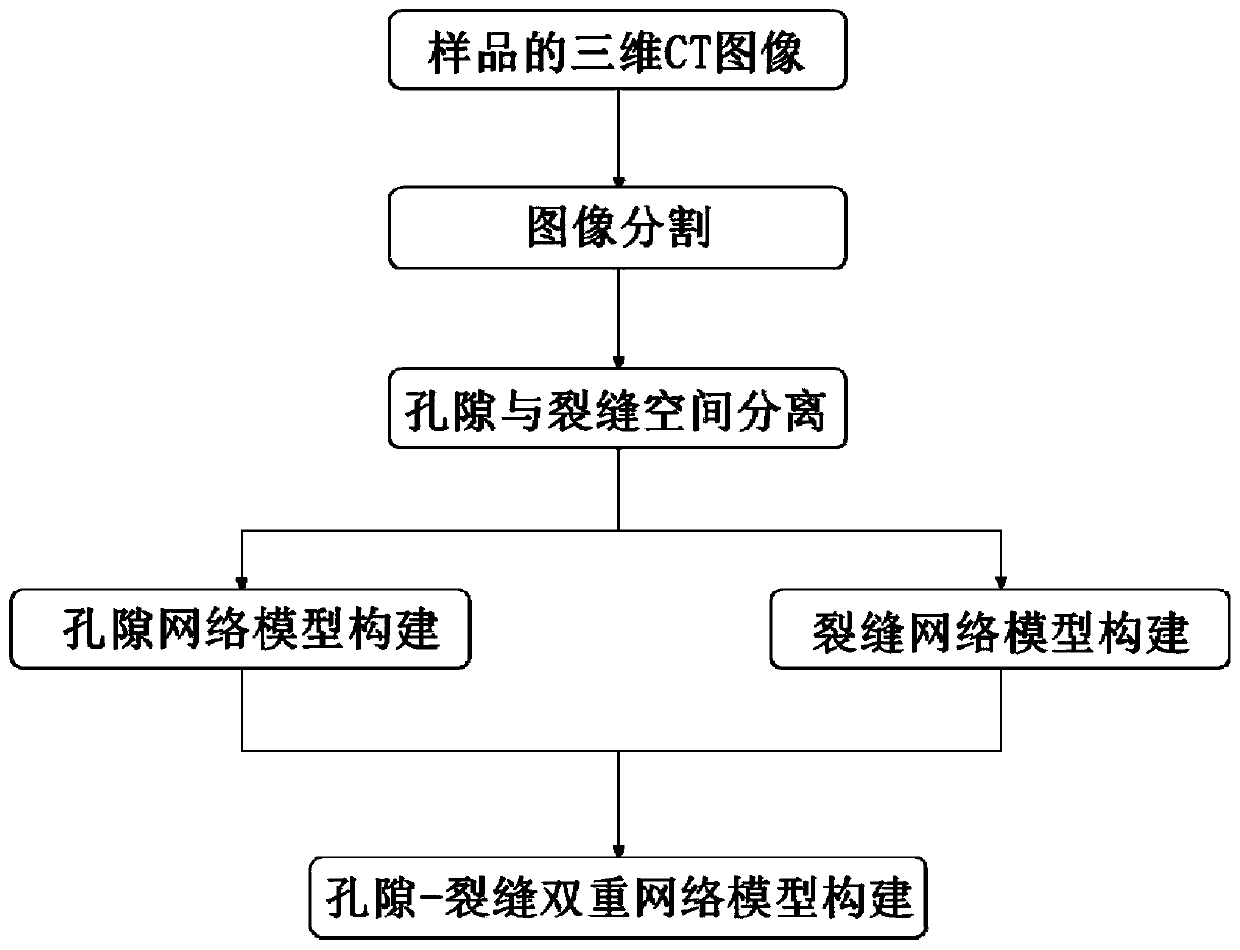

[0059] This embodiment provides a dual-medium carbonate rock pore-fracture dual network model construction method, such as figure 1 Shown:

[0060] Include the following steps:

