Patents

Literature

143 results about "Mandible/Mandibular" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

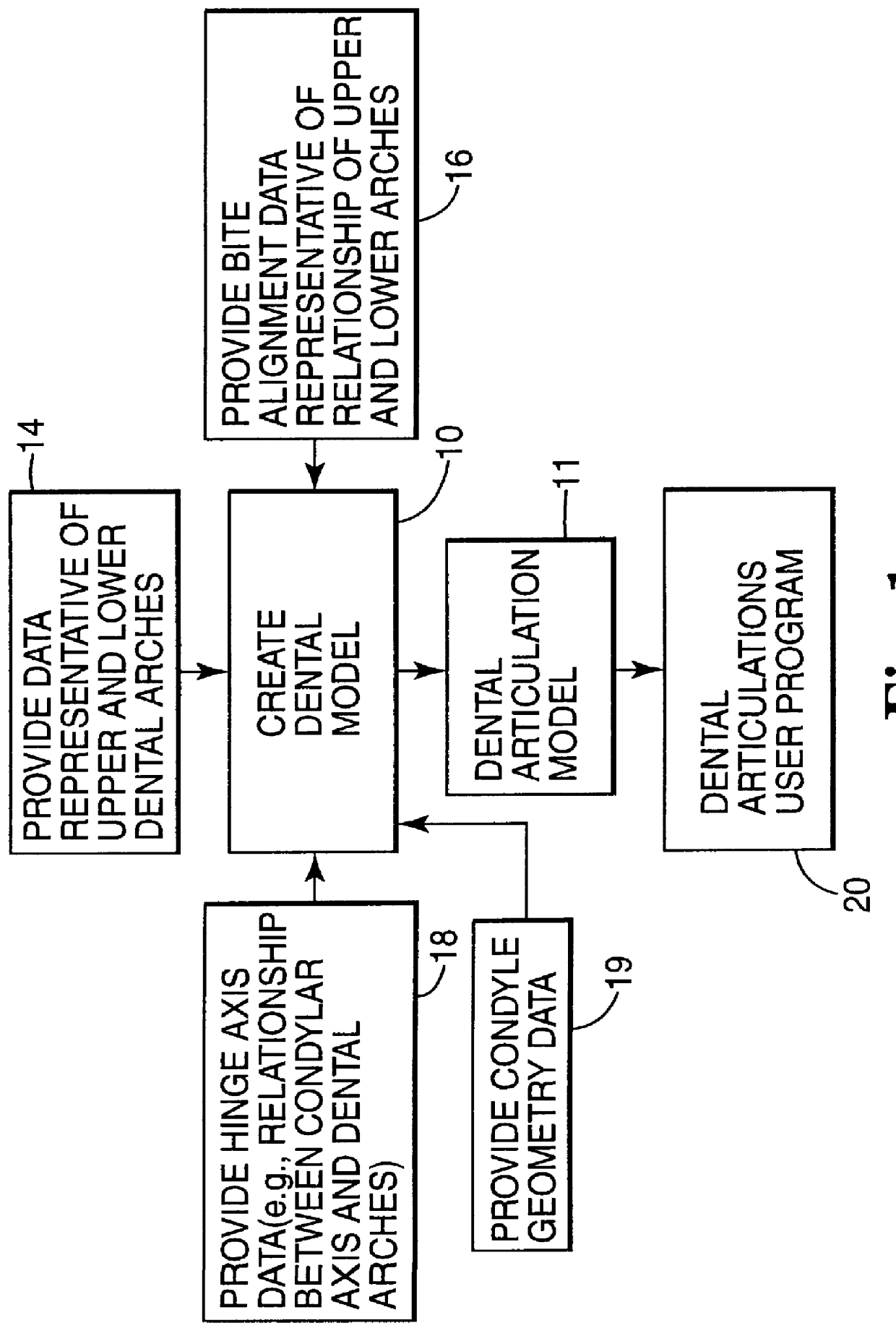

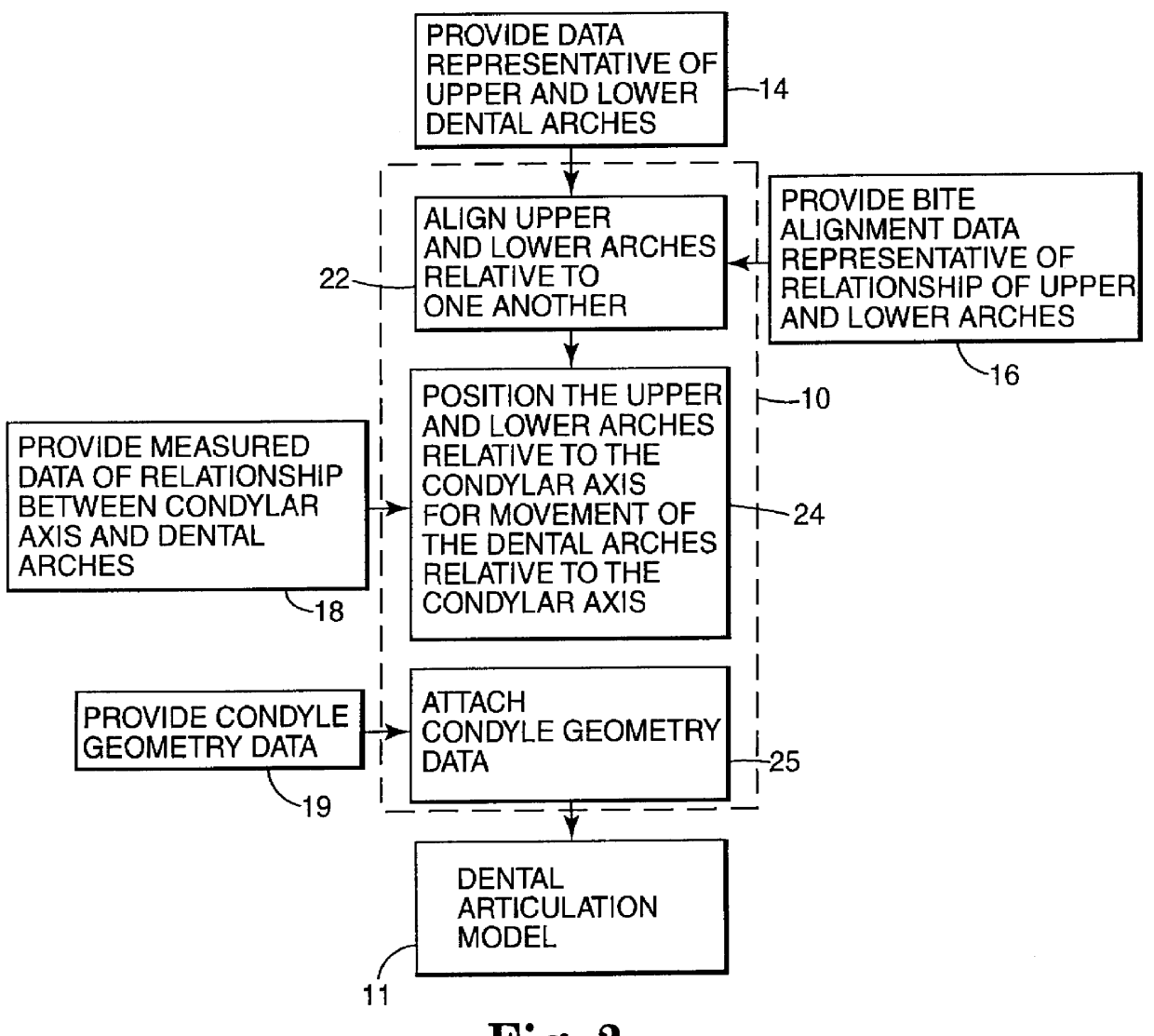

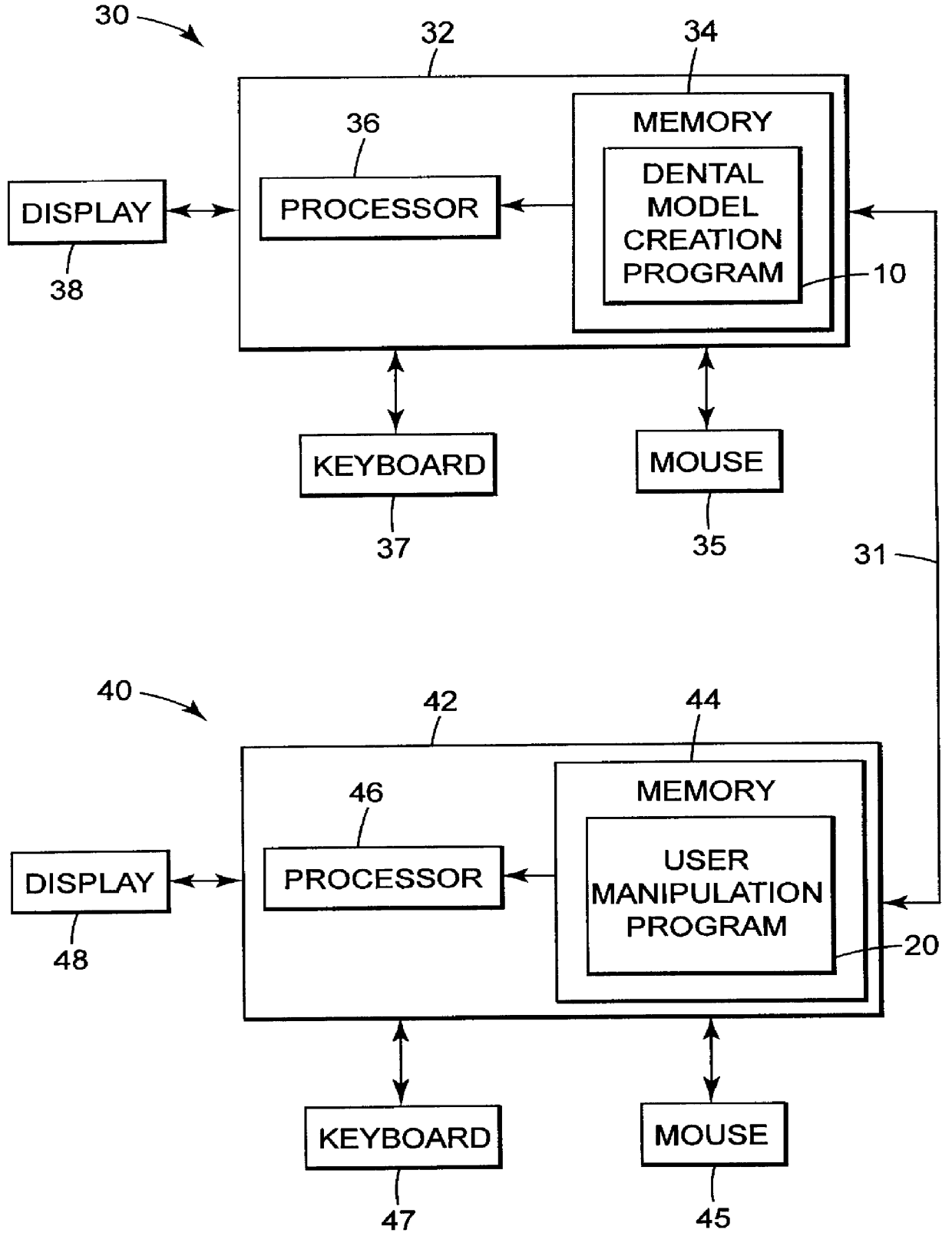

Methods for use in dental articulation

A computer implemented method of creating a dental model for use in dental articulation includes providing a first set of digital data corresponding to an upper arch image of at least a portion of an upper dental arch of a patient, providing a second set of digital data corresponding to a lower arch image of at least a portion of a lower dental arch of the patient, and providing hinge axis data representative of the spatial orientation of at least one of the upper and lower dental arches relative to a condylar axis of the patient. A reference hinge axis is created relative to the upper and lower arch images based on the hinge axis data. Further, the method may include bite alignment data for use in aligning the lower and upper arch images. Yet further, the method may include providing data associated with condyle geometry of the patient, so as to provide limitations on the movement of at least the lower arch image when the arch images are displayed. Further, a wobbling technique may be used to determine an occlusal position of the lower and upper dental arches. Various computer implemented methods of dental articulation are also described. For example, such dental articulation methods may include moving at least one of the upper and lower arch images to simulate relative movement of one of the upper and lower dental arches of the patient, may include displaying another image with the upper and lower dental arches of the dental articulation model, and / or may include playing back recorded motion of a patient's mandible using the dental articulation model.

Owner:3M INNOVATIVE PROPERTIES CO +1

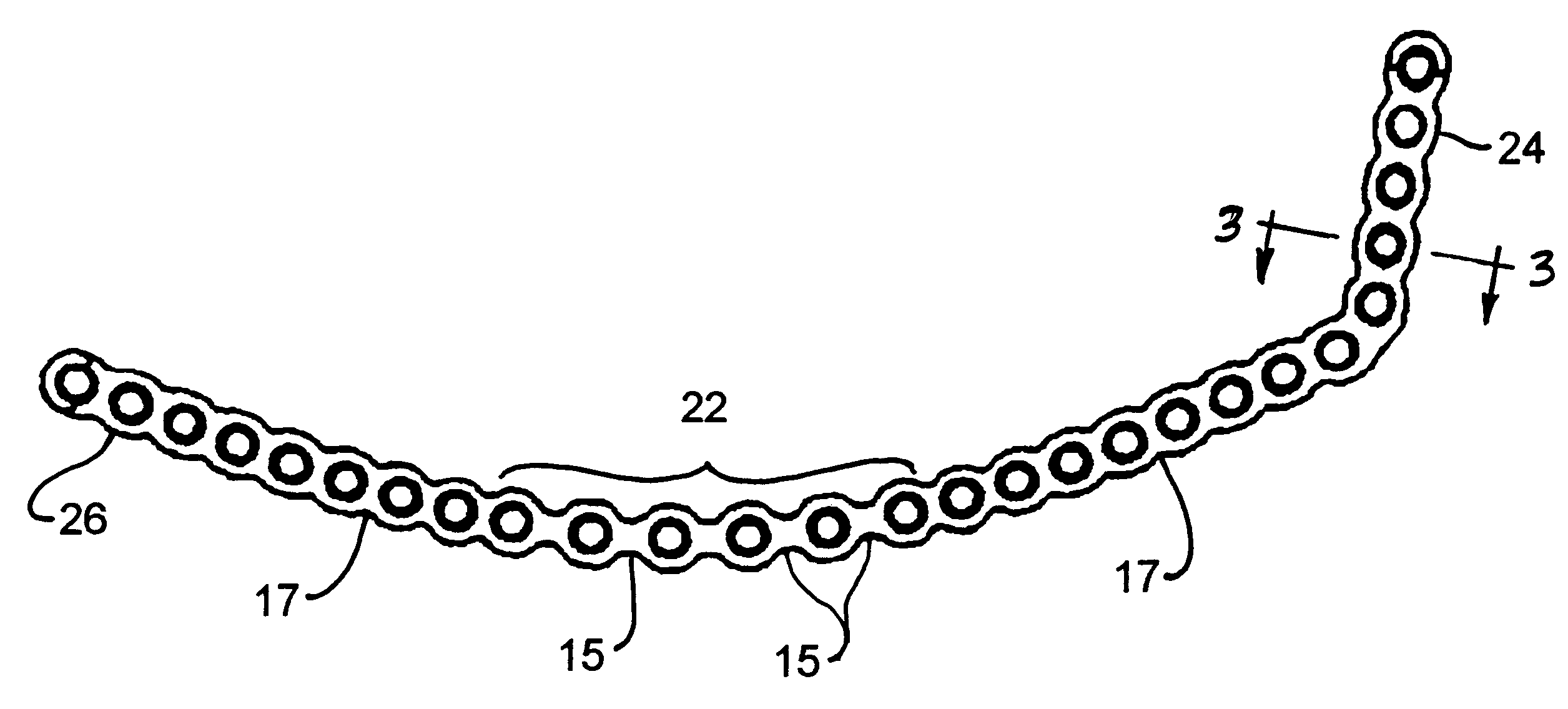

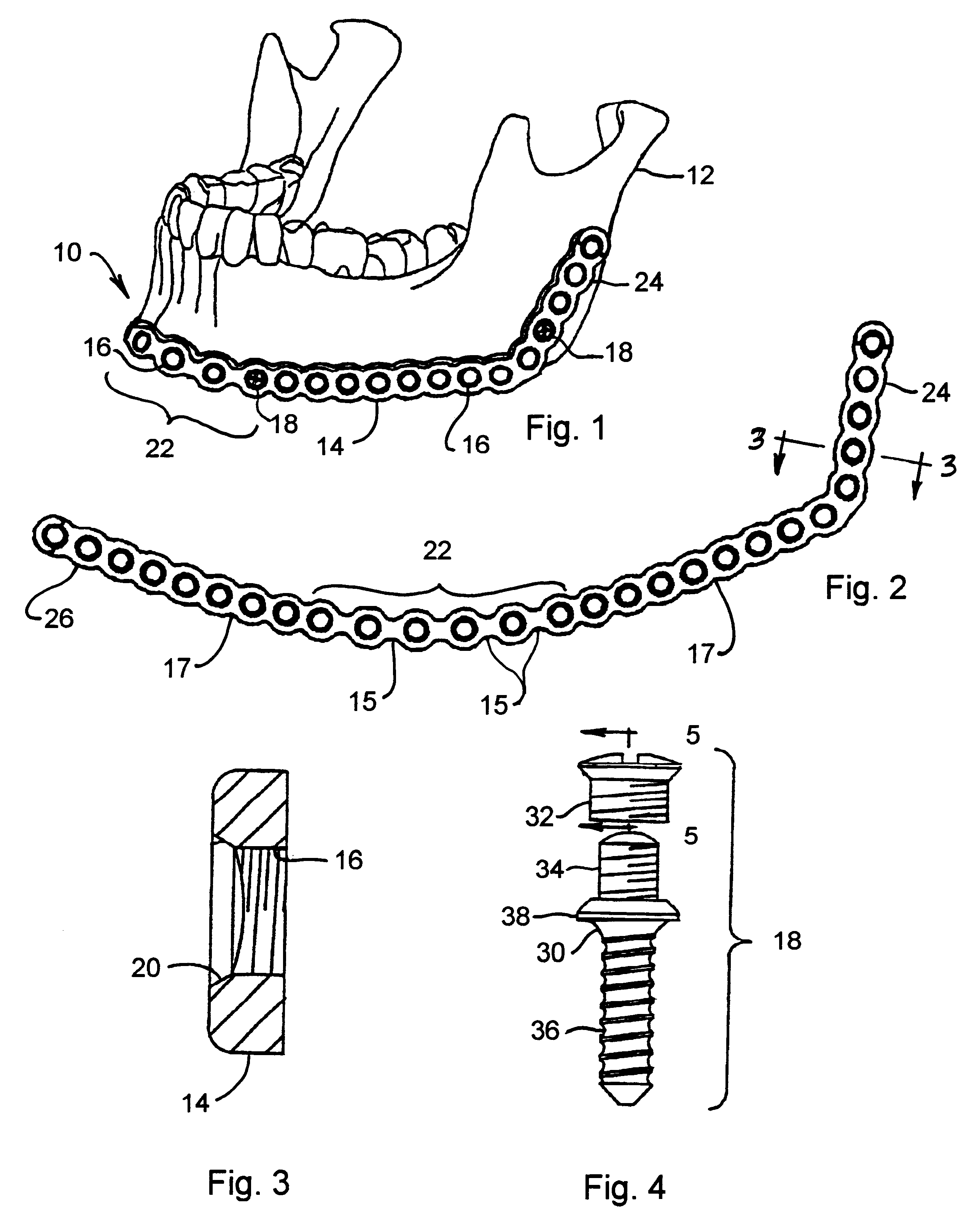

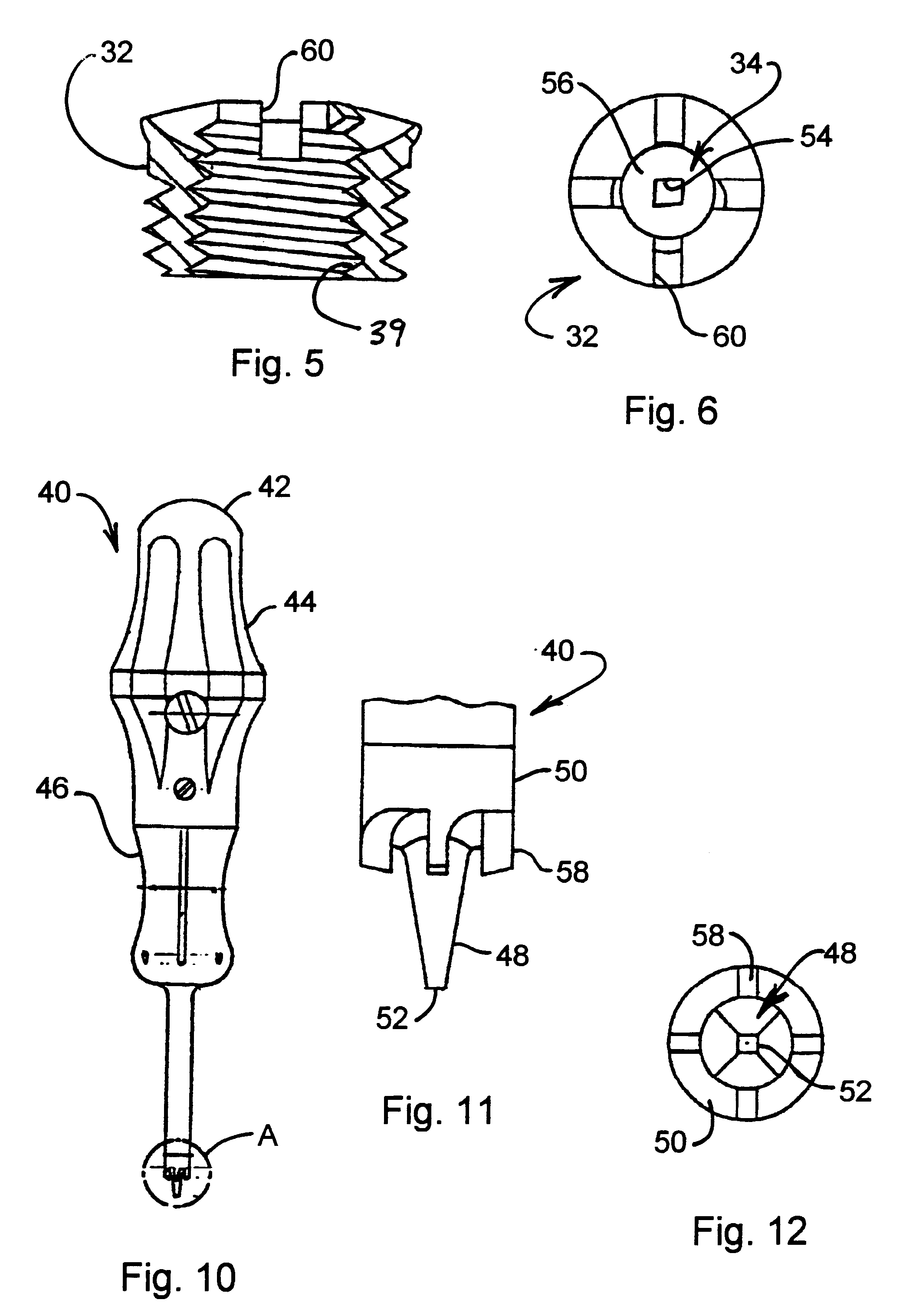

Method and apparatus for mandibular osteosynthesis

InactiveUS6423068B1Enhanced bending easeWiden the optionsInternal osteosythesisBone platesEngineeringSymphysis

An apparatus for osteosynthesis of a mandible. An elongated plate has a plurality of apertures. The plate has a first portion, a second portion, and a central portion intermediate the first and second portions. Each of the apertures within the first portion and within the second portion are disposed in relatively close spaced relationship, and each of the apertures within the central portion are disposed in relatively widely spaced relationship. The width of the plate between apertures is less in the central portion than in the first portion. The plate is more easily bent within the central portion than within the first portion, and can be bent to a relatively small radius in the central portion without distorting the apertures within the central portion. The central portion is sized and located to overlie the symphysis of the mandible.

Owner:ZIMMER BIOMET CMF & THORACIC

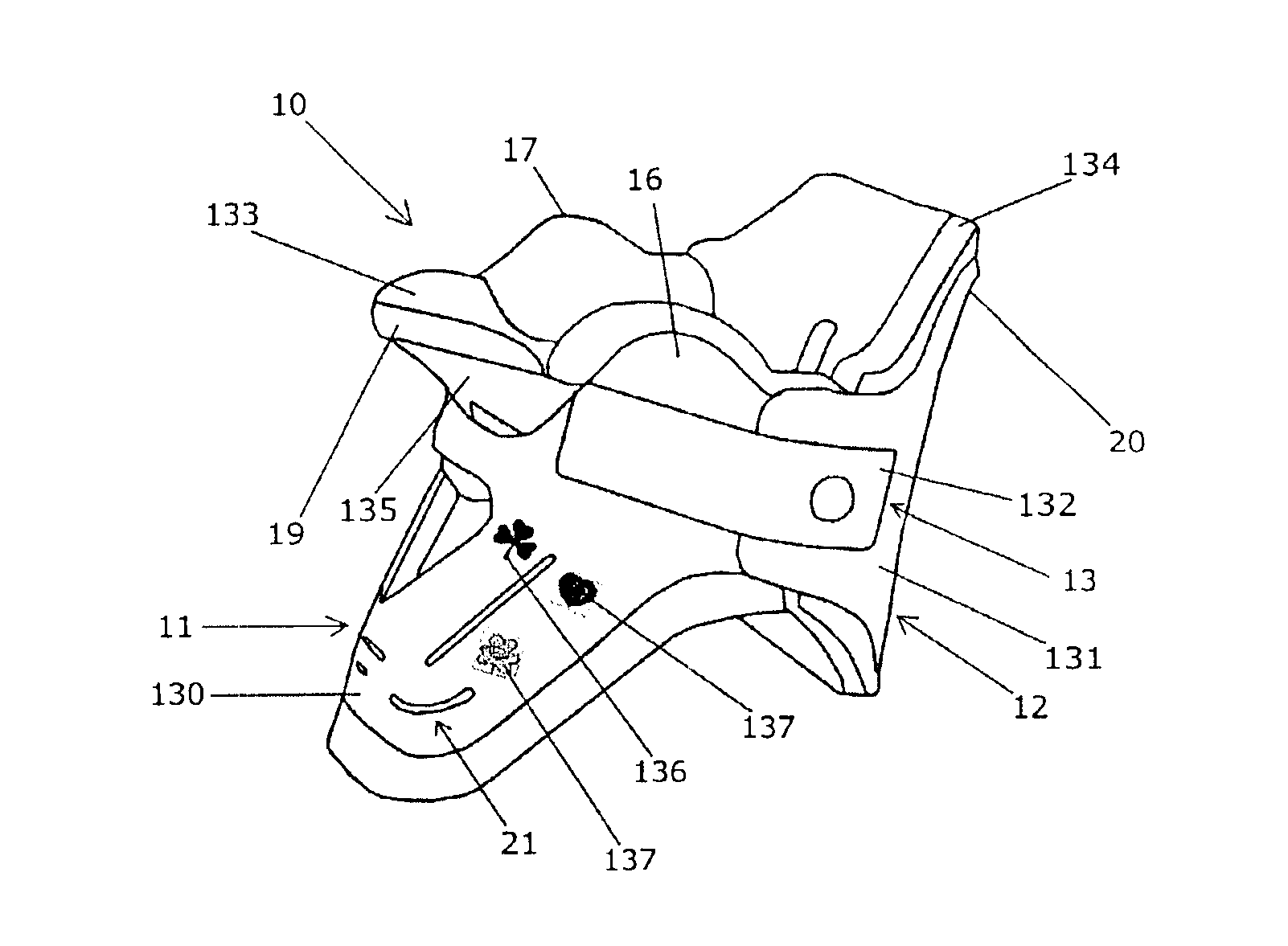

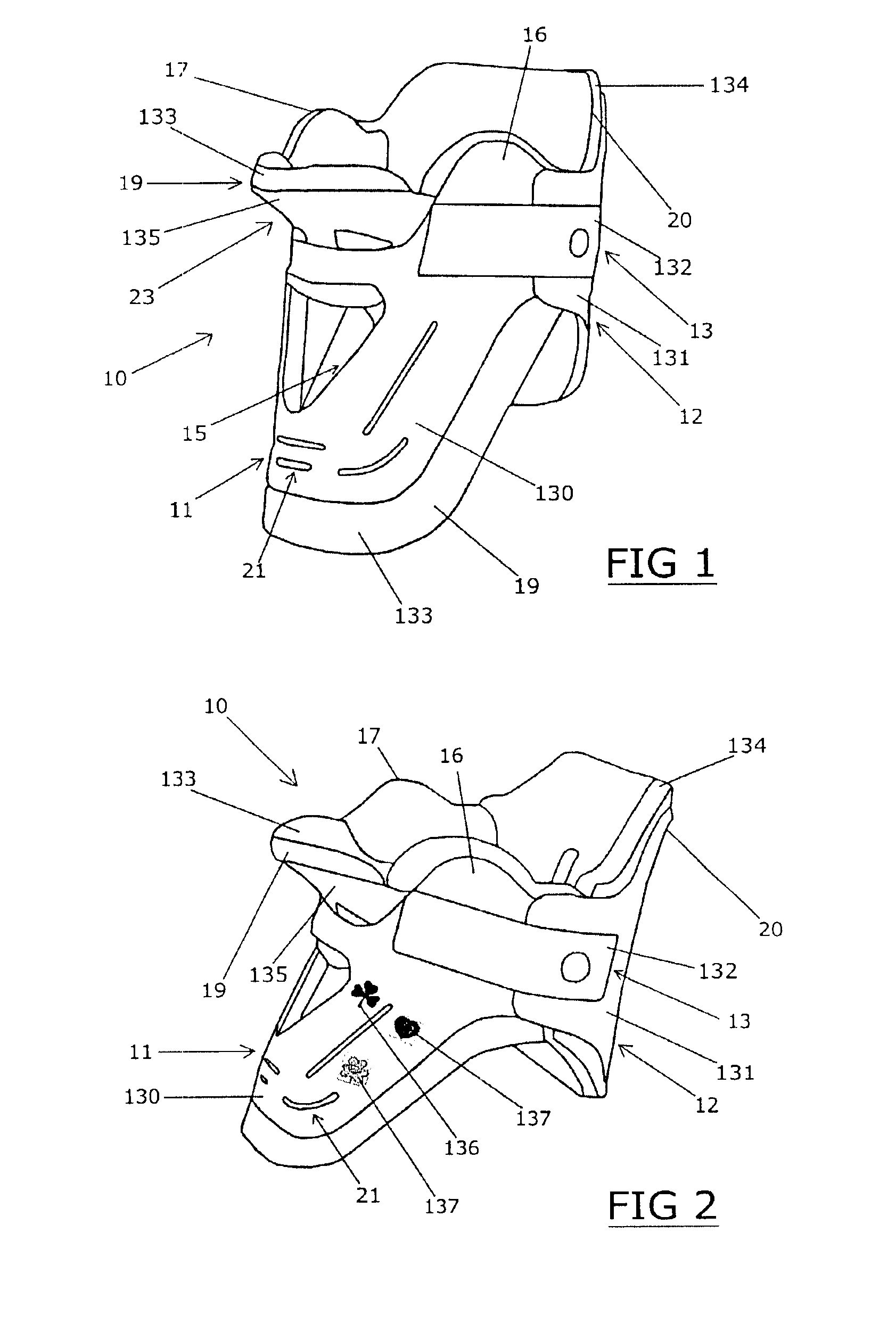

Cervical collar device

InactiveUS6872188B2Patient compliance is goodImprove visibilitySurgeryFractureOccipital boneBiomedical engineering

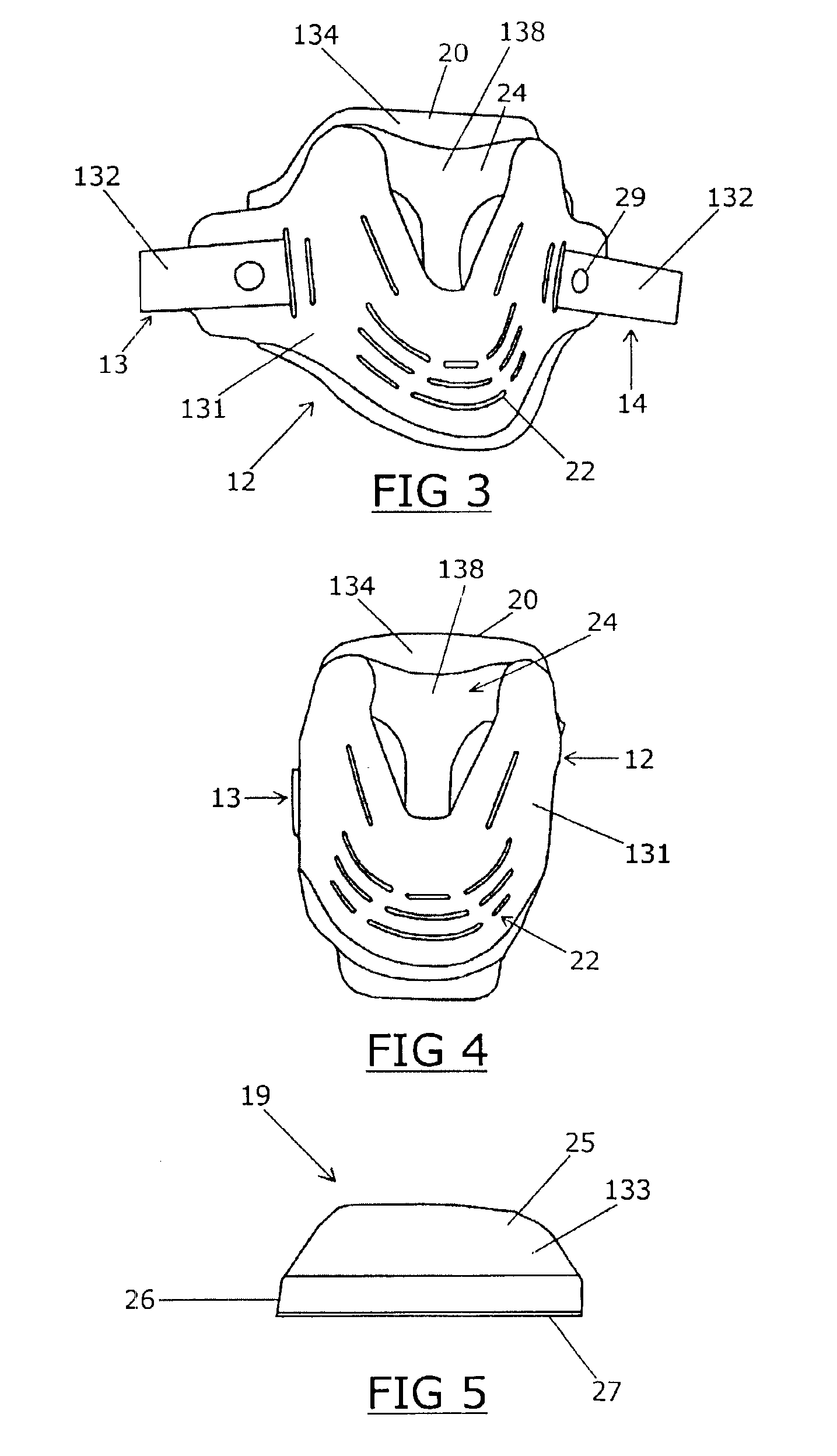

A cervical collar assembly to immobilize the neck and head of a user. The assembly includes an adjustable and conformable shell member having a pad member secured on its interior to engage the skin of the user. The shell member is comprised of a front member, a back member and means to adjustably join the front and back members. A chin support member is adjustably secured to the front member and an occipital support member is secured to the back member. The front and back members are provided with a plurality of elongated slits which permit the shell member to conform to the neck and head areas of the user. Further, the front member is provided with opposing upwardly extending tab members to engage the mandibula of a user's jaw to aid in the immobilization of the neck and head of the user. Cervical collar device size identifiers are further provided.

