Fibula shaping board for use in mandibular reconstruction

A mandible and fibula technology, which is applied in the field of mandibular reconstruction and fibula shaping plate, can solve the problems of long production cycle, unfavorable fixation, and large clinical randomness, and achieves the effect of small individual differences and improved accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

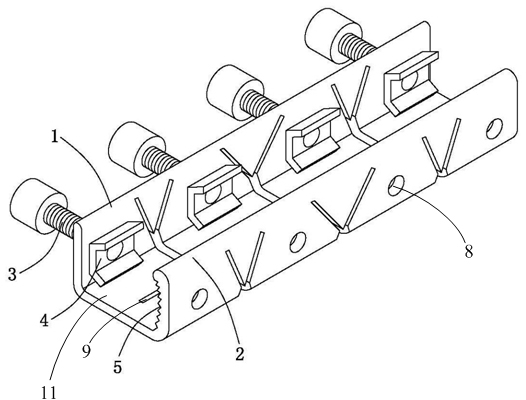

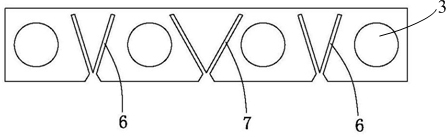

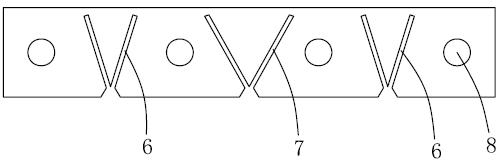

[0030] Such as figure 1 , Figure 4 As shown, the mandibular reconstruction fibula shaping plate is made of medical titanium alloy, and includes an arcuate groove and an adjustment screw 3. The arcuate groove is used to accommodate the fibula, and includes an anterior side 1, a bottom surface 11, and a posterior side 2. The adjustment screw 3 pass through the front side 1 of the arcuate slot, and a bracket 4 is provided at one end where the adjustment screw 3 passes through the front side 1 of the arcuate slot, and the arcuate slot is provided with three osteotomy slots for guiding the cutting of the reciprocating bone saw blade. bone orientation, such as figure 2 , image 3 , Figure 5 As shown, the osteotomy groove is composed of a linear groove 10 arranged on the bottom surface 11, an osteotomy angle arranged on the front side 1 and an osteotomy angle on the back side 2, the osteotomy angle is a v-shaped groove, and the front The osteotomy angle of side 1 and the oste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com