Patents

Literature

82 results about "Dental occlusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Relationship of all the components of the masticatory system in normal function; has special reference to the position and contact of the maxillary and mandibular teeth for the highest efficiency during the excursive movements of the jaw that are essential for mastication.

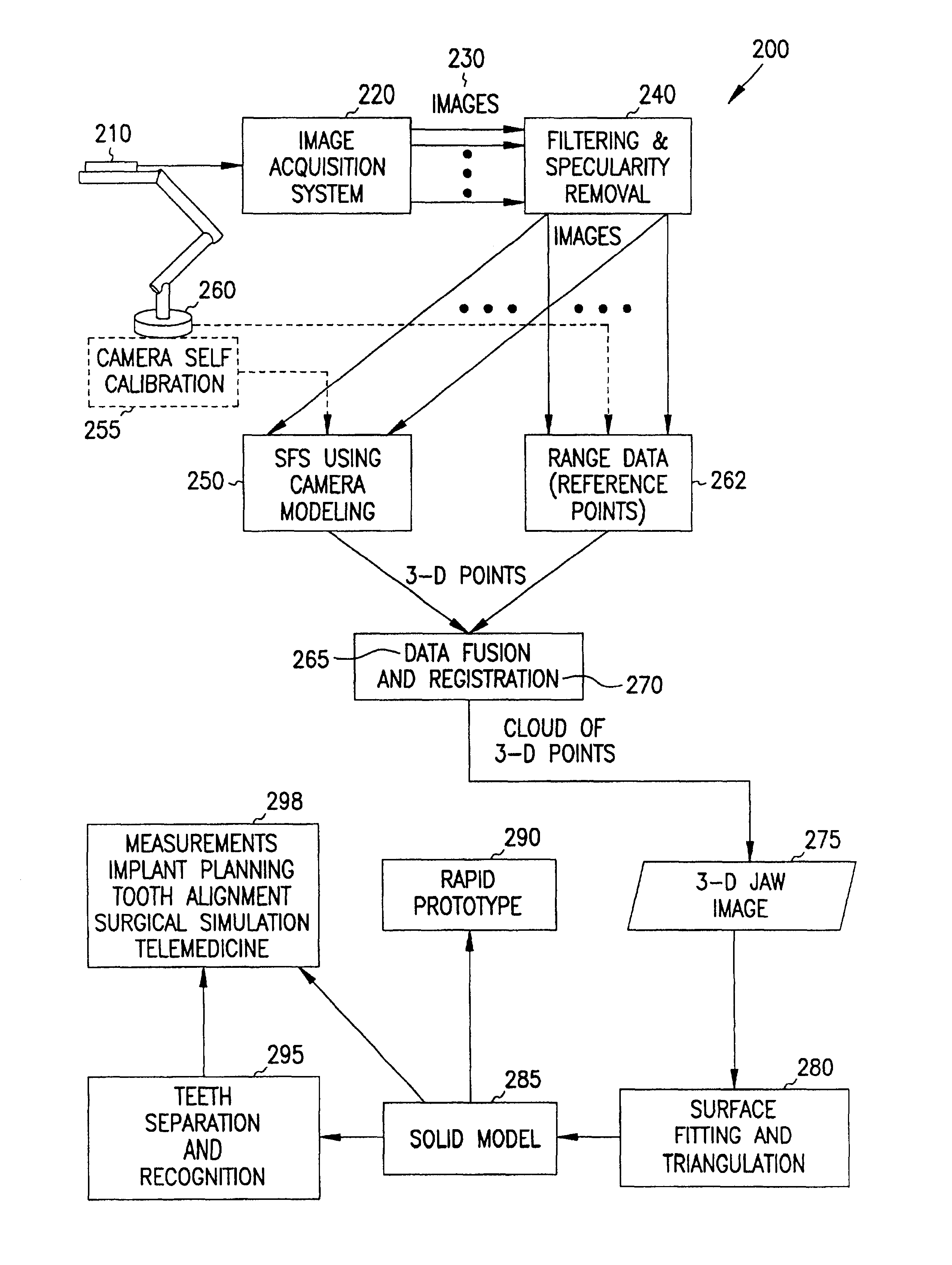

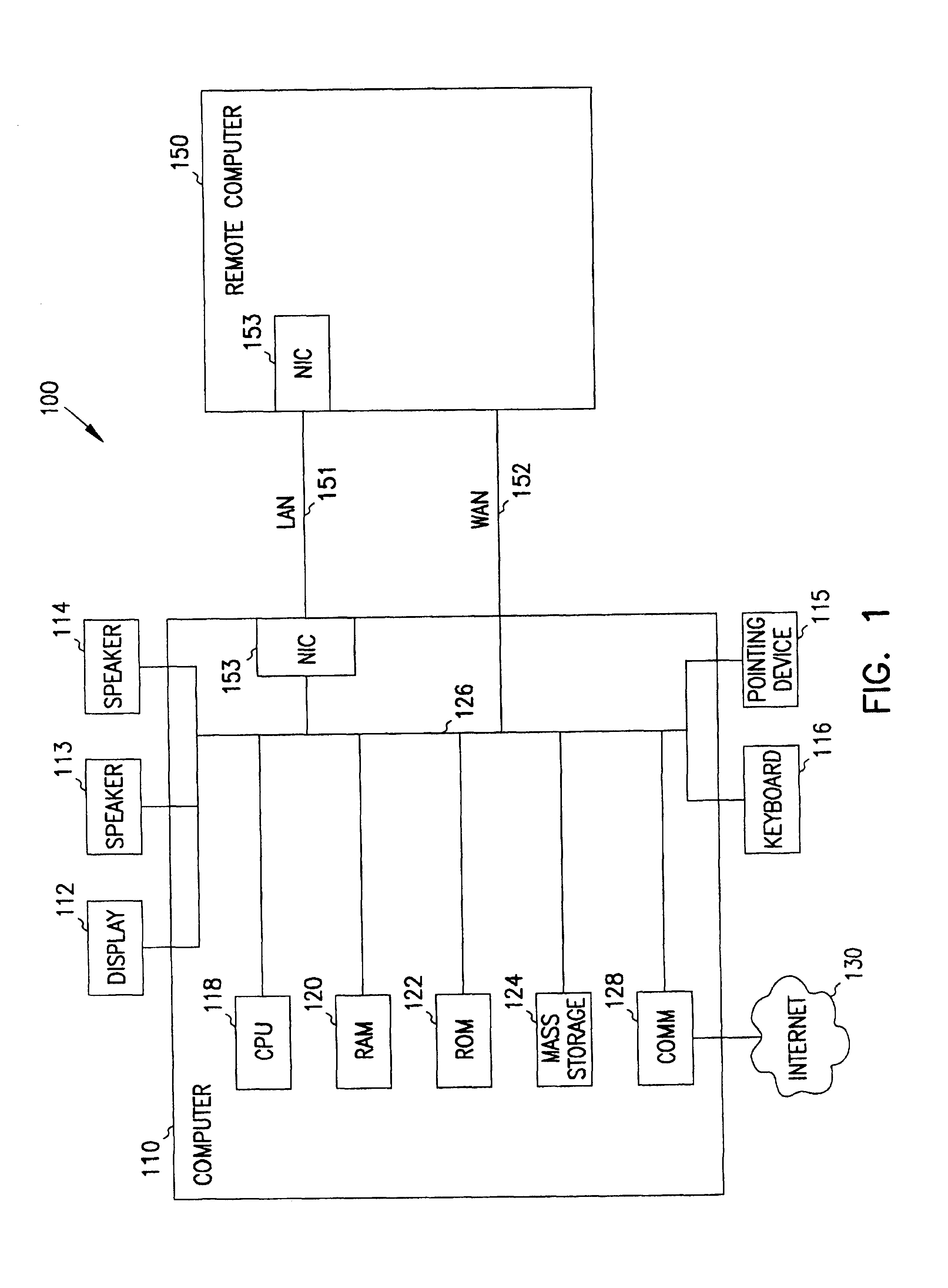

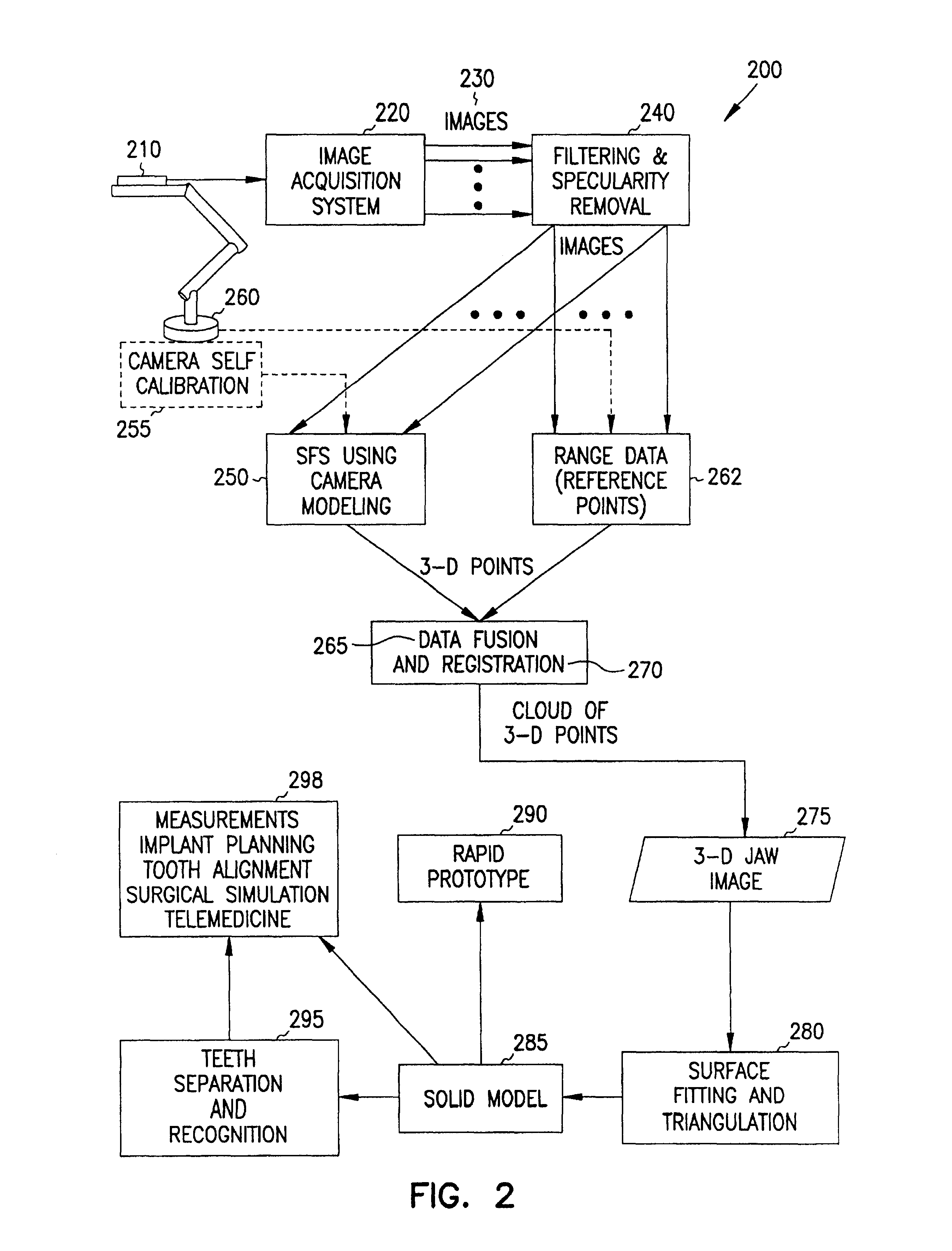

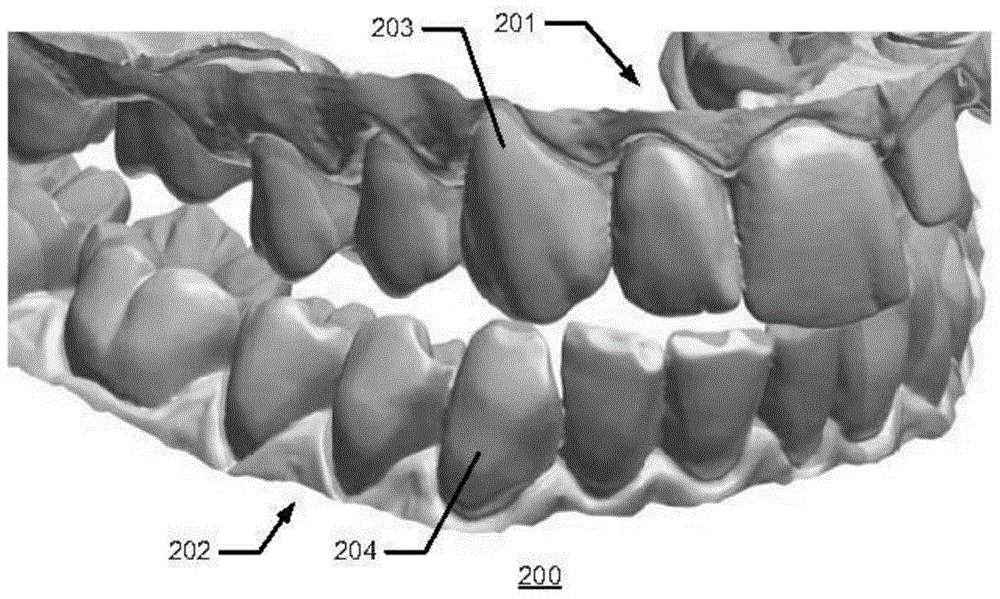

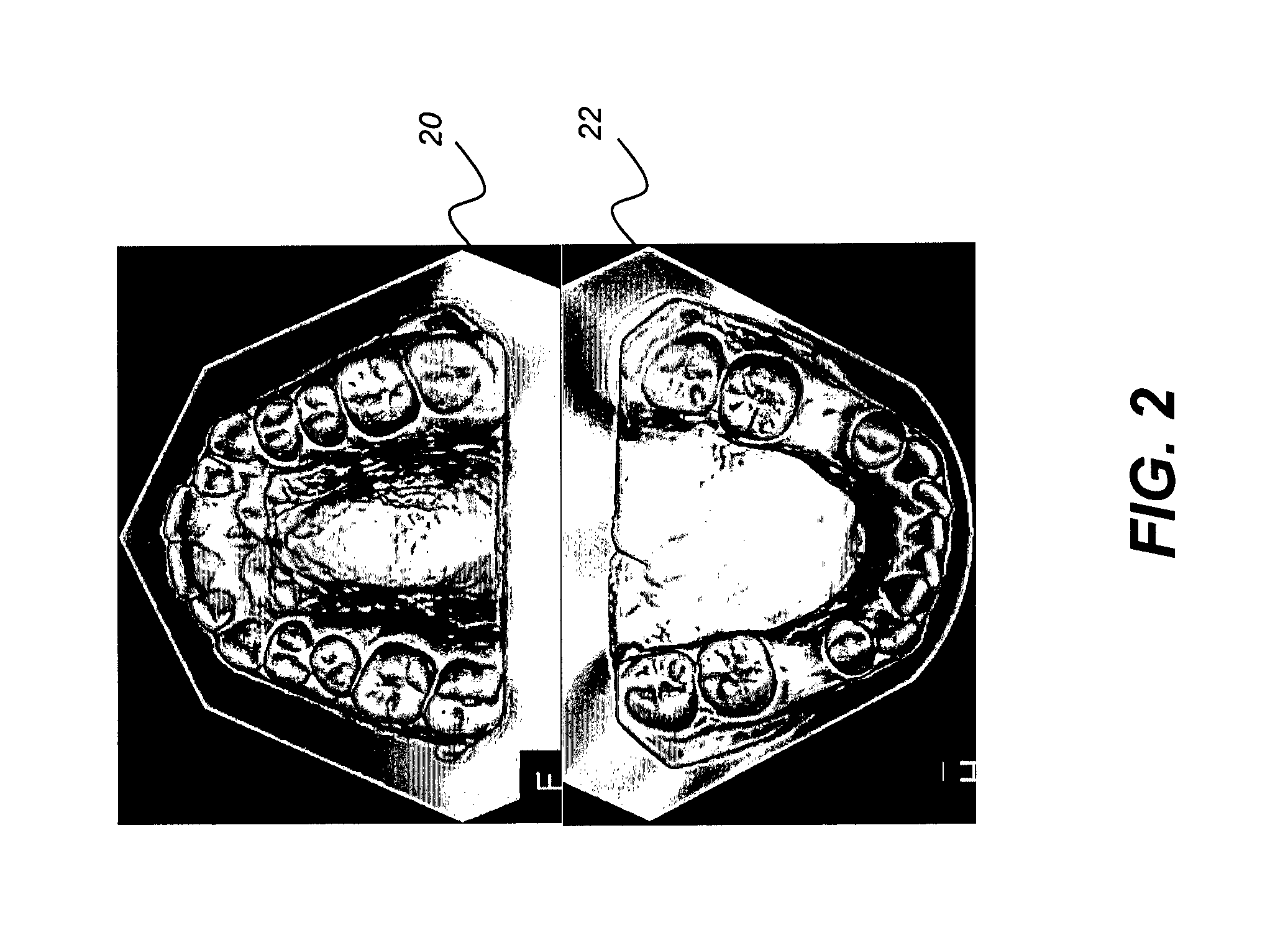

System and method for 3-D digital reconstruction of an oral cavity from a sequence of 2-D images

Systems and methods are provided through which a model-based vision system for dentistry which assists in diagnosis, treatment planning and surgical simulation. The present invention includes an integrated computer vision system that constructs a three-dimensional (3-D) model of the patient's dental occlusion using an intra-oral video camera. A modified shape from shading technique, using perspective projection and camera calibration, extracts the 3-D information from a sequence of two-dimensional images of the jaw. Data fusion of range data and 3-D registration techniques develop a complete 3-D digital jaw model. Triangulation of the 3-D digital model is then performed, and optionally, a solid 3-D model is reconstructed.