Owner:PMT

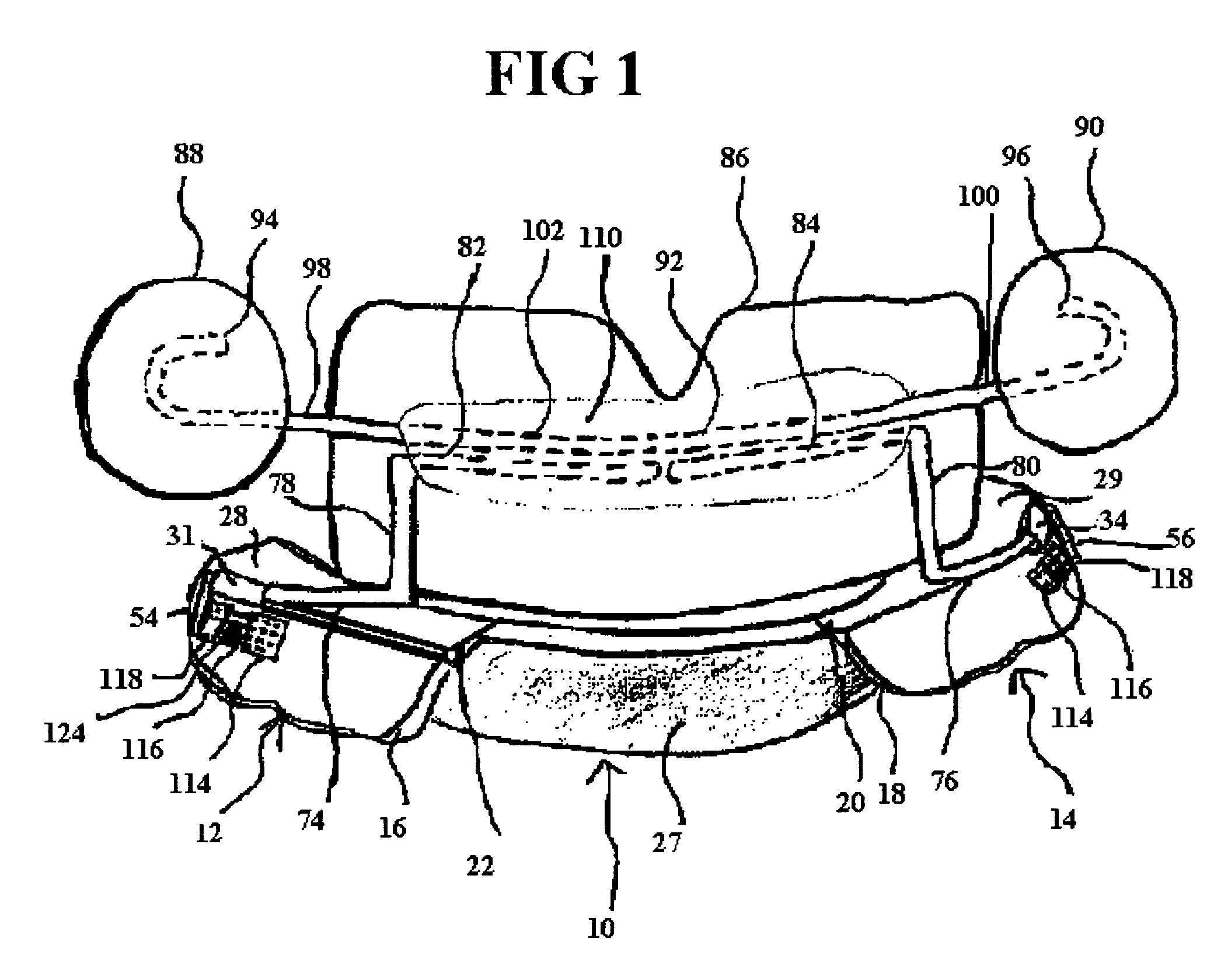

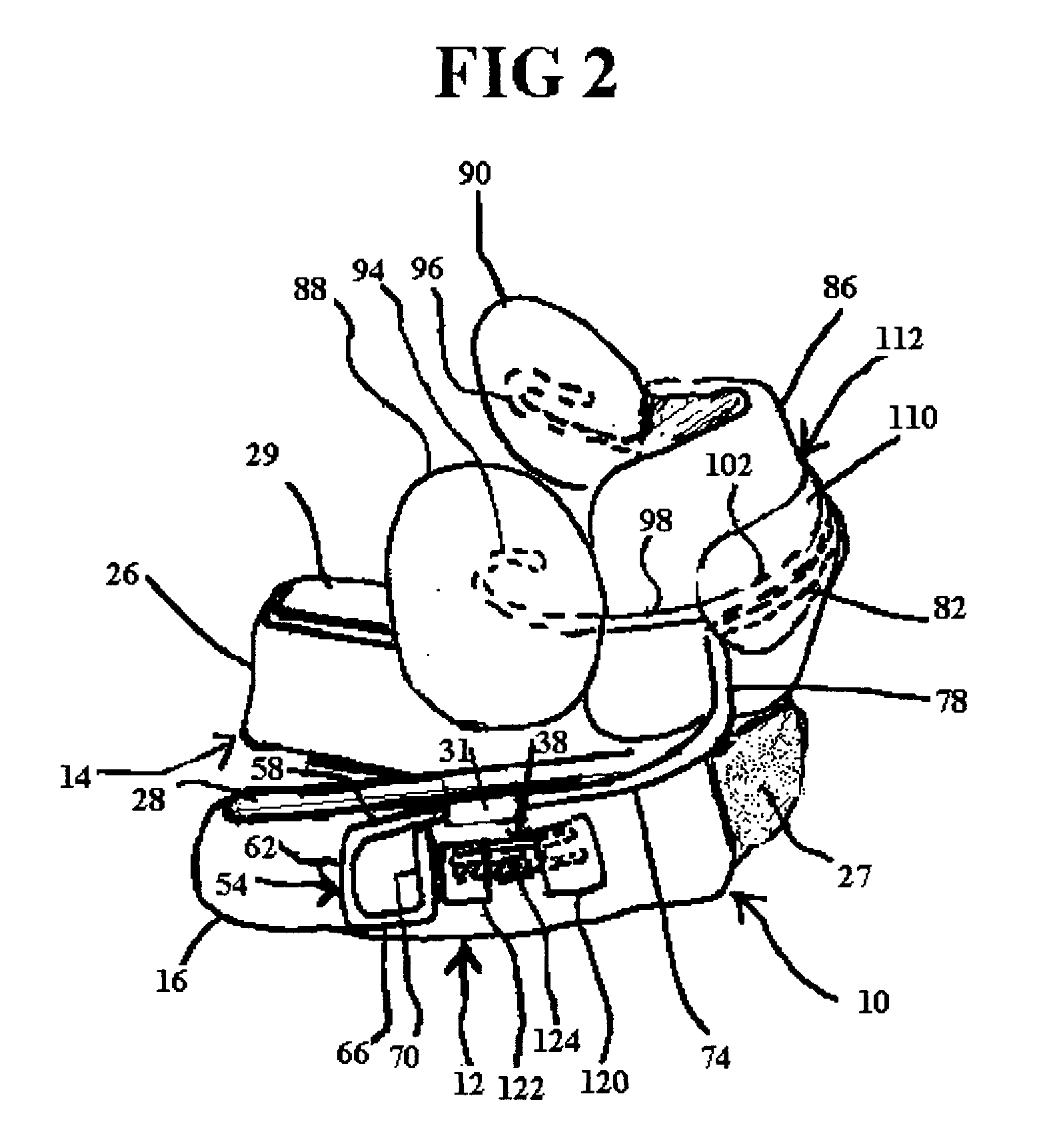

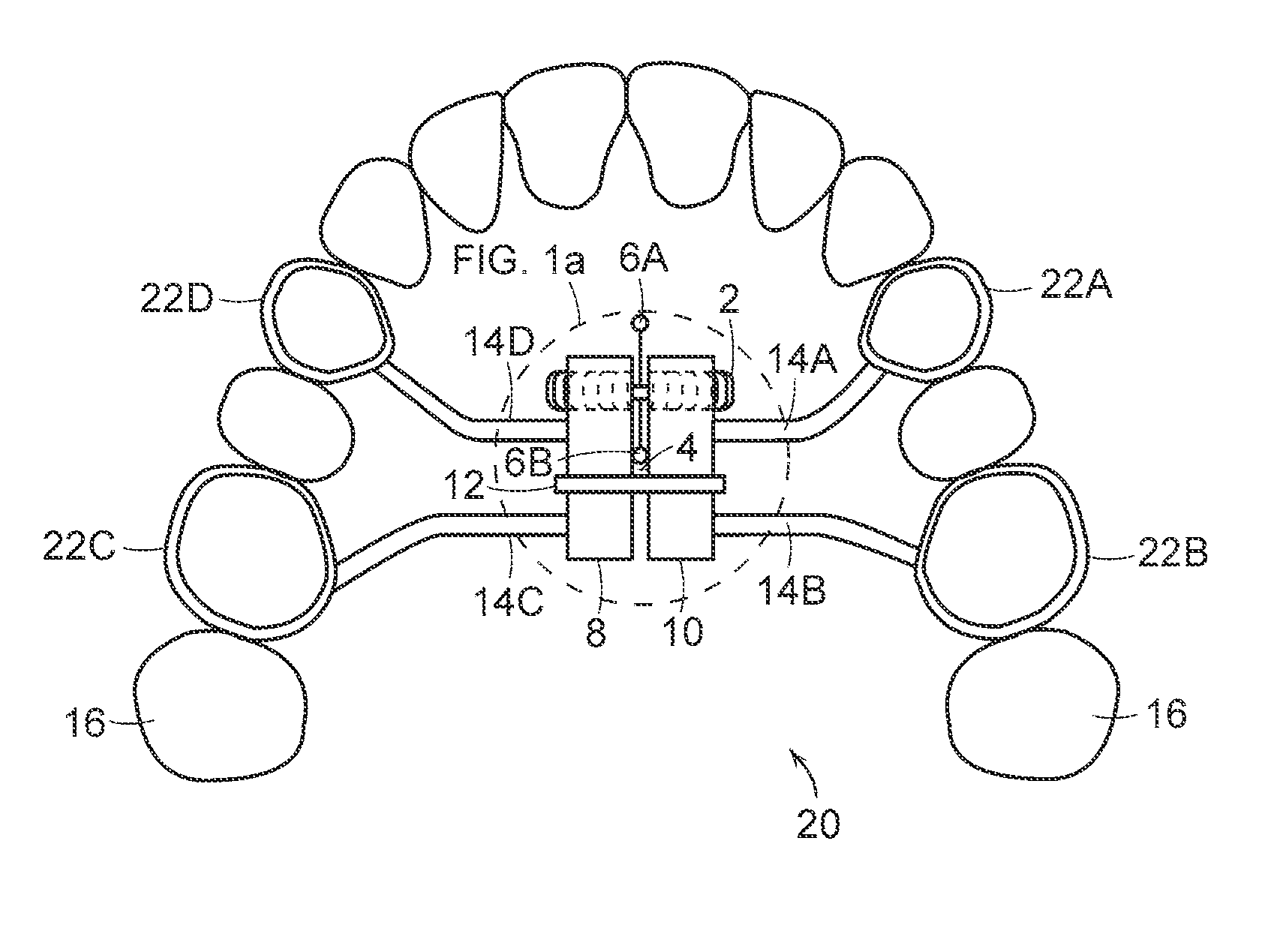

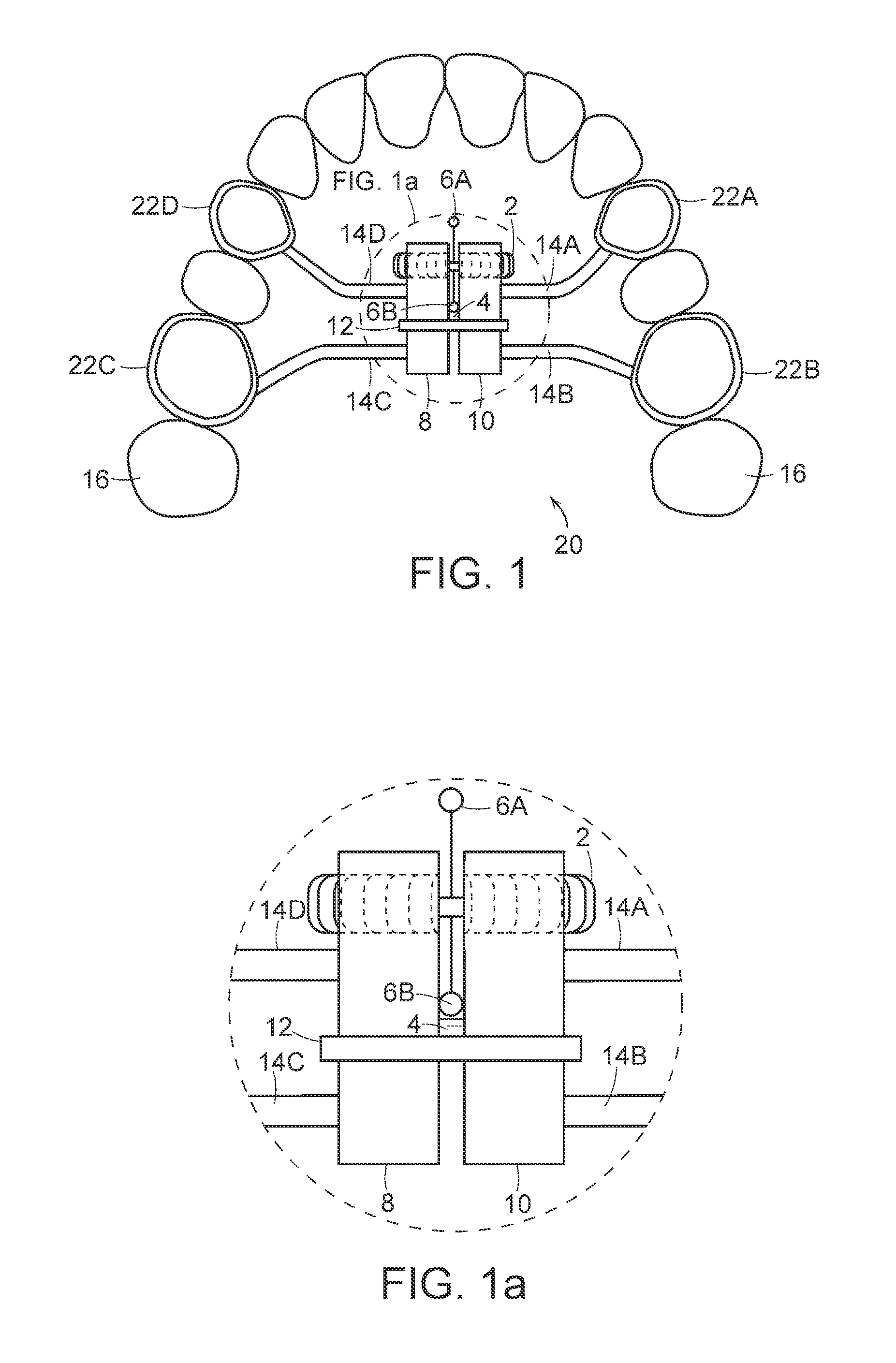

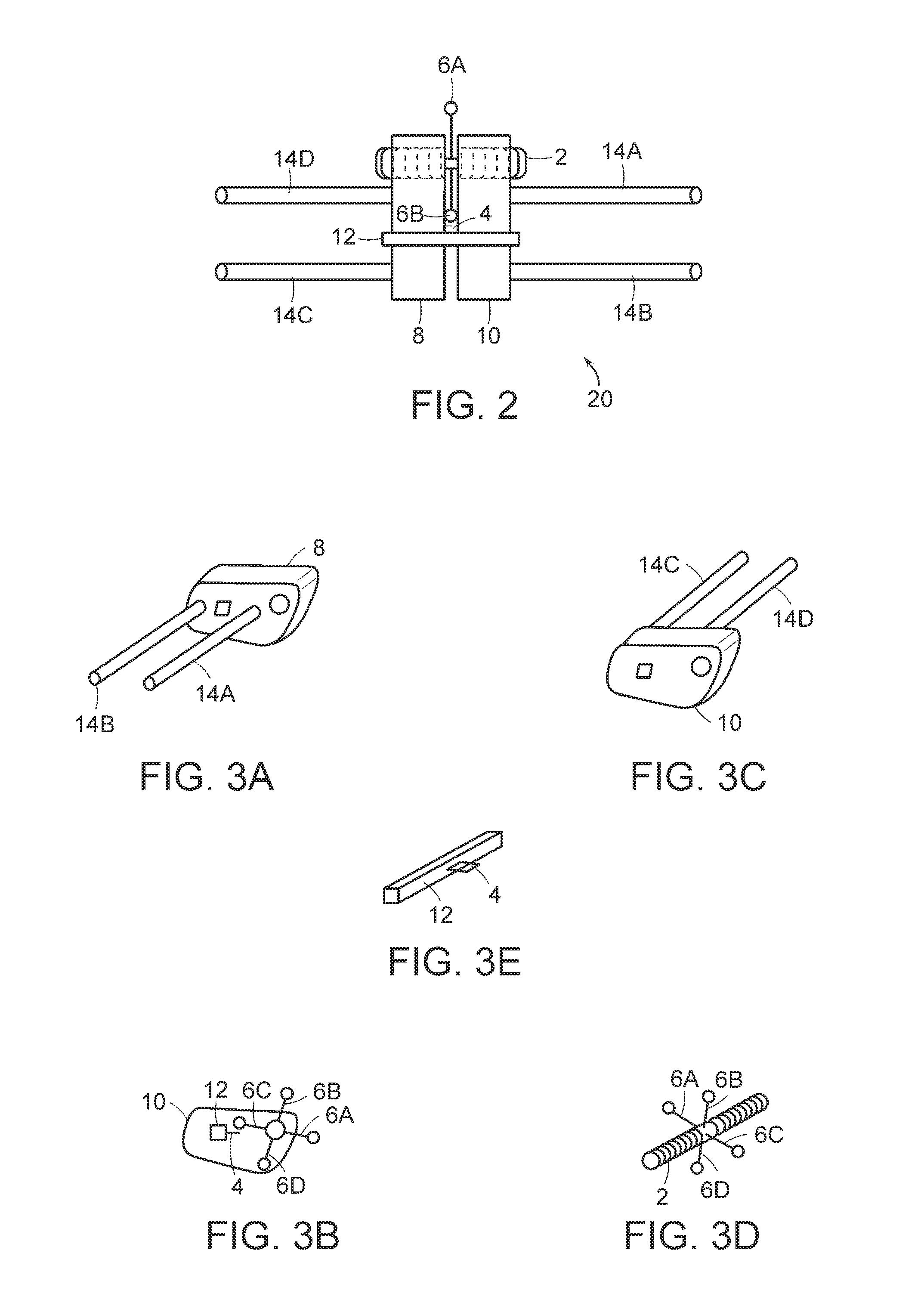

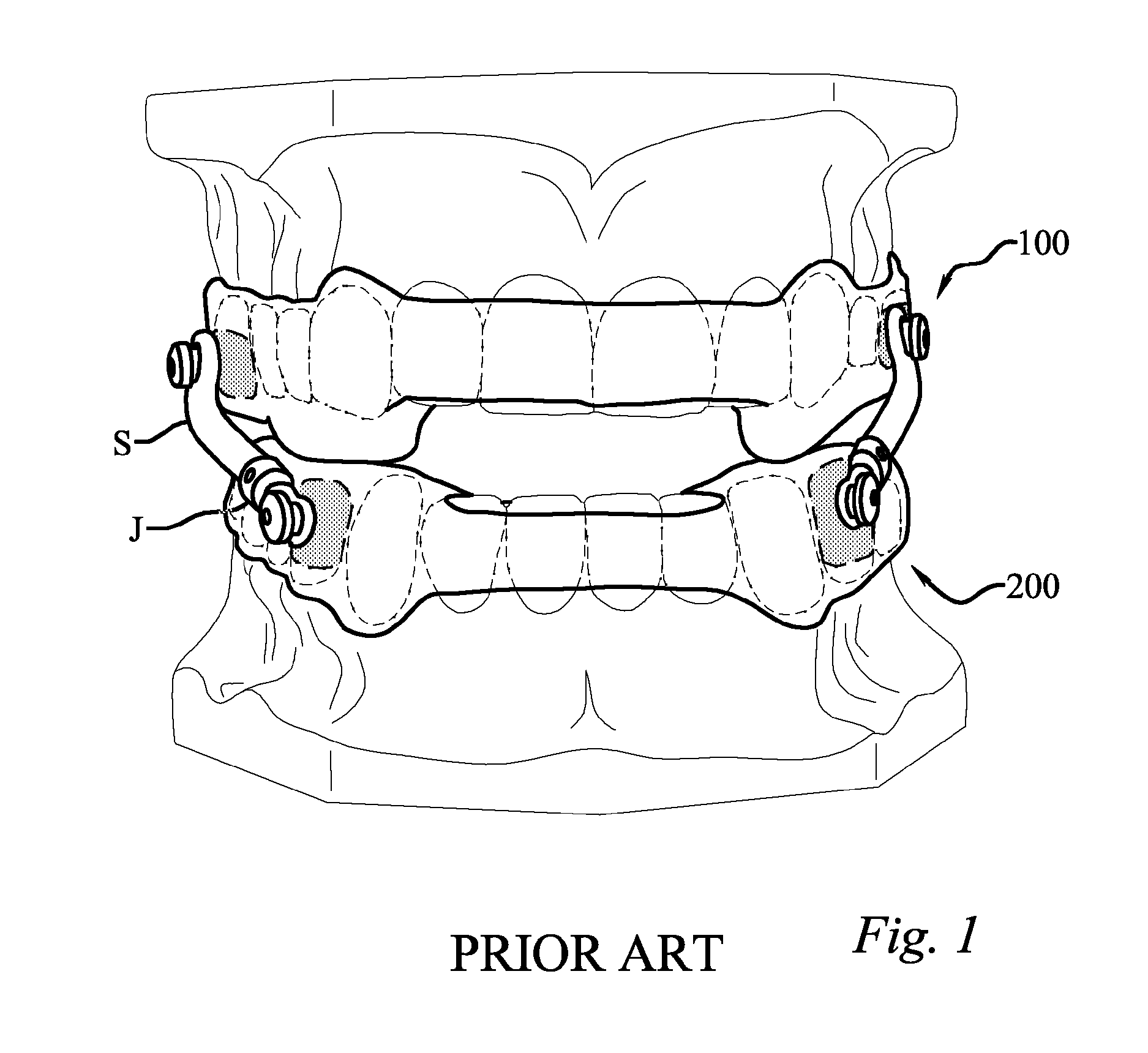

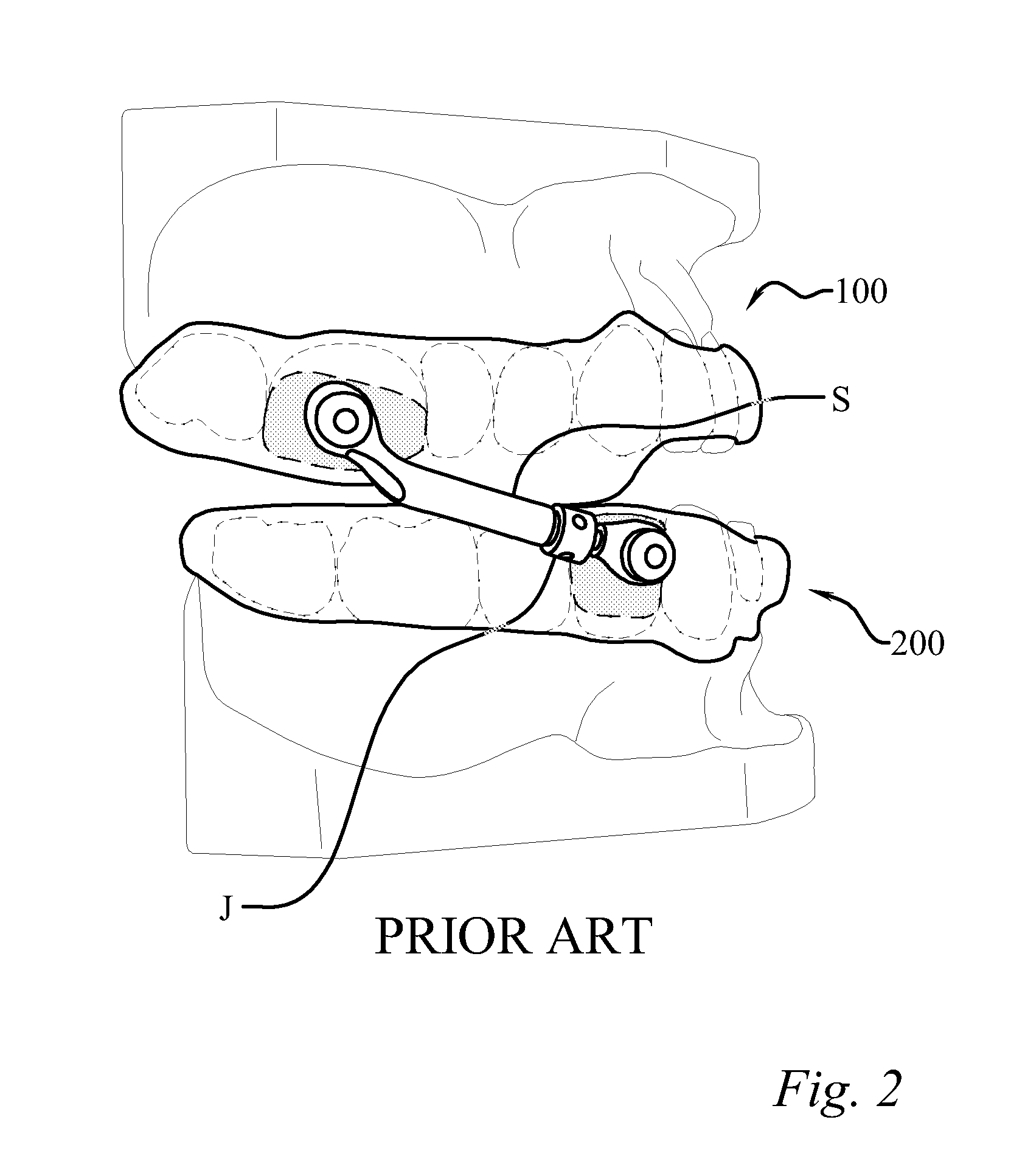

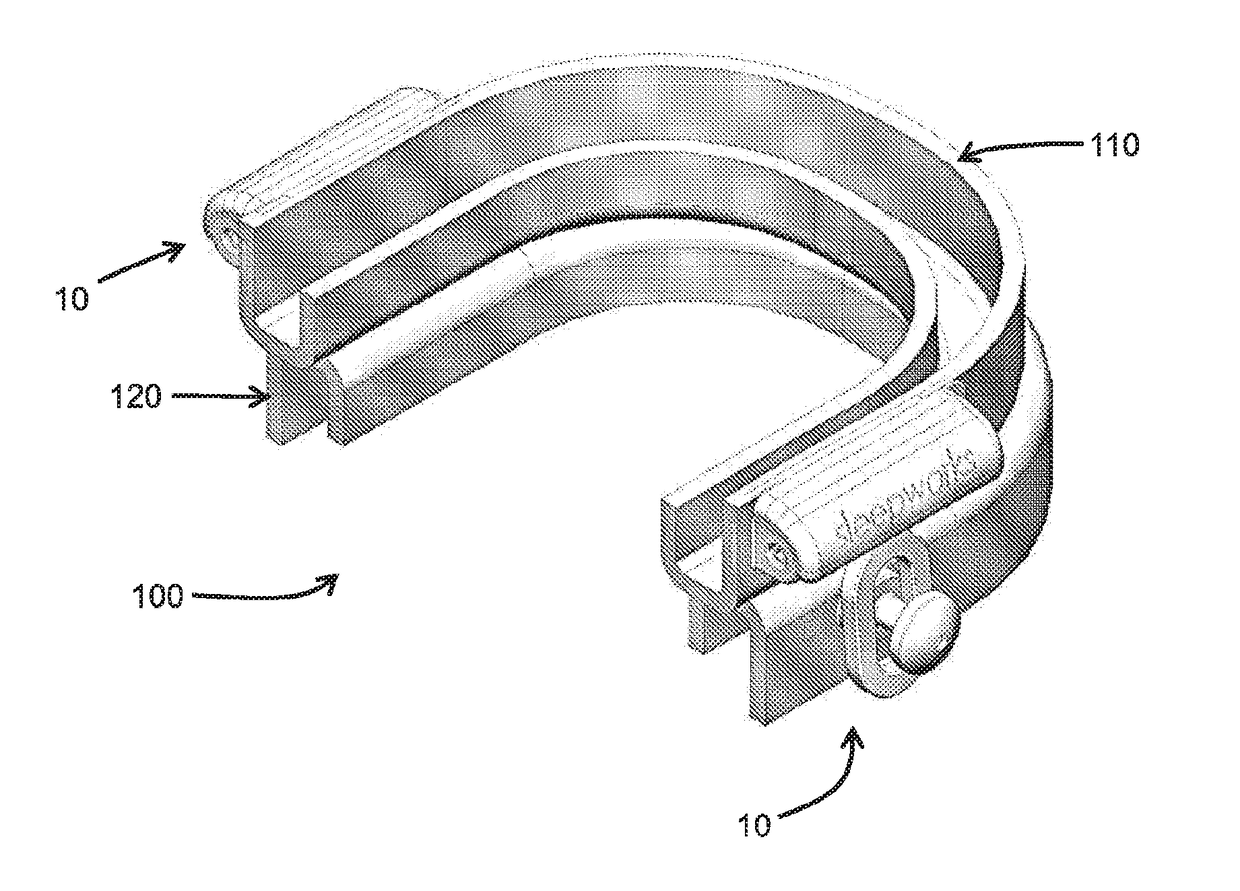

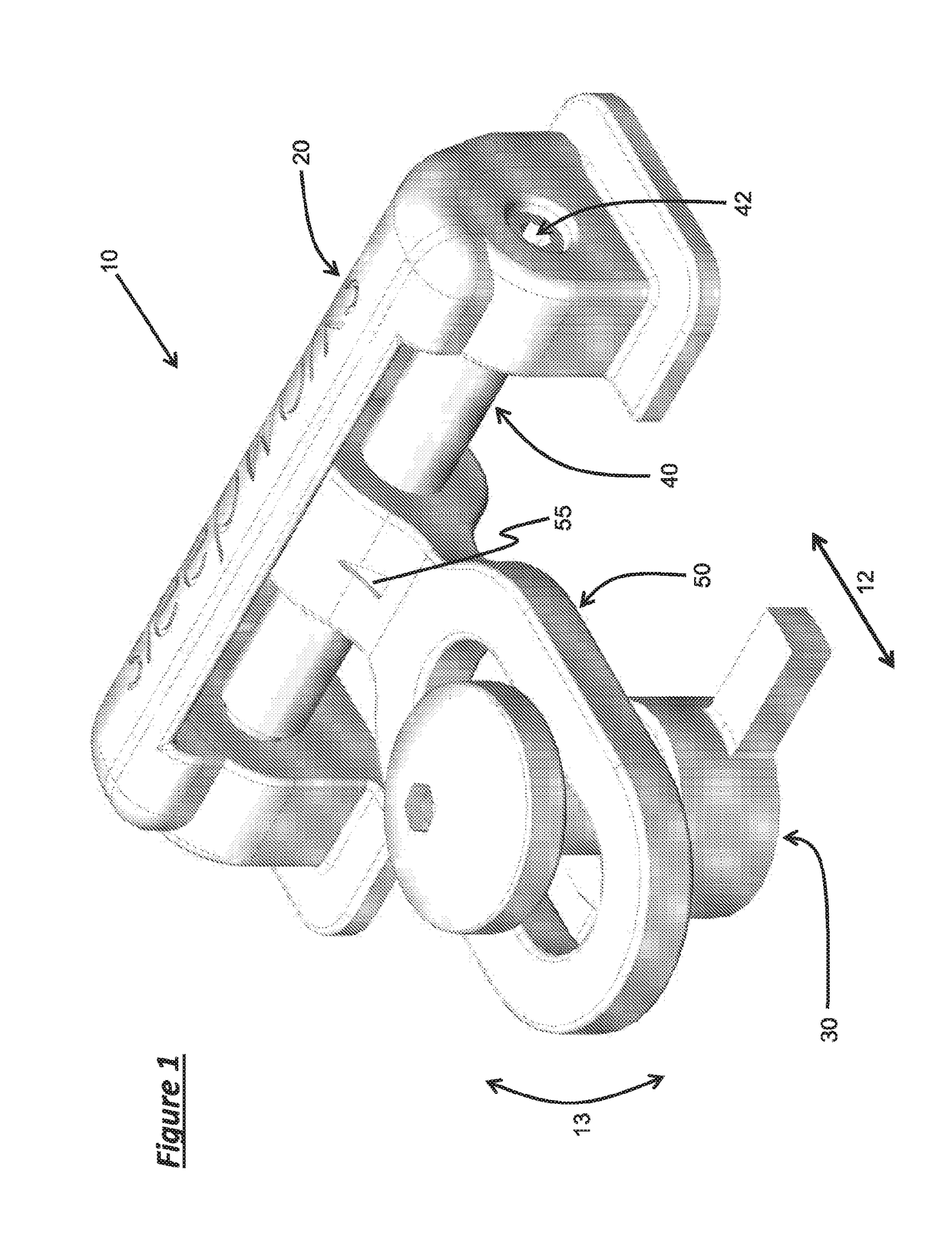

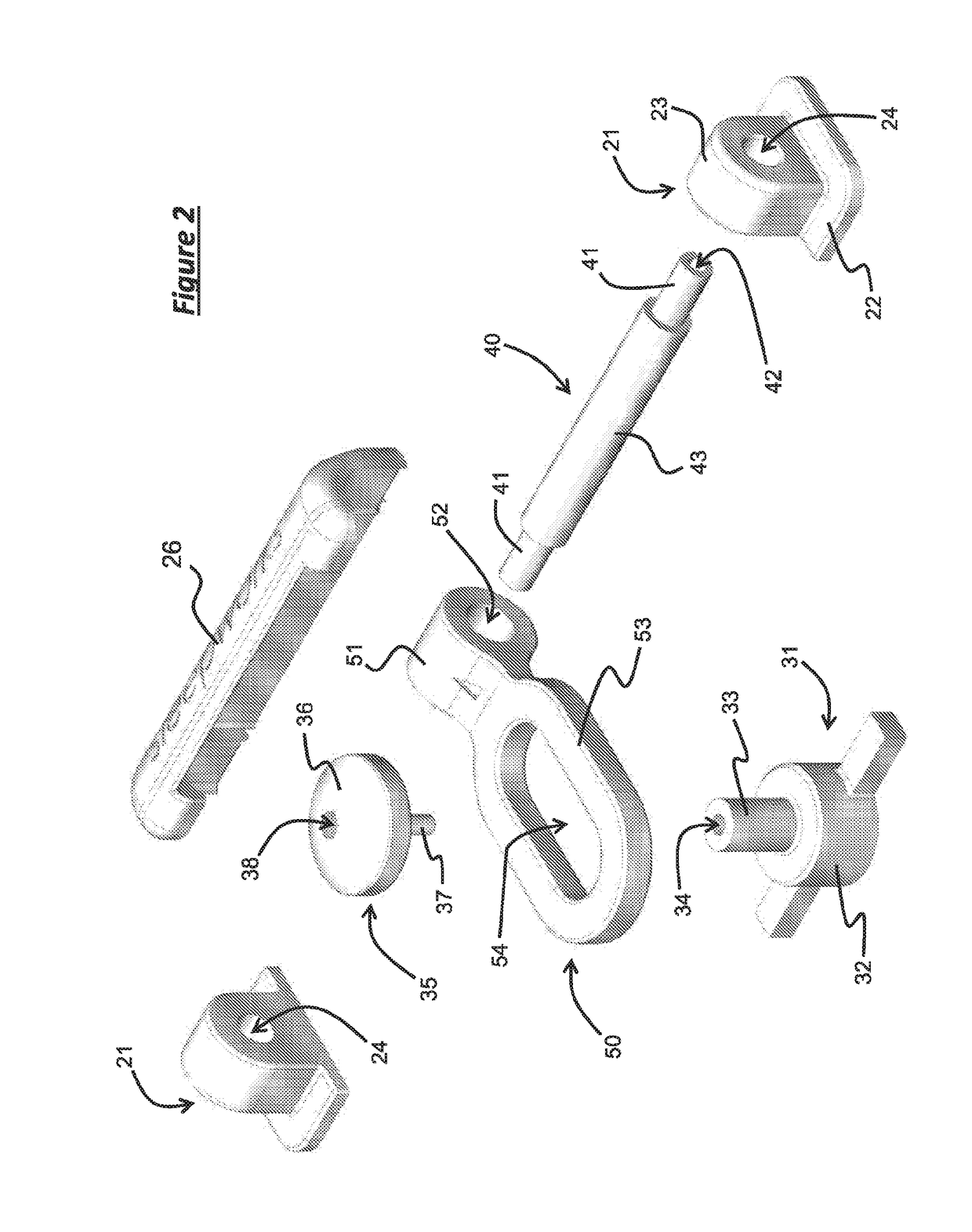

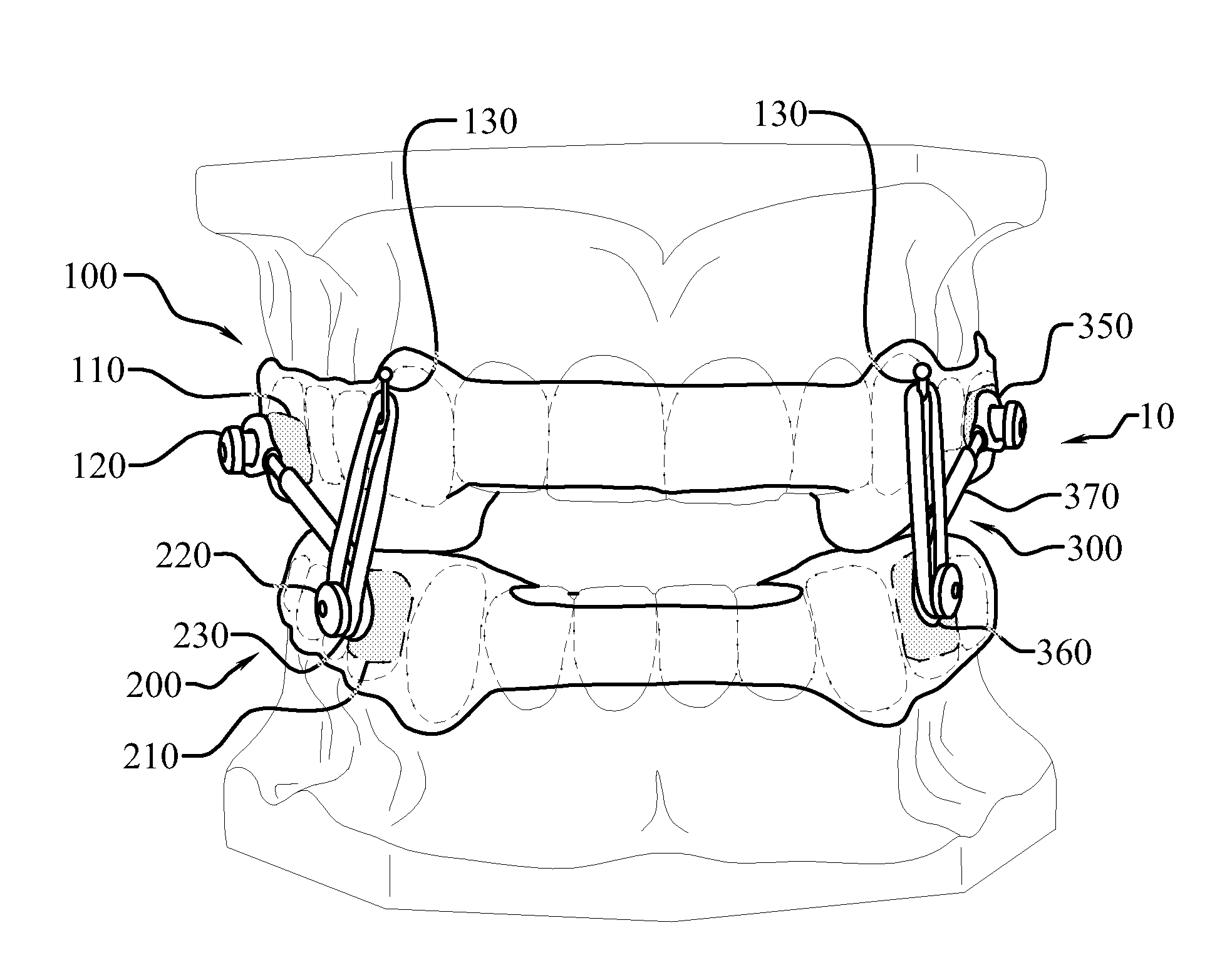

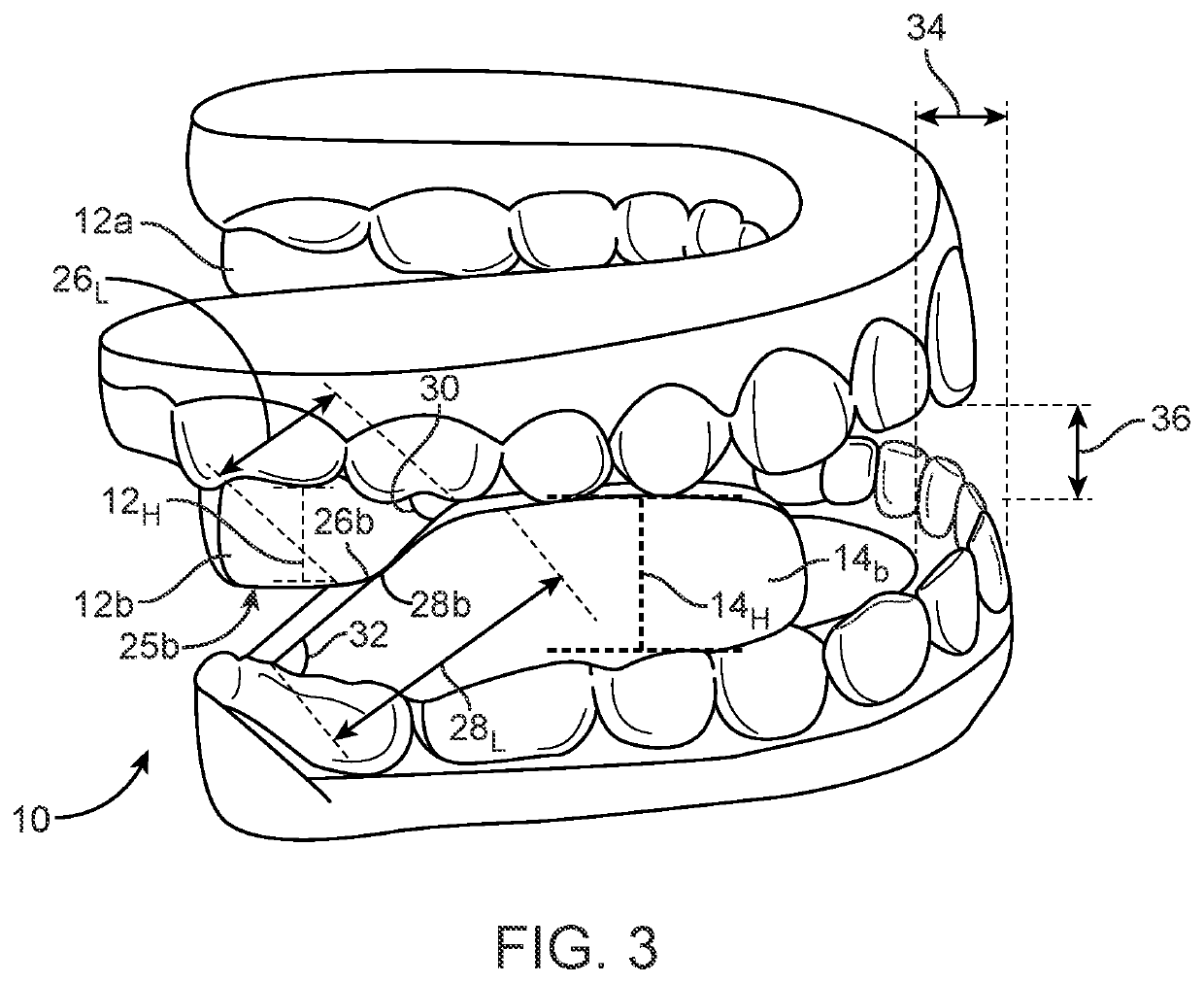

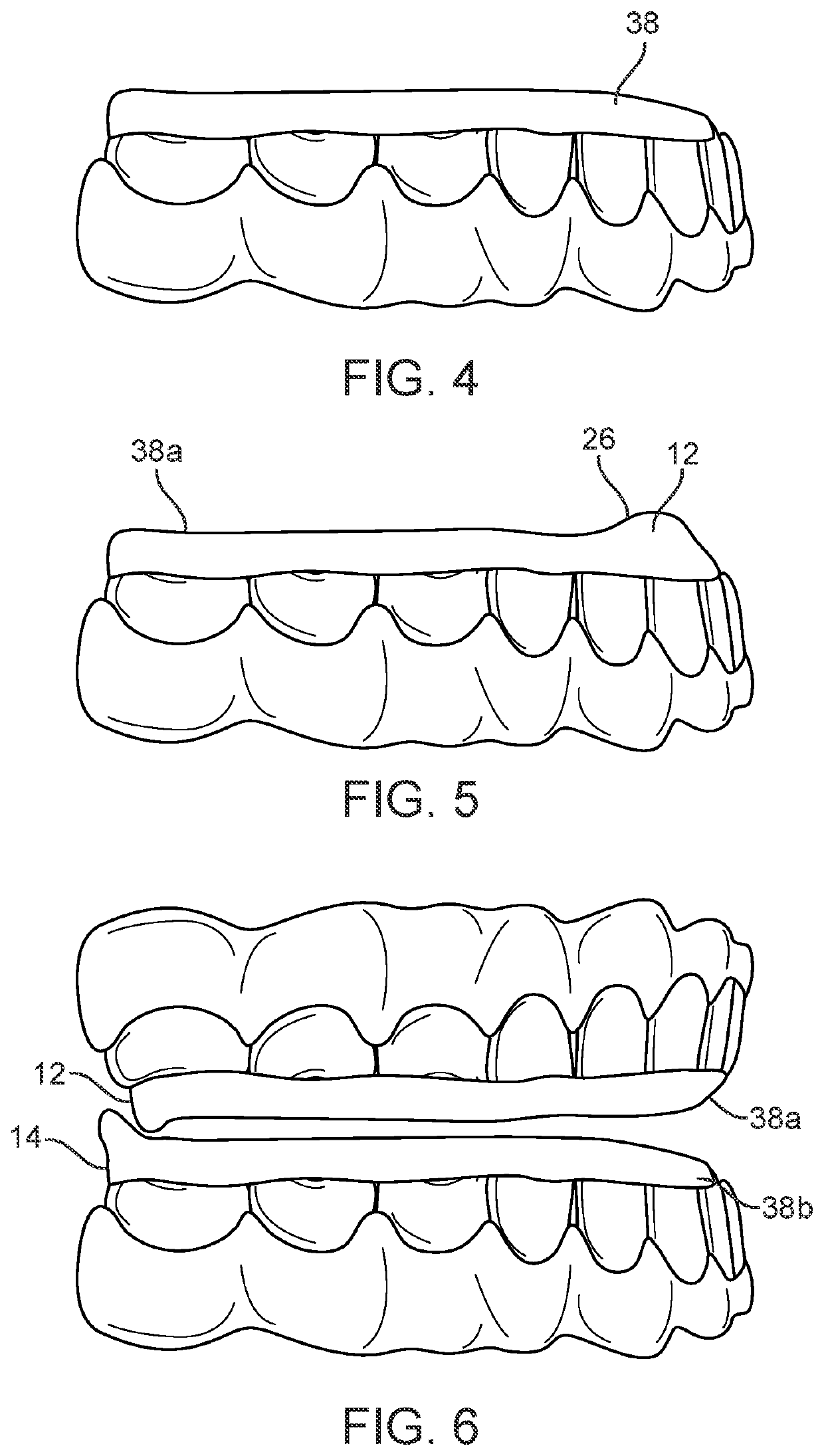

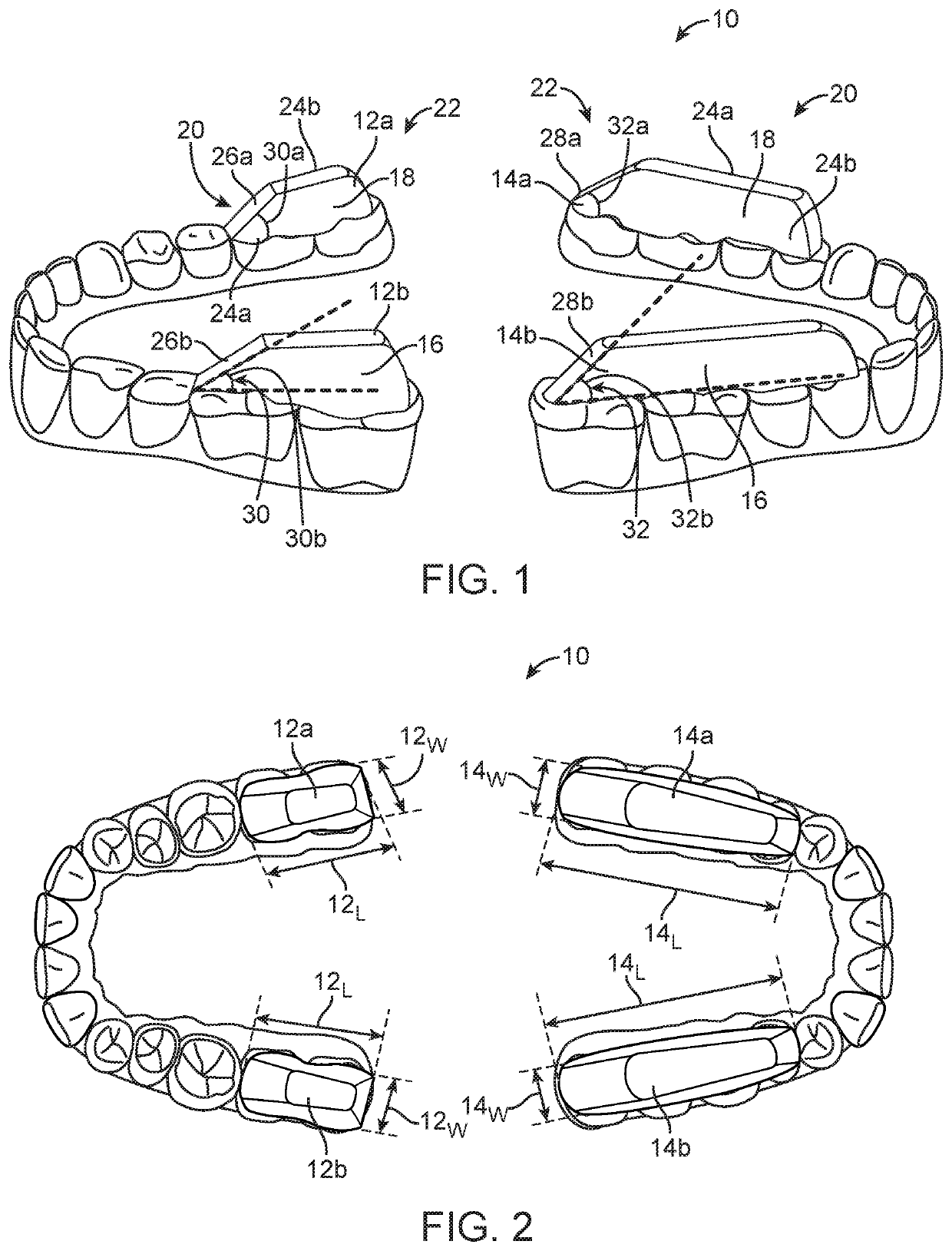

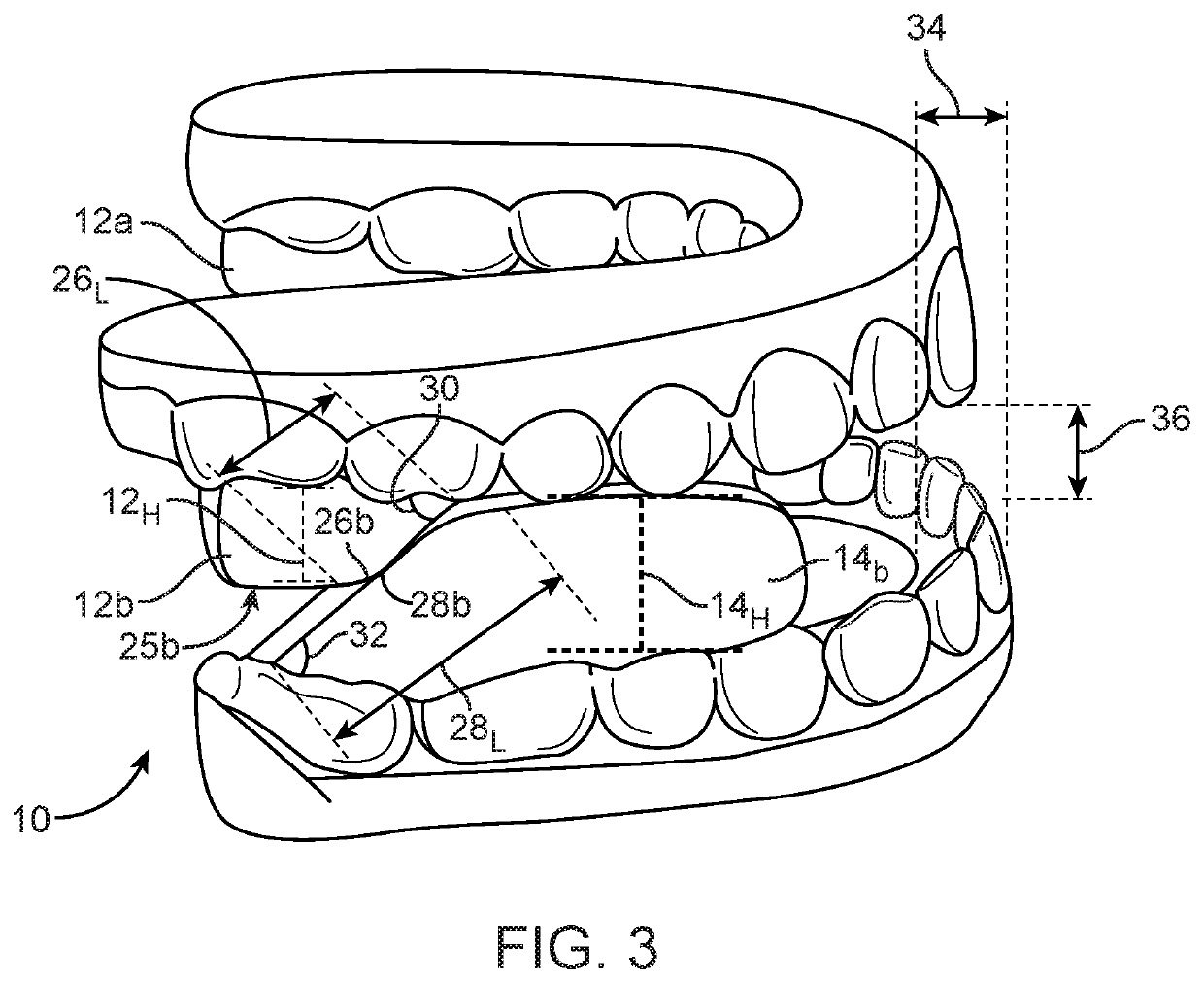

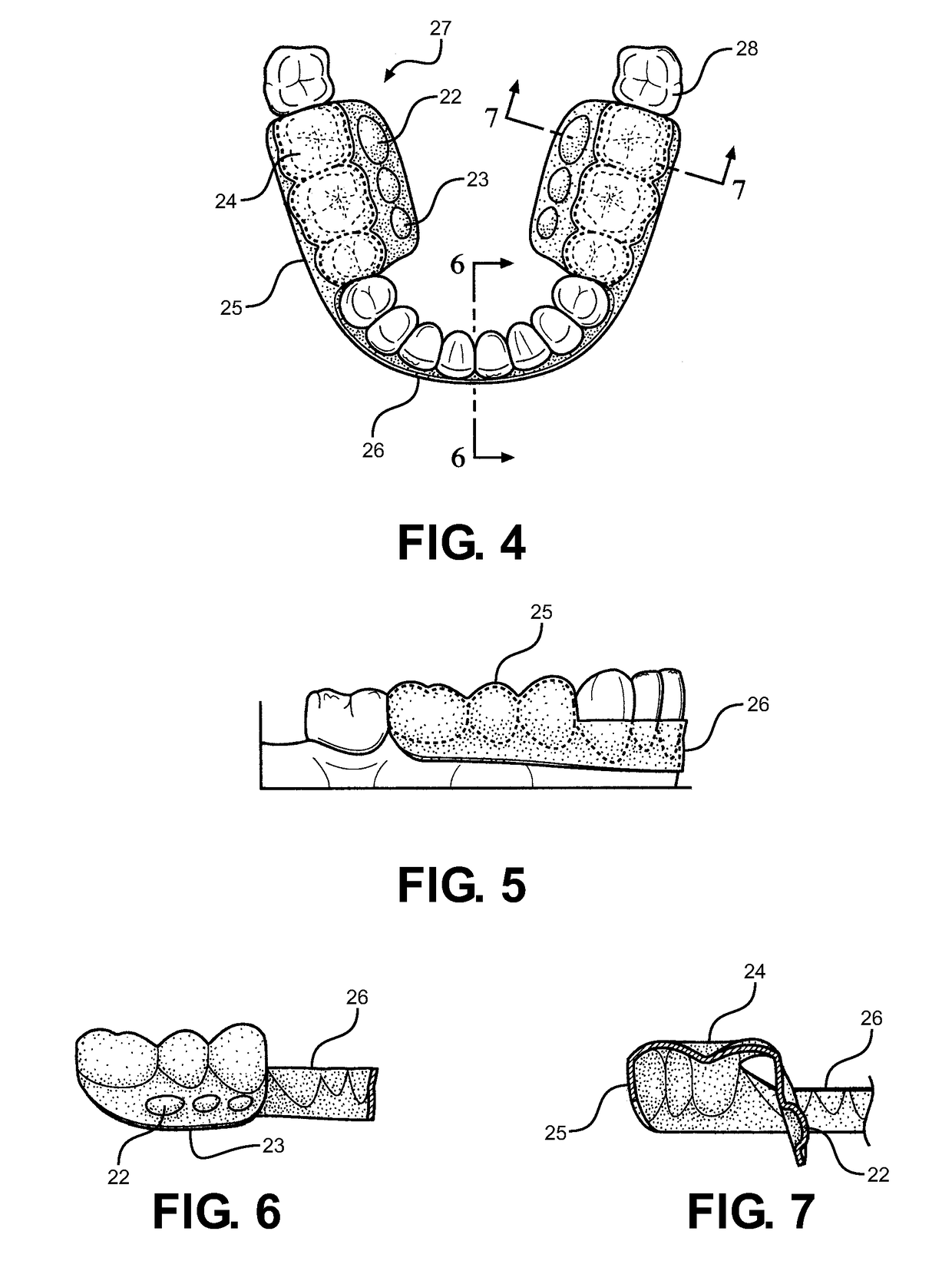

Mandible positioning devices

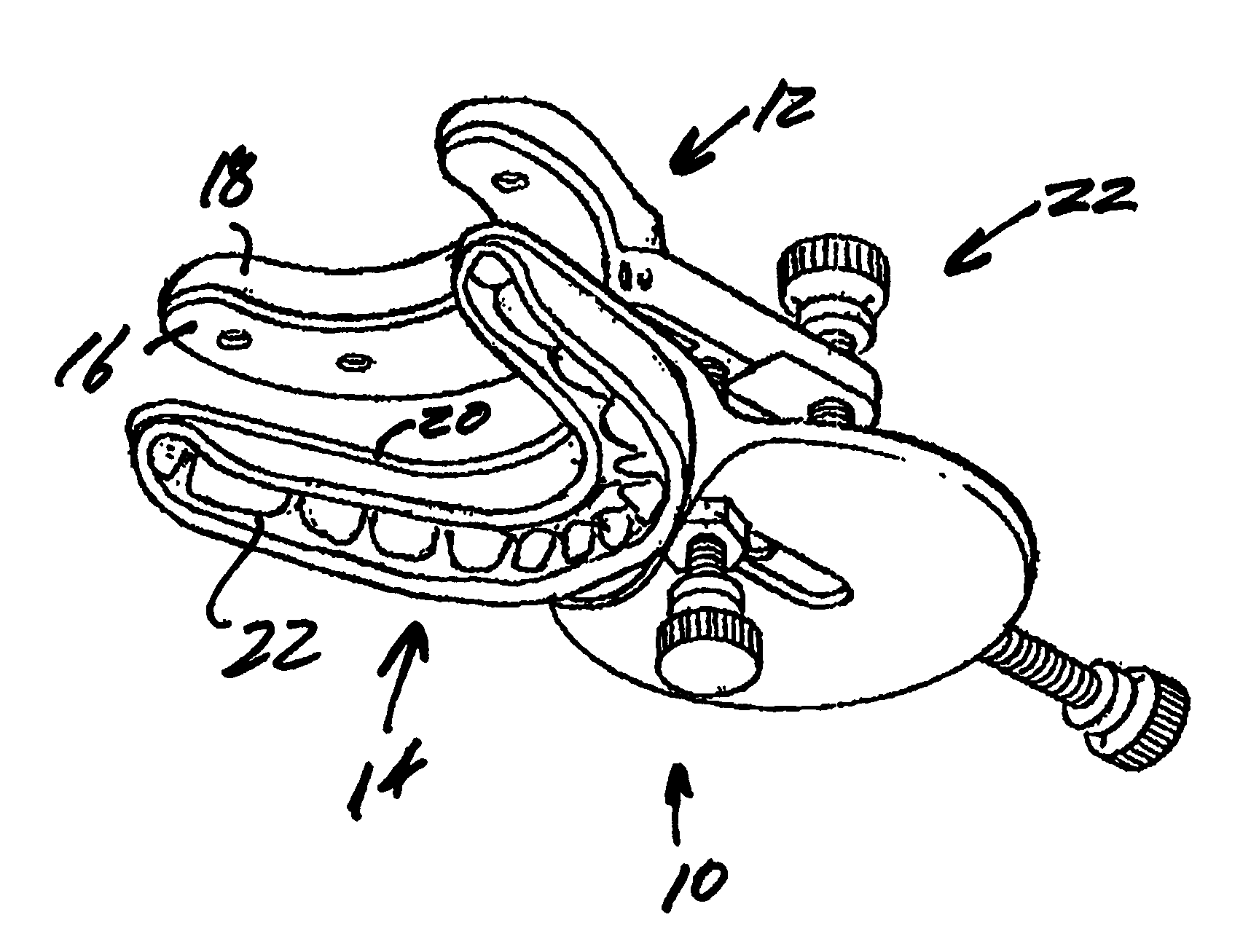

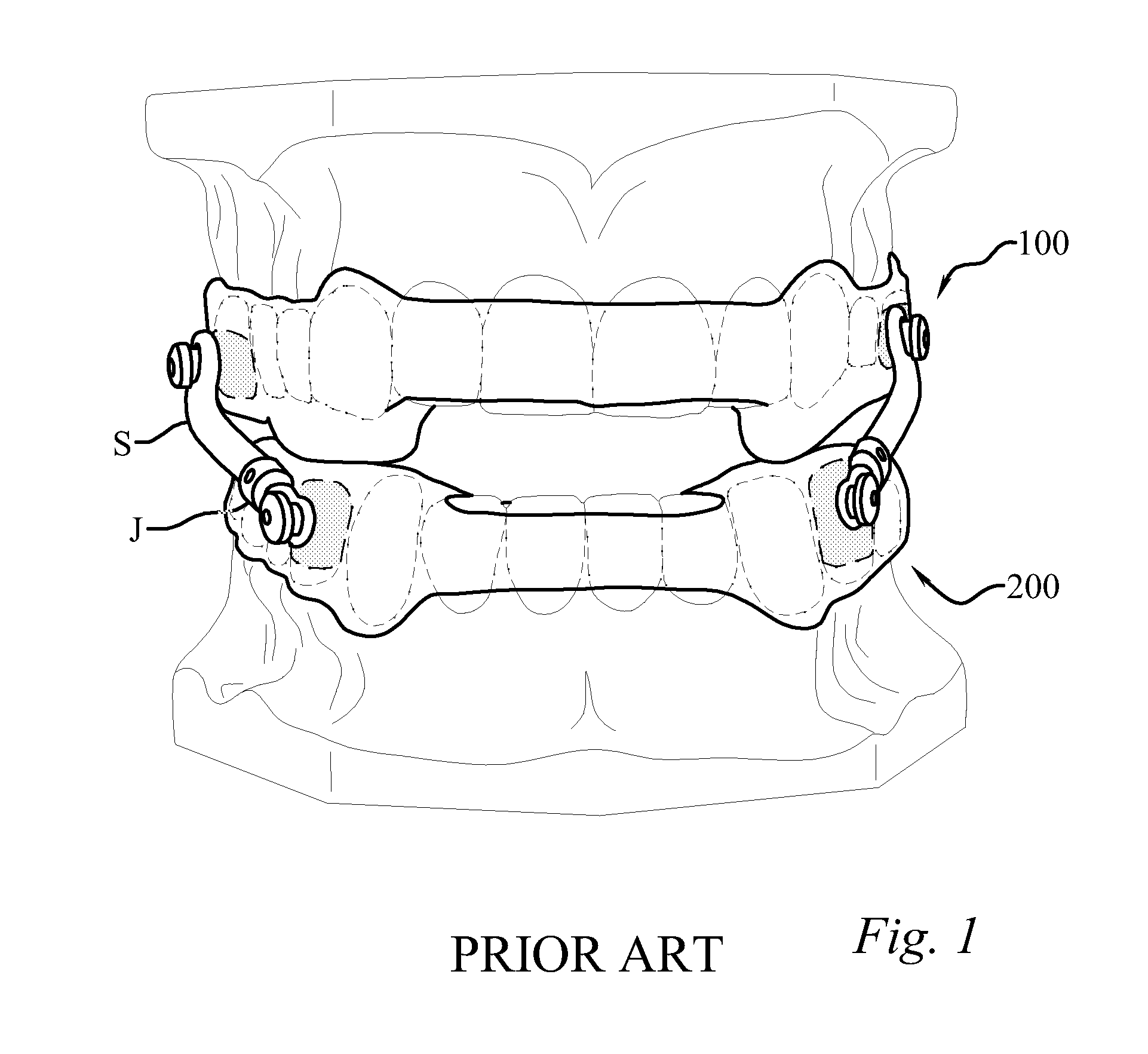

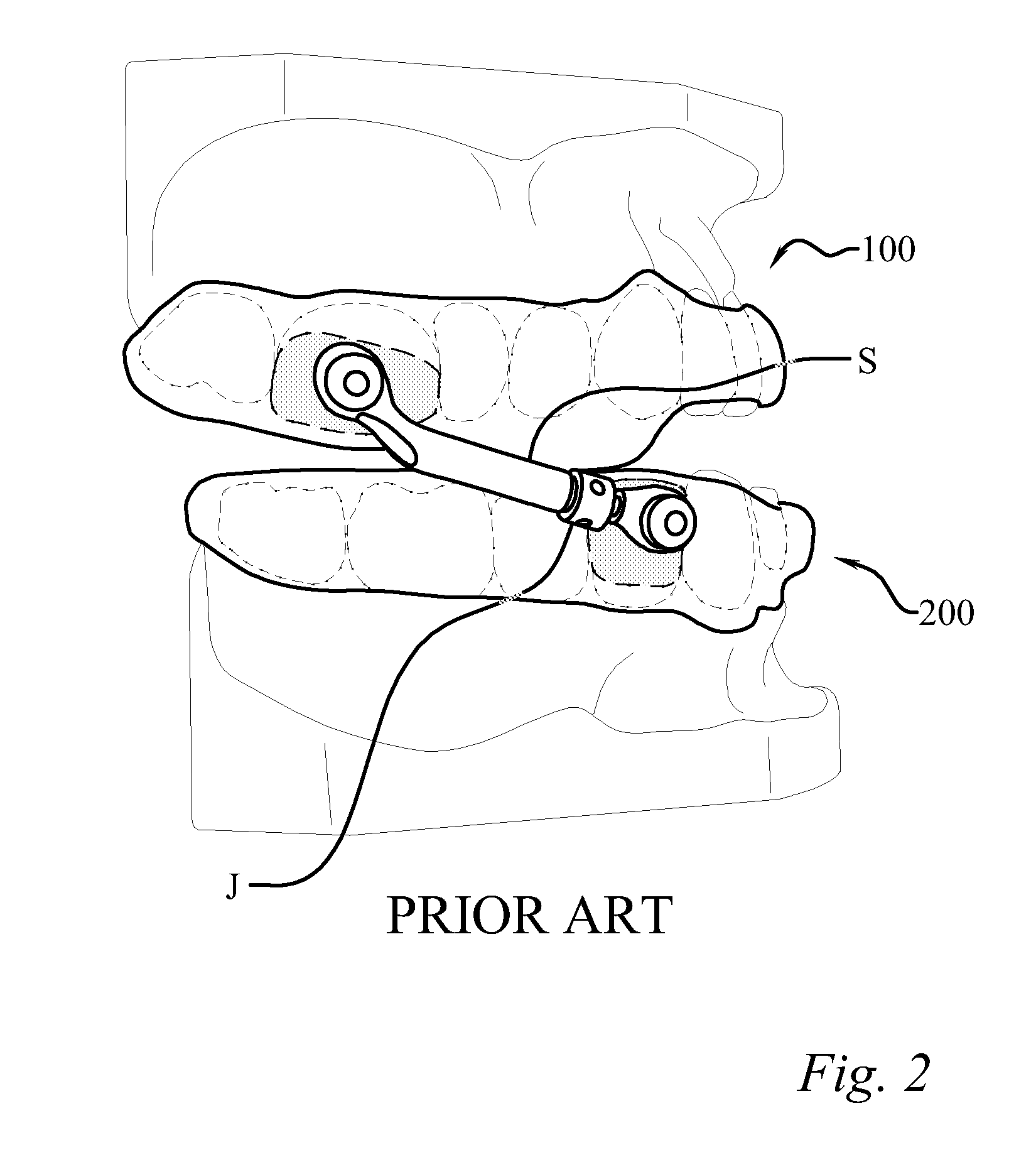

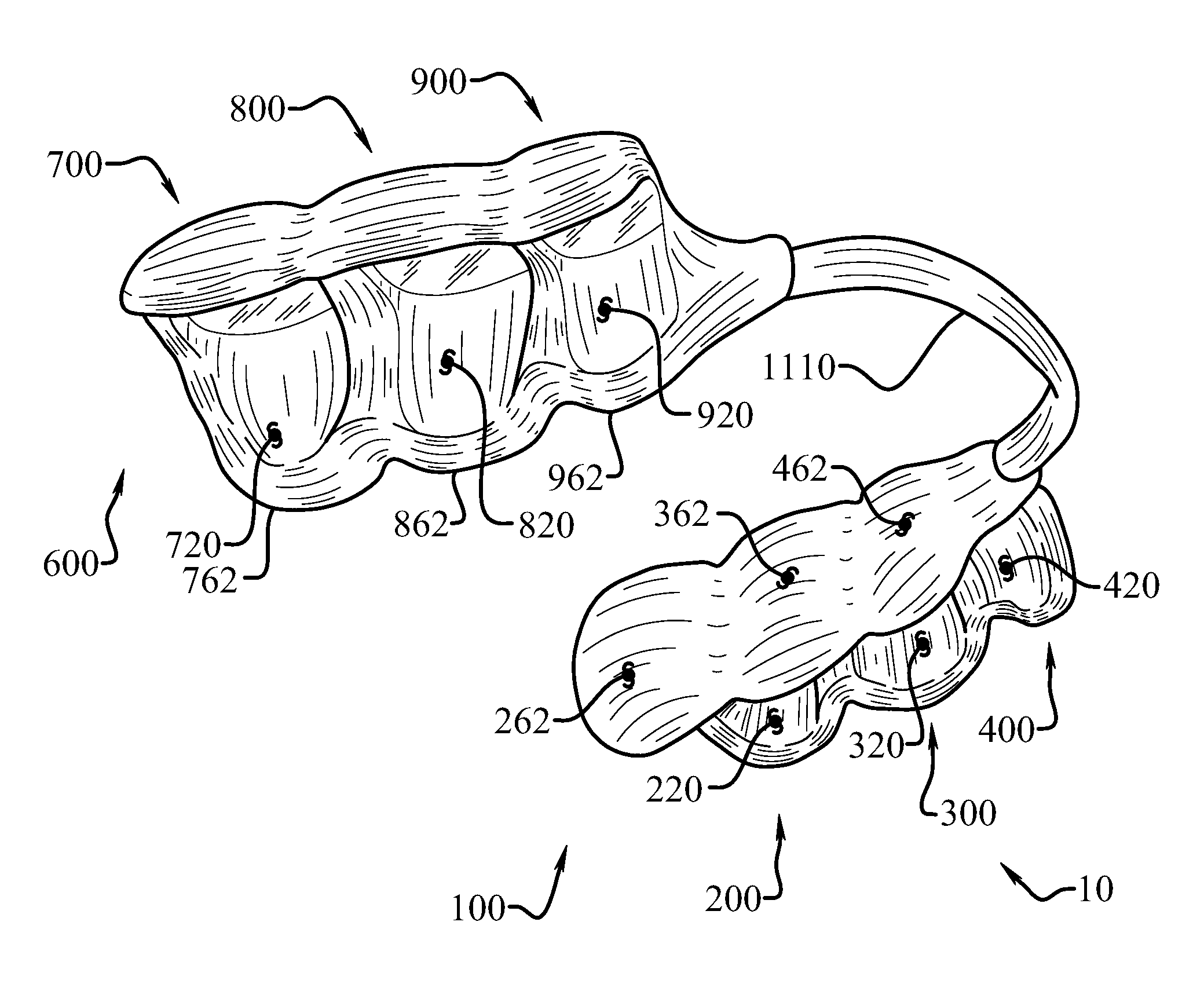

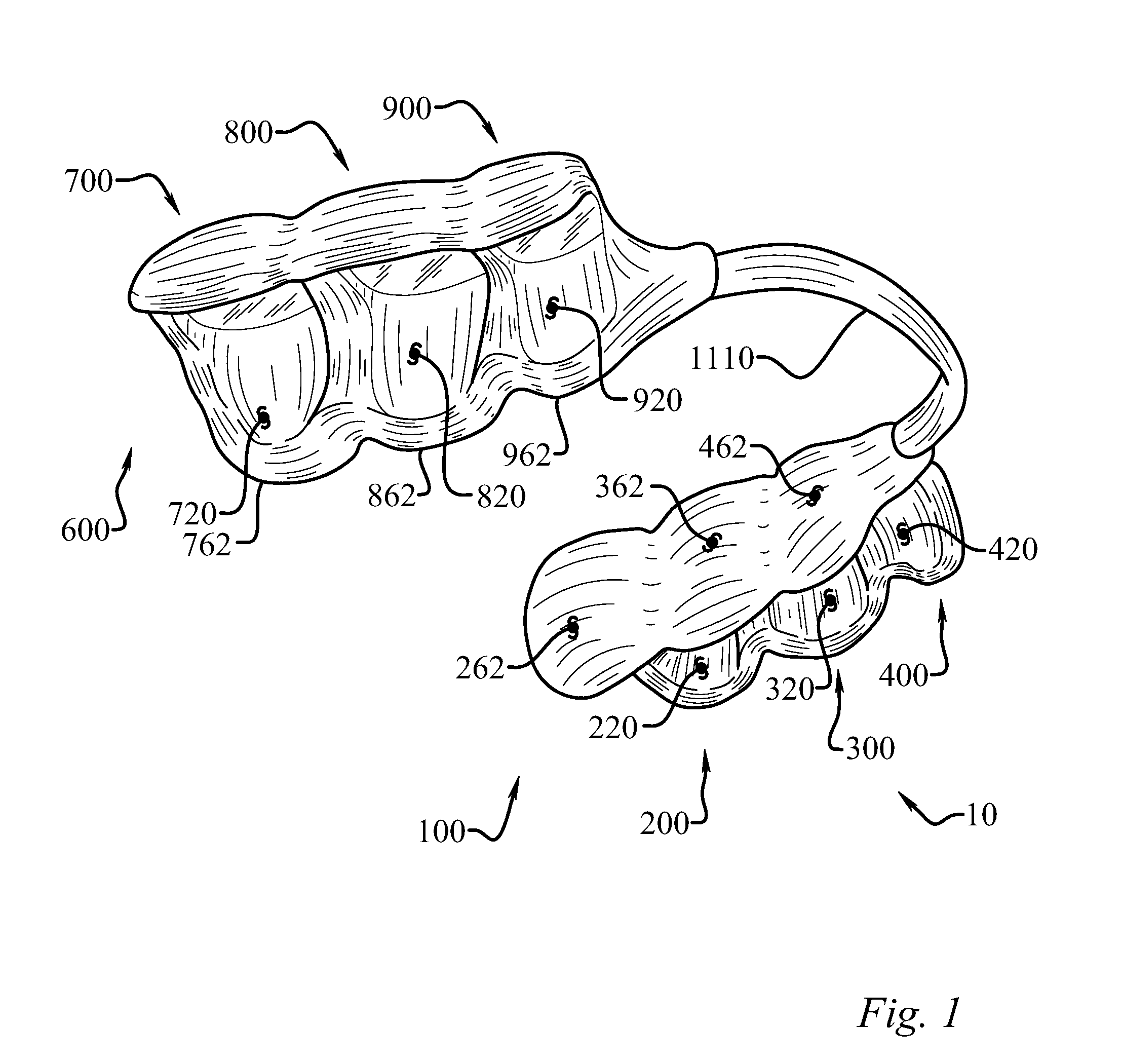

A pharyngeal airway adjuster, or mandible positioning device, has a maxillary dentition engagement component and a mandibular dentition engagement component, each on opposite sides of a plane extending therebetween. An adjustable connection couples the maxillary dentition engagement component with the mandibular dentition engagement component. The adjustable connection has a first adjustment screw having a longitudinal axis parallel to the plane and a second adjustment screw having a longitudinal axis perpendicular to the plane. The first and second adjustable screws are independently adjustable and structured to effect horizontal and vertical displacement, respectively, of the maxillary dentition engagement component relative to the mandibular dentition engagement component. The pharyngeal airway adjuster has a number of indicators adapted to indicate the amount of forwardly and rearwardly displacement effected by the first adjustment screw and / or the amount of upwardly and downwardly displacement effected by the second adjustment screw.