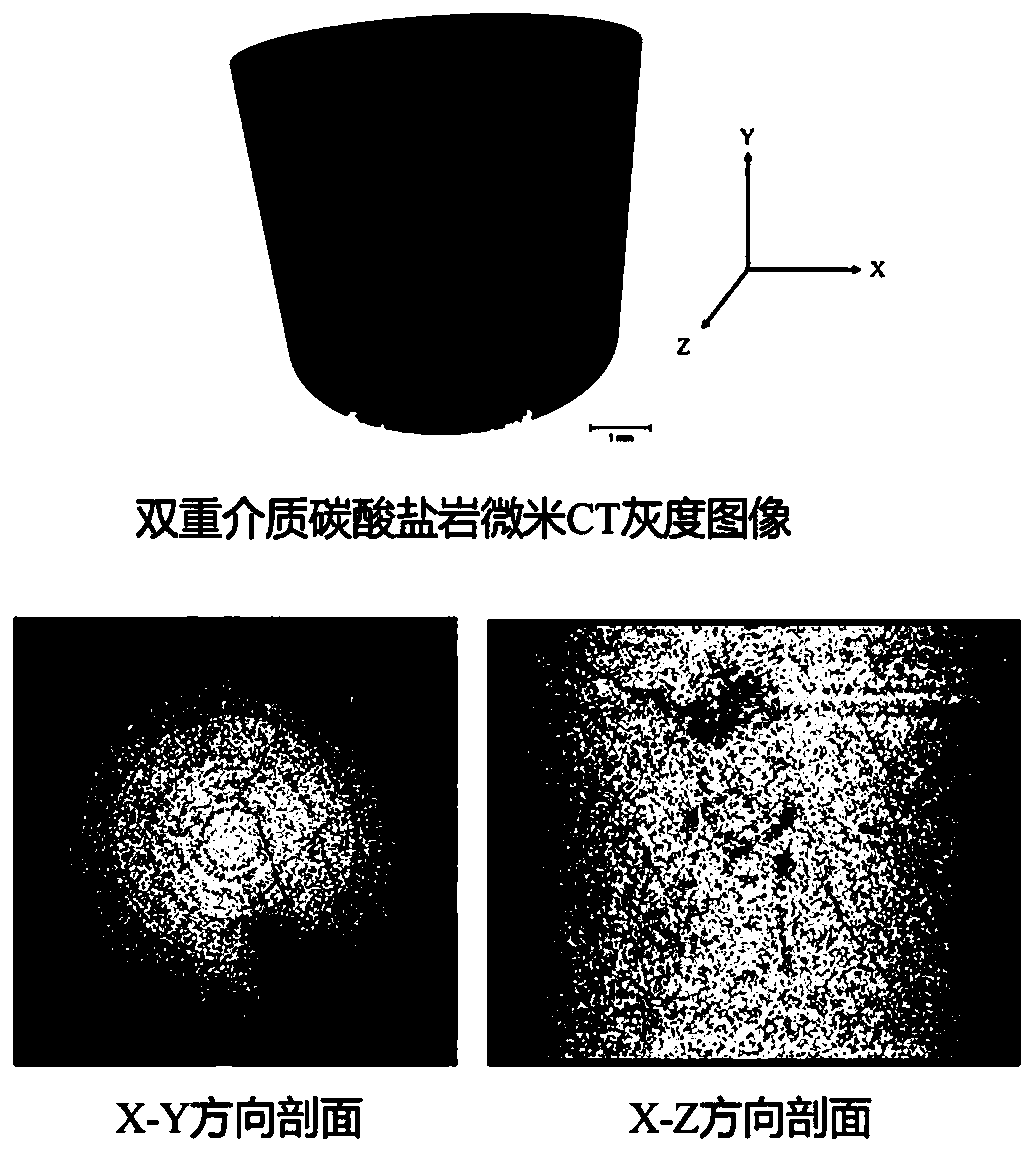

[0061] Step 1: Use micro-CT to scan the dual-media carbonate sample to obtain a non-destructive three-dimensional image of the real sample.

[0062] Step 2: Using image segmentation technology to extract the space of pores and fractures from the 3D image obtained in Step 1. Since the pores and fractures are extracted as the same phase at this time, it is necessary to further separate the two to achieve the purpose of building a network model separately.

[0063] Step 3: Perform morphological analysis on the pore and fracture space extracted in step 2, calculate the three-dimensional length and three-dimensional minimum width information of each pore / fracture, and divide the pores and fractures by the ratio of the two.

[0064] Step 4: For the fracture space separated in step 3, first use the center...

Embodiment 2

[0069] As an optimization of the above embodiment, the distinction between the pore space and the fracture space can be effectively separated by calculating the ratio of the three-dimensional length and the three-dimensional minimum width of the pores and fractures, and selecting an appropriate threshold. Three-dimensional length measurement is to place each pore / fracture such as Figure 5 In the coordinate system shown, take 18 degrees as a step along the θ and φ directions respectively, search from 0 degrees to 162 degrees, and record the distance between the beginning and the end of each step, and the largest distance is the three-dimensional length. Two parallel planes made in the three-dimensional length direction and in contact with the edge of the pores / cracks are rotated around the three-dimensional length direction, and the minimum distance between the two planes is the three-dimensional minimum width. Since the fracture is flat, the ratio of its three-dimensional len...

