Automatic tracking and dispensing method based on production line

An automatic tracking and assembly line technology, which is applied to the surface coating device, spray device, coating, etc., can solve the problem of small batch, multi-batch, multi-type product production scenarios and fixture accuracy that cannot be satisfied by the production line. High requirements, rising labor costs, etc., to achieve the effect of improving equipment reuse rate, reducing equipment complexity, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] A preferred embodiment of the present invention:

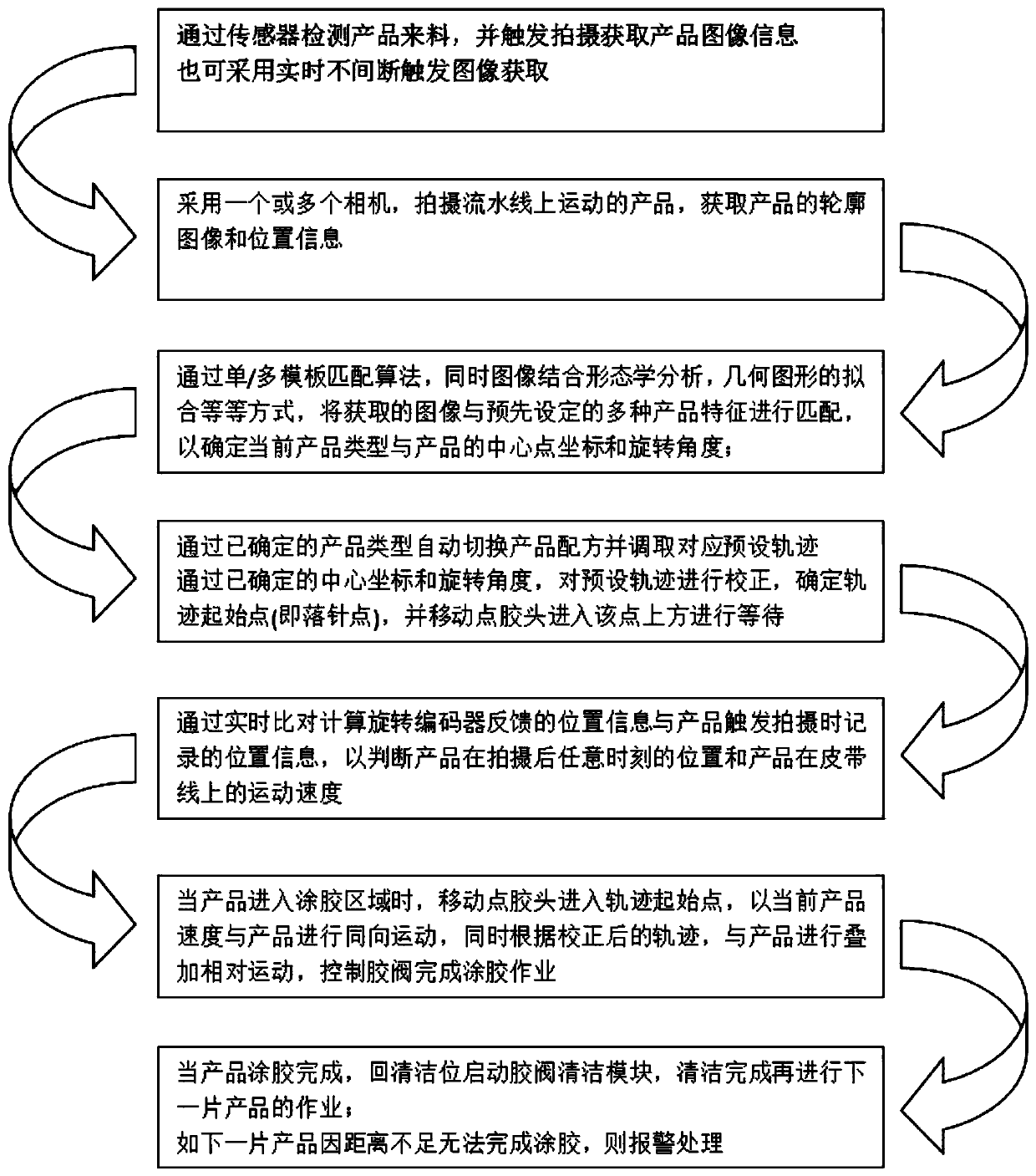

[0052] A pipeline-based automatic tracking dispensing method includes the following steps:

[0053] Step 1: Incoming Material Induction

[0054] The sensor detects the incoming material, and triggers the shooting to obtain the image information of the incoming material, and can also use real-time uninterrupted trigger image acquisition.

[0055] Sensor triggering means: when the product reaches the camera position, it triggers to take pictures. Generally, sensors include but are not limited to: through-beam light sources, reflective optical fibers, metal proximity sensors, and mechanical micro-motion sensors.

[0056] Real-time uninterrupted touch refers to: the camera image is continuously taken in real time, and the global image preprocessing analysis (gray histogram tool, etc.), is compared with the empty material state, and whether the incoming material enters the field of view is dynamically monitored.

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com