Owner:PHILIPS RS NORTH AMERICA LLC

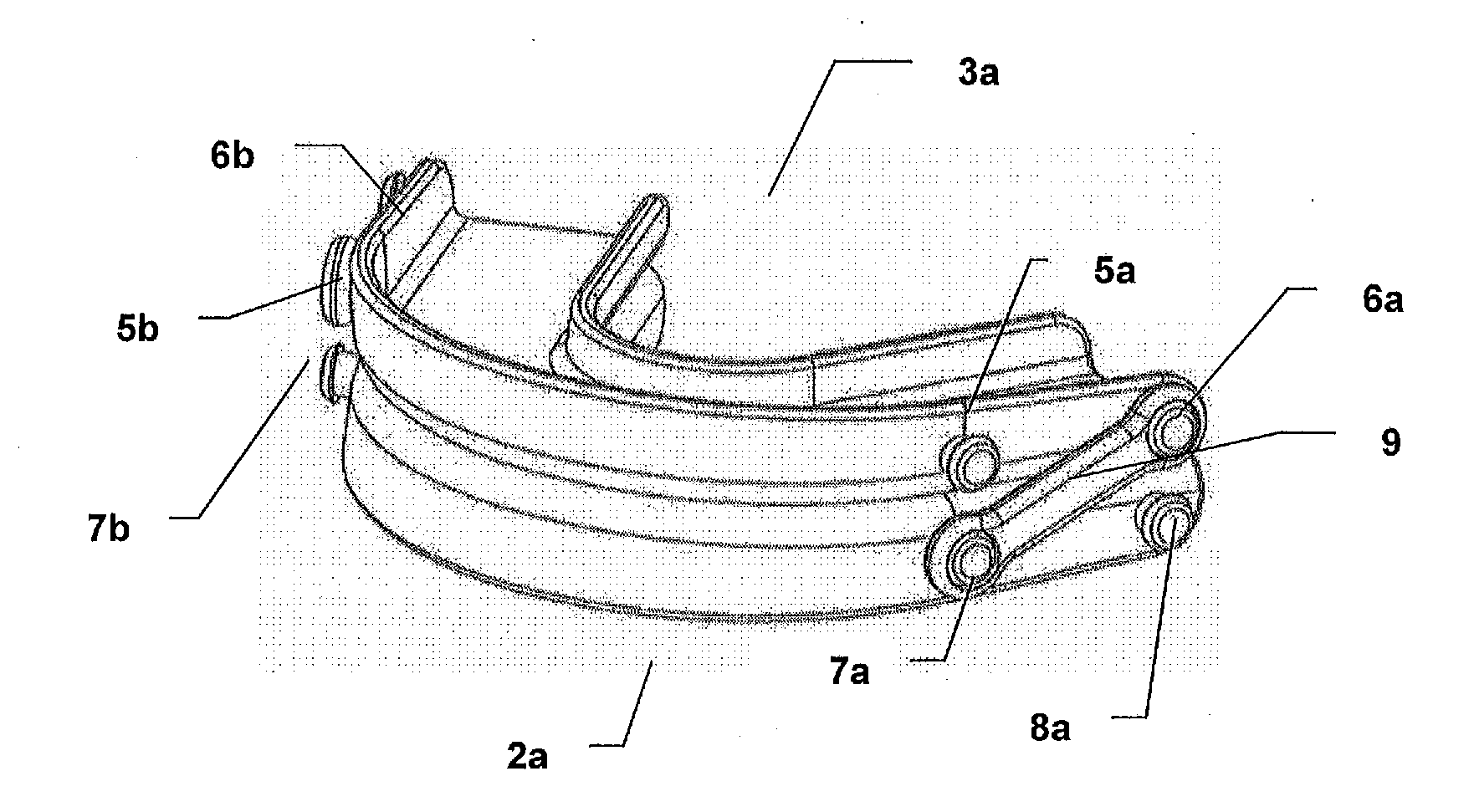

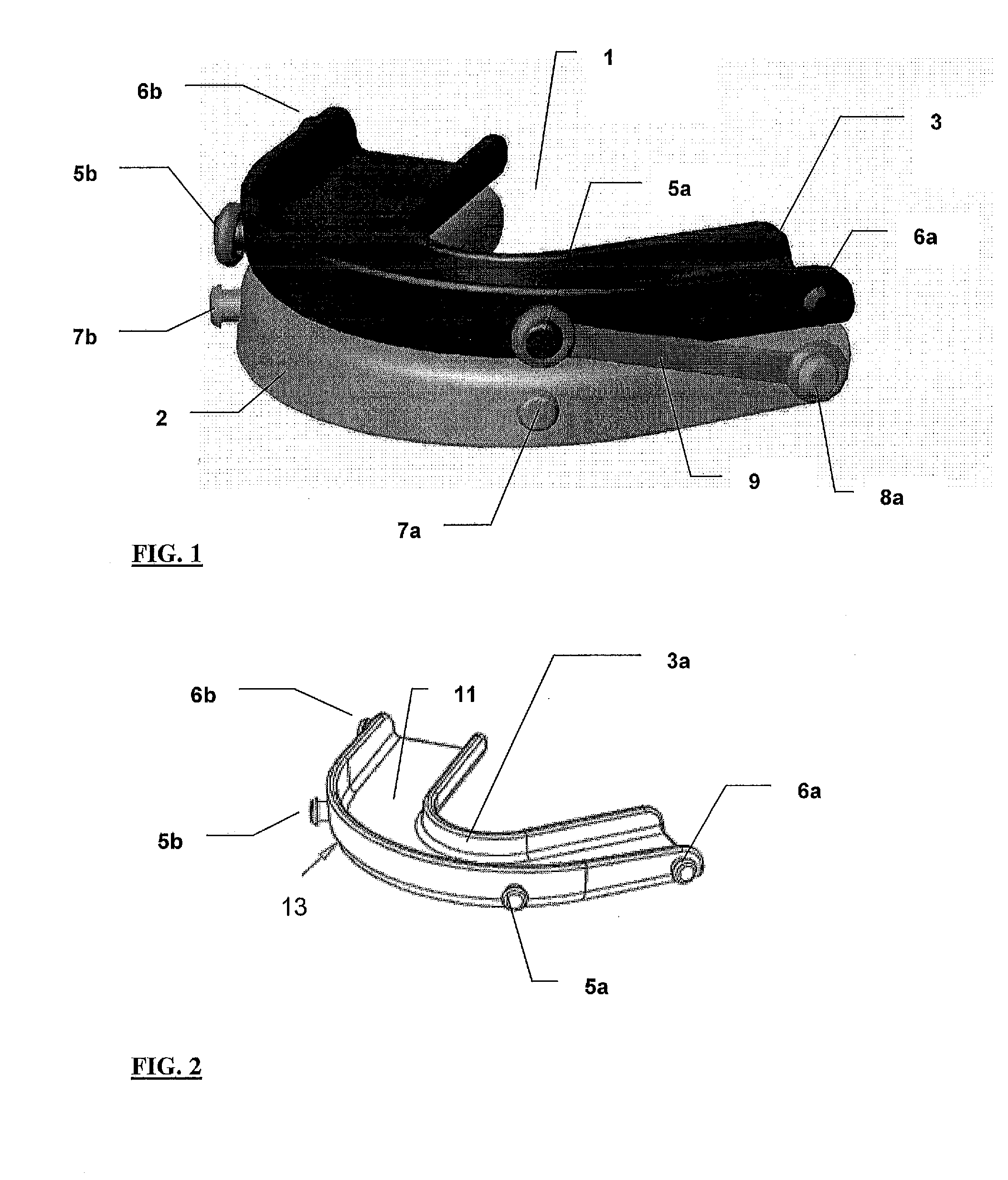

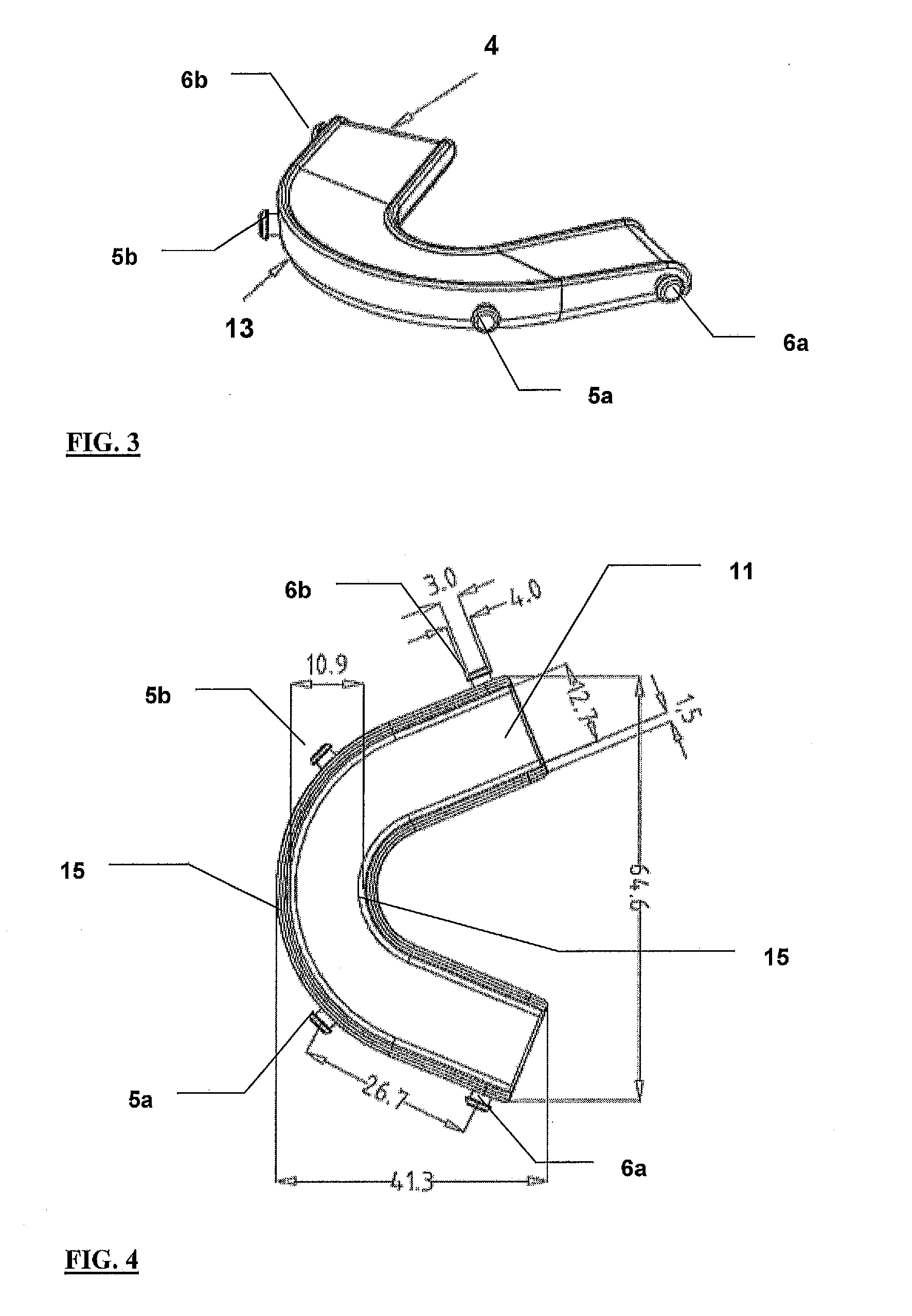

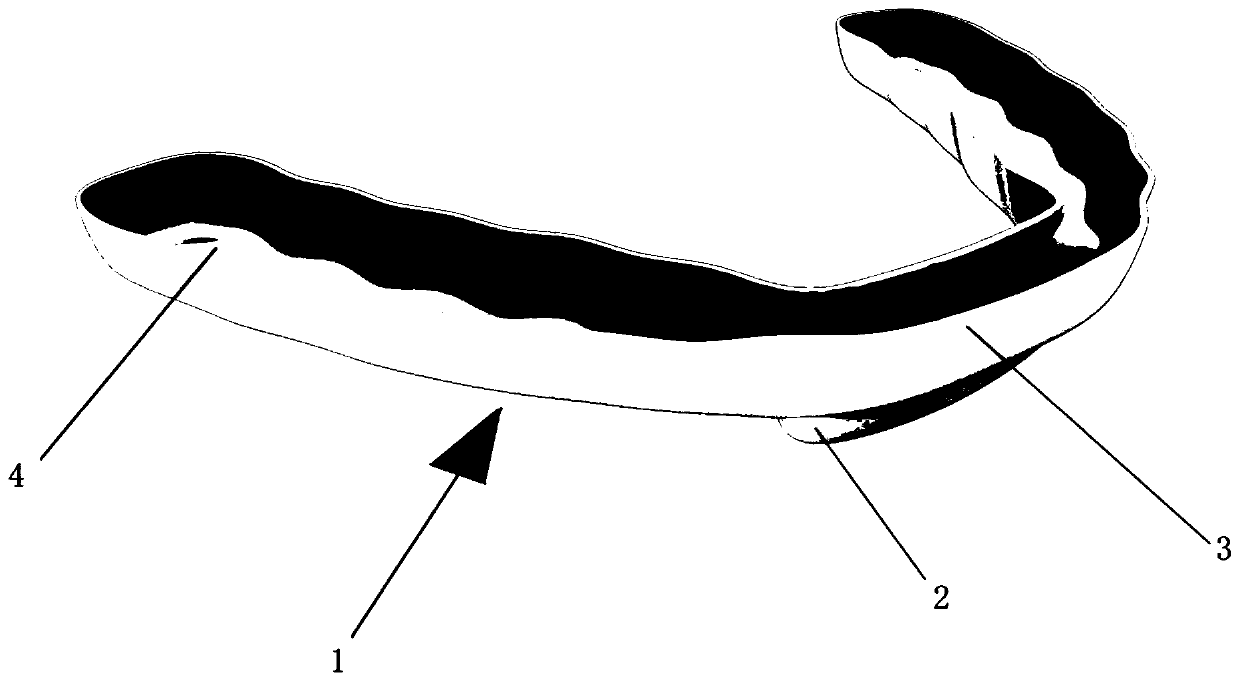

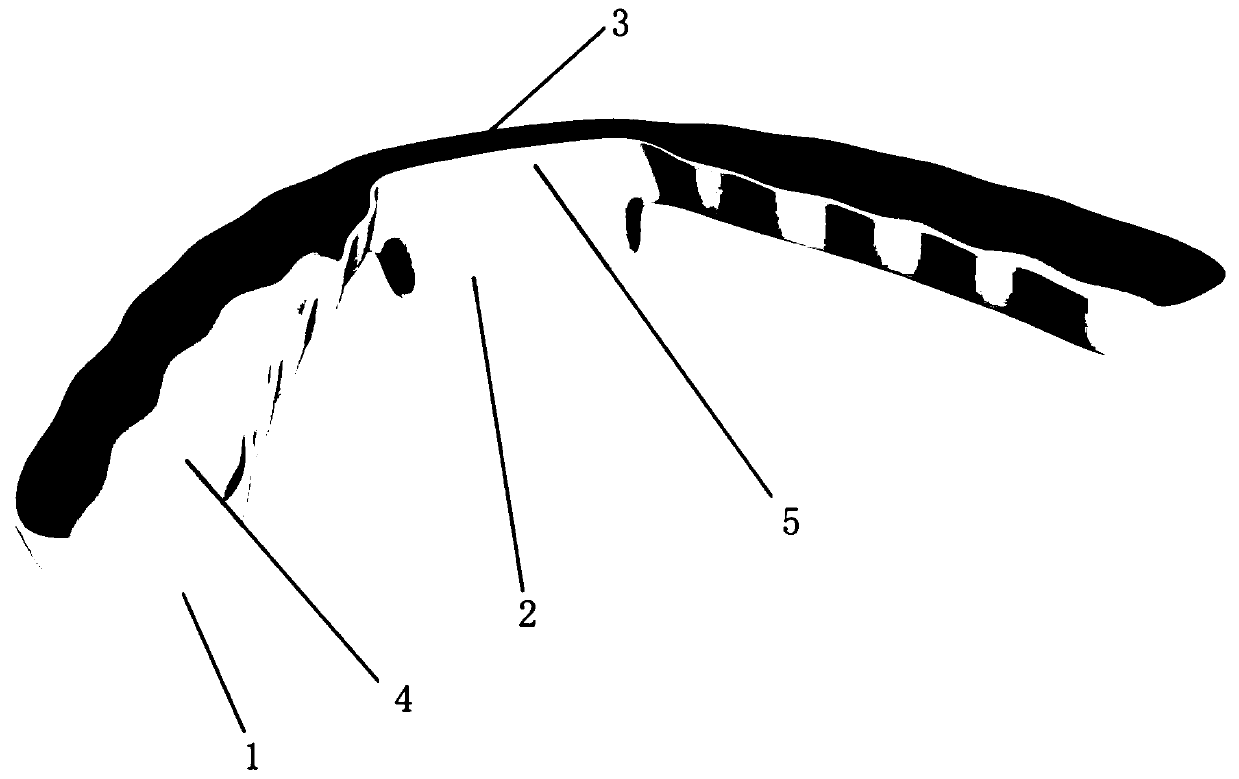

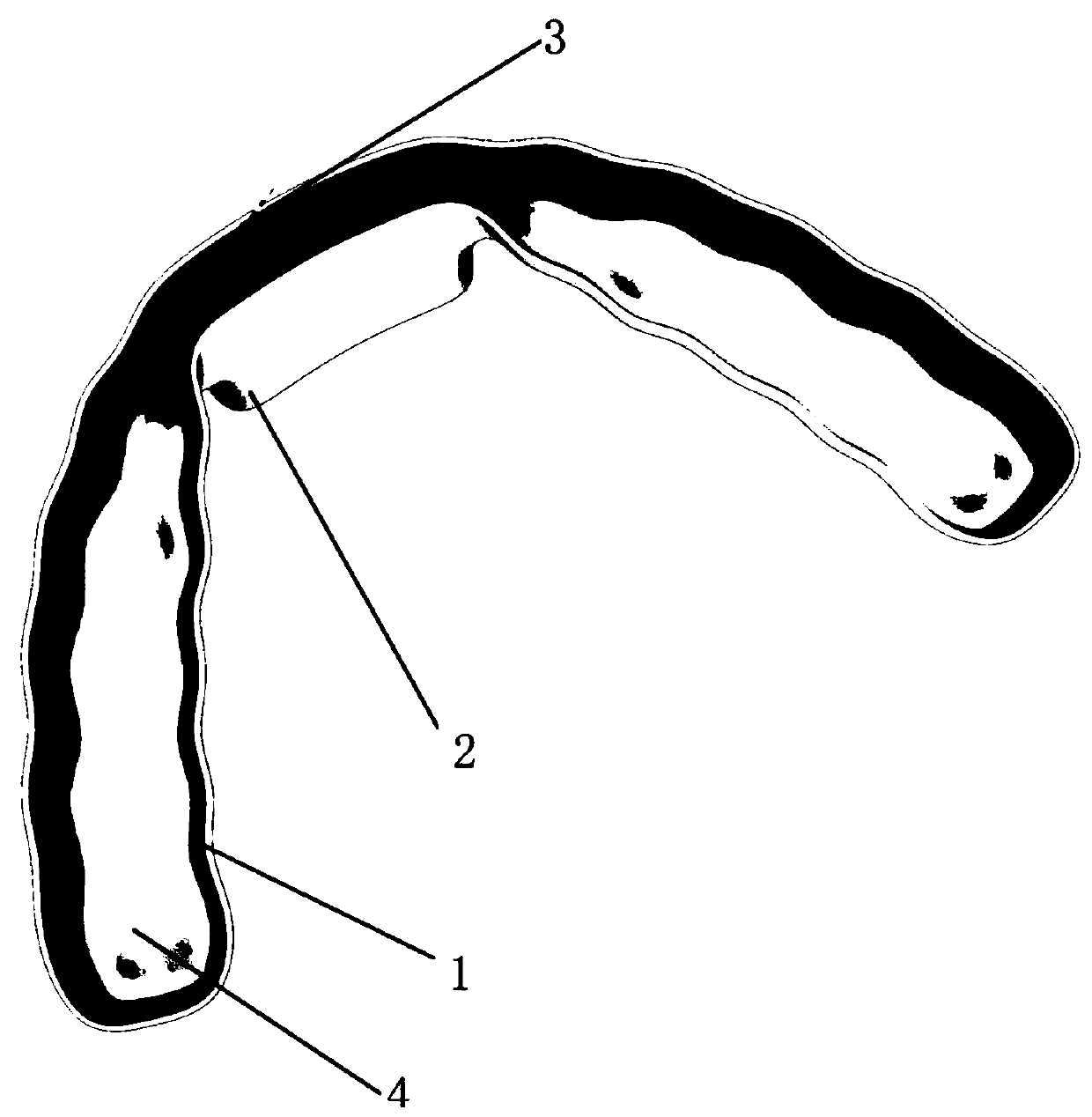

Adjustable mandibular protrusion splint for treating snoring and obstructive sleep apnea

InactiveUS20110155144A1Avoid timeEasy to adjustOthrodonticsMetal rolling stand detailsEngineeringMandibular prognathism

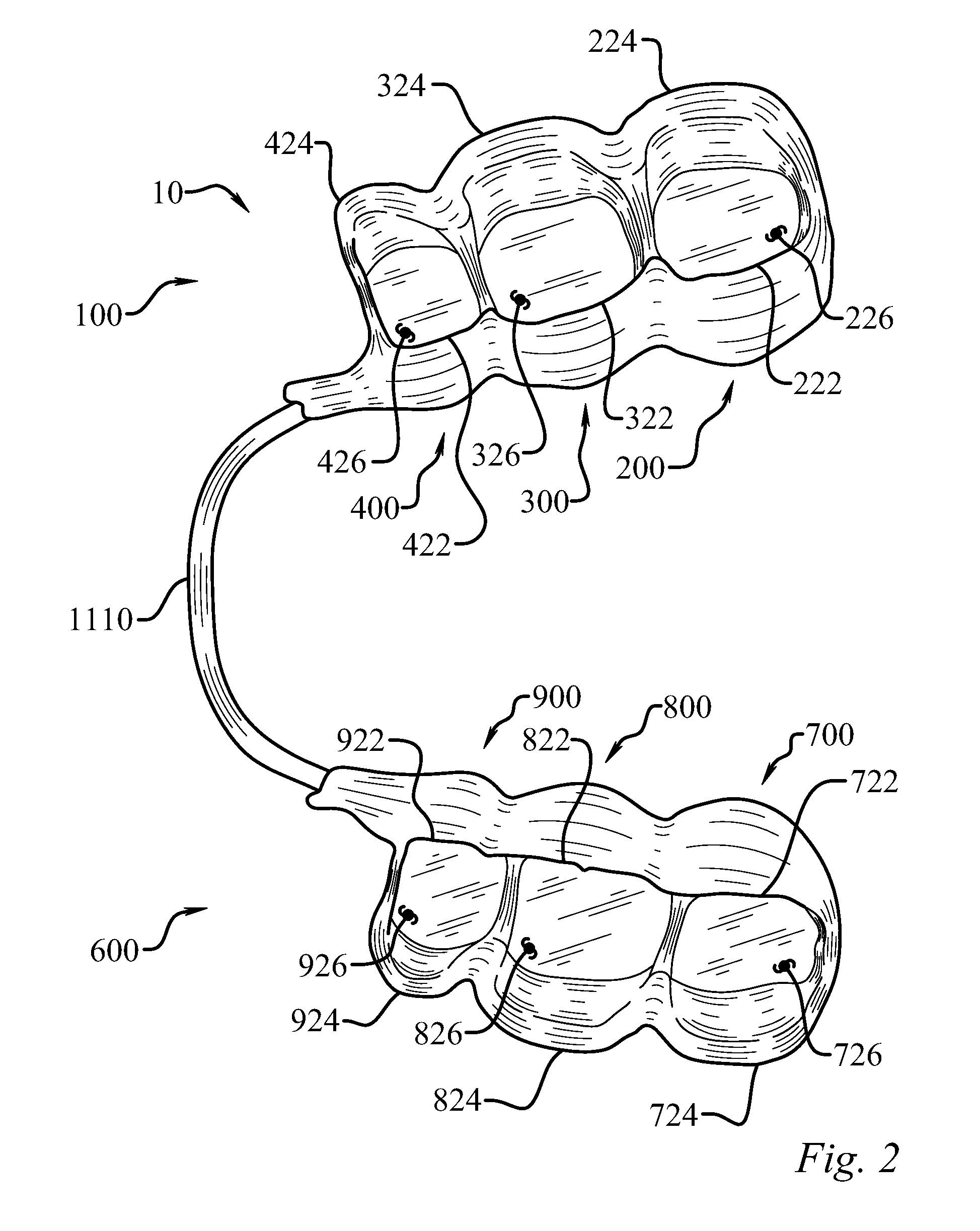

A two-part mandibular protrusion splint (1) for preventing at least one of snoring and obstructive sleep apnea. The mandibular protrusion splint (1) comprises both a lower part (2) and an upper part (3) and each part includes a shaping and flexurally rigid tray (2a, 3a) which is open, during use, towards the mandibula and the maxilla. Each tray comprises a thermoplastic filler material (4, 5) which can be shaped in a manner of a dental brace to fit the human maxilla and mandibula. Both the trays comprise one or more fixing knobs (5a, 5b, 6a, 6b, 7a, 7b, 8a, 8b), on the respective outer sides thereof, for fastening to a protrusion holder (9). The protrusion holder (9) is rotatably fastened to a fixing knob (5a, 5b, 6a, 6b, 7a, 7b, 8a, 8b), on each of the mandibular tray and the maxillar tray, for bring the mandibula into an anterior position.

Owner:TOUSSSAINT WINFRIED

Dental appliance for improving airflow through nasal-pharyngeal airway

ActiveUS20040177852A1Increase airflowReduce airflow resistanceRespiratorsBreathing filtersNasopharyngeal airwayNasal dilators

A dental device comprises an intraoral nasal dilator and a mandibular repositioner working synergistically as an anti-snoring device. The device has a lower segment of thermoplastic material which is formed to fit over the lower teeth and is connected to an upper section of molded material extending between the upper jaw and the upper lip by a wire connector. The wire connector has mechanisms allowing adjustment of the lower jaw positioning. A wire extension with acrylic pads at end is bonded in the midline of the flange and extends out so that the pads stretch the tissue of the lip and lateral nasal walls preventing collapse during respiration while the anterior repositioning of the lower jaw maintains opening of the posterior pharyngeal airway during sleep functioning as an anti-snoring device. Additional applications of the intraoral nasal dilator include incorporation into sports mouth guards using a variety of materials.

Owner:ABRAMSON MARK

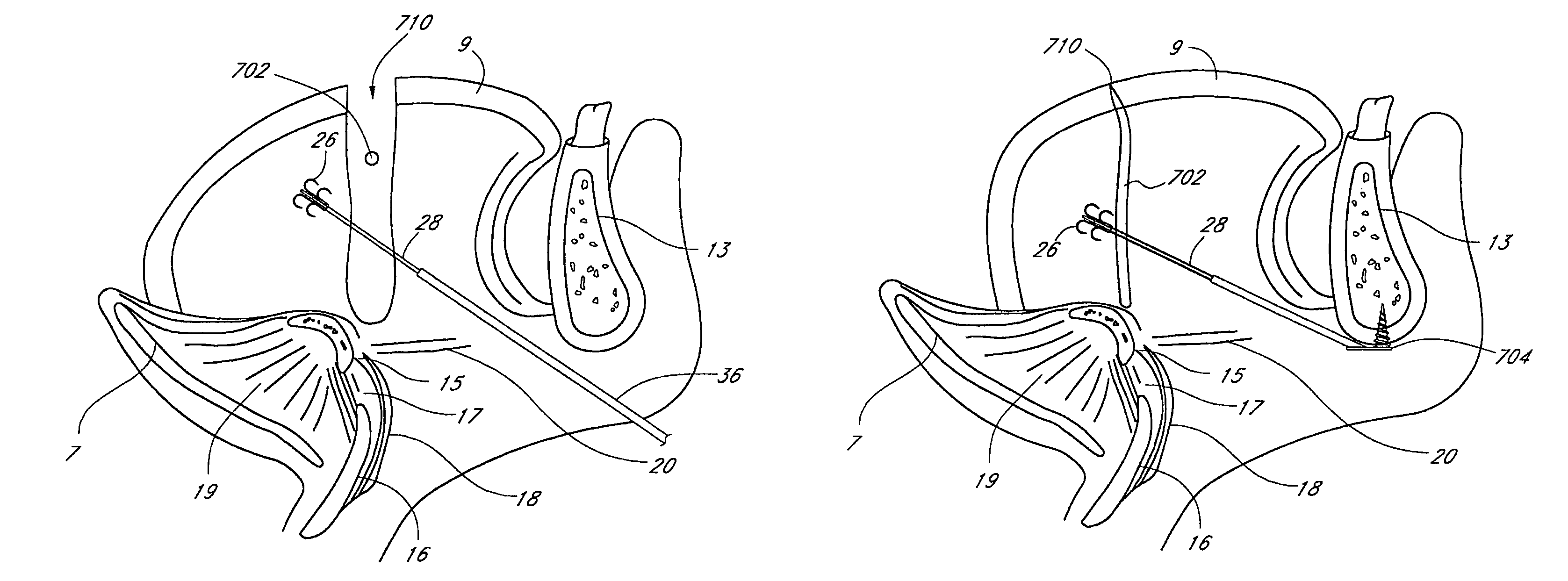

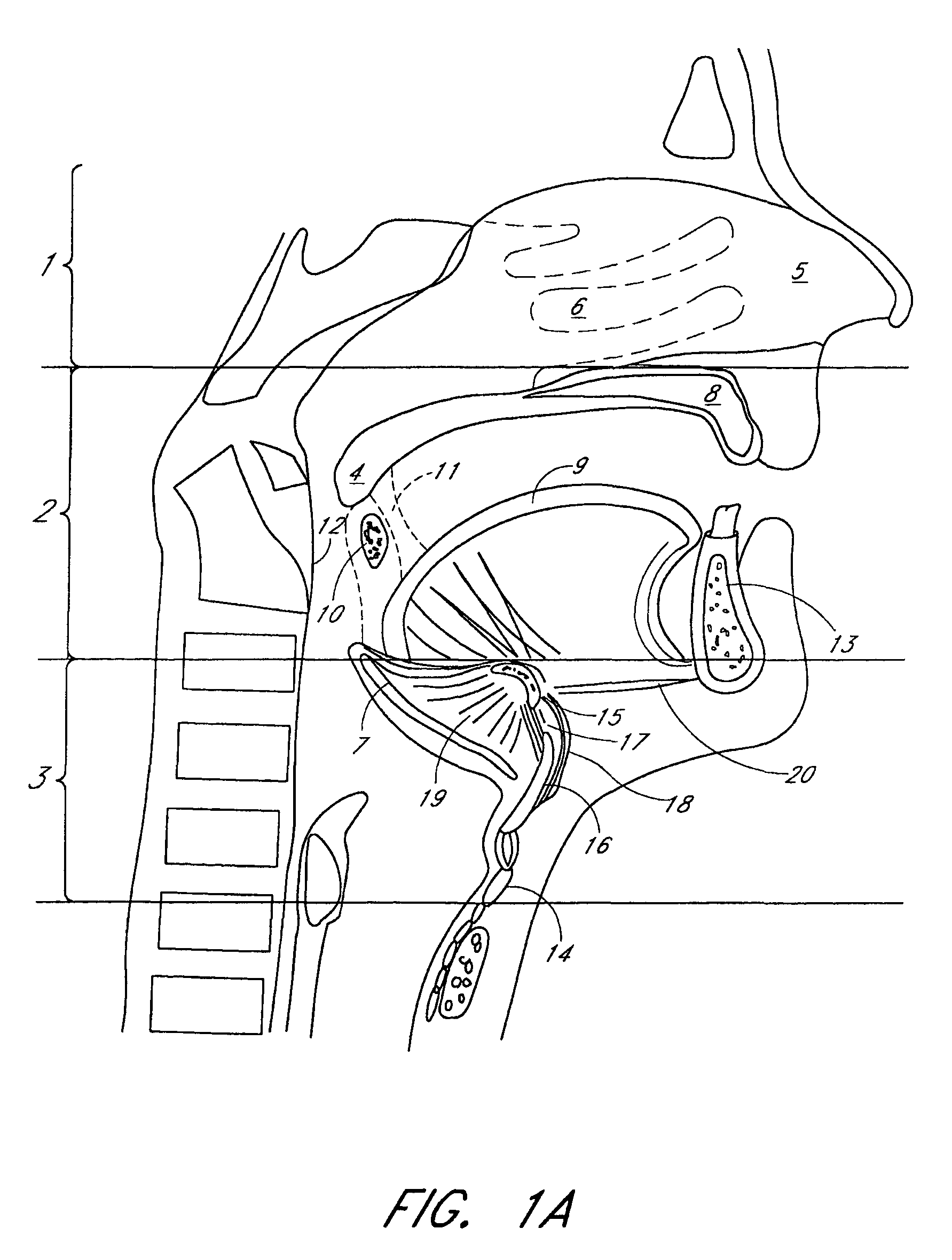

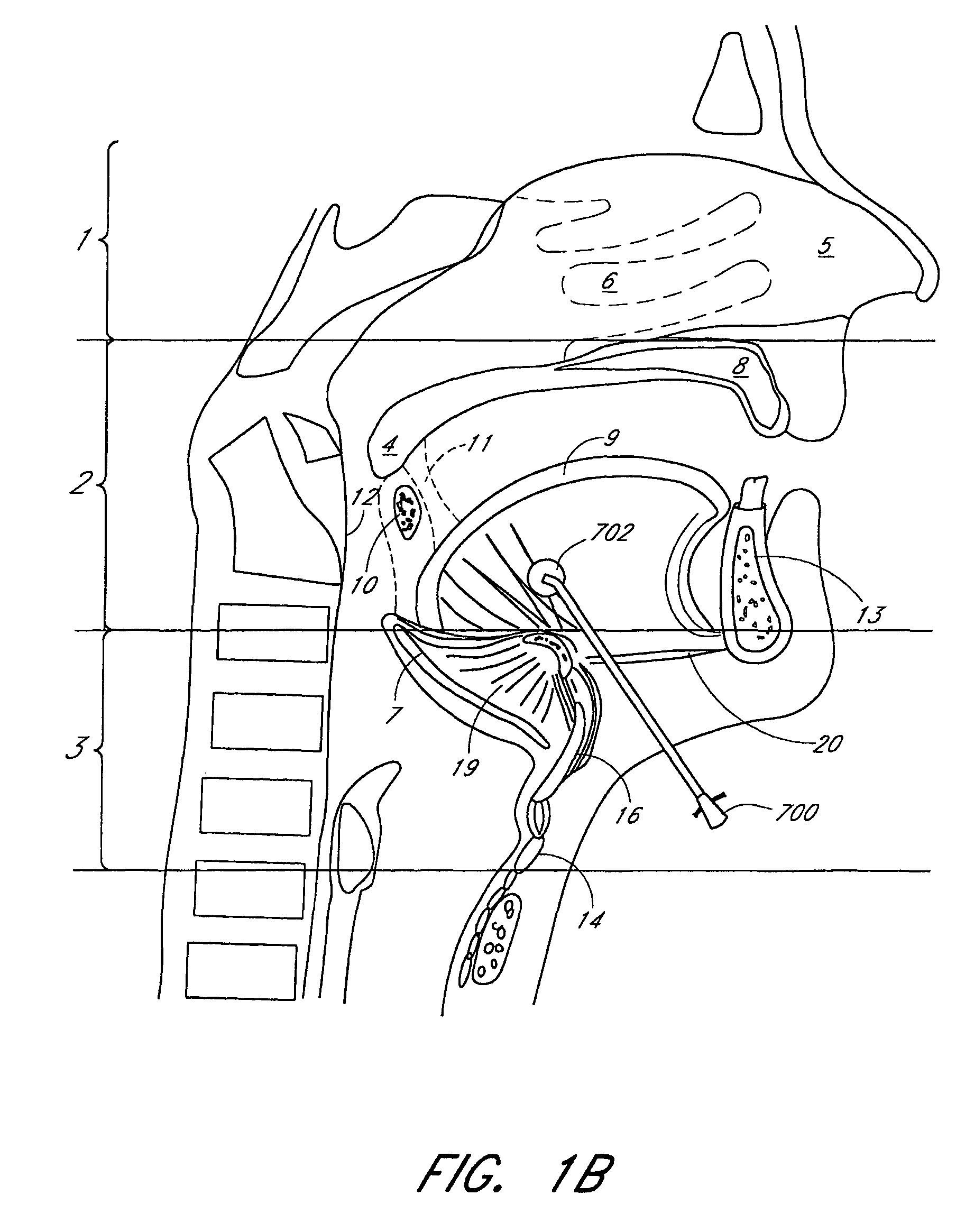

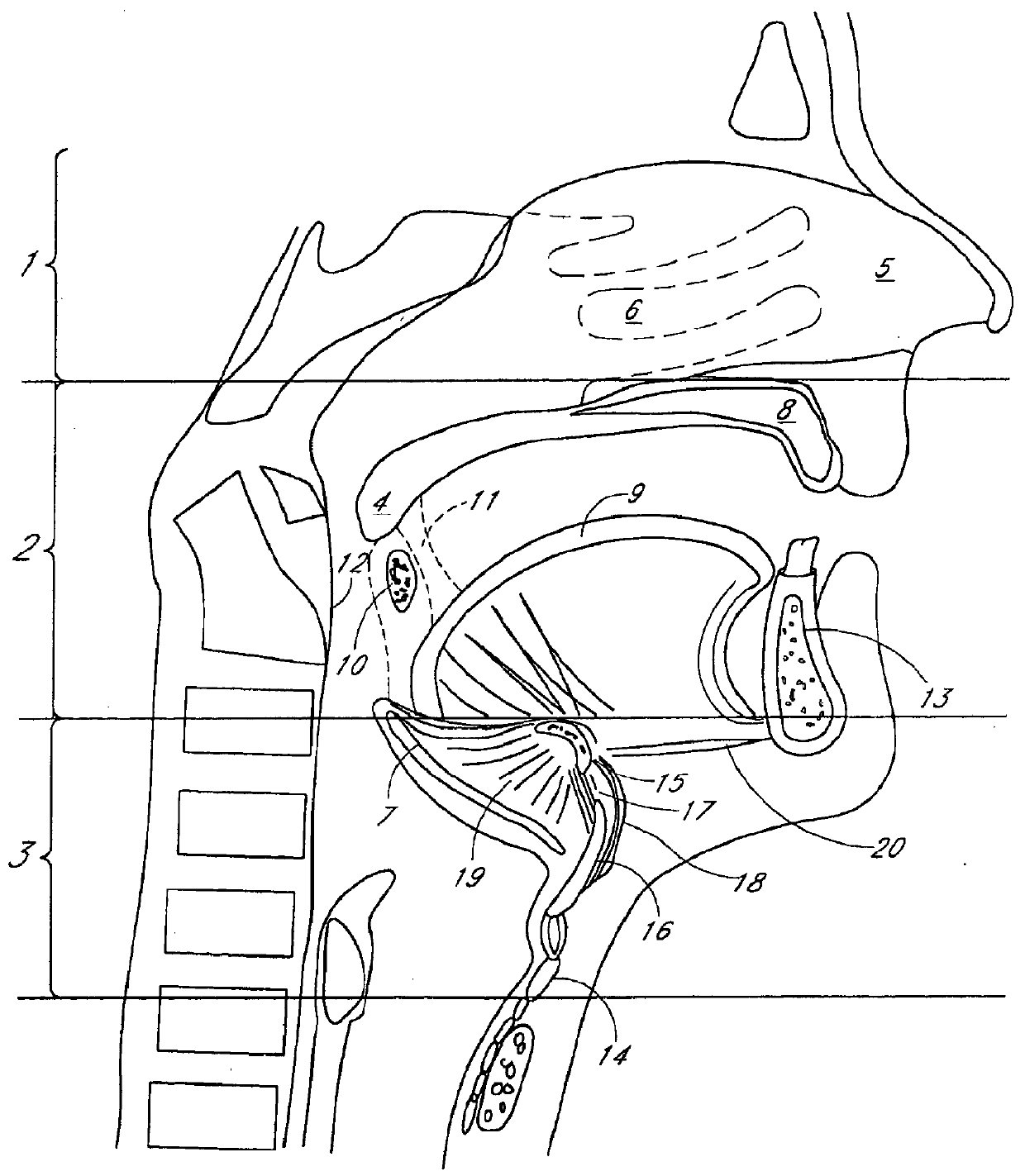

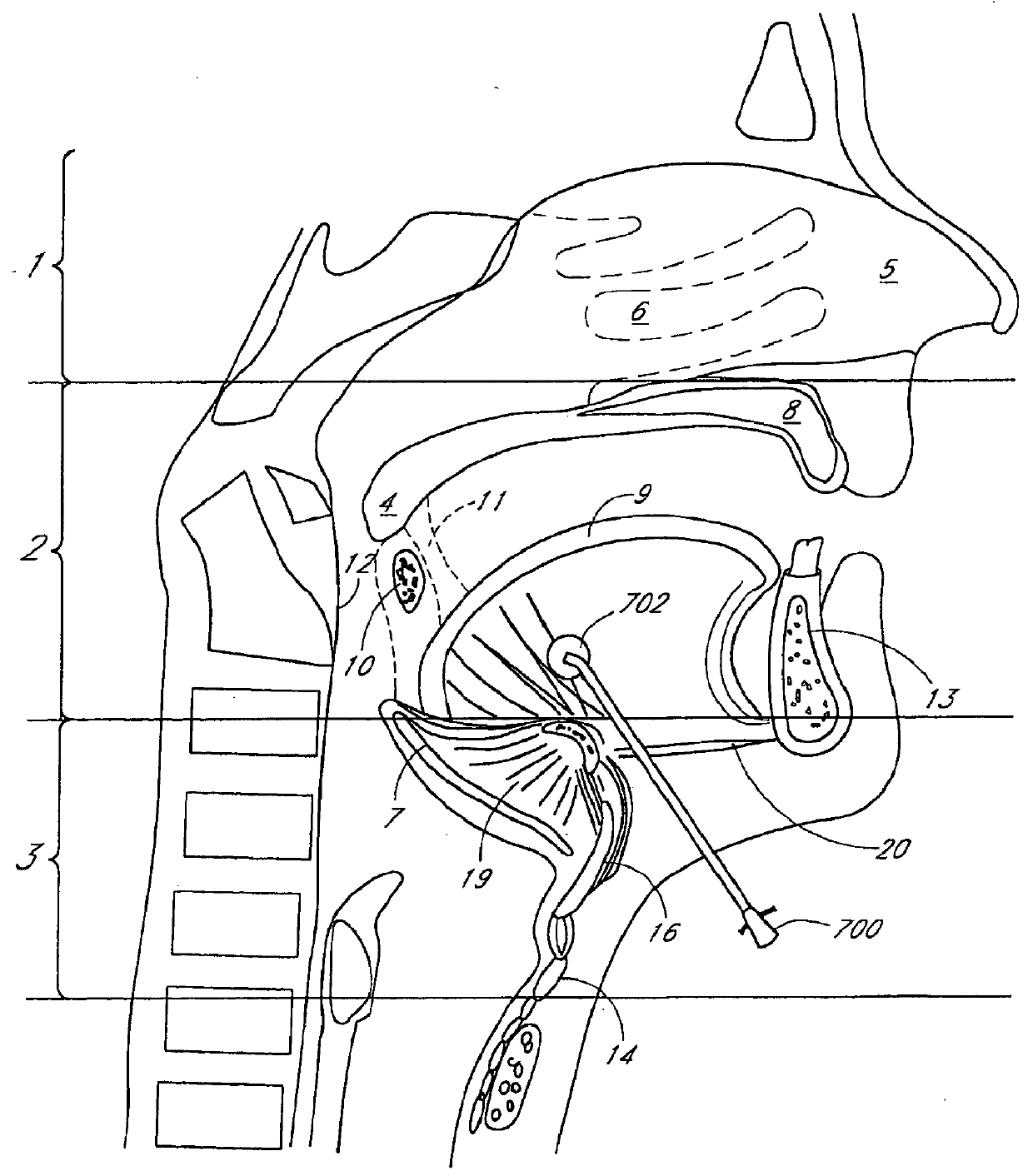

Glossoplasty using tissue anchor glossopexy with volumetric tongue reduction

Methods and devices are disclosed for remodeling the tongue. One or more spaces or cavities are formed in the tongue using, for example, surgical or RF ablative techniques. The cavities can be closed or collapsed by inserting a tethered soft tissue anchor into the tongue and attaching the tethered portion of the soft tissue anchor to a bony structure such as the mandible or hyoid bone in order to exert a collapsing force on the one or more spaces or cavities. The insertion pathway of the tethered soft tissue anchor may pass adjacent to or even through one or more cavities. Also disclosed herein is a tongue remodeling system that includes means for creating a space in the tongue, and a tissue anchor configured to close the space. The tissue anchor may be tethered or expandable.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Palatal expansion device and methods

InactiveUS20070218416A1Promote activationMore patient friendlyOthrodonticsDental toolsEngineeringBiological activation

The present invention relates to a palatal expansion device that has a screw having an activator (e.g., one or more activation arms) wherein the screw connects two blocks, each block having an opening for receiving the screw; a stabilizer attached to the blocks; and an anti-wind-back mechanism (e.g., a spring extension) positioned opposite the activation mechanism. In another embodiment, the present invention includes a palatal expansion device that has at least one screw, wherein the screw connects with one or more blocks and the blocks have an opening for receiving the screw. The device further includes one or more stabilizers attached to the blocks; a ratchet that engages the screw; and a built-in activator that communicates with the ratchet. This design allows essentially unidirectional rotation of the screw. The ratchet system includes, in one aspect, a pin / pocket arrangement, or a ratchet wheel / spring arrangement. The present invention involves kits and methods for expanding the maxillary arch or mandible using the palatal expansion devices of the present invention.