Embodiment 3

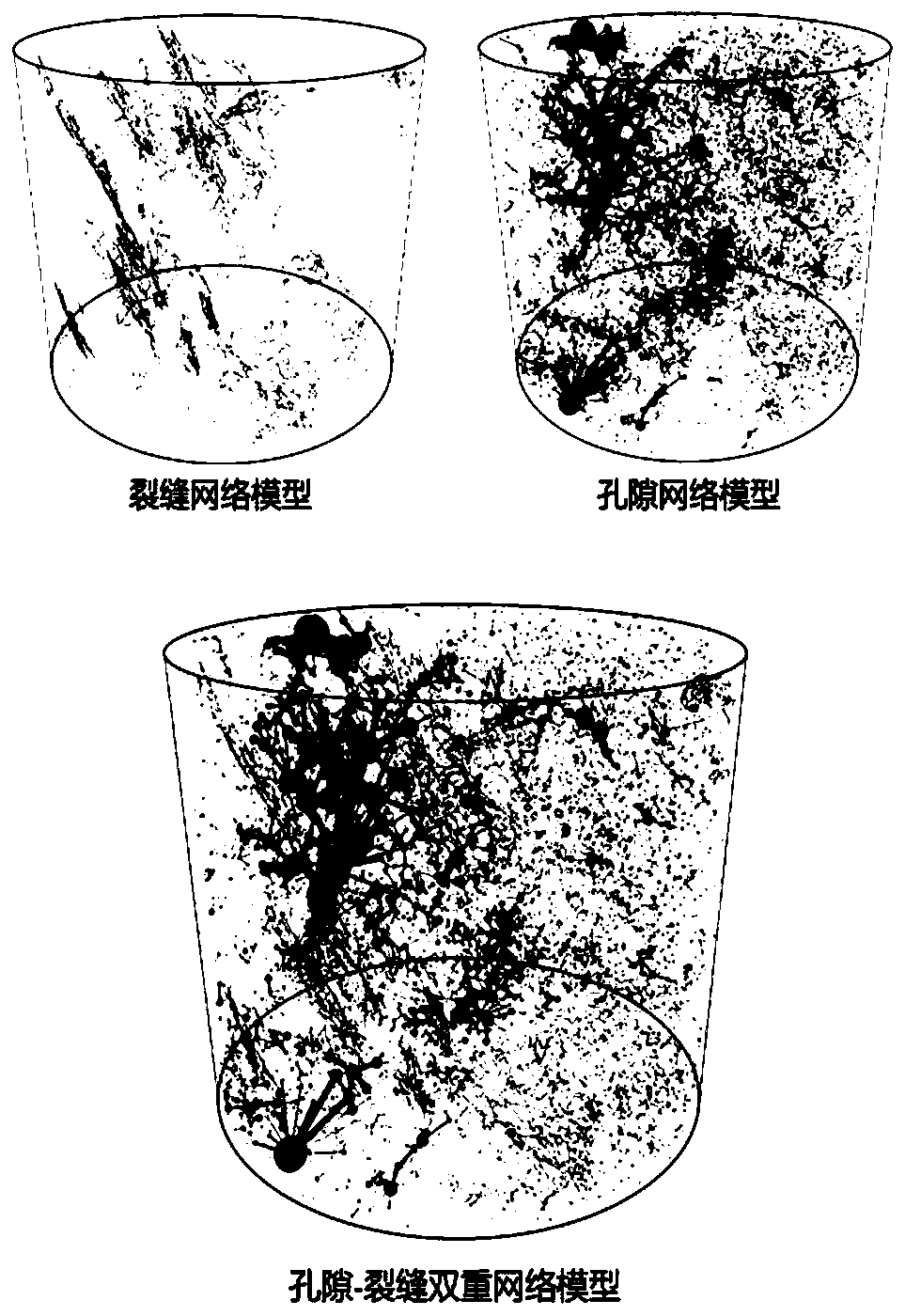

[0071] As an optimization of the above embodiment, when constructing the network model of the fracture space separated in step 3, the following operations are sequentially adopted to obtain the fracture network model:

[0072] 1. Extraction of the center line: First, a value is given to each voxel of the digital core model of the fracture, which is the distance from the voxel to the nearest rock skeleton; then, the digital core model of the fracture is continuously refined according to the distance map. until a continuous chain of voxels remains, such as Figure 7 As shown in , the voxel chain is the extracted centerline of the fracture.

[0073] 2. Taking each centerline voxel on the centerline as the basic point, first use the expansion algorithm to determine the possible search space. After finding the range of the skeleton voxel closest to each voxel, the shrinkage algorithm is used to identify the inscribed sphere corresponding to the central voxel; finally, the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com