Owner:KELES AHMET OZLEM

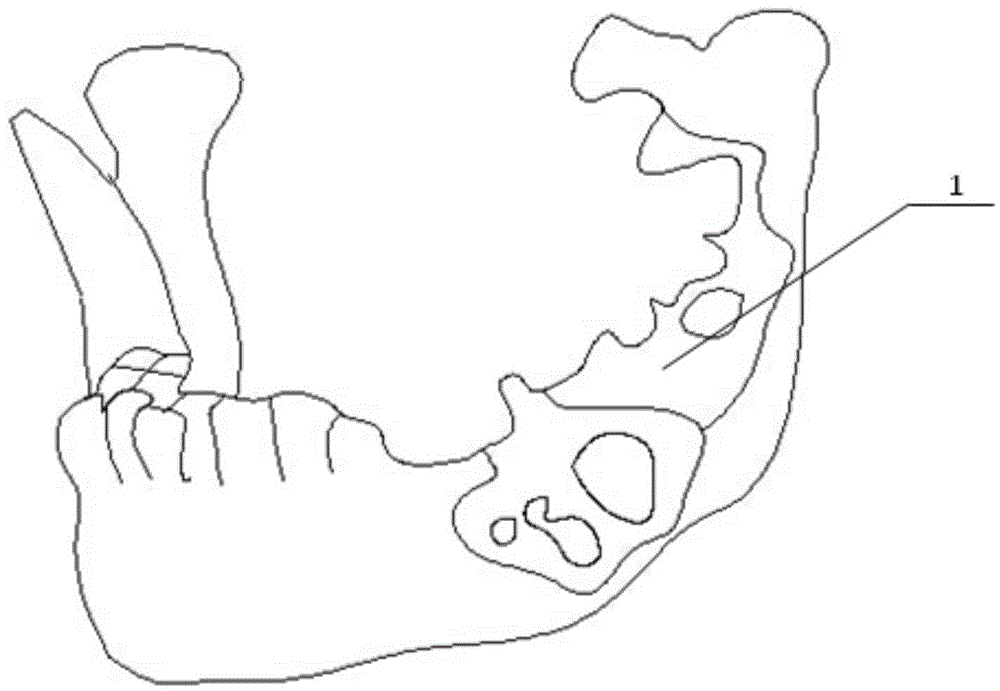

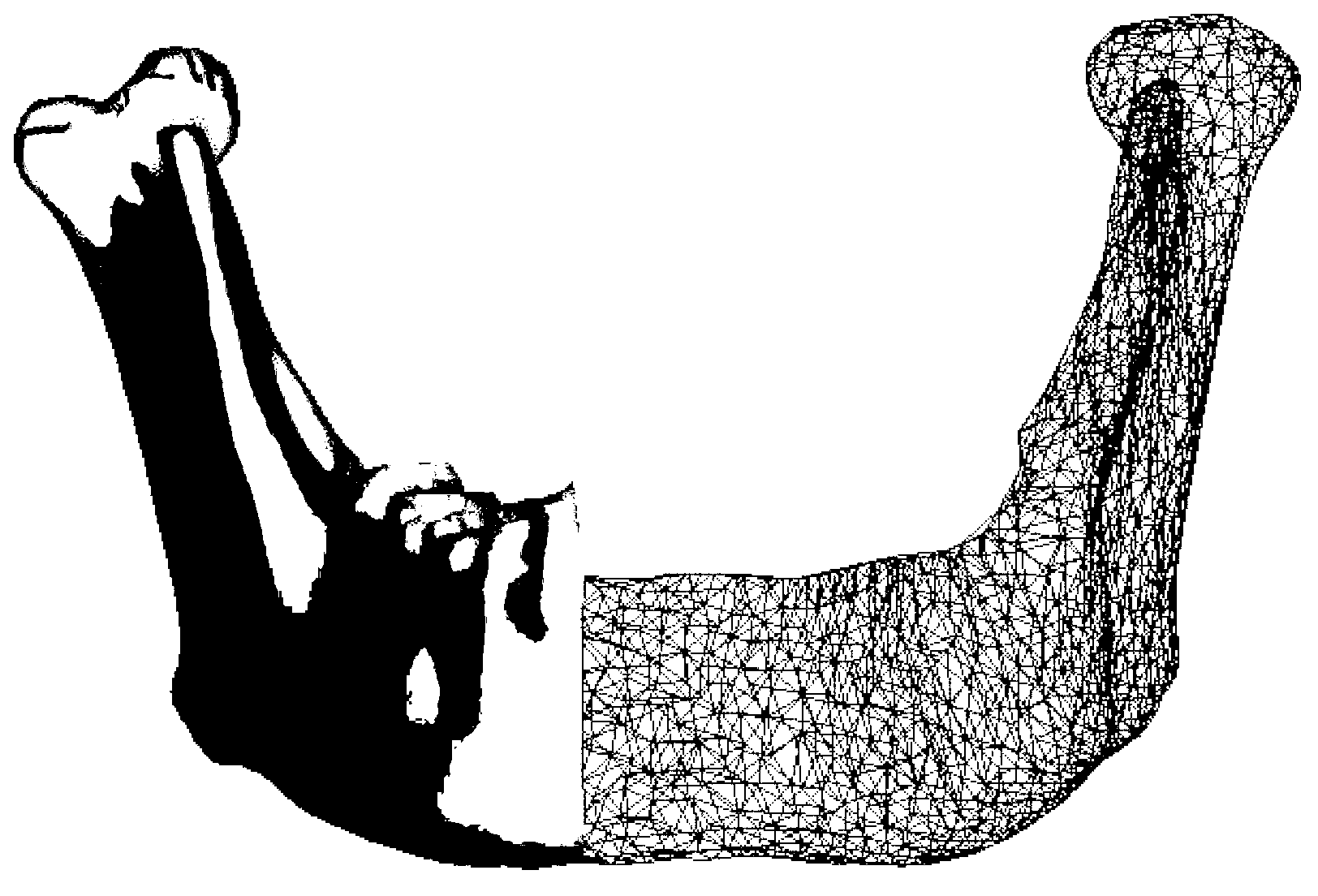

Fibular flap repairing mandible defect operation guiding template and manufacturing method

InactiveCN104825235AImprove accuracyImprove efficiencyDiagnosticsSurgeryThree dimensional modelSurface fitting

The invention discloses a manufacturing method for a fibular flap repairing mandible defect operation guiding template. The manufacturing method for the fibular flap repairing mandible defect operation guiding template comprises the steps that a mandible three-dimensional model and a fibula three-dimensional model are rebuilt, a lesion area is determined, and the target fibula is determined; the lesion area is excised, and a jaw non-lesion area model and a lesion area model are saved; the inner surface of a jaw cutting locating guiding template is attached to the outer surface of the lesion area model; the area where the fibula three-dimensional model and fibula subsection models are placed is partitioned to form a fibula repairing area; the inner surface of a fibula molding guiding template is entirely attached to the cheek side surface of the fibula repairing area; the inner surface of a fibula cutting locating guiding template is entirely attached to the outer surface of the corresponding fibula subsection model; the jaw cutting locating guiding template, the fibula molding guiding template and the fibula cutting locating guiding template are molded. The fibular flap repairing mandible defect operation guiding template and the manufacturing method have the advantages that the bone cutting scheme of the fibula and the molding position of each section of the fibula can be accurately controlled, the precise implement of a fibular flap transplanting repairing mandible defect operation is guaranteed, the operation time is shortened for the fibular flap repairing mandible defect operation.

Owner:6D DENTAL TECH

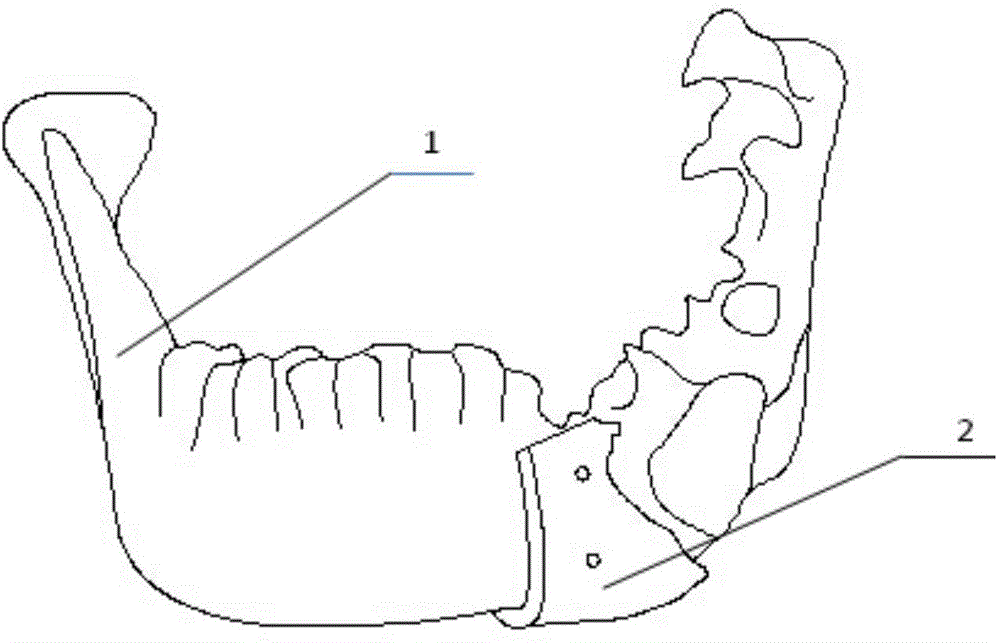

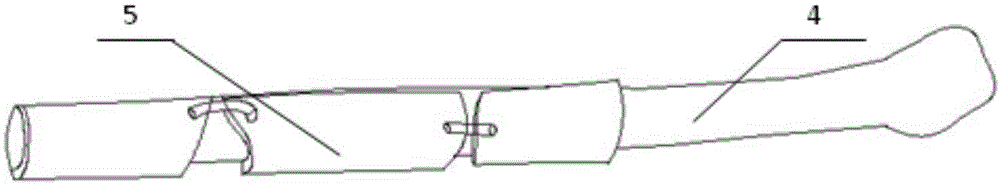

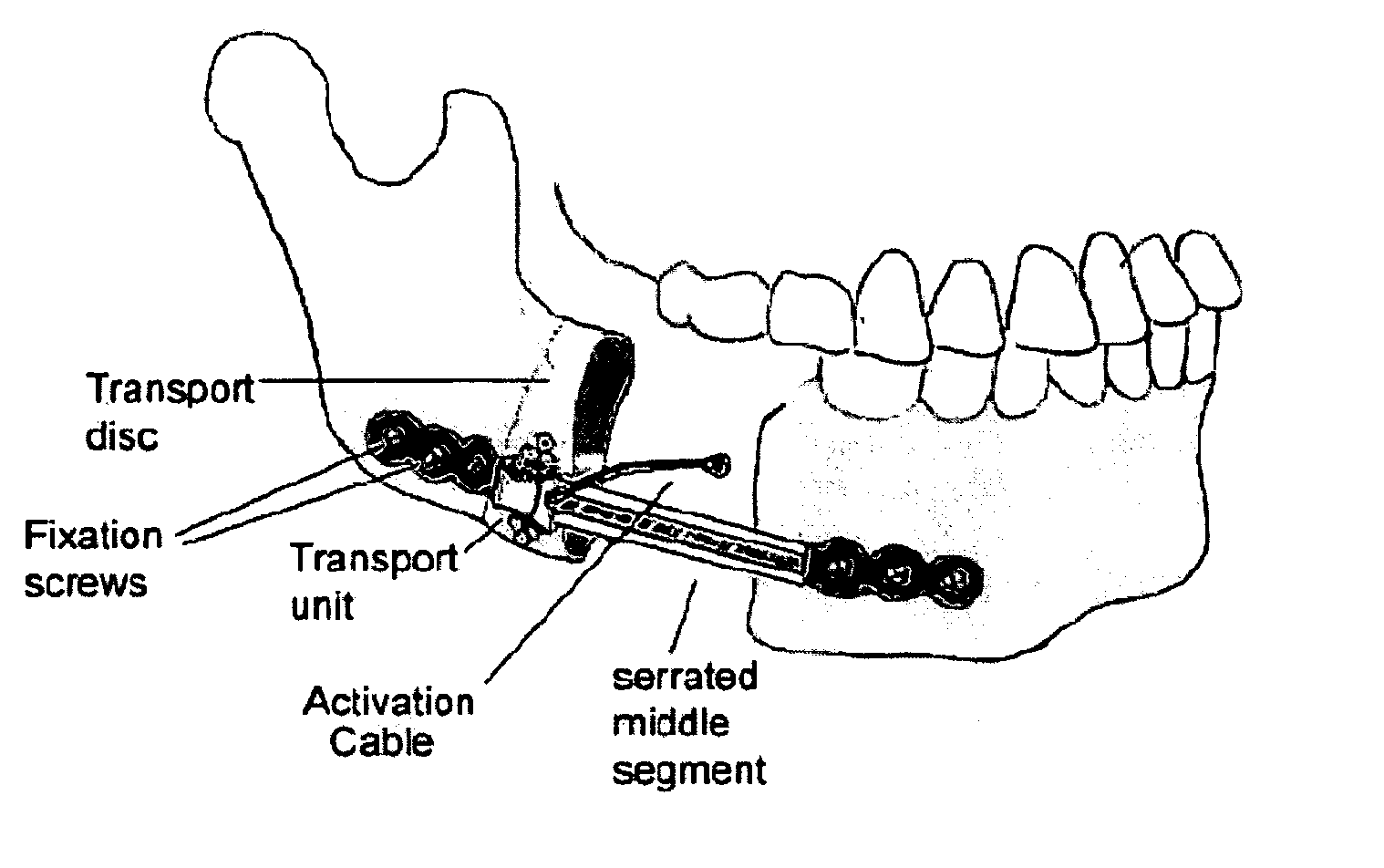

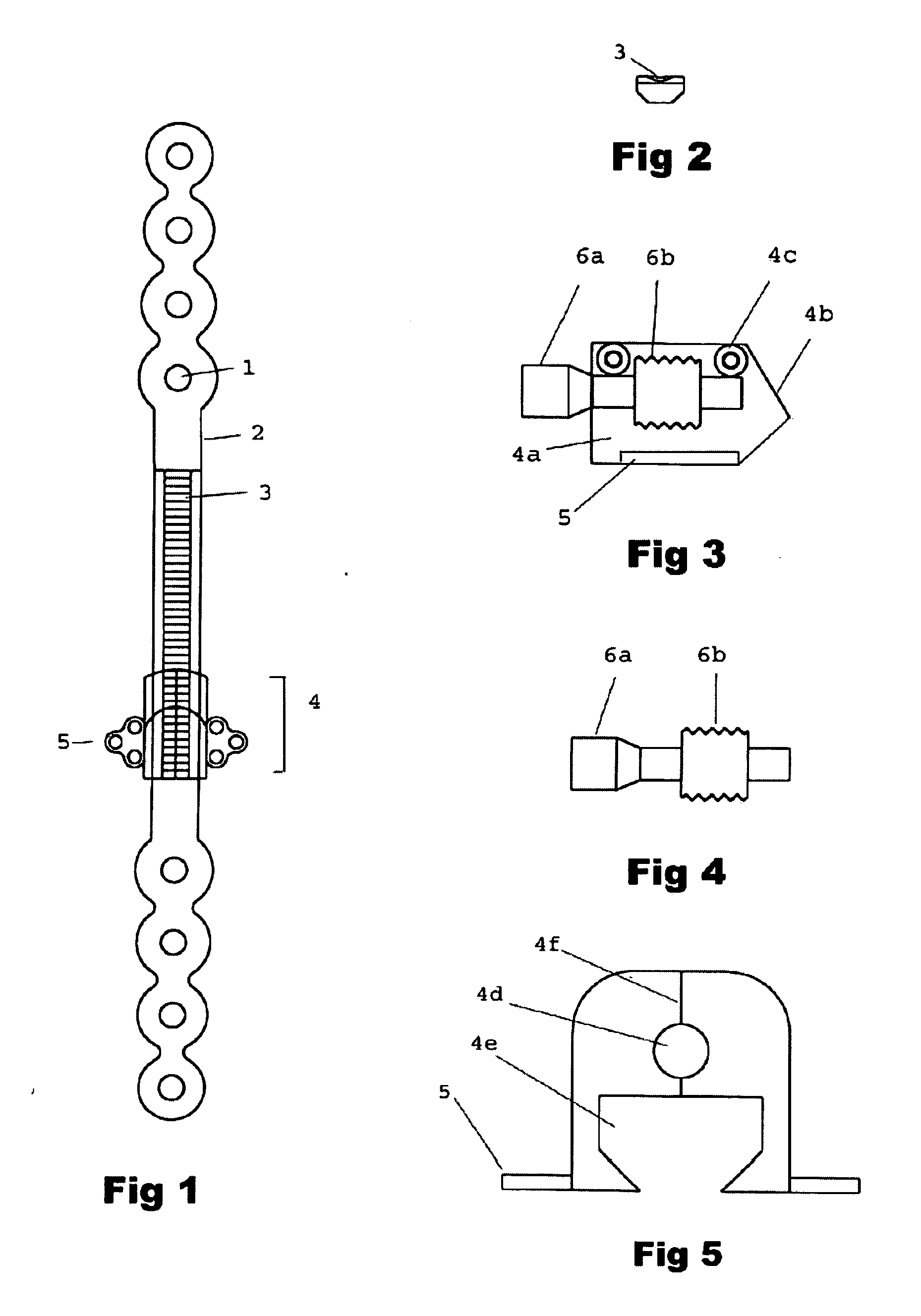

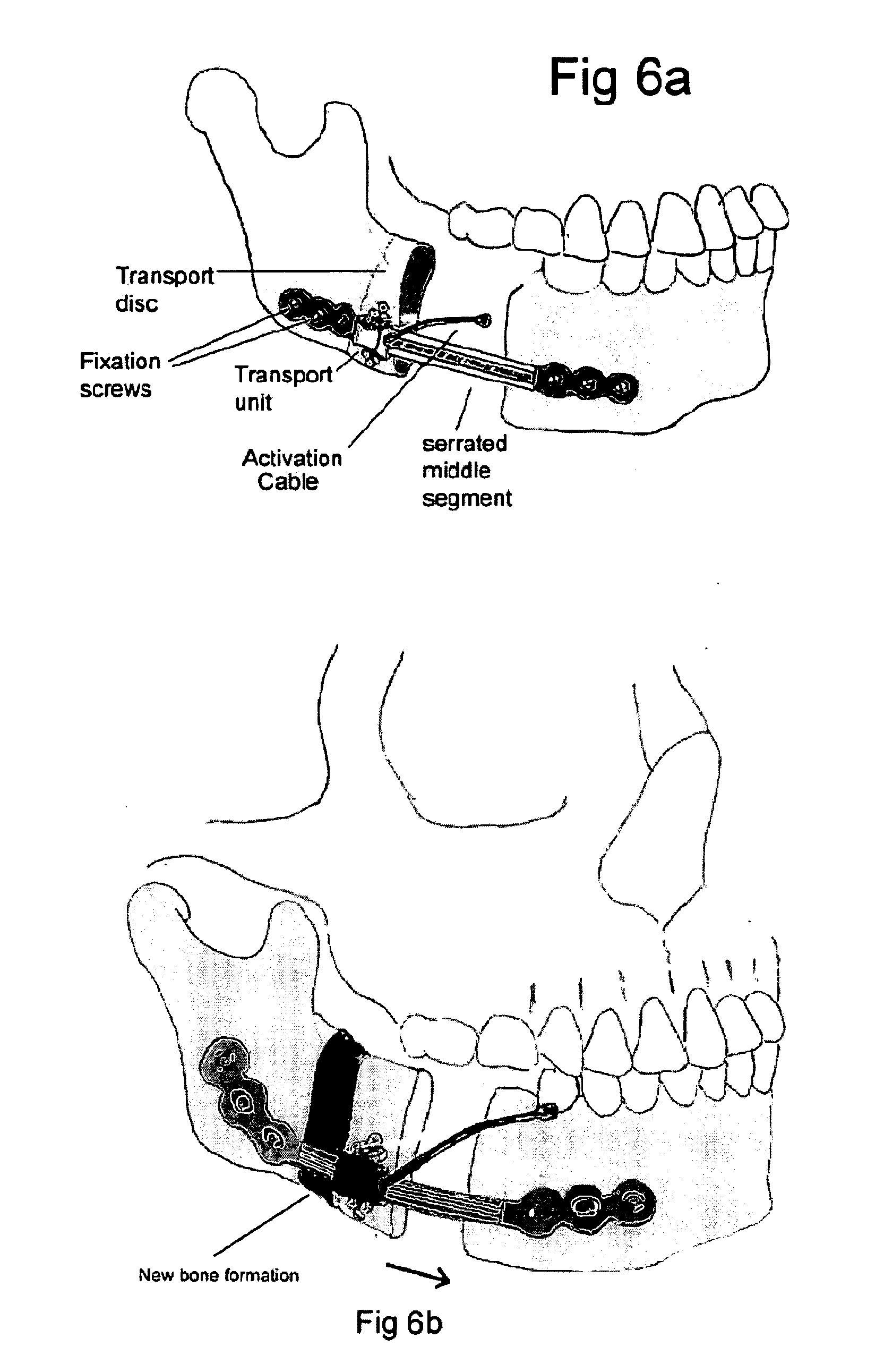

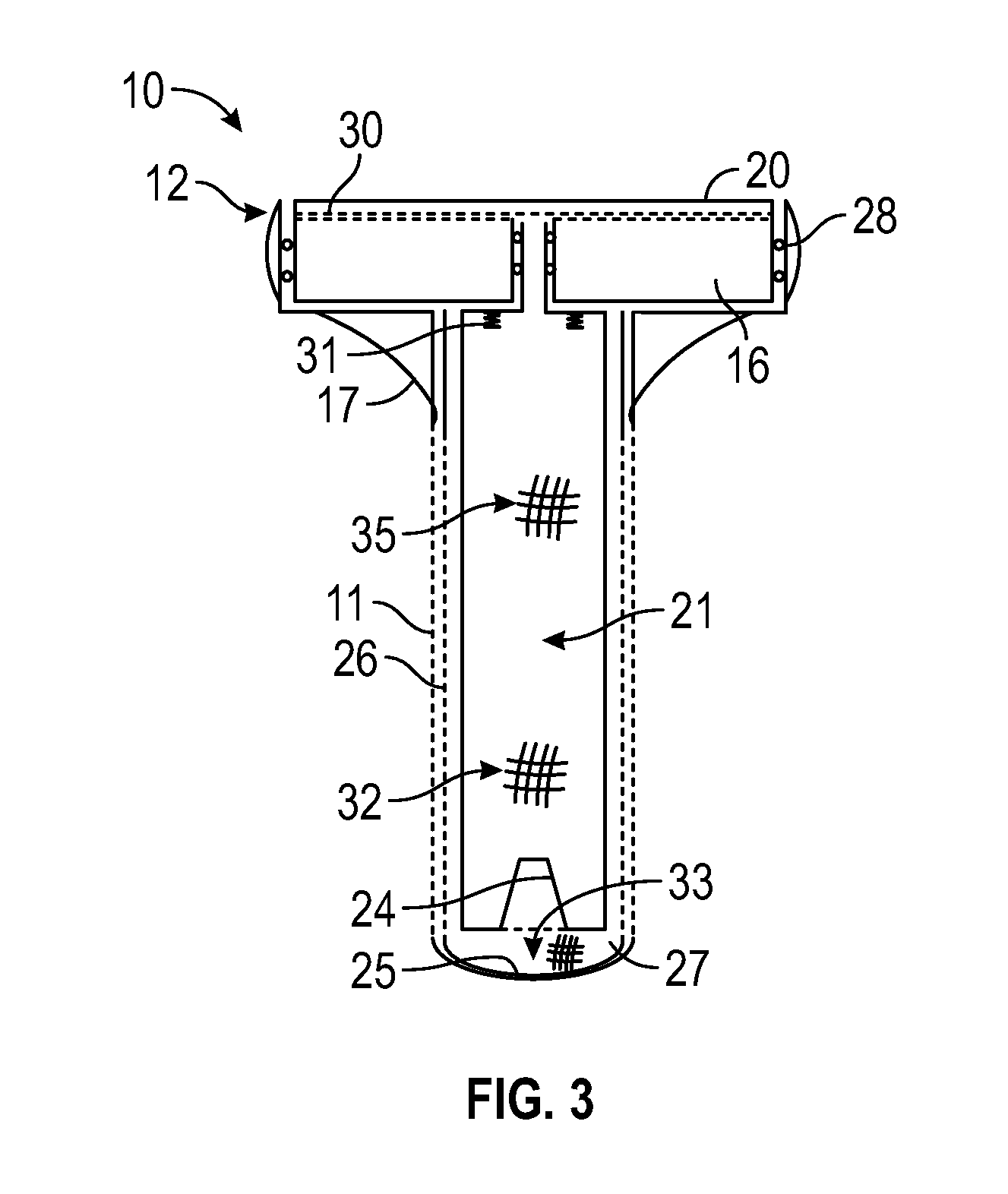

Mandibular bone transport reconstruction plate

This device can be used to create new bone to fill a gap in the mandible after surgical excision. It uses a bone reconstruction plate as a distraction device. The reconstruction plate fixes the bone stumps on both sides of the bone gap. In the middle segment of the plate overlying the bone gap, the transport bone disc is carried on a transport unit that moves along a rail on the outer surface of the reconstruction plate.

Owner:CRANIOTECH ACR DEVICES

Anti-obstructive airway dental orthotic

ActiveUS8875713B2Facilitates a passive closure of the jawIncrease spaceTeeth fillingSnoring preventionKnee orthosisMaxilla/Maxillary

An anti-obstructive airway dental orthotic is described. The orthotic includes a maxillary retainer and a mandibular retainer releasably attaching to a plurality of teeth of a wearer. The retainers are attached by at least one strut, either variable in length or of a plurality of lengths, which exert a forward force on the lower jaw, tending to advance the mandible relative to the maxilla. This advancement of the lower jaw promotes a less obstructed airway in the wearer, while fenestrations in the retainers may allow for greater comfort and tongue movement.

Owner:METZ JAMES

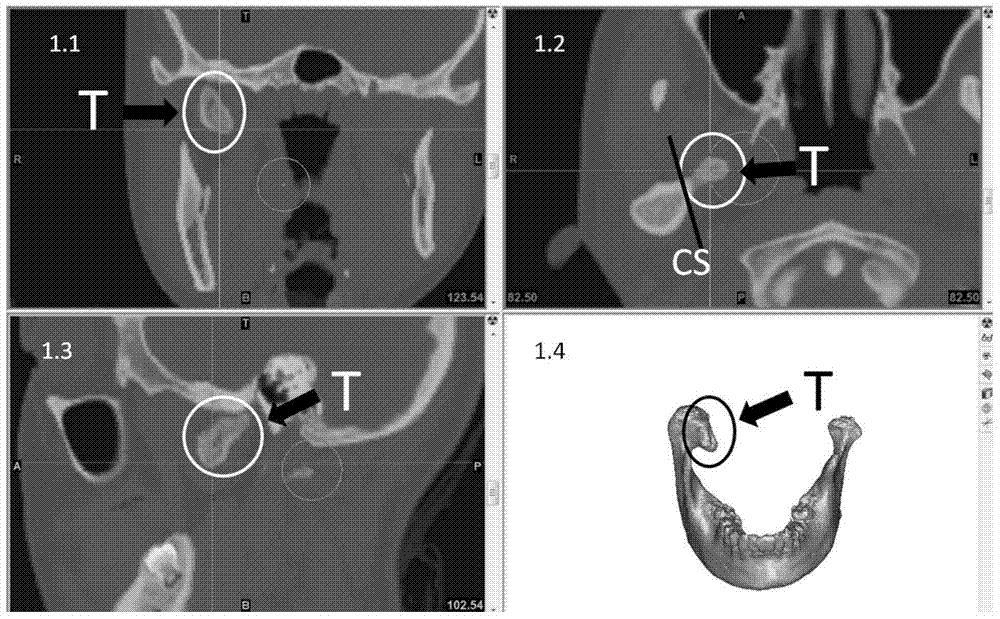

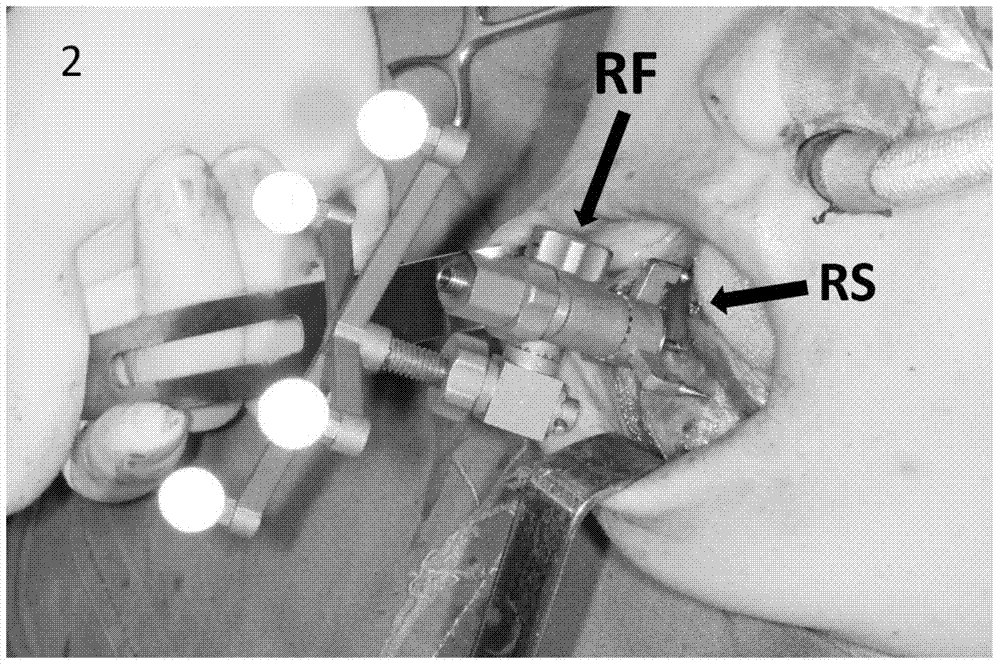

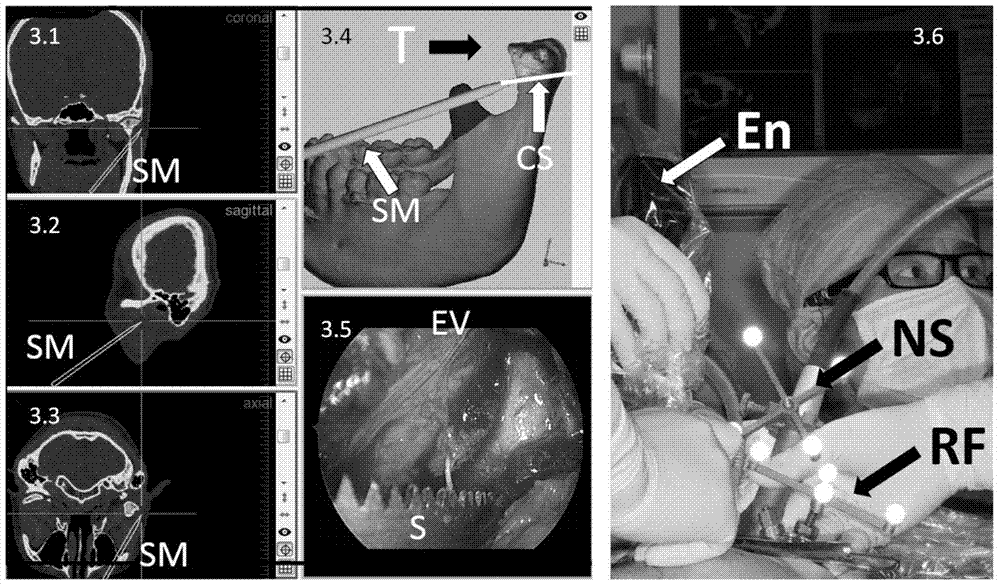

Application of digitization technology to oral approach mandibular condylar lesion surgical excision

InactiveCN104720877APostoperative cosmetic effectMinimally invasiveSpecial data processing applicationsSurgical sawsDigital imagingNavigation system

The invention relates to application of a digitization technology to oral approach mandibular condylar lesion surgical excision. The application comprises the following steps: planting five self-tapping titanium screws into a mandible of a patient to be used as registration mark points of a navigation system in a surgery; photographing maxillofacial region CT (Computed Tomography) scanning and storing in a DICOM (Digital Imaging and Communications in Medicine) format; establishing a patient lesion three-dimension pattern; designing an osteotomy face and an osteotomy range according to a lesion boundary; introducing navigation software in an STL (Standard Template Library) format to reestablish a three-dimensional geometrical model; mounting a navigation reference frame, and registering by using a navigation positioning probe and the mark points; setting an incision and dissecting and separating a joint capsule under an endoscope view to expose a condylar process; searching an osteotomy face position by using the positioning probe and calibrating a coordinate of a bone saw; adjusting the bone saw to the position of the osteotomy face and the cutting angle; and under the guidance of the incision stretched endoscope probe and a navigation positioning image, carrying out condylar osteotomy by holding the bone saw via a surgery doctor. By the aid of the application, the surgery doctor can accurately cut off condylar tumors according to preoperative plans, so the ideals of minimally invasive surgery and accurate surgery are uniformed.

Owner:王旭东 +1

Mandibular reposition device and coupling therefor

Owner:LAMBERT GEOFFREY JAMES +1

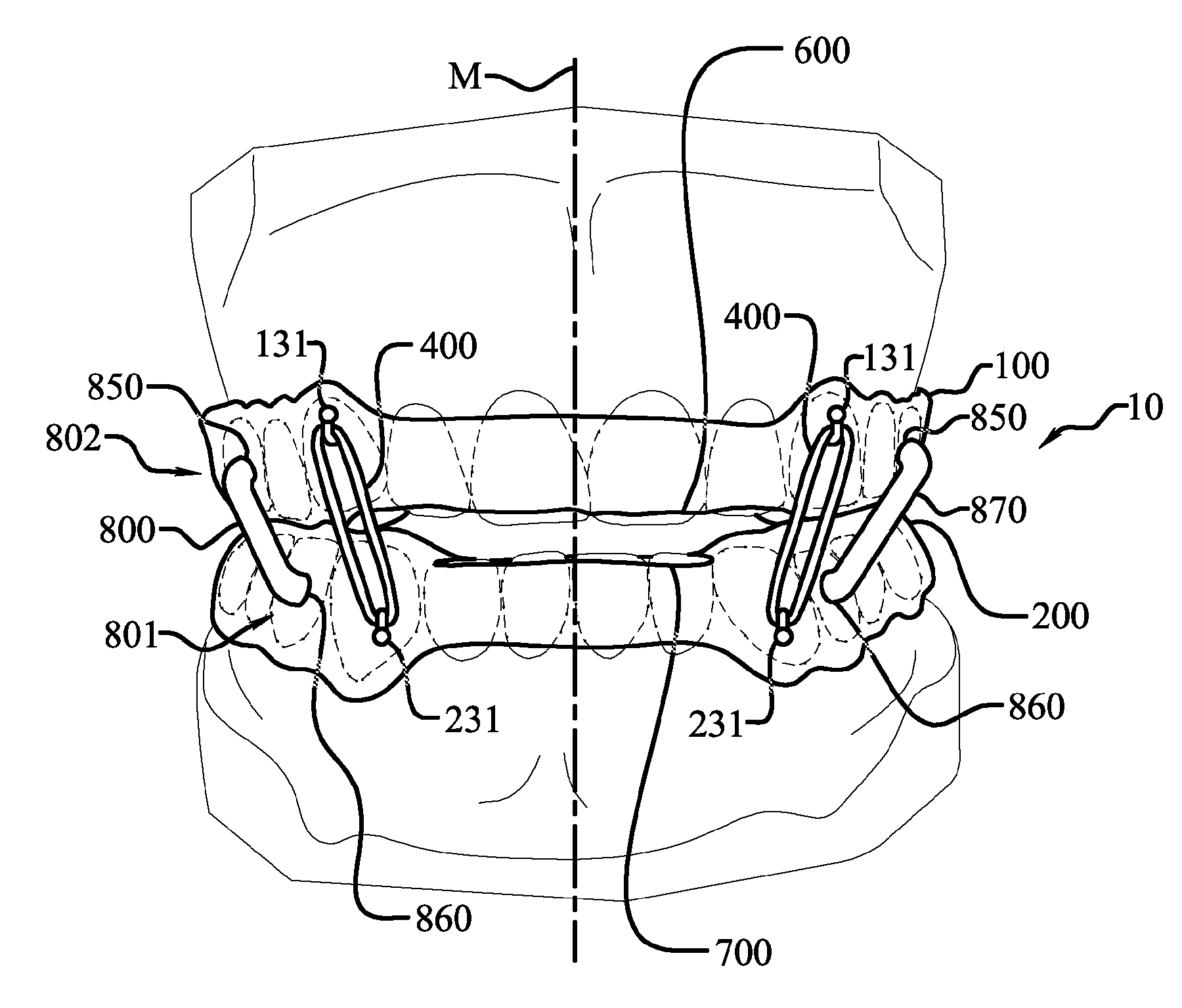

Anti-obstructive airway dental orthotic

ActiveUS20130074848A1Facilitates a passive closure of the jawIncrease spaceSnoring preventionNon-surgical orthopedic devicesMaxilla/MaxillaryTongue movement

An anti-obstructive airway dental orthotic is described. The orthotic includes a maxillary retainer and a mandibular retainer releasably attaching to a plurality of teeth of a wearer. The retainers are attached by at least one strut, either variable in length or of a plurality of lengths, which exert a forward force on the lower jaw, tending to advance the mandible relative to the maxilla. This advancement of the lower jaw promotes a less obstructed airway in the wearer, while fenestrations in the retainers may allow for greater comfort and tongue movement.

Owner:METZ JAMES

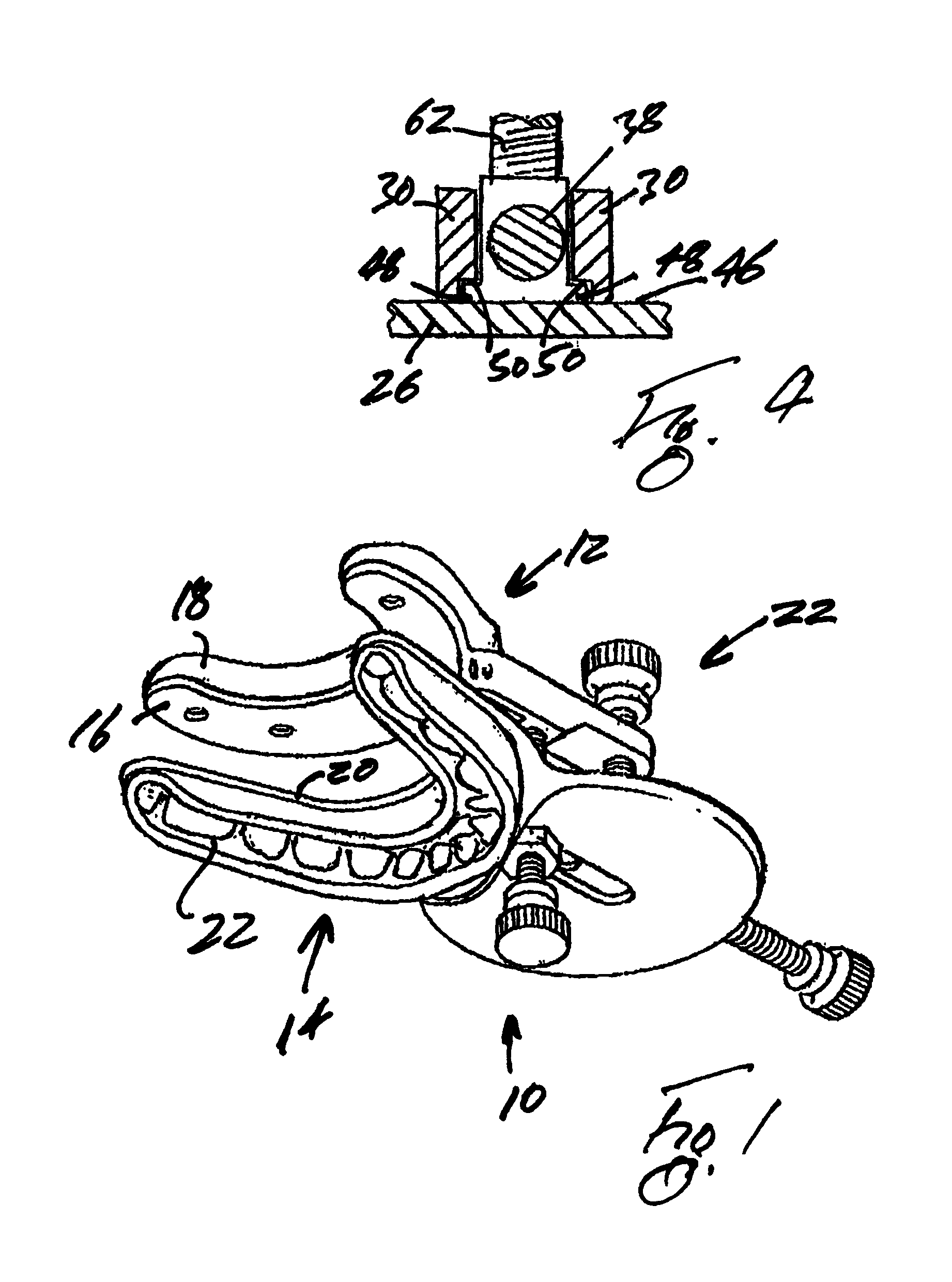

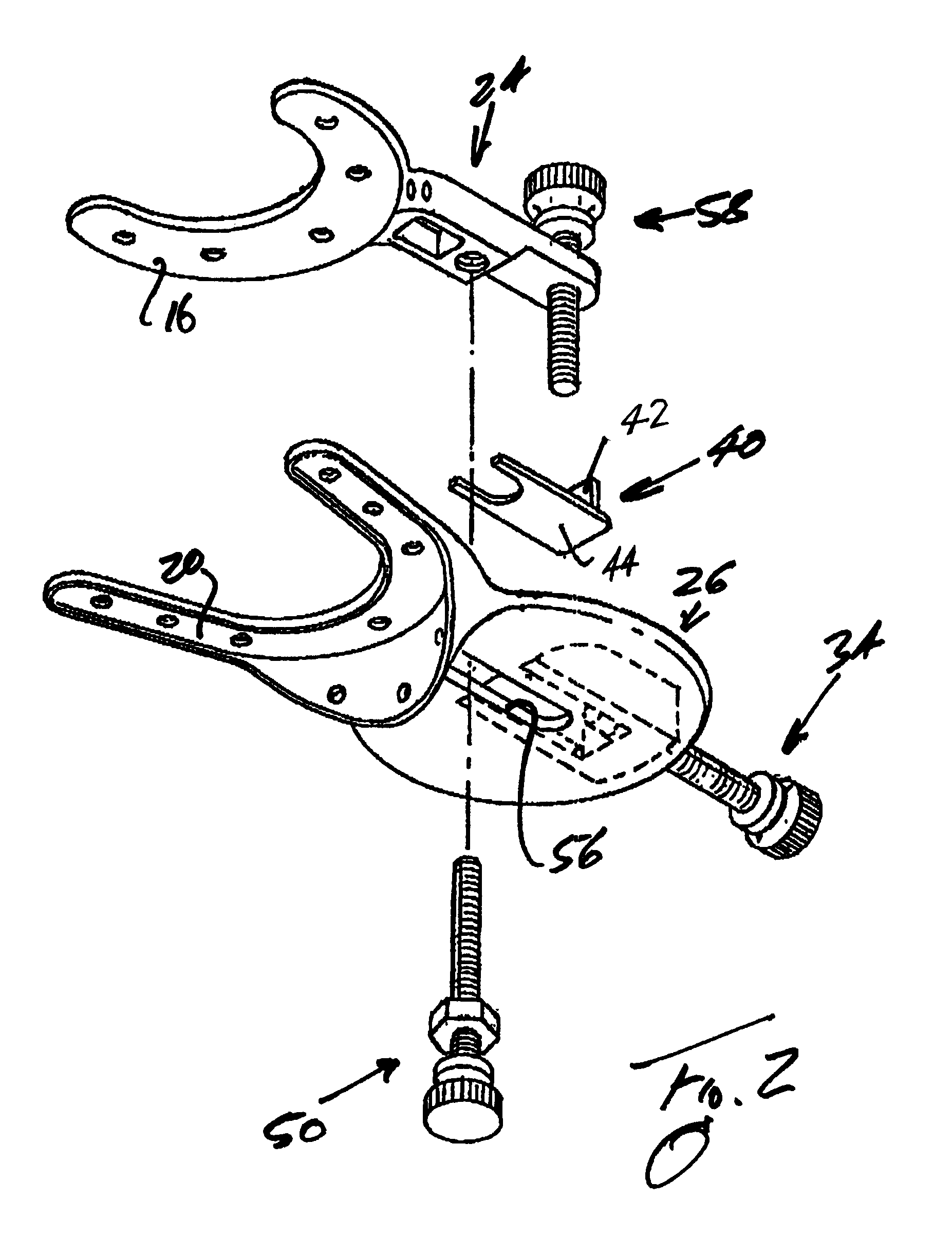

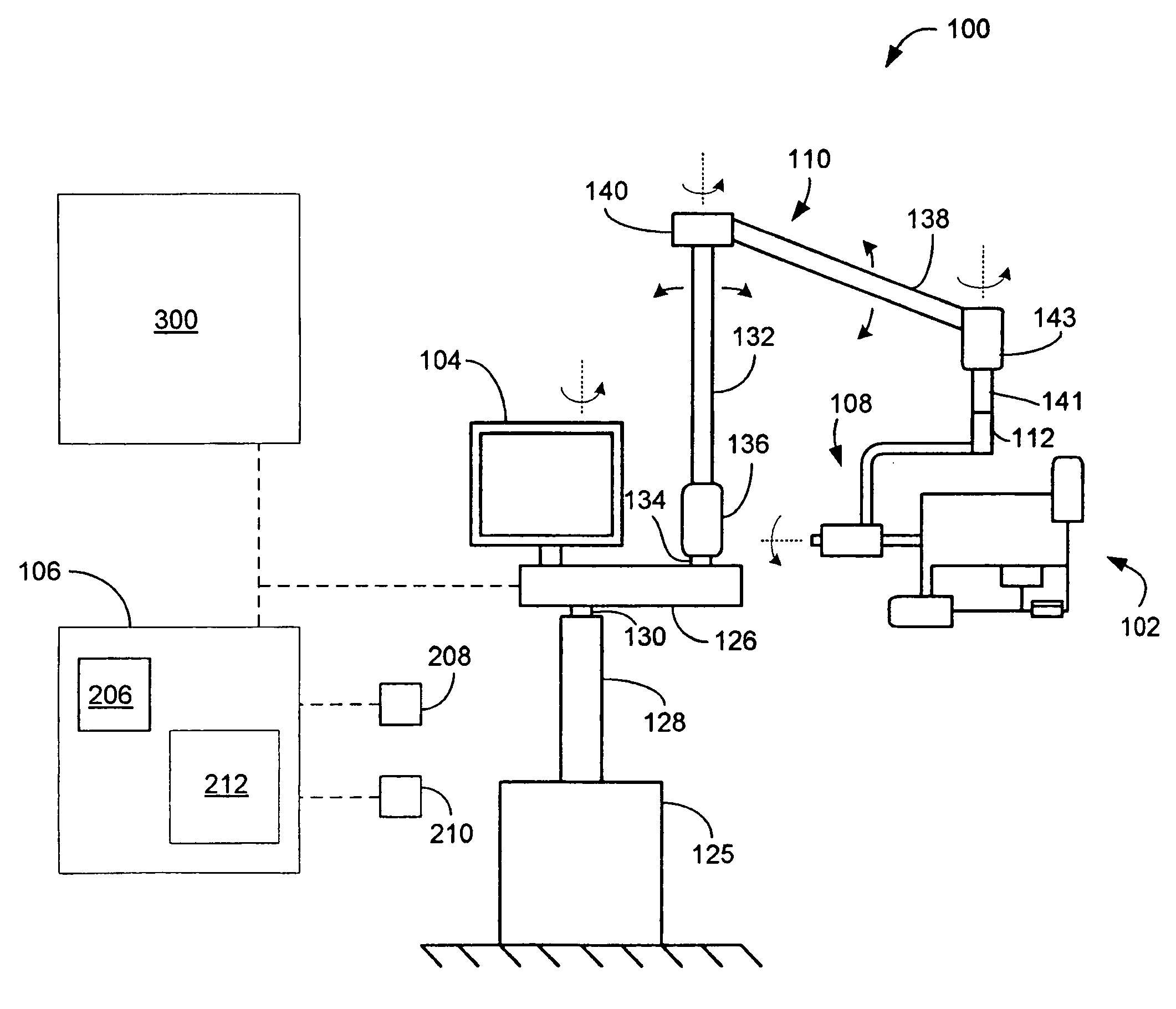

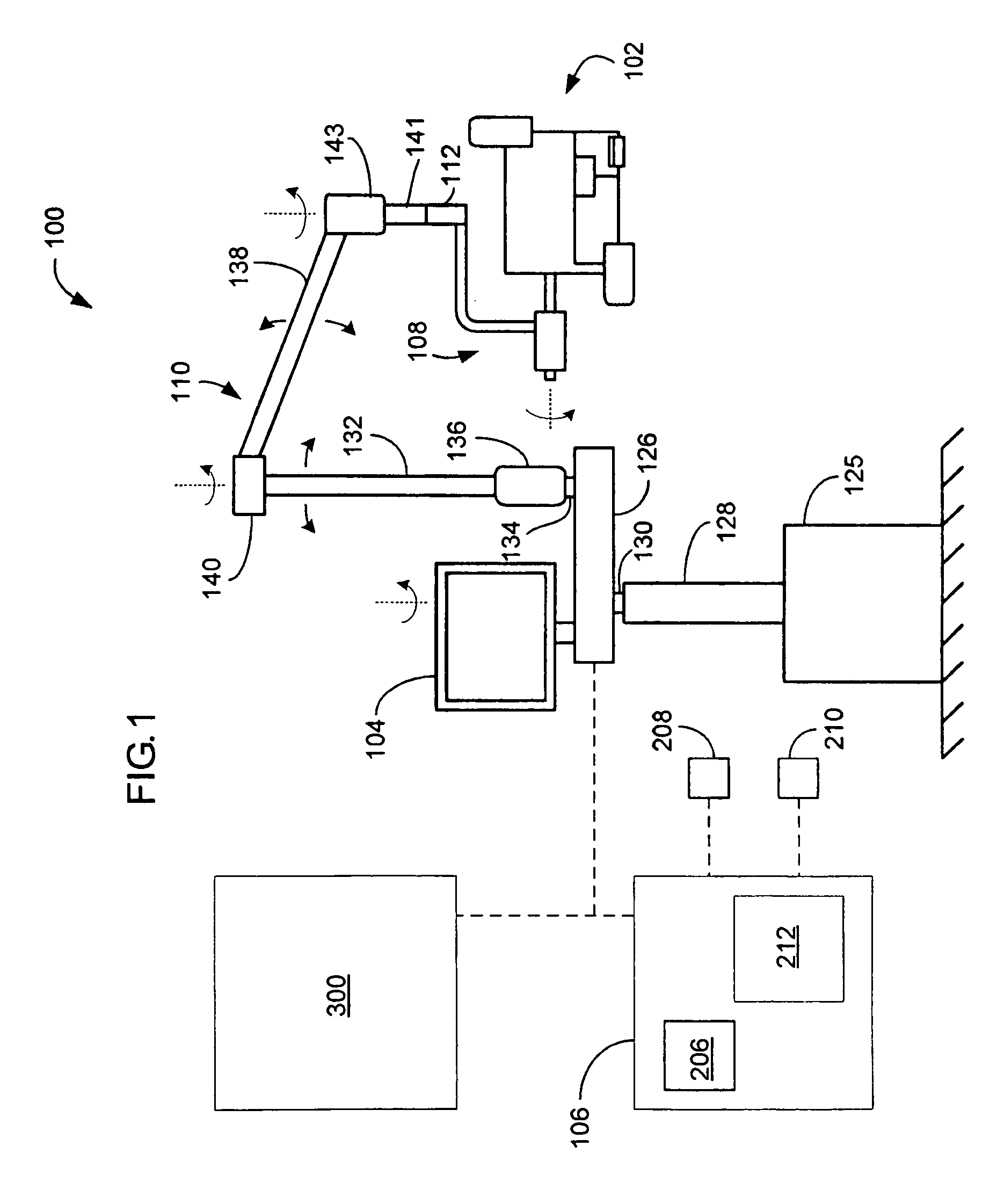

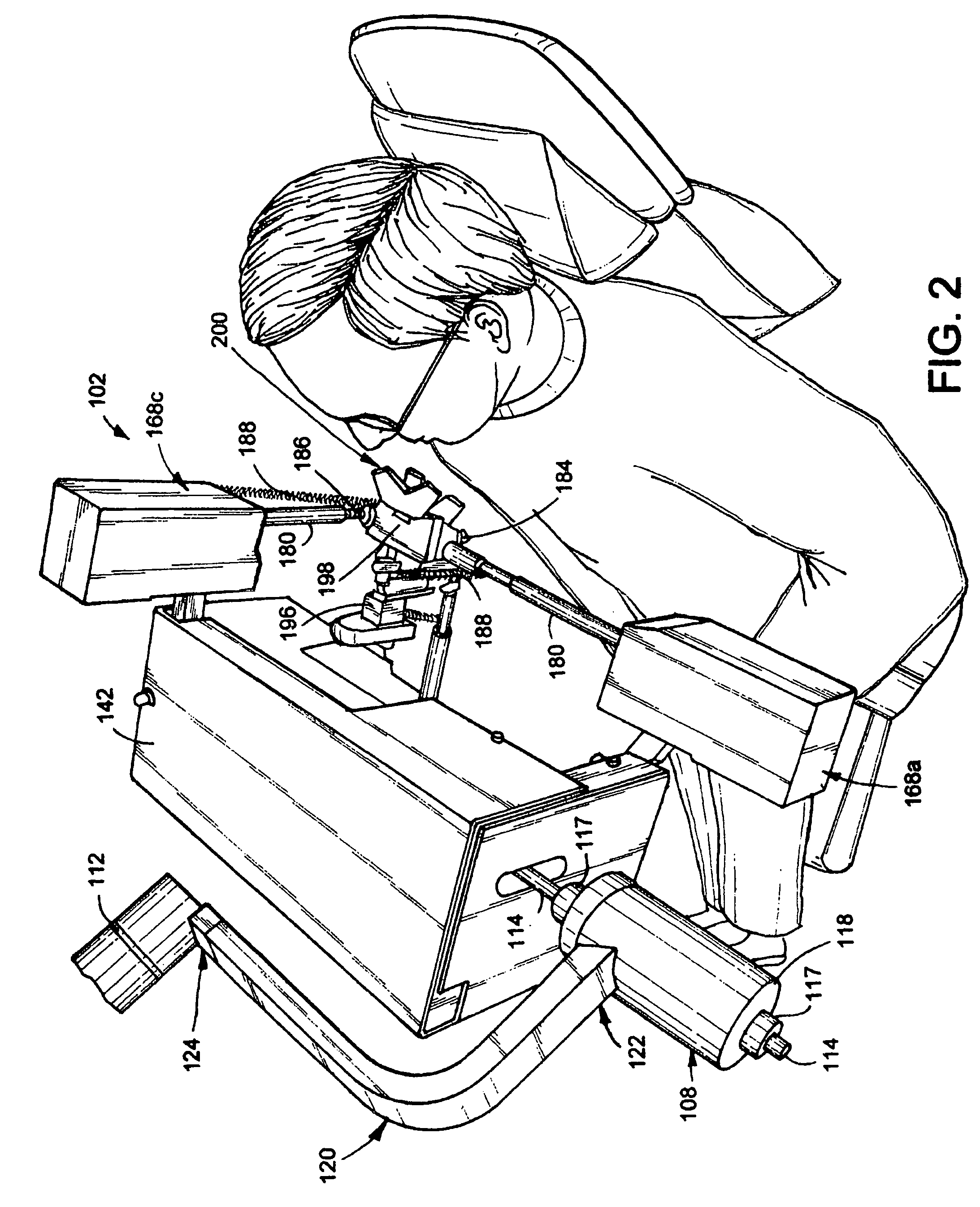

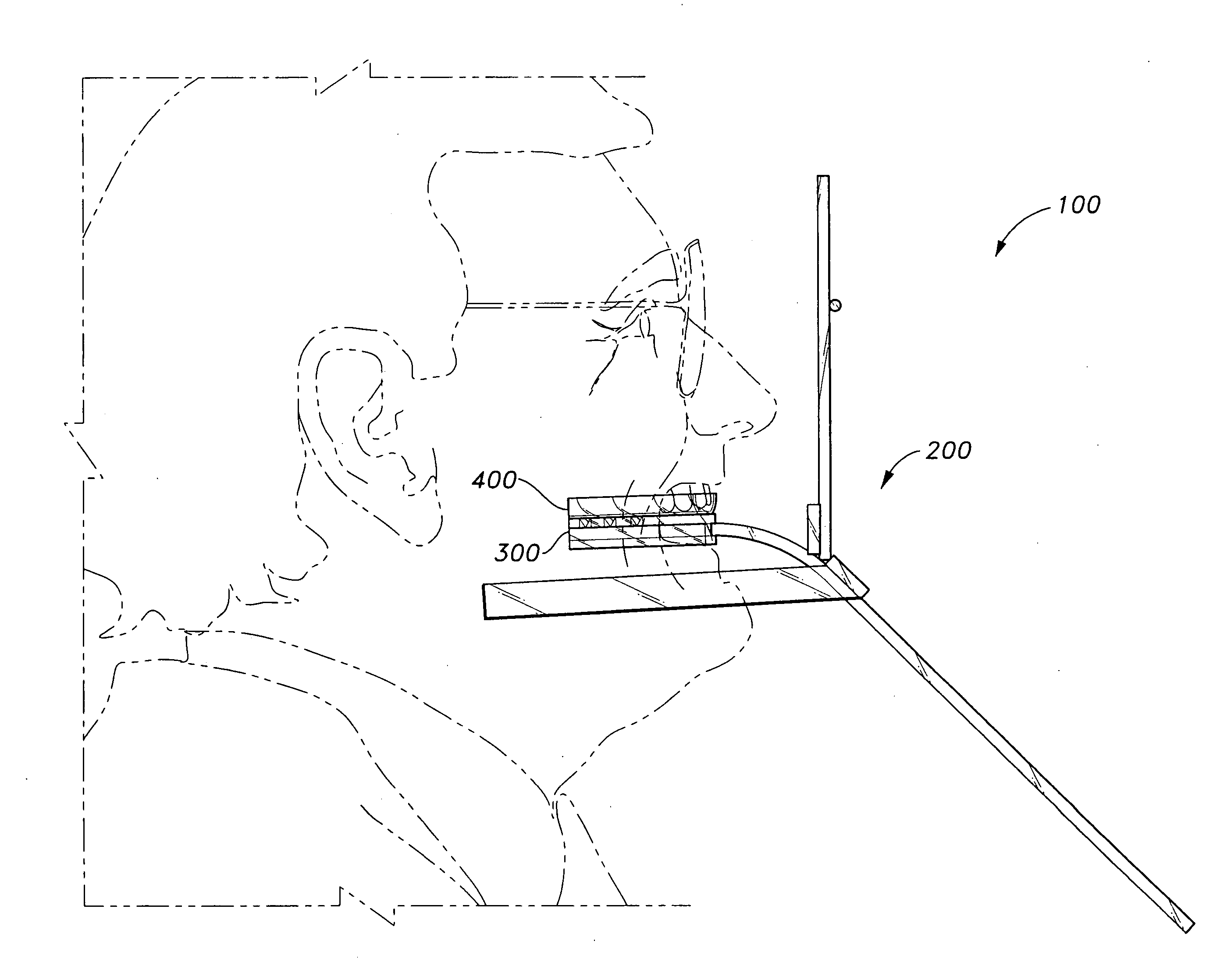

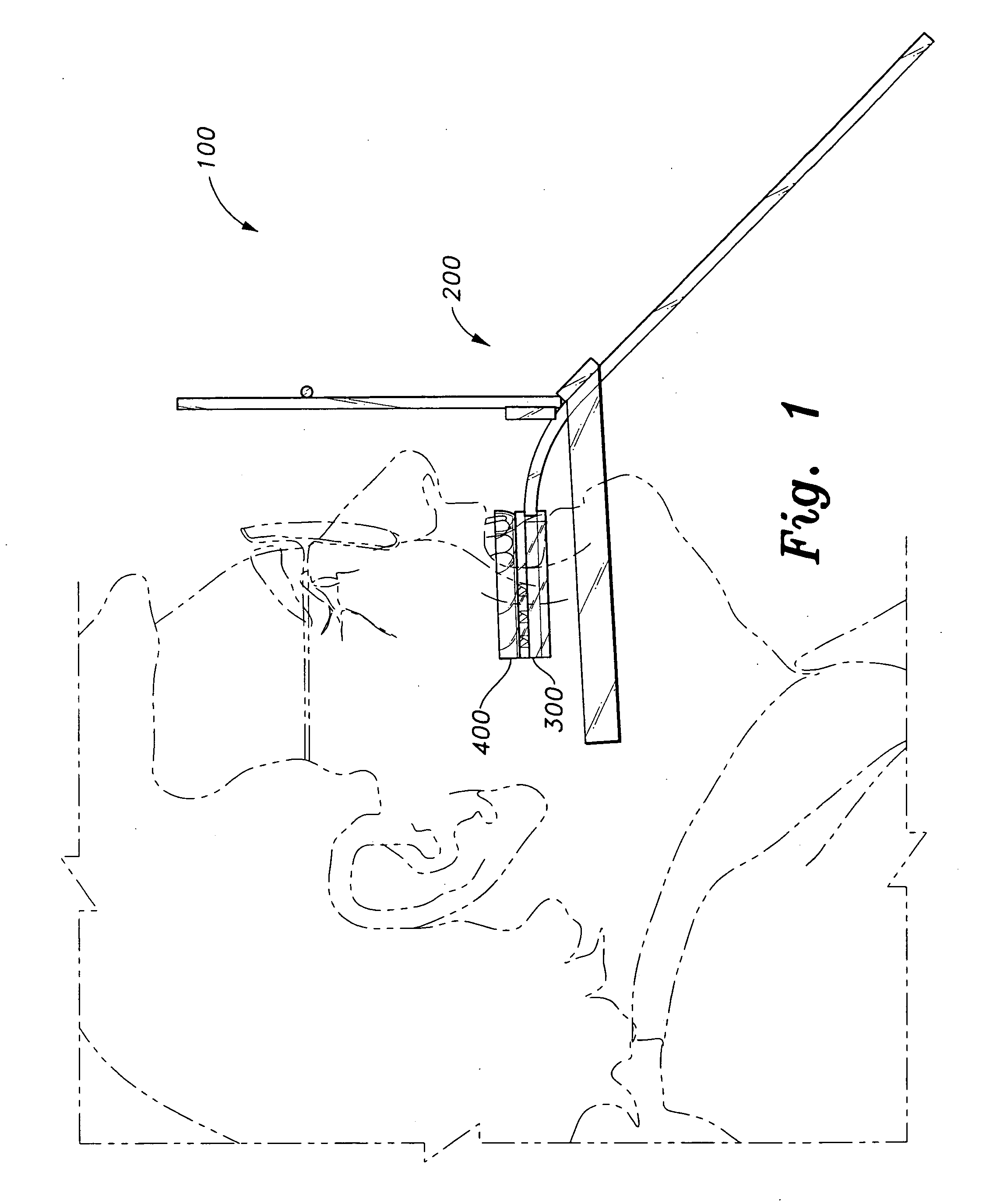

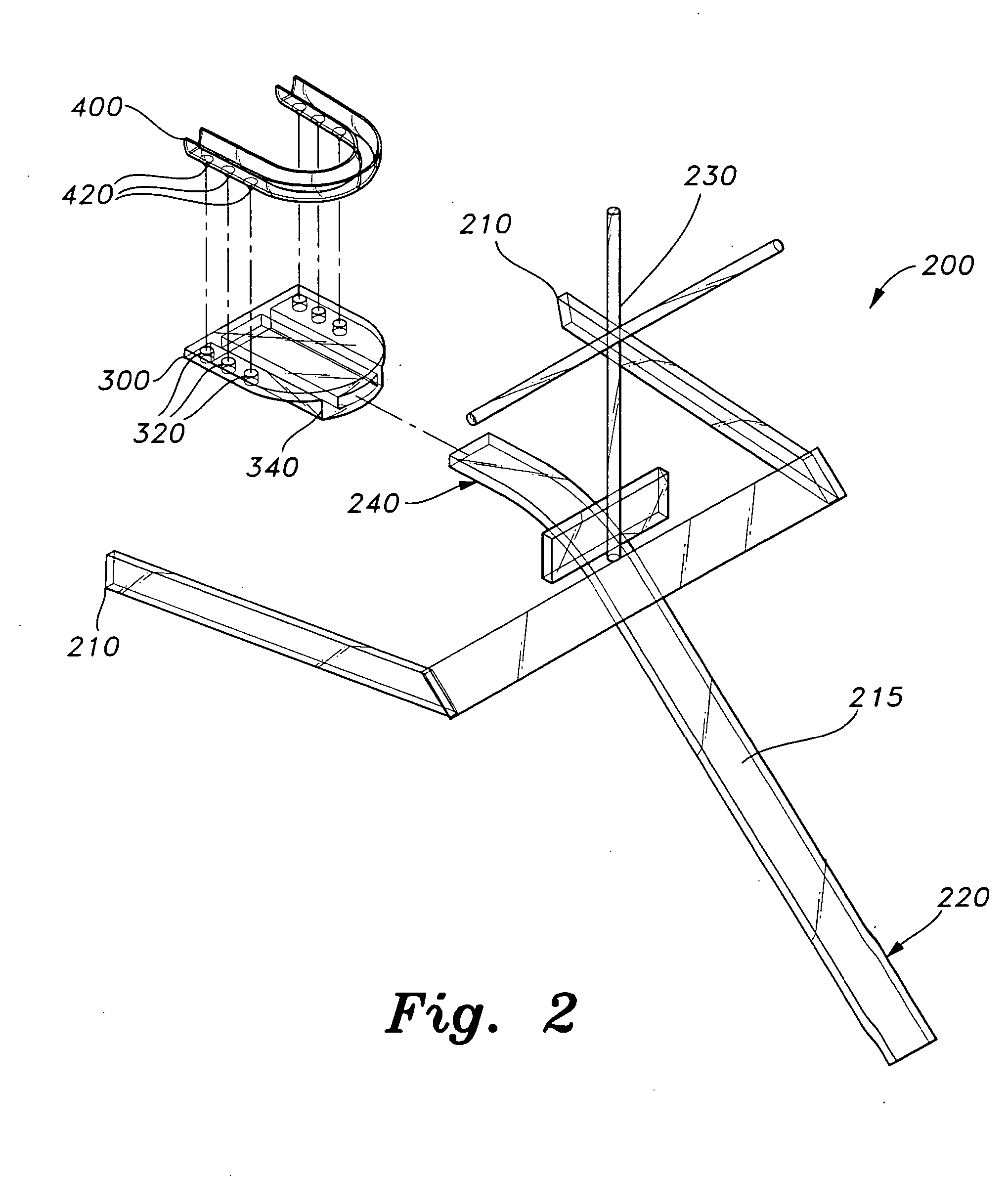

Apparatus and method for recording mandibular movement

An apparatus for use in dentistry to obtain positional data related to movement of a mandible about a maxilla comprises a rigid support frame for supporting a maxilla support member, a positionable mandibular member and sensing assemblies. The support member fixedly attaches to the support frame. The mandibular member is positionable proximate the maxilla member. The sensing assemblies attach to the support frame and connect to the mandibular member to obtain positional data related to the movement of the mandibular member. The positional data is collected by a computing device and stored in a data storage medium as time history files. The files can then be transformed into usable information to replicate the mandibular movement in real time either virtually or mechanically.

Owner:GNATH TECH DENTAL SYST

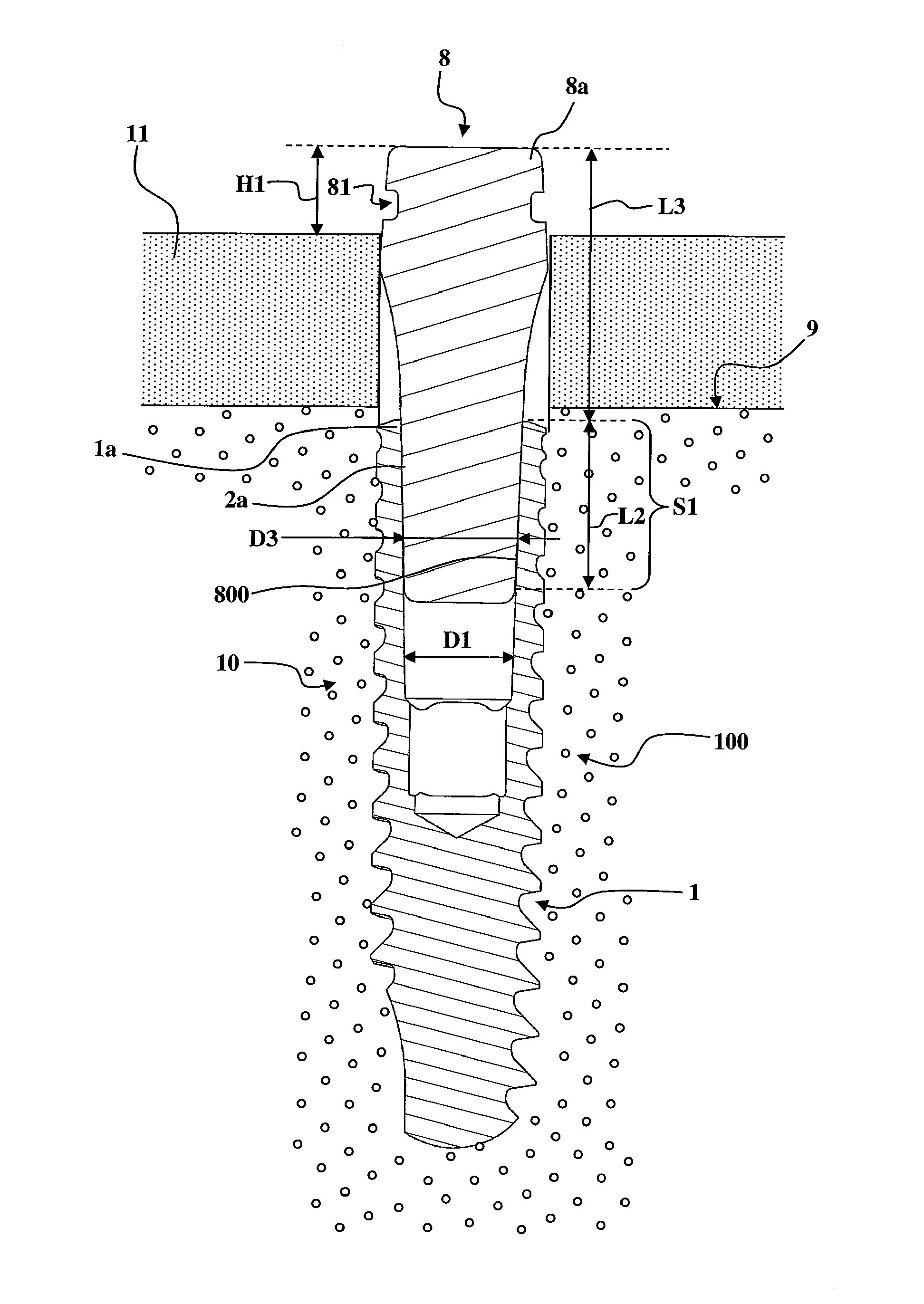

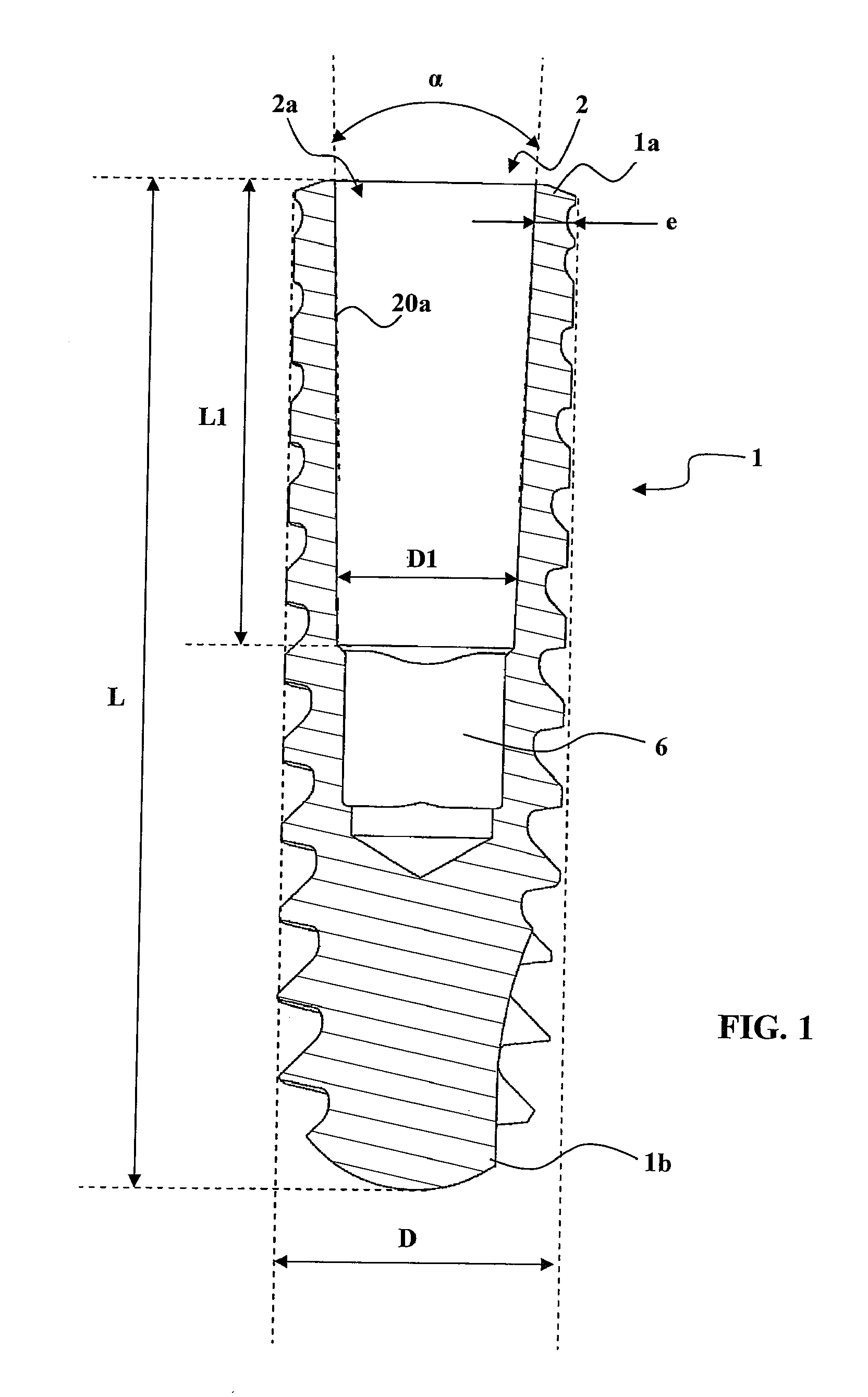

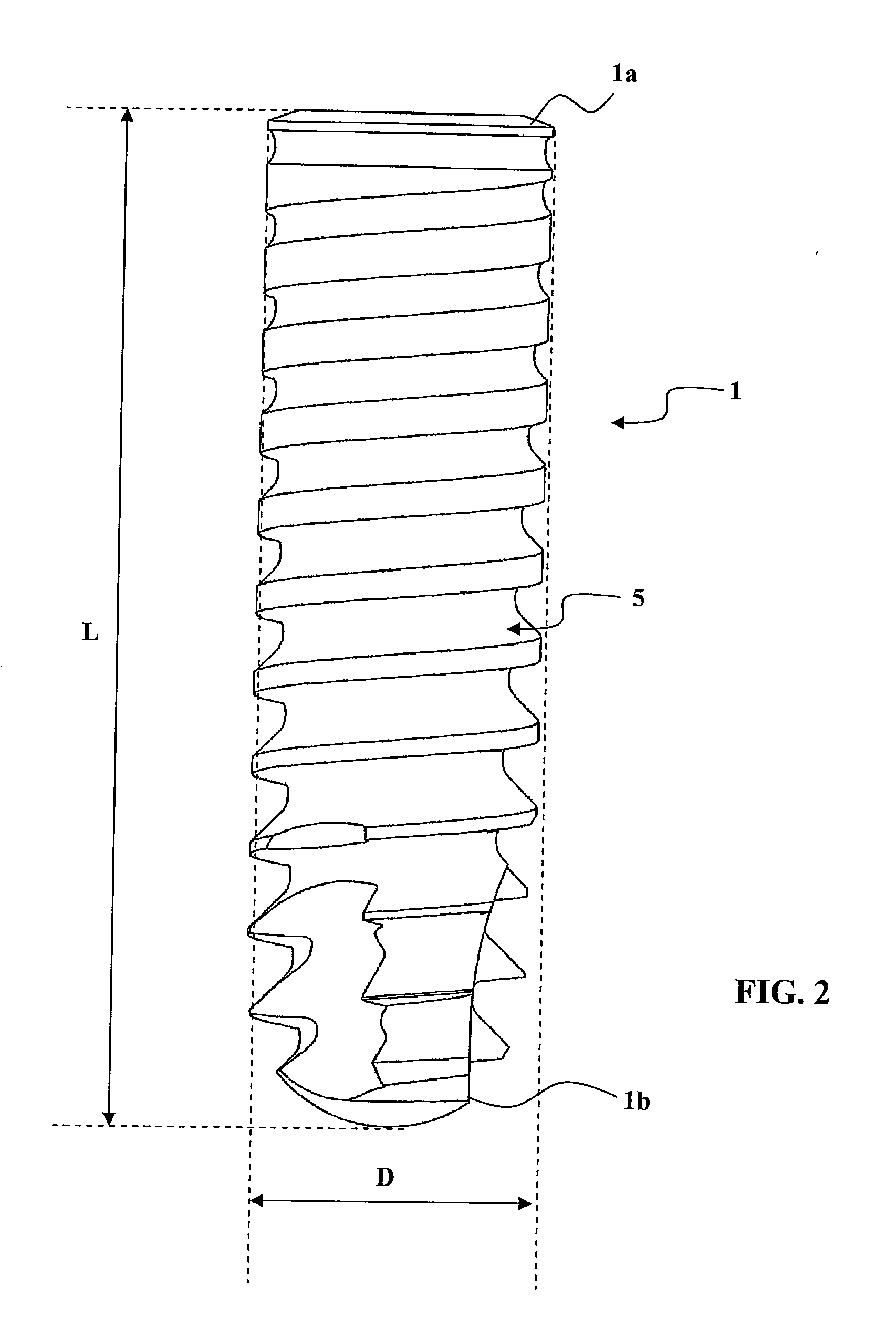

Conically tapered dental implant

InactiveUS20120237900A1Avoids constant thinningAvoid stress concentrationDental implantsDental implantMandibular nerve

A dental implant (1) is intended to be inserted into the maxillary or mandibular bone of a patient, extending between a distal connection end (1a) and a proximal anchoring end (1b). The dental implant (1) has a maximum outside diameter (D) less than 3 mm over its entire length (L) and is provided with a receiving device (2) having a conically tapered female cavity (2a).

Owner:ANTHOGYR

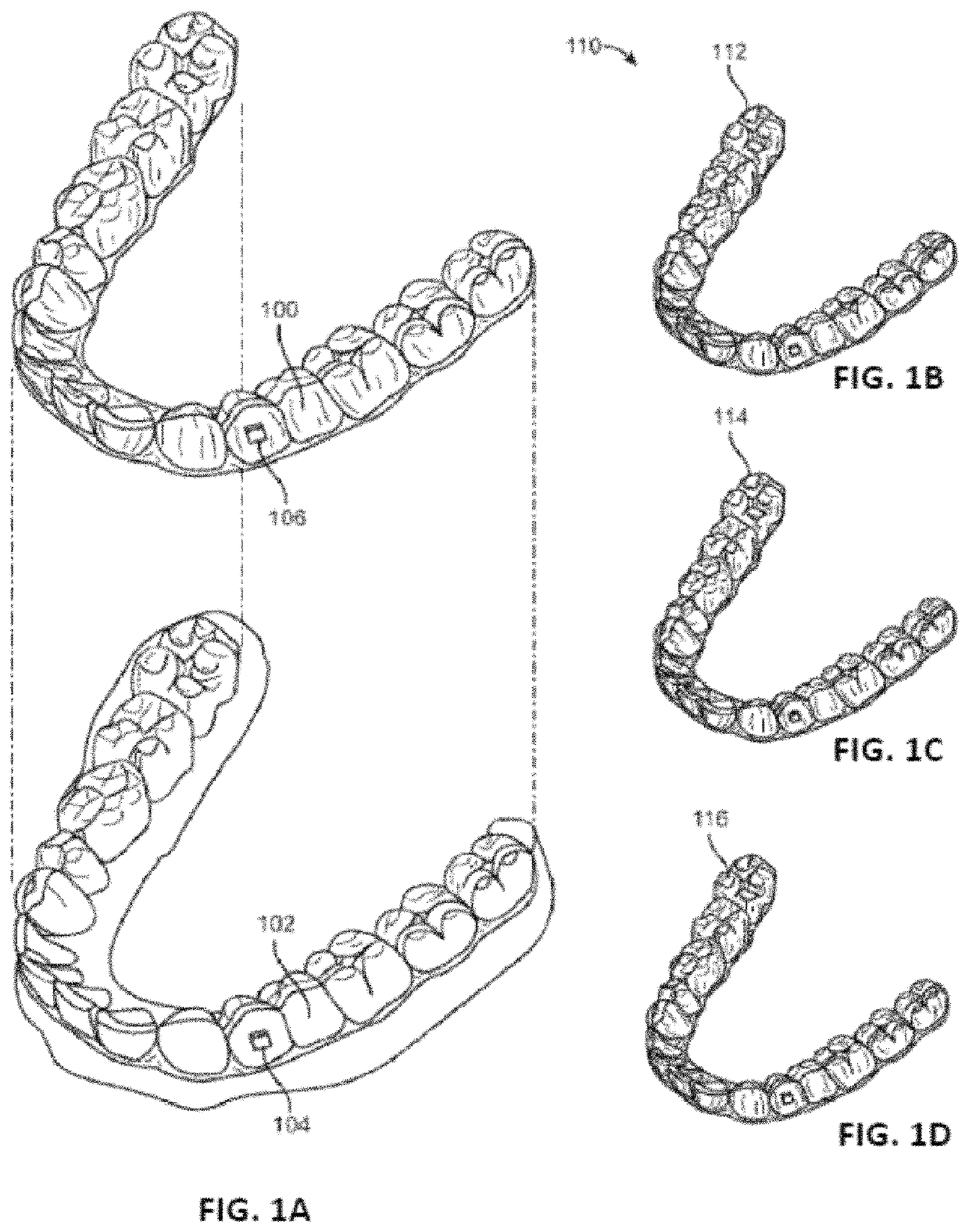

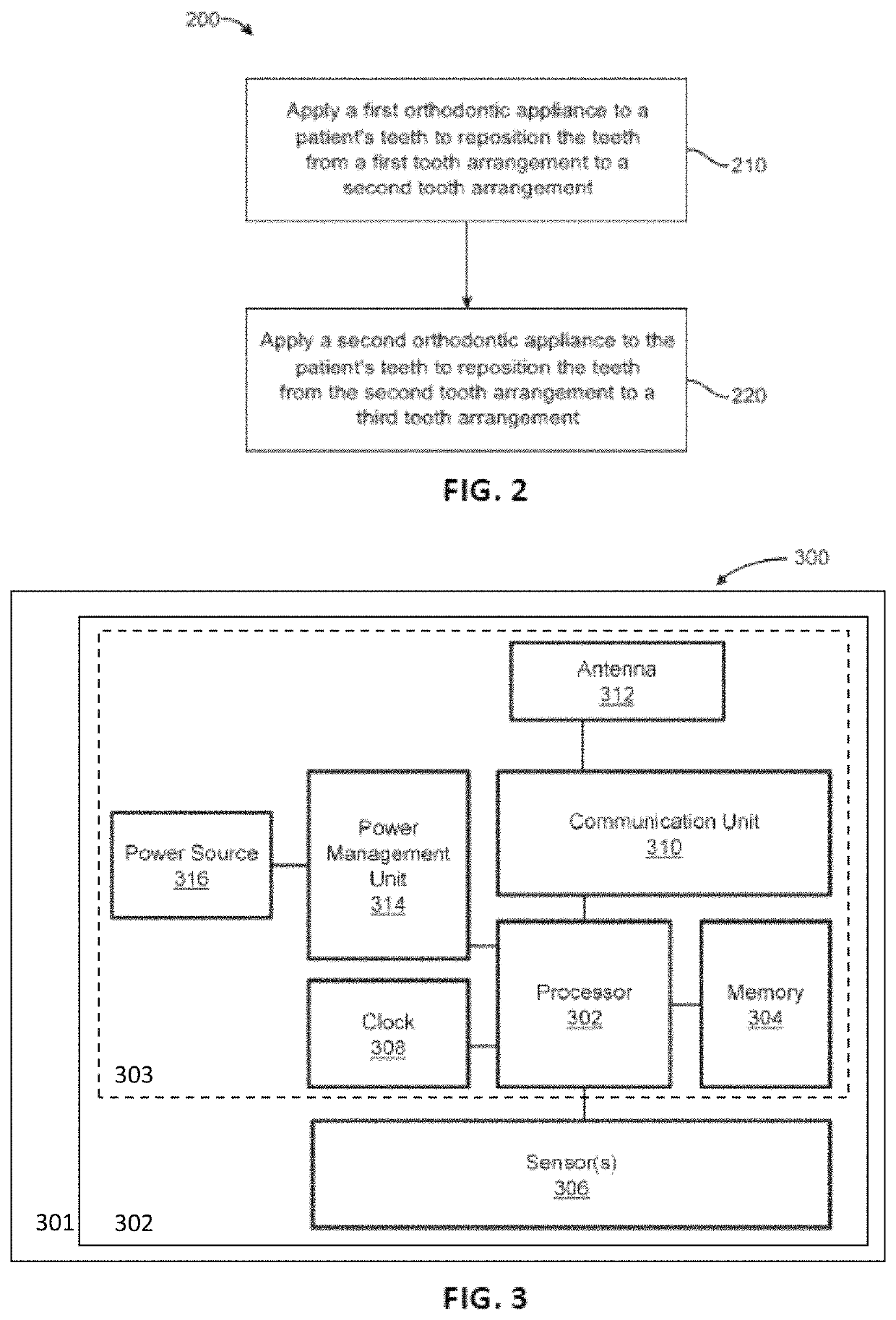

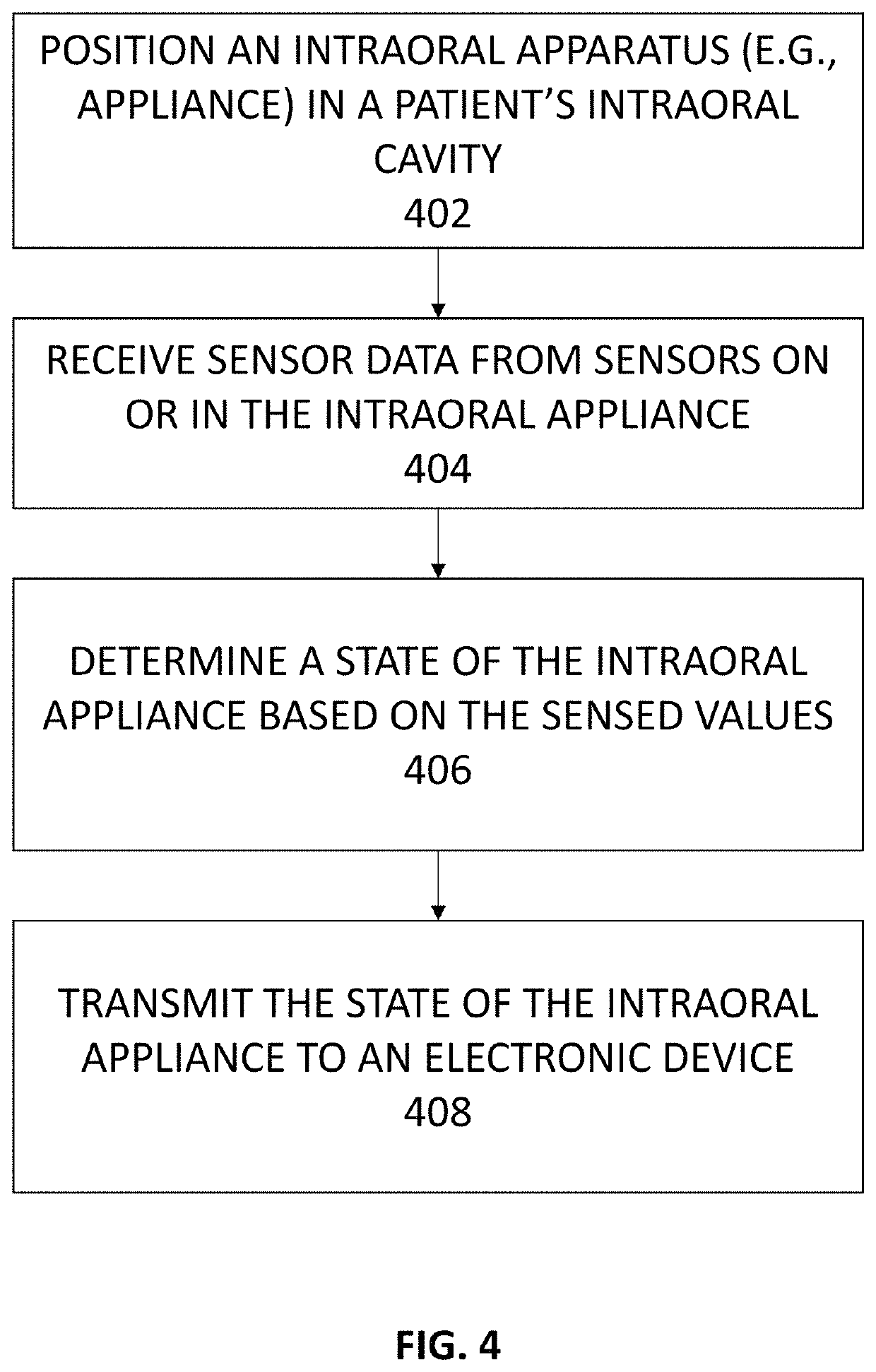

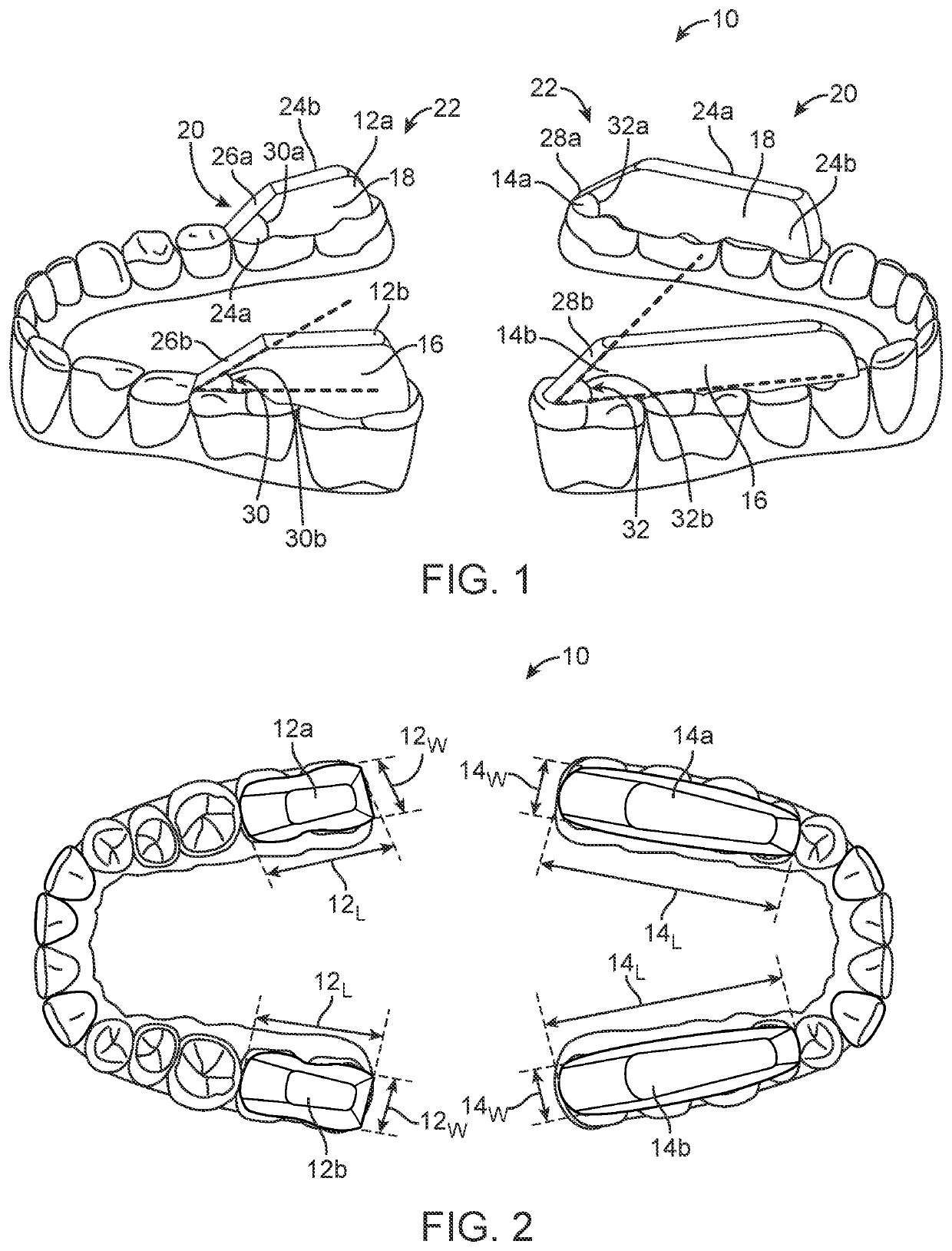

Sensors for monitoring oral appliances

Detection of a state of an oral appliance (such as an aligner, palatal expander, mandibular repositioning device, etc.) to determine if the oral appliance is functioning properly and / or if it has developed a defect.

Owner:ALIGN TECH

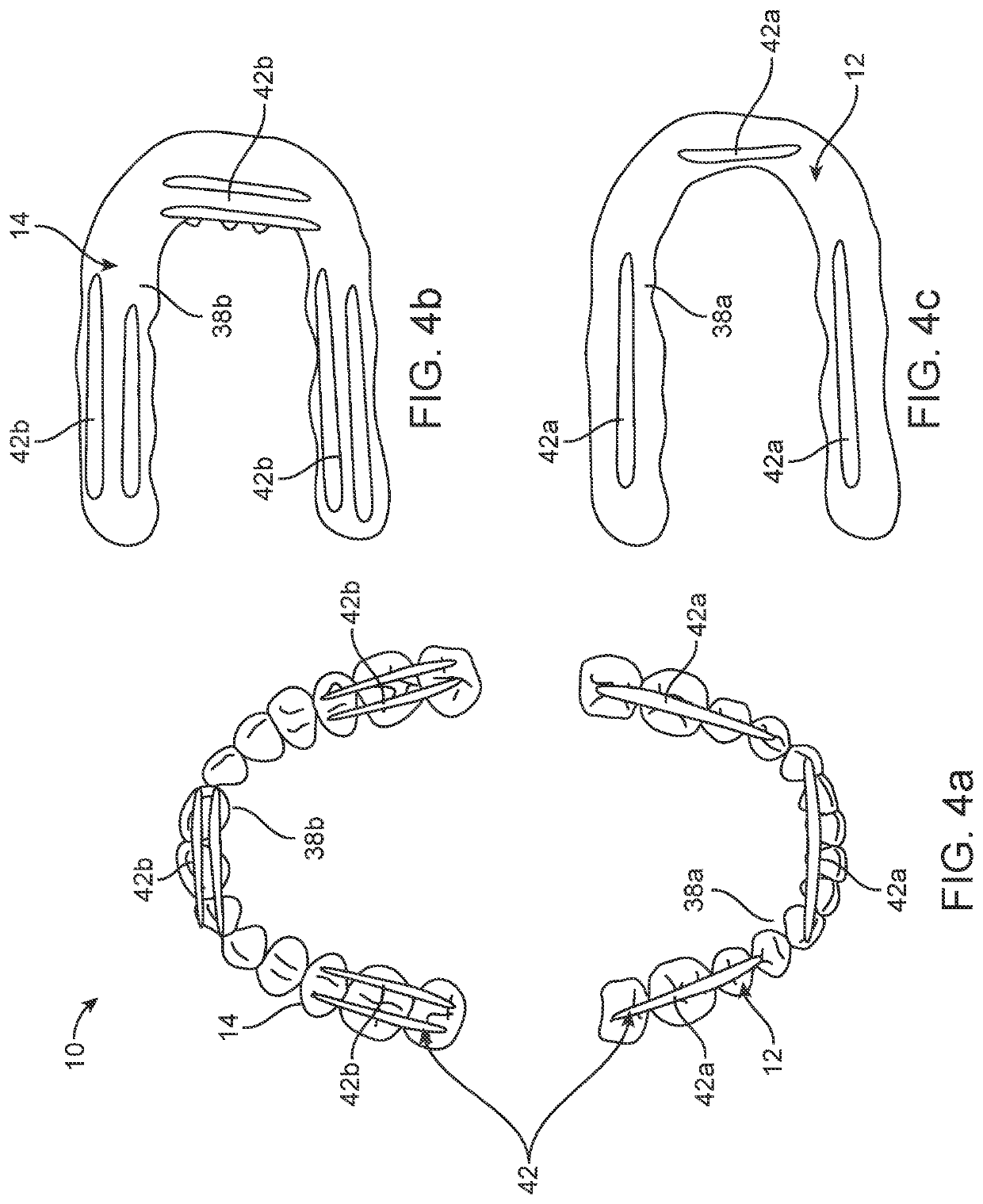

Combined orthodontic movement of teeth with airway development therapy

Systems, devices and methods are disclosed for reshaping airways concurrently with dental and / or orthodontic treatment. The systems can have a series of two or more oral appliances configured to progressively reposition the maxillary and mandibular teeth in two or more successive steps. Each oral appliance in the series can have one or more maxillary blocks, one or more mandibular blocks, a maxillary oral tray, and a mandibular oral tray. One or more maxillary blocks can be attached to or integrated with the maxillary oral tray. One or more mandibular blocks can be attached to or integrated with the mandibular oral tray. The maxillary and mandibular oral trays can be configured to move one or more teeth from a tooth first position to a tooth second position. The maxillary and mandibular blocks can be configured to interact with one another to treat sleep breathing disorders.

Owner:ULAB SYST INC

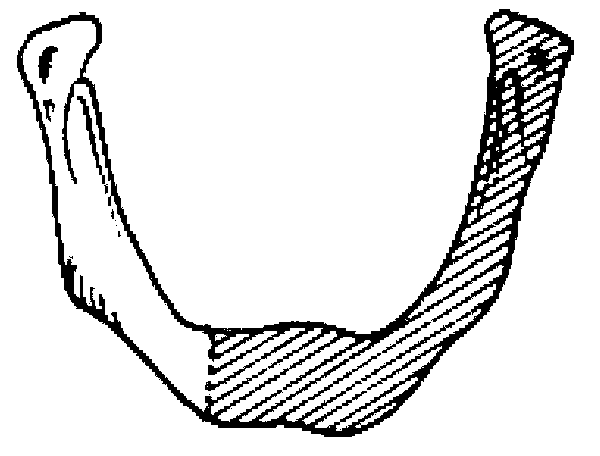

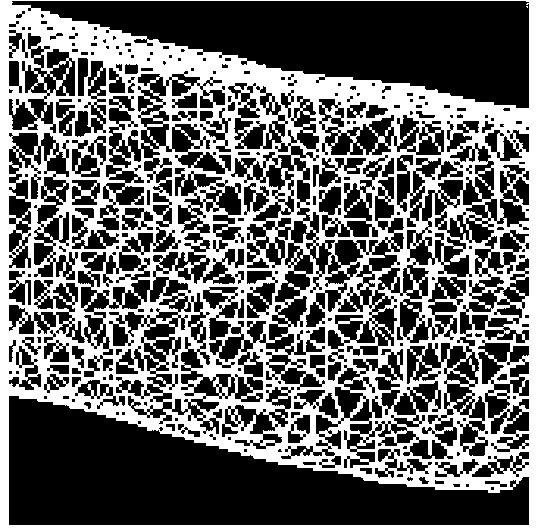

Manufacturing method for personalized bracket for repairing of center plane across mandibular defect

InactiveCN103300946AGood biocompatibilityImprove biological activityBone implantComputed tomographyDentures

The invention discloses a manufacturing method for a personalized bracket for the repairing of a center plane across mandibular defect. The method comprising the following steps: designing a repairing model for a personalized profile and an internal microstructure of an individual defect through CT scanning in combination with a curved surface reperforating way; acquiring a repair body for the defect area through a cutting algorithm; manufacturing the repair body through BOOL arithmetic design via an EBSM method; implanting a three-dimensional reticular metallic support in the mandible defect area; fixing the repair body and two bone stumps through titanium bolts; adding ossifying material and autologous bone marrow stromal cells; and stitching soft tissues and conducting implant implanting after the completion of ossifying, so as to complete denture restoration. The method provided by the invention can better promote and guide the growth of the bones, has a good synosteosis effect for the implant and the around bones, and is suitable for long-term repairing.

Owner:GENERAL HOSPITAL OF PLA

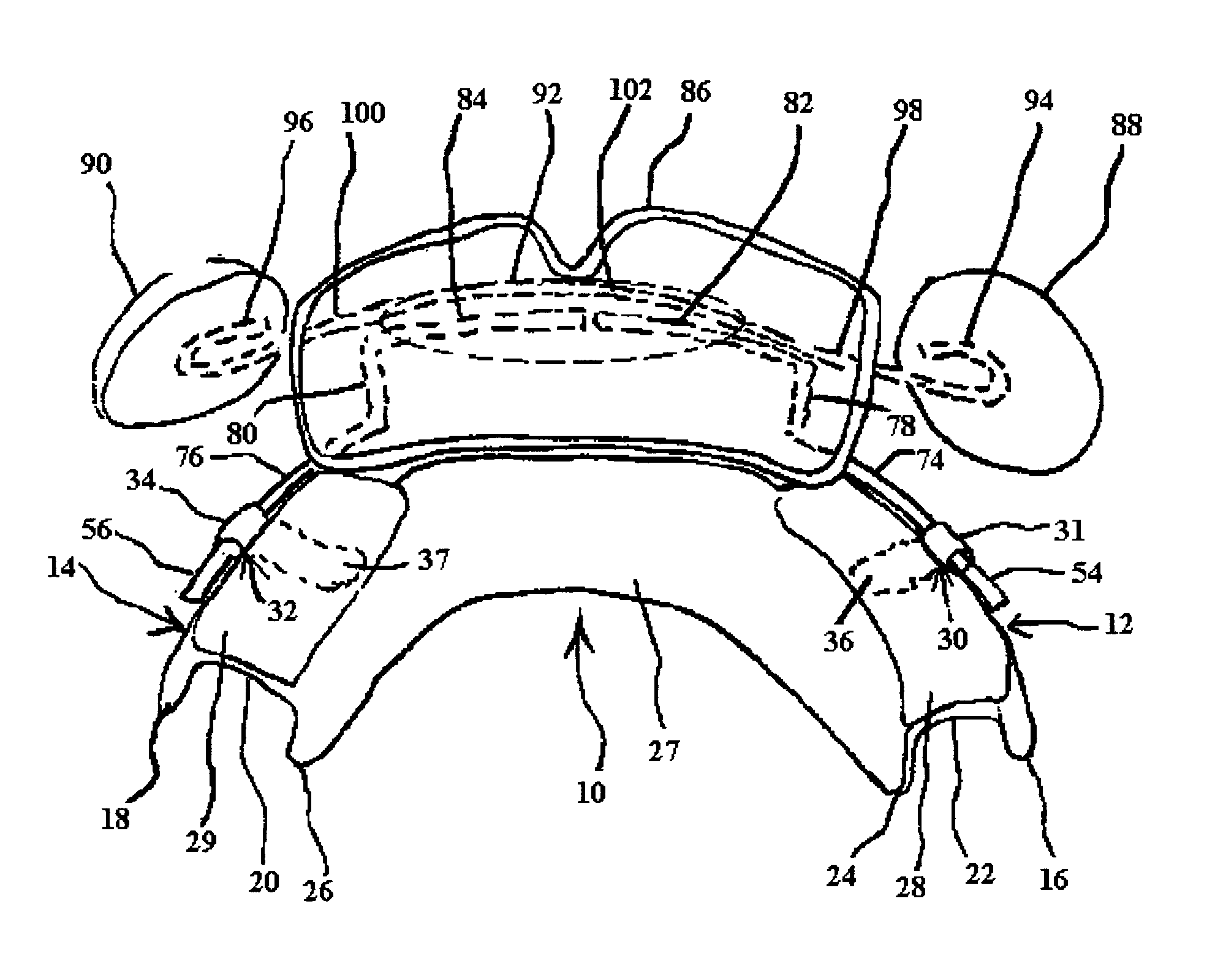

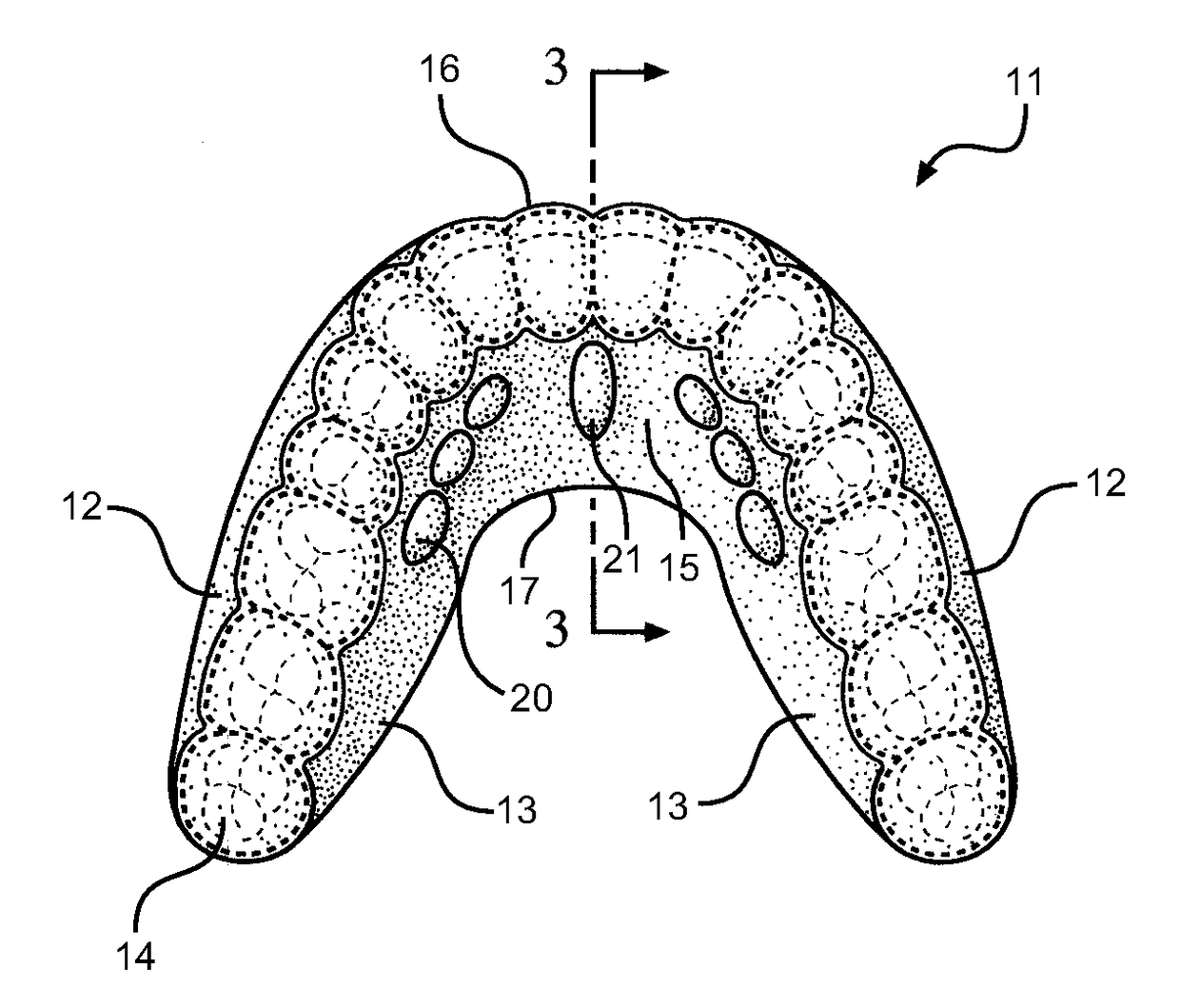

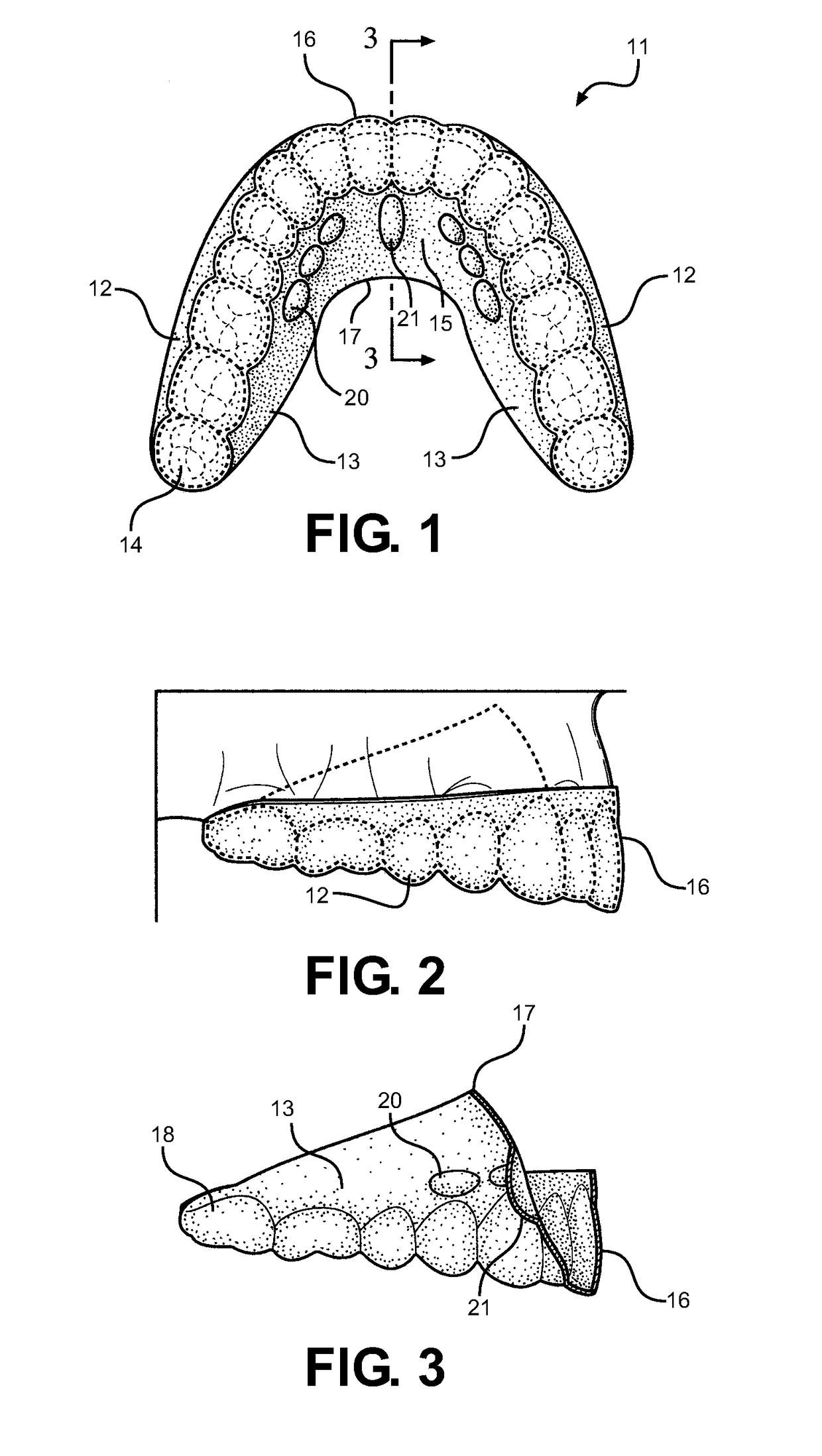

Dental splints and apparatus and method for making dental splints

InactiveUS20060121407A1Relieve painPain and discomfortOthrodonticsTeeth fillingCruciformBody of mandible

The dental splints are used for treating temporomandibular disorders, clenchers, bruxism and headaches resulting from improper alignment of the jaws. The dental splints include a maxillary splint and a mandibular splint. Both splints are formed from stents having a U-shaped trough filled with a dental acrylic and cured in situ on the patient's maxillary teeth and mandibular teeth, respectively. The apparatus includes a maxillary plane analyzer and a holding plate. The holding plate is a U-shaped plate having a central slot for receiving a stem of the plane analyzer and a plurality of recesses for receiving temporary cleats extending from the maxillary stent. The plane analyzer includes a handle, a U-shaped base mounted on the handle and including a pair of arms adapted for extending to either side of the mandible, a stem extending between the arms of the base, and a cruciform upright mounted on the handle.

Owner:DYLINA TIM J

Manufacturing method of repositioning biteplate for treating temporal-mandibular joint disc recoverable forward displacement and repositioning biteplate

PendingCN110667102AIndividualFit closelyAdditive manufacturing apparatusOthrodonticsMetatarsal bone partComputer printing

The invention discloses a manufacturing method of a biteplate for treating temporal-mandibular joint disc displacement by 3D printing. The manufacturing method comprises the following steps: (1) mandible condyle process positions of patients are recorded and fixed; (2) craniomaxillofacial surfaces of the patients are shot to obtain conical beam CT data of the patients; (3) upper and lower jawboneparts of the patients are rebuilt; and the head positions of the patients are adjusted according to frankfort planes of the patients; (4) bone tissue CT values, teeth and occlusalf surface areas are selected from three-dimensional drawing software for three-dimensional rebuilding of occulsalf surface data of the patients; (5) occulsalf surface three-dimensional models of the patients are rebuilt in the three-dimensional drawing software; (6) interference parts of the occulsalf surface three-dimensional models are removed; (7) the occulsalf surface three-dimensional models are guided into 3D printer mated software; (8) upper jaw parts and lower jaw parts of occlusal pads are designed; and (9) a 3D printer is used for printing to finish manufacturing of the occlusal pads. Through projectionsformed on the inner side of the biteplate, lower teeth cannot retreat due to stop by lower jaw projections of the biteplate, so that the lower jaws of the patients are maintained in a protraction state to treat the temporal-mandibular joint disc recoverable forward displacement.

Owner:天津市口腔医院

Combined orthodontic movement of teeth with temporomandibular joint therapy

Systems, devices and methods are disclosed for concurrently treating temporomandibular joint dysfunction (TMD) and orthodontically moving teeth. The devices can have an orthodontic aligner and a TMD treatment device. The devices can be configured to concurrently reposition a mandible and orthodontically move one or more teeth.

Owner:ULAB SYST INC

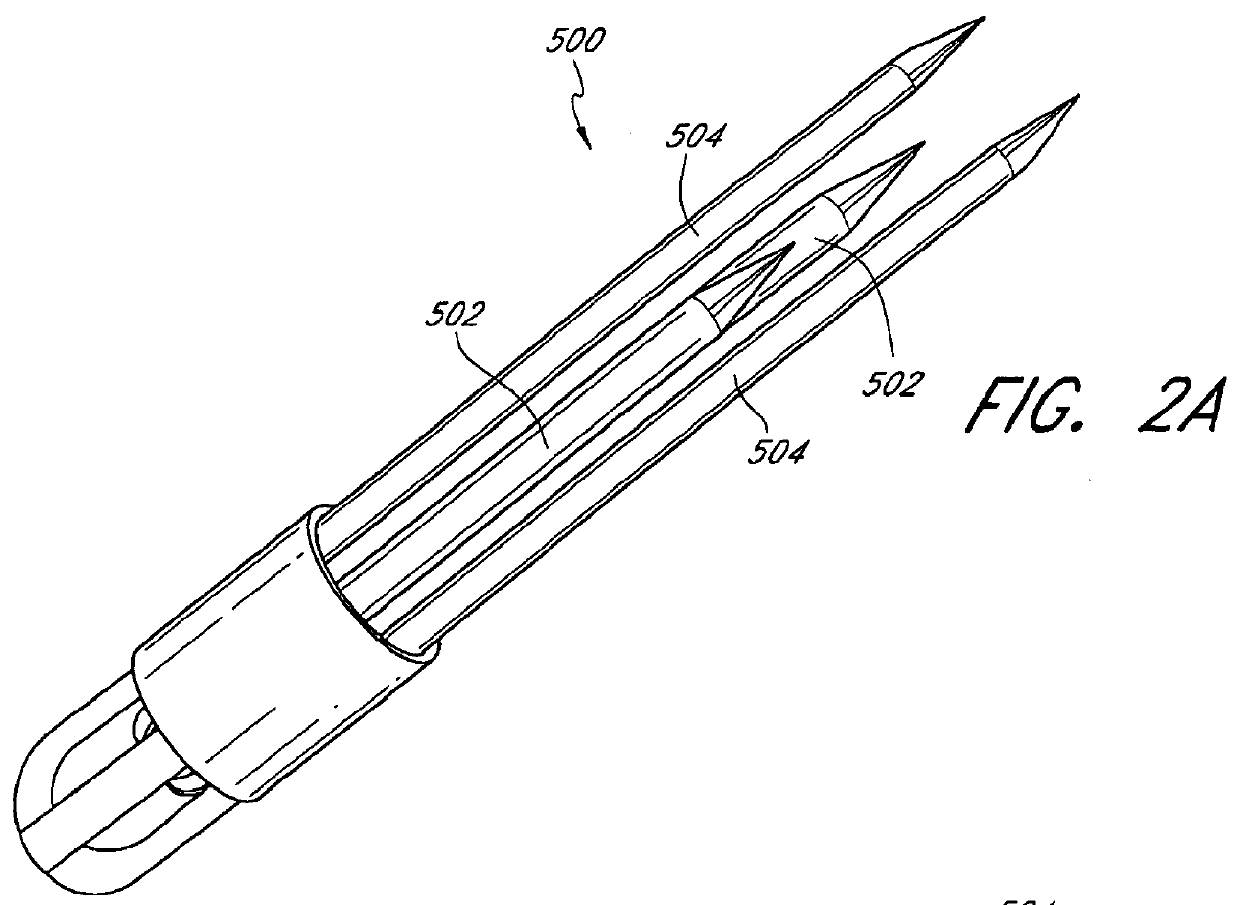

Method and Oral Appliance for Improving Air Intake and Reducing Bruxism

ActiveUS20180207022A1Numerous medical conditionImprove performanceChiropractic devicesSnoring preventionDiseaseThroat

Provided is a soft flexible oral appliance having protuberances that mimic naturally occurring dental Tori. An upper, palatial appliance and a lower, mandibular appliance may be used in conjunction or separately to alleviate a variety of disorders, improve facial tone, and increase physical performance. The appliances are lightweight, thin, and do not prohibit normal speech patterns when in use Small protuberances are strategically molded along key surfaces of each appliance to stimulate nerves in the tongue and affect forward protrusion. Forward positioning of the tongue dilates the airways of the throat improving breathing while the use is sleeping, playing sports, or talking. It also reduces bruxing or grinding of the teeth. A method is further provided, for adding protuberances to other types of oral appliances, thereby conferring some of the benefits listed above on appliances originally intended for other dental uses.

Owner:DENTAL CHOICE HLDG LLC

Dental Bur

In one embodiment, a dental bur includes a proximal shank, an intermediate cutting section, and a smooth, rounded distal tip. The cutting section includes (i) a frustum-shaped portion connected at its larger-diameter end to the shank and (ii) a curved portion that provides a transition between the smaller-diameter end of the frustum-shaped portion and the rounded tip, where the outer surfaces of the frustum-shaped portion and the curved portion are both sufficiently abrasive to remove bone tissue due to the presence of surface grit and / or flutes that provide bone-cutting edges. The dental bur reduces and flattens the bone tissue of the maxillary and mandibular bones for surgical dental implants without unwanted soft tissue damage.

Owner:SMAIL DOUGLAS BRUCE

Device for the diagnosis of inflammatory tissues in dental applications

ActiveUS20150017101A1Maximum sensitivityAvoid couplingUltrasonic/sonic/infrasonic diagnosticsCompounds screening/testingMedicineMaxilla/Maxillary

The document proposes a diagnostic chewing gum for identifying the presence of inflammatory tissues in the mouth, in particular in or adjacent to the mandible, the maxilla, an implant or the teeth of a user, comprising a base material or particles (3) embedded and / or attached to said base material; an element (1, 5-7), like e.g. a releasable flavor molecule, attached to said base material and / or said particles, for the generation of a change in the chewing gum directly detectable by the user; wherein the element (1, 5-7) generates the change upon direct or indirect contact with a marker (4), e.g. a proteolytic enzyme, which is released by inflammatory tissue in response to bacterial mediators.

Owner:THOMMEN MEDICAL

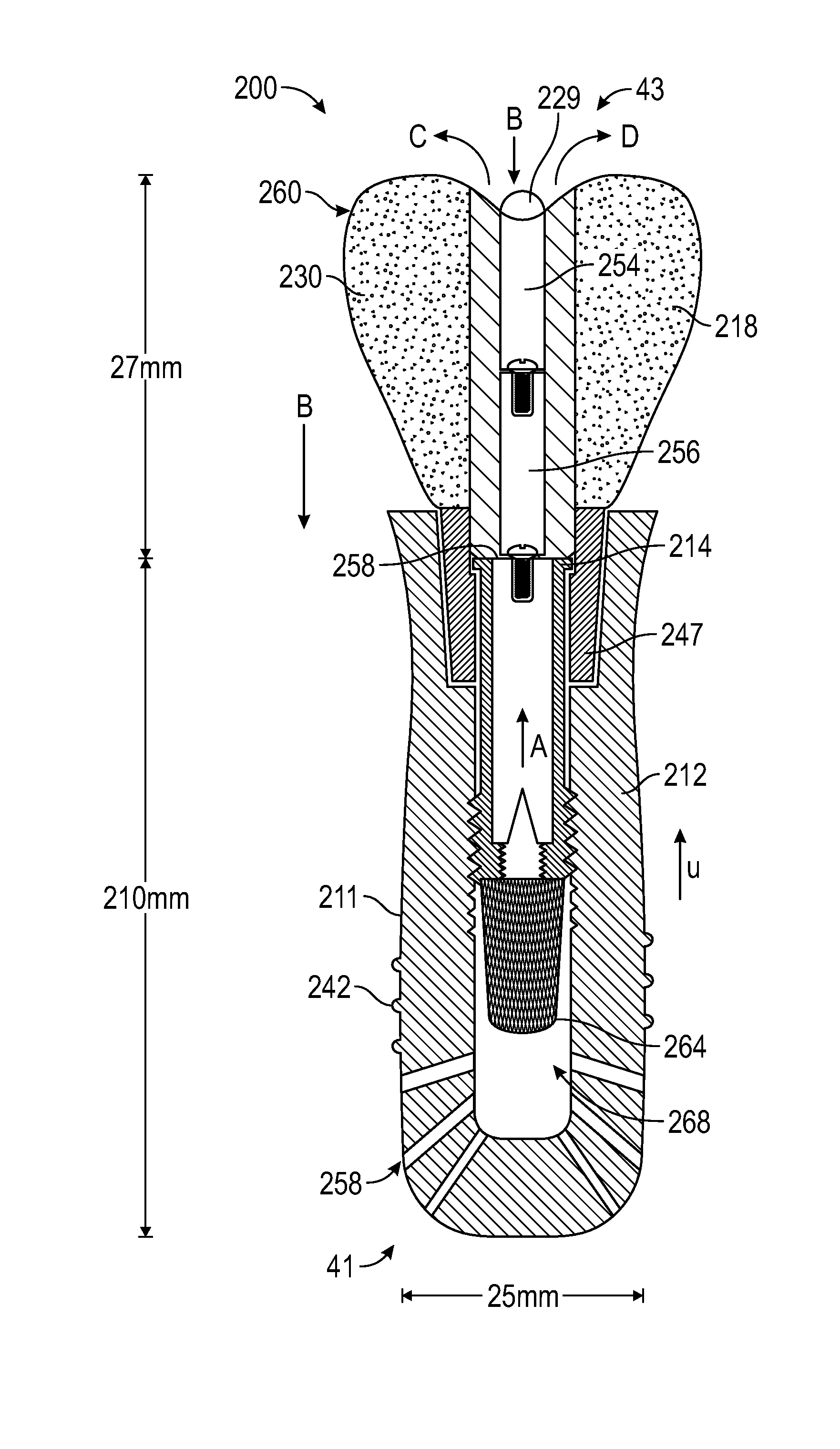

Artificial Salivary Gland

ActiveUS20160278909A1Restore saliva flowConstant rateDental implantsTeeth fillingArtificial salivasIon-exchange resin

Artificial salivary gland devices and assemblies are provided. The present disclosure provides artificial salivary pump / gland devices and assemblies, and related methods of use. One embodiment utilizes the interstitial / marrow fluid reservoir within the underlying mandibular or maxillary bone as a source for replacement saliva. The salivary pump / assembly, which is implantable in the mandibular or maxillary bone as a dental implant and driven by incidental tooth contact and masticatory forces, harvests interstitial / marrow fluid and treats it via semi-permeable membrane technology and soluble particles as a continuously available saliva replacement. Masticatory forces and tooth contact power the pump to both harvest interstitial / marrow fluid and drive flow through a bed of ion-exchange resins and / or soluble particles to adjust fluid chemistry providing a continuously available saliva-like solution. Exemplary devices and assemblies can also be utilized to introduce beneficial bacteria into the oral cavity and / or be utilized as a delivery system for drugs / therapeutic agents.

Owner:UNIV OF CONNECTICUT

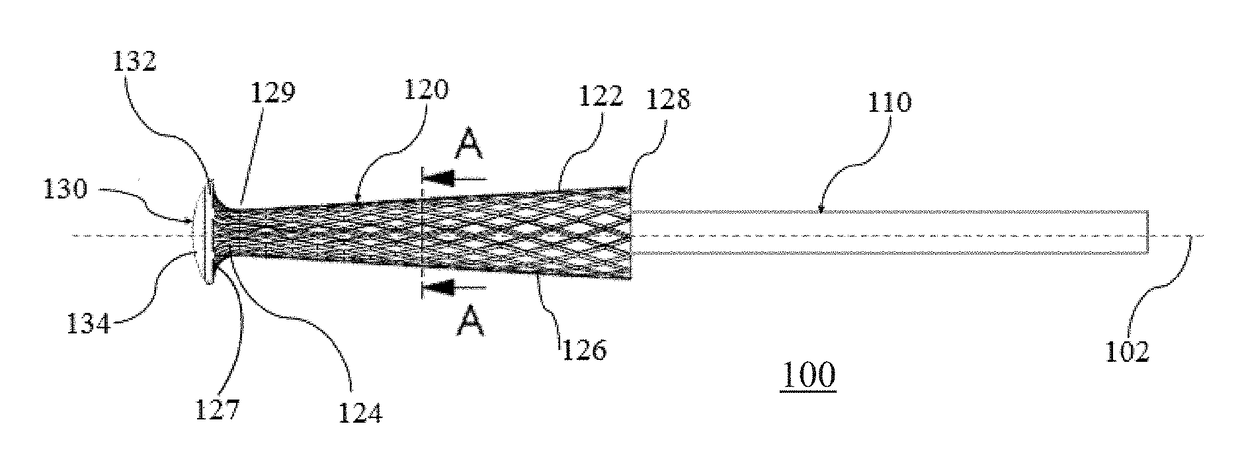

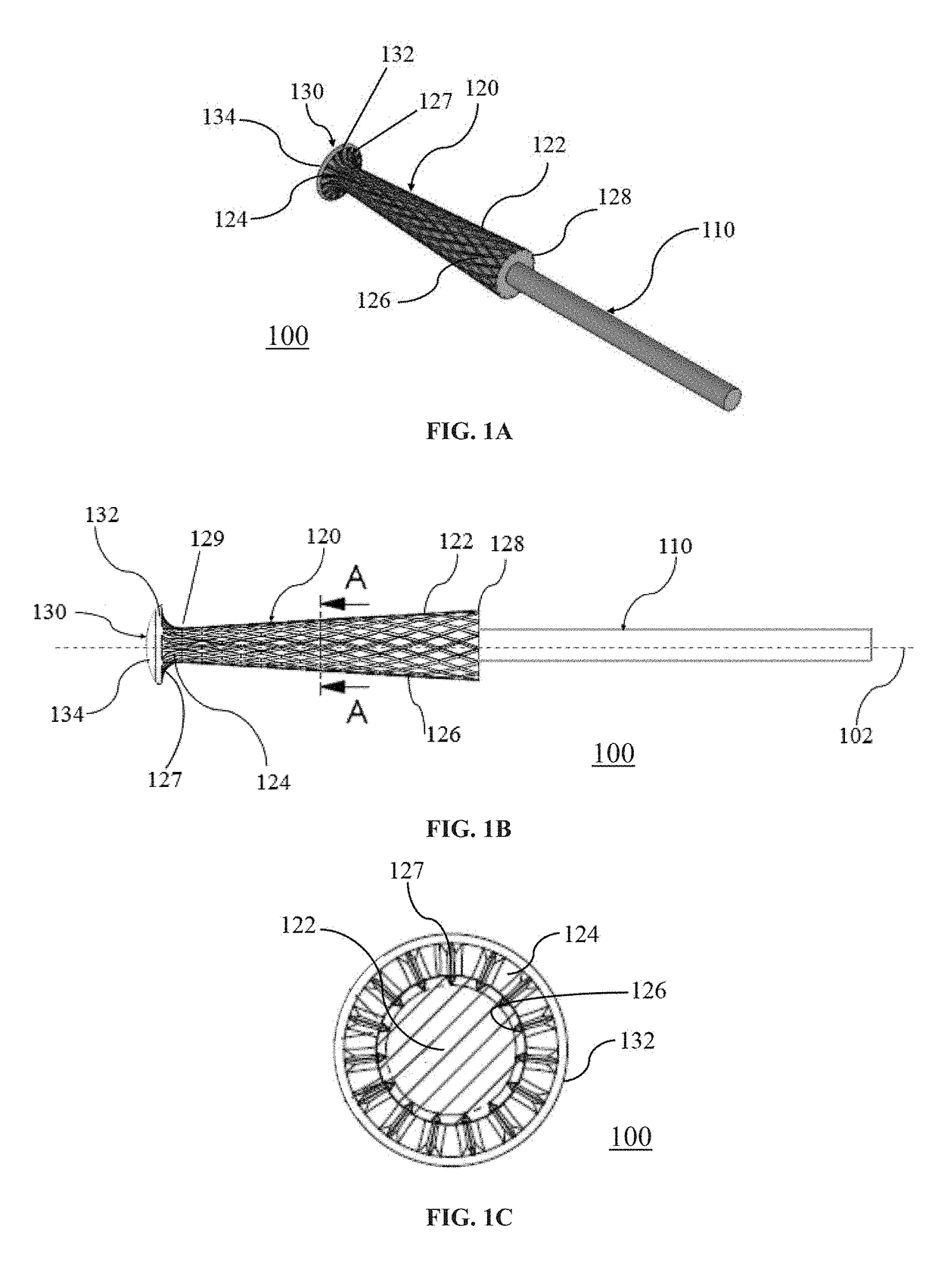

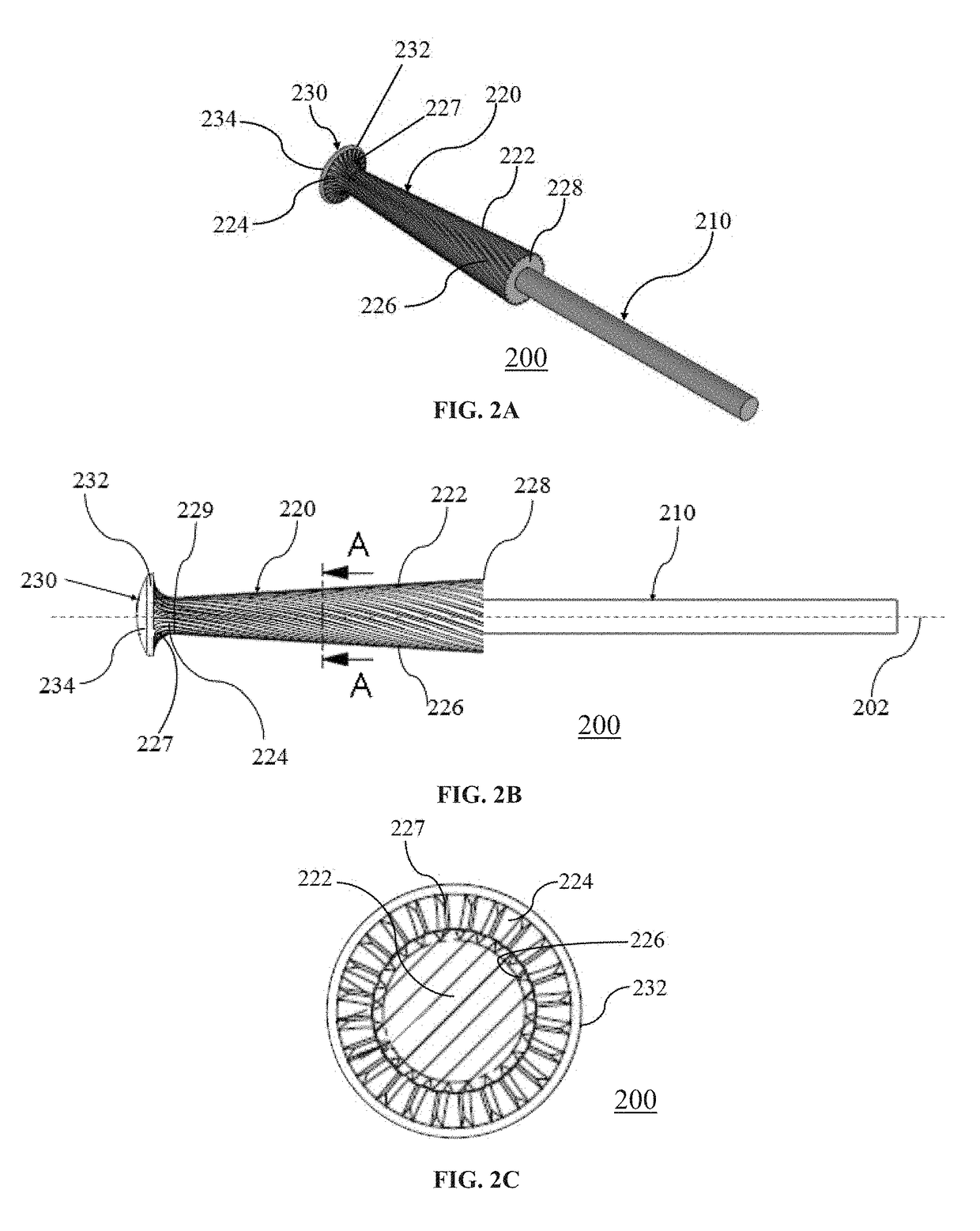

Glassoplasty using tissue anchor glossopexy with volumetric tongue reduction

ActiveUS20120216818A1Fully deformedPrevent crashSuture equipmentsSurgical needlesRf ablationCoreoplasty

Methods and devices are disclosed for remodeling the tongue. One or more spaces or cavities are formed in the tongue using, for example, surgical or RF ablative techniques. The cavities can be closed or collapsed by inserting a tethered soft tissue anchor into the tongue and attaching the tethered portion of the soft tissue anchor to a bony structure such as the mandible or hyoid bone in order to exert a collapsing force on the one or more spaces or cavities. The insertion pathway of the tethered soft tissue anchor may pass adjacent to or even through one or more cavities. Also disclosed herein is a tongue remodeling system that includes means for creating a space in the tongue, and a tissue anchor configured to close the space. The tissue anchor may be tethered or expandable.

Owner:KONINKLIJKE PHILIPS NV

Dental orthotic

ActiveUS20120028205A1Increase oxygen concentrationOthrodonticsTeeth fillingKnee orthosisOxygen level

A dental orthotic covering a plurality of teeth is provided for improving various obstructive syndromes of the human upper airway. The orthotic may be relatively thickened on the lingual side of the orthotic, compared to the facial or occlusal side; and in particular may relatively thickened in the more posterior aspects of the lingual side of the orthotic as compared to the more anterior aspects of the lingual side of the orthotic. The orthotic may be formed of one piece or two, and may be purely mandibular, or may be coupled to a maxillary orthotic. A method of progressive fitting of the orthotic for optimization of a patient's blood oxygen level is described.

Owner:METZ JAMES

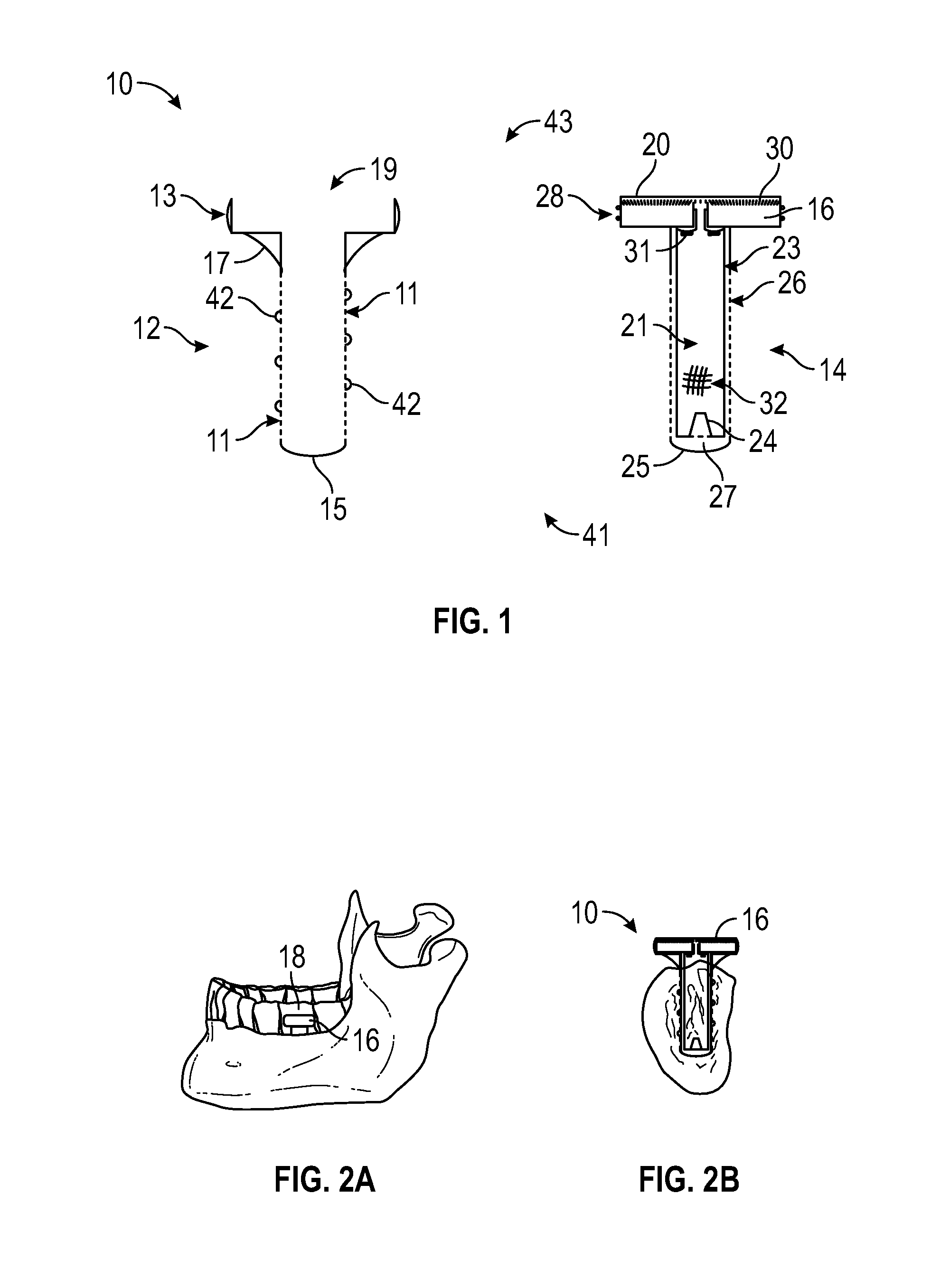

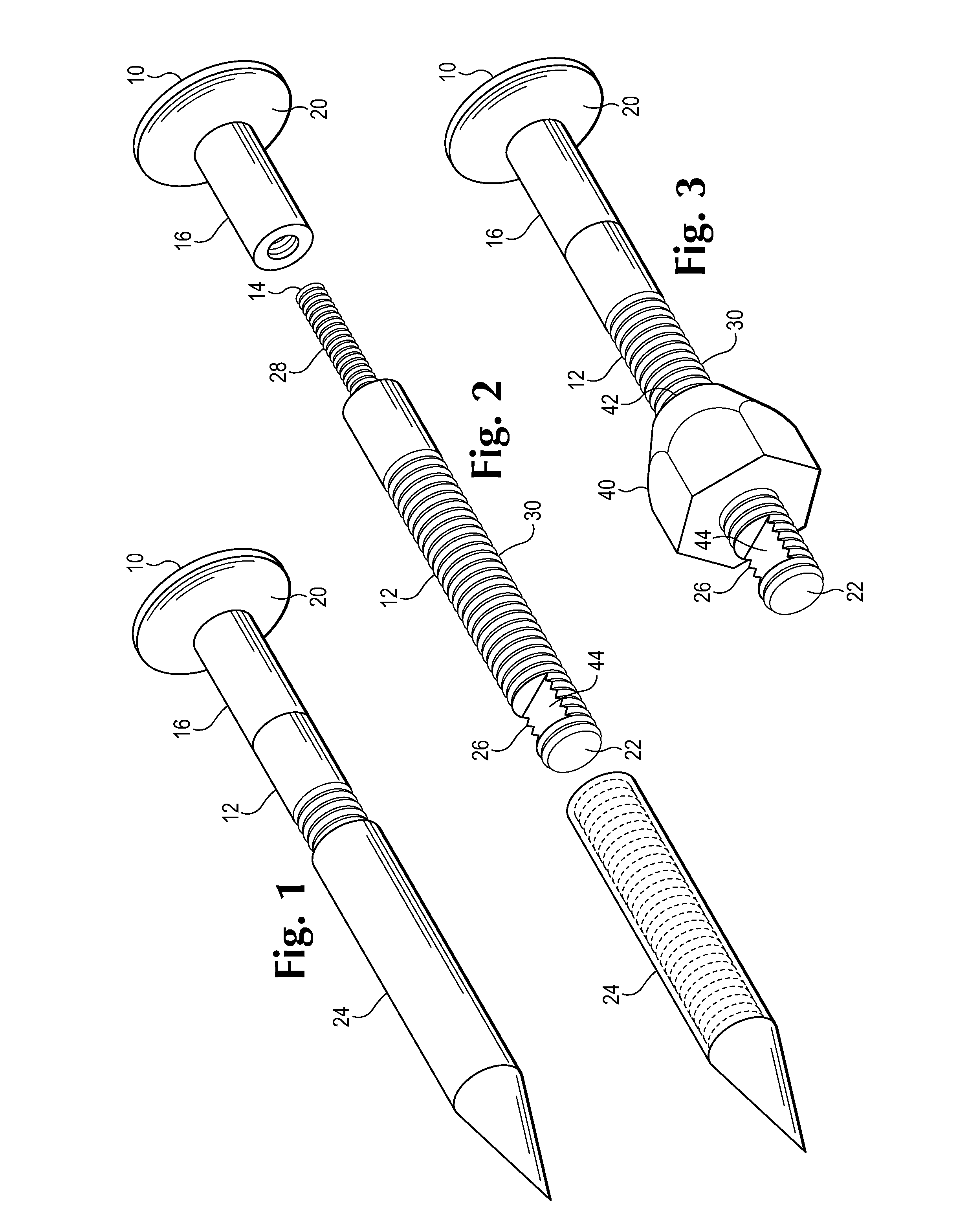

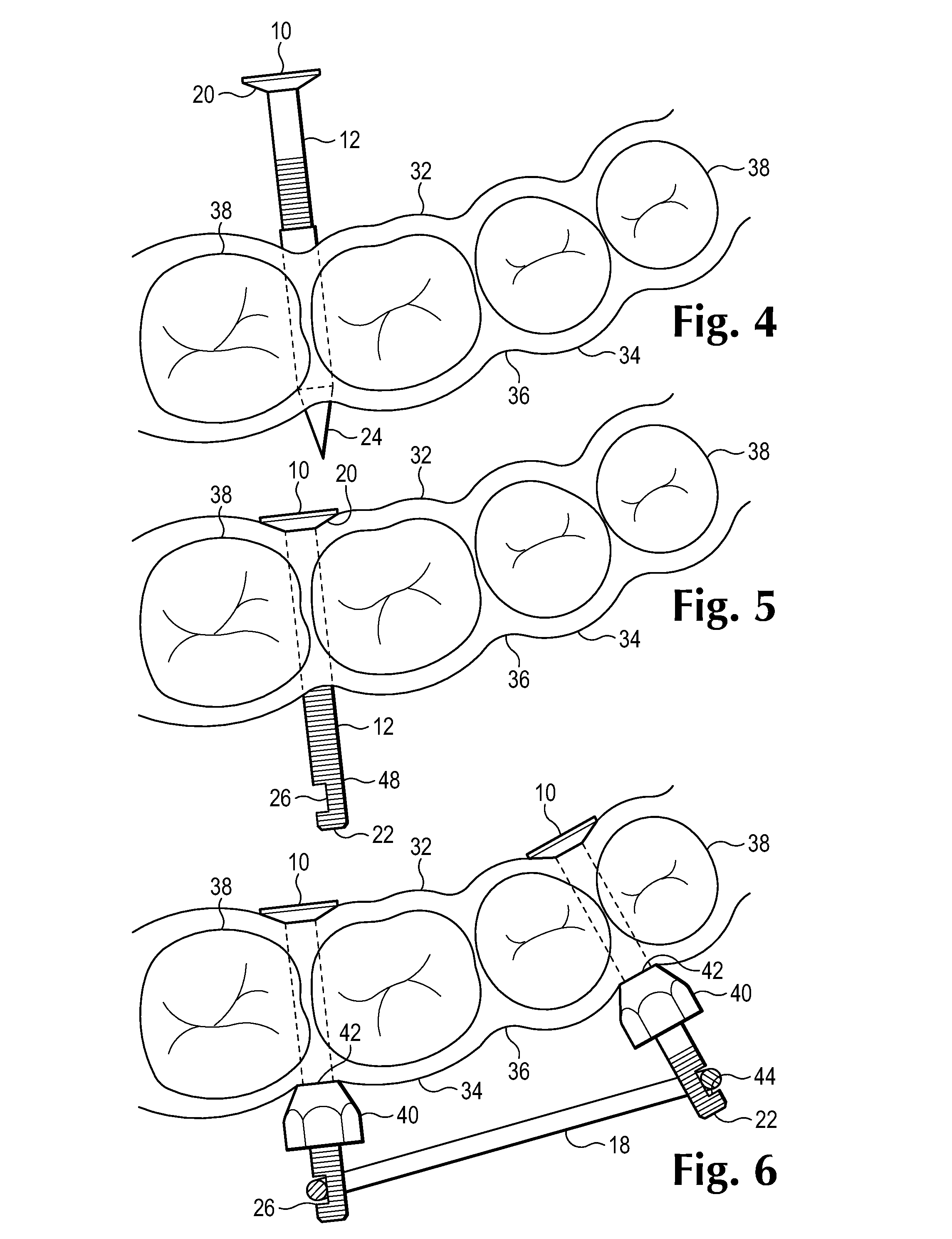

Method and apparatus for maxillo-mandibular fixation

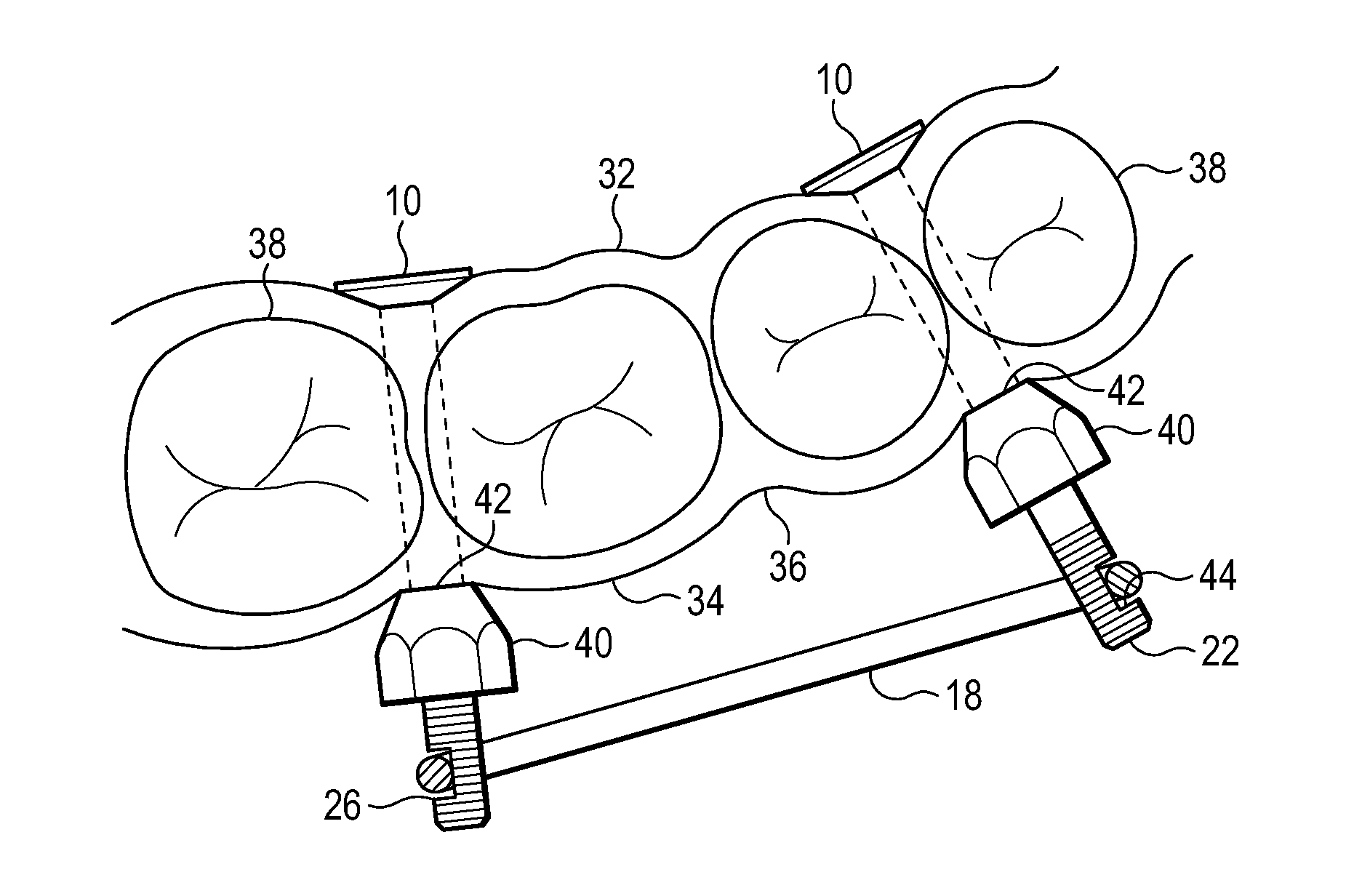

Apparatus and method of use which can be used to immobilize maxilla and mandible in dental occlusion utilizing the tissue of the interdental space.

Owner:STUPAK HOWARD D

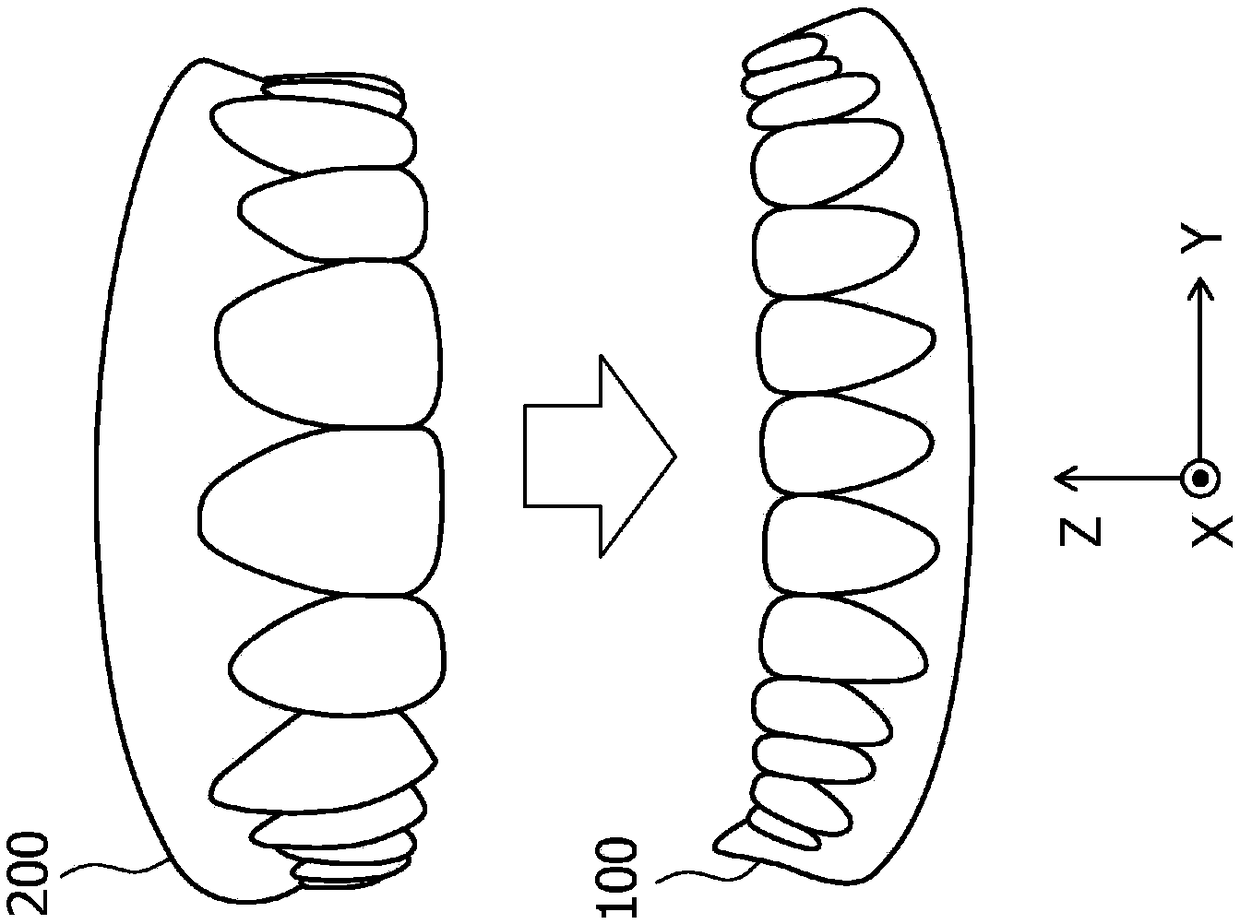

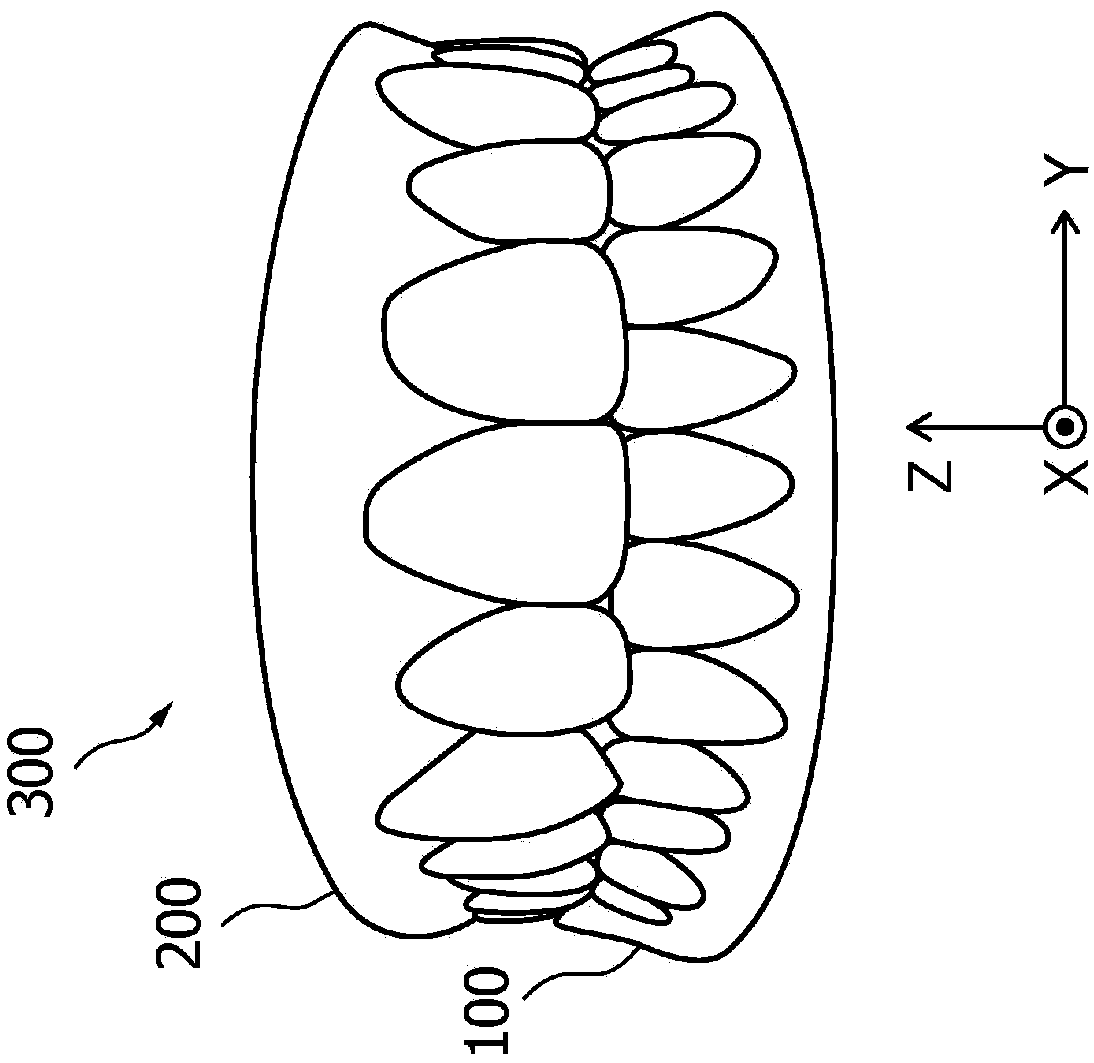

Occlusal state identifying method, occlusal state identifying apparatus

Provided is an occlusal state identifying method executed by a processor included in an occlusal state identifying apparatus. The occlusal state identifying method includes obtaining maxillary shape data and mandibular shape data; arranging a maxillary image including a plurality of maxillary teeth corresponding to the obtained maxillary shape data and a mandibular image including a plurality of mandibular teeth corresponding to the obtained mandibular shape data such that corresponding teeth oppose each other; executing a moving process of moving at least one of the arranged maxillary image and mandibular image by executing a dynamic simulation; and identifying a positional relationship between the maxillary image and the mandibular image after the moving process as a positional relationship corresponding to an occlusal state of the maxillary teeth included in the maxillary image and the mandibular teeth included in the mandibular image.

Owner:FUJITSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com