Owner:UNIV OF LOUISVILLE RES FOUND INC

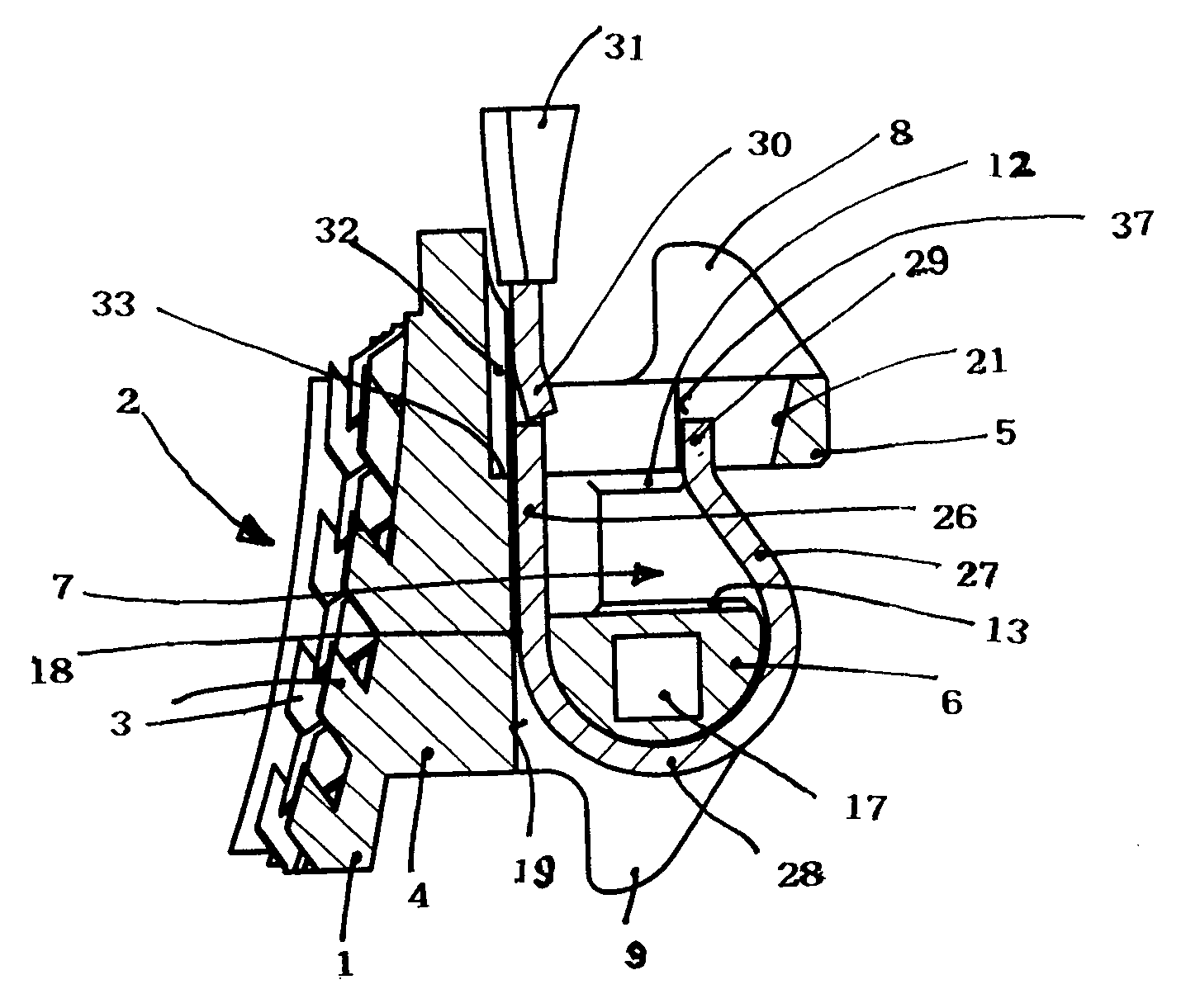

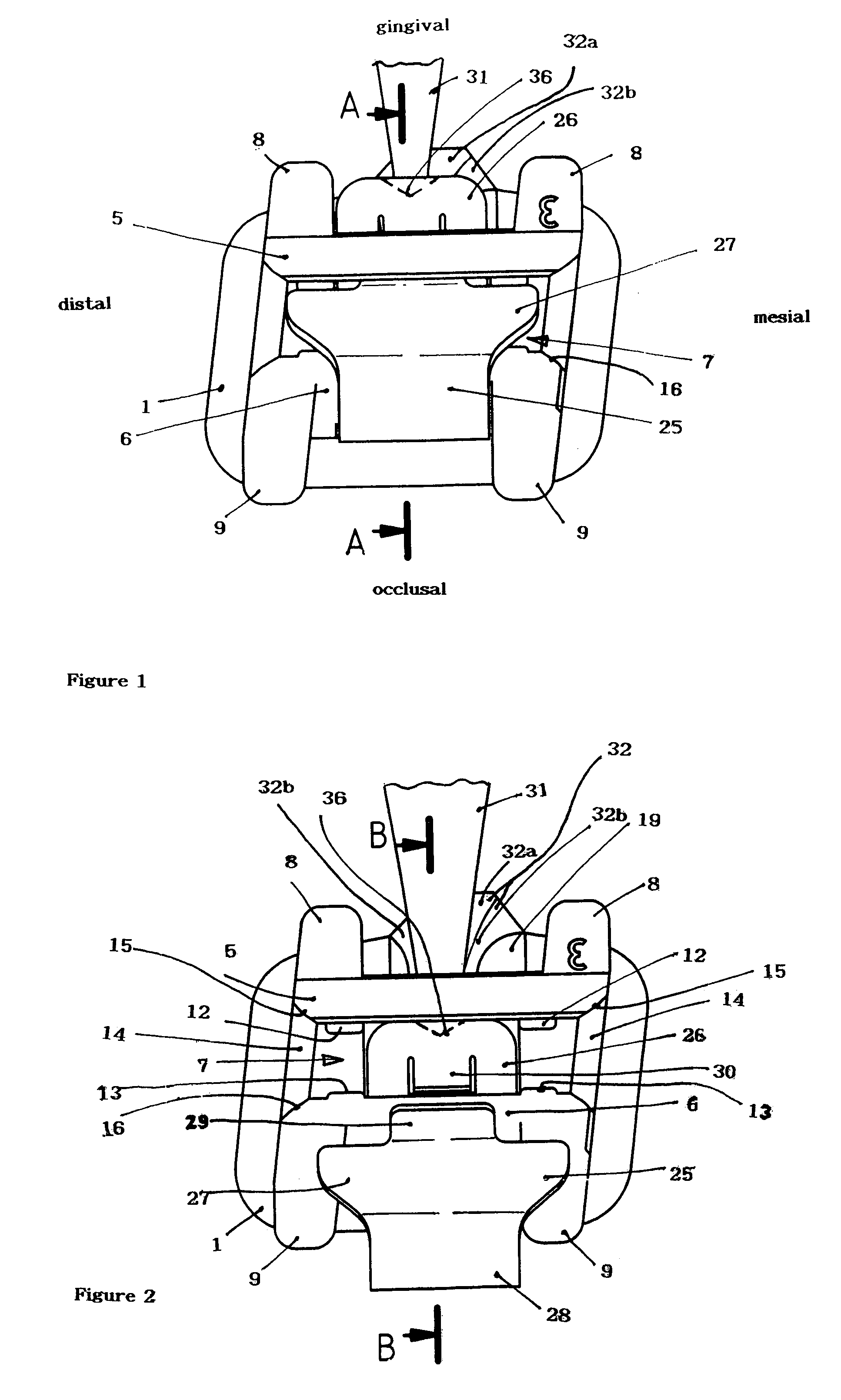

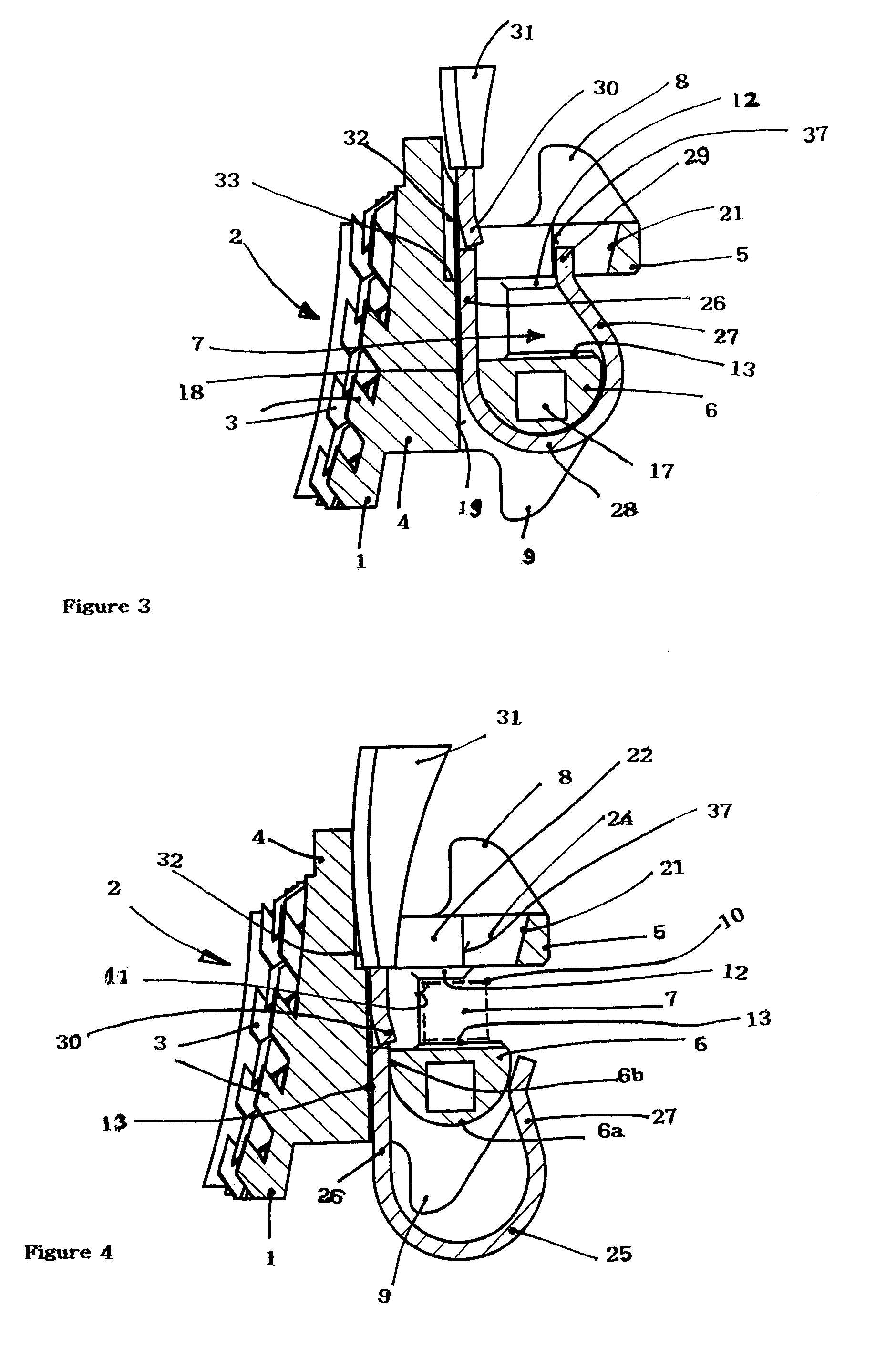

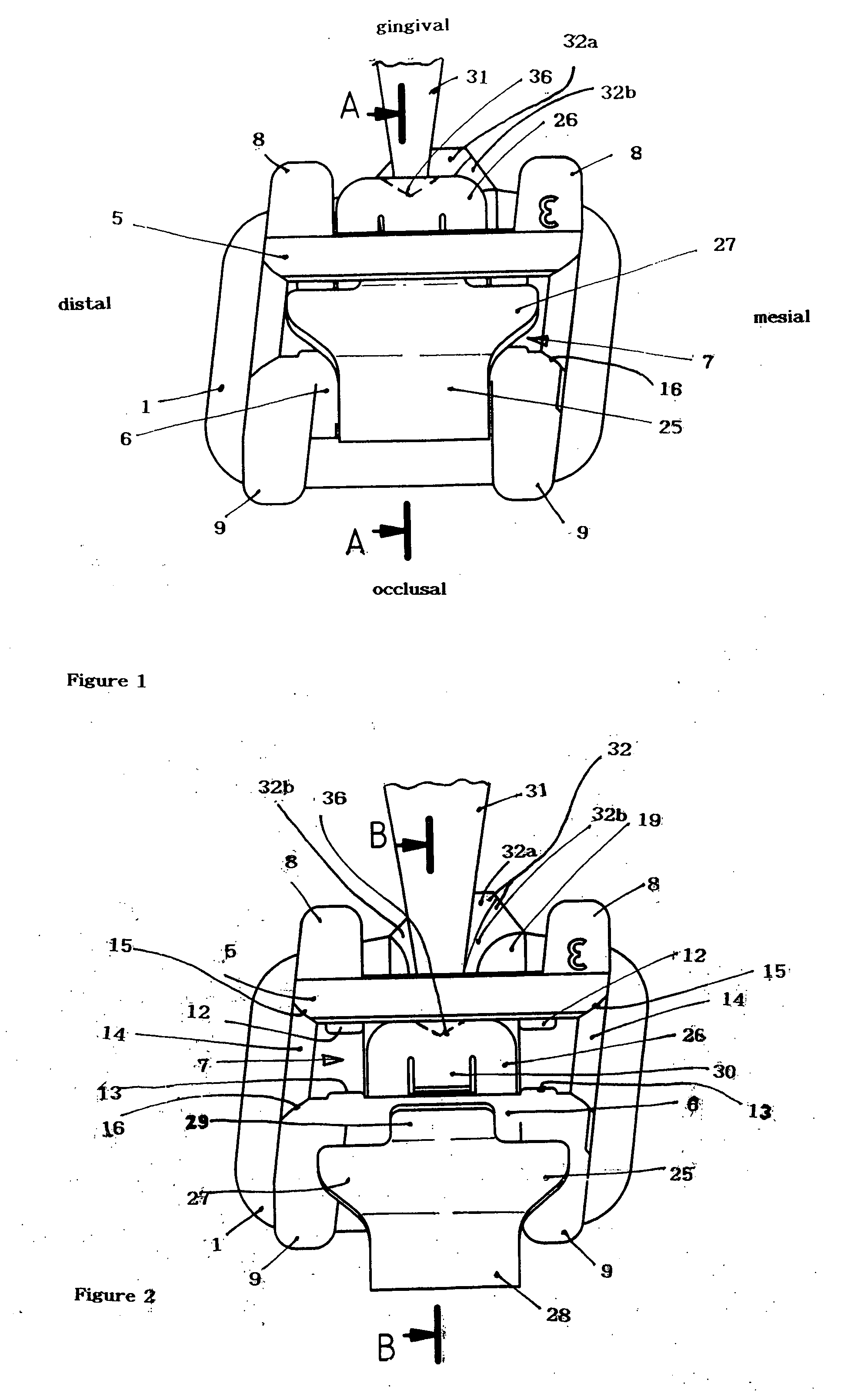

Self-ligating bracket for use in orthodontics

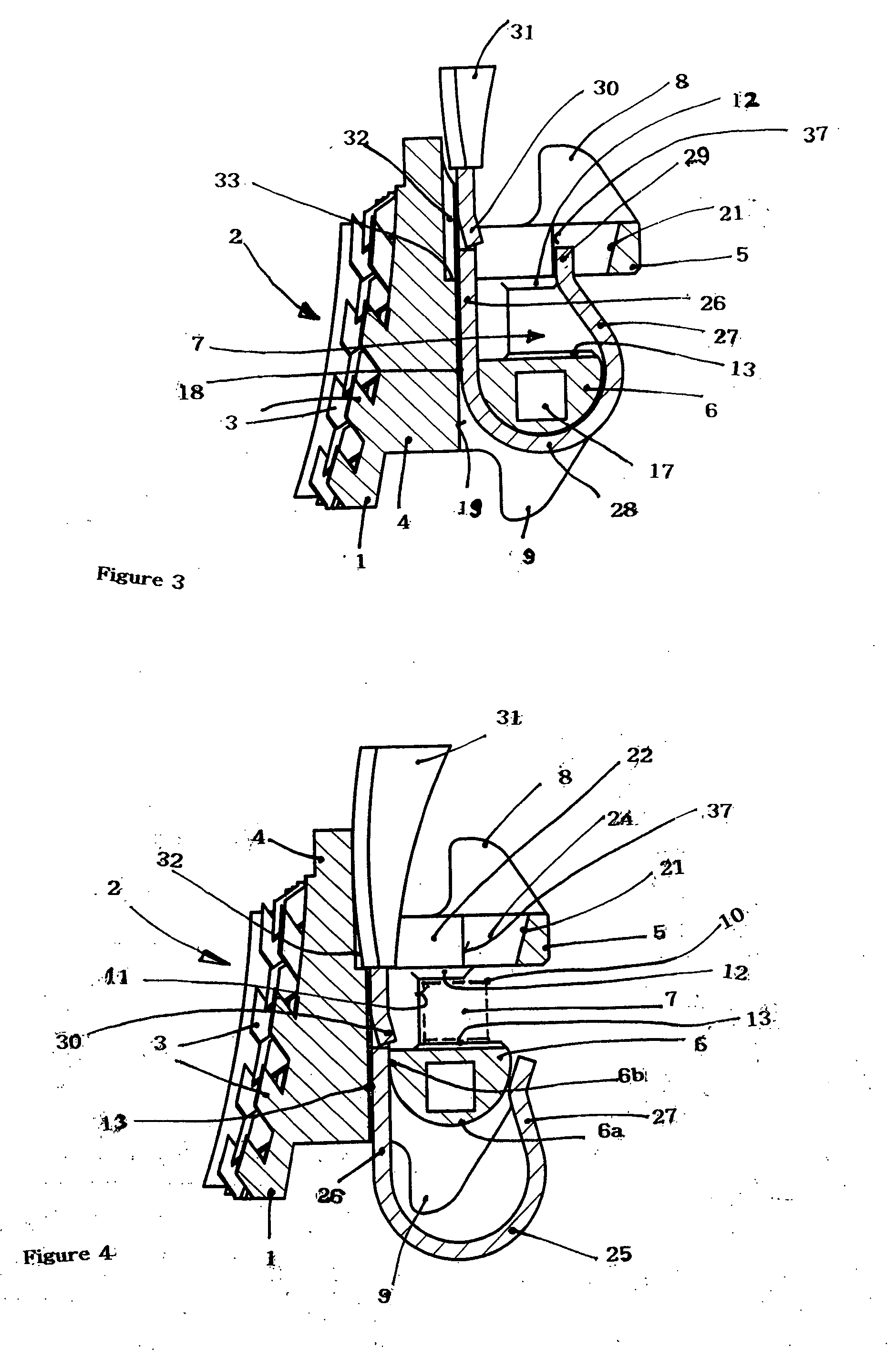

The invention describes is a self-ligating bracket for use in orthodontics having a base (1); a support (4) arranged on the base (1); an occlusal wall (6) with at least one occlusal ligature wing (9) extending from the support (4); a gingival wall (5) with at least one gingival ligature wing (8) extending from the support (4); a slot (7) separating the occlusal wall (6) and the gingival wall (5) one from the other and extending continuously in the mesial-to-distal direction; a second slot (18) which extends continuously through the support (4) in the gingival-to-occlusal direction, and which is limited by a lingual surface (19) and by a labial surface (6a); and a resilient clip (25) having a labial leg (27) and a lingual leg (26) that are connected one to the other by an occlusal section (28); the lingual leg (26) being received in the second slot (18) and being arranged for displacement in the slot in the gingival-to-occlusal direction between a closed position in which the labial leg (27) extends into a recess (24) in the gingival wall (5) and an open position of the clip (25) in which the tip of the labial leg (27) rests on the occlusal wall (6). A tongue (30), directed toward the occlusal wall (6), is cut out from the lingual leg (26) of the clip (25) and is bent off in the labial direction so that an acute angle is enclosed between the tongue and the lingual leg (26) of the clip (25).

Owner:BERNHARD FOERSTER GMBH 75172 PFORZHEIM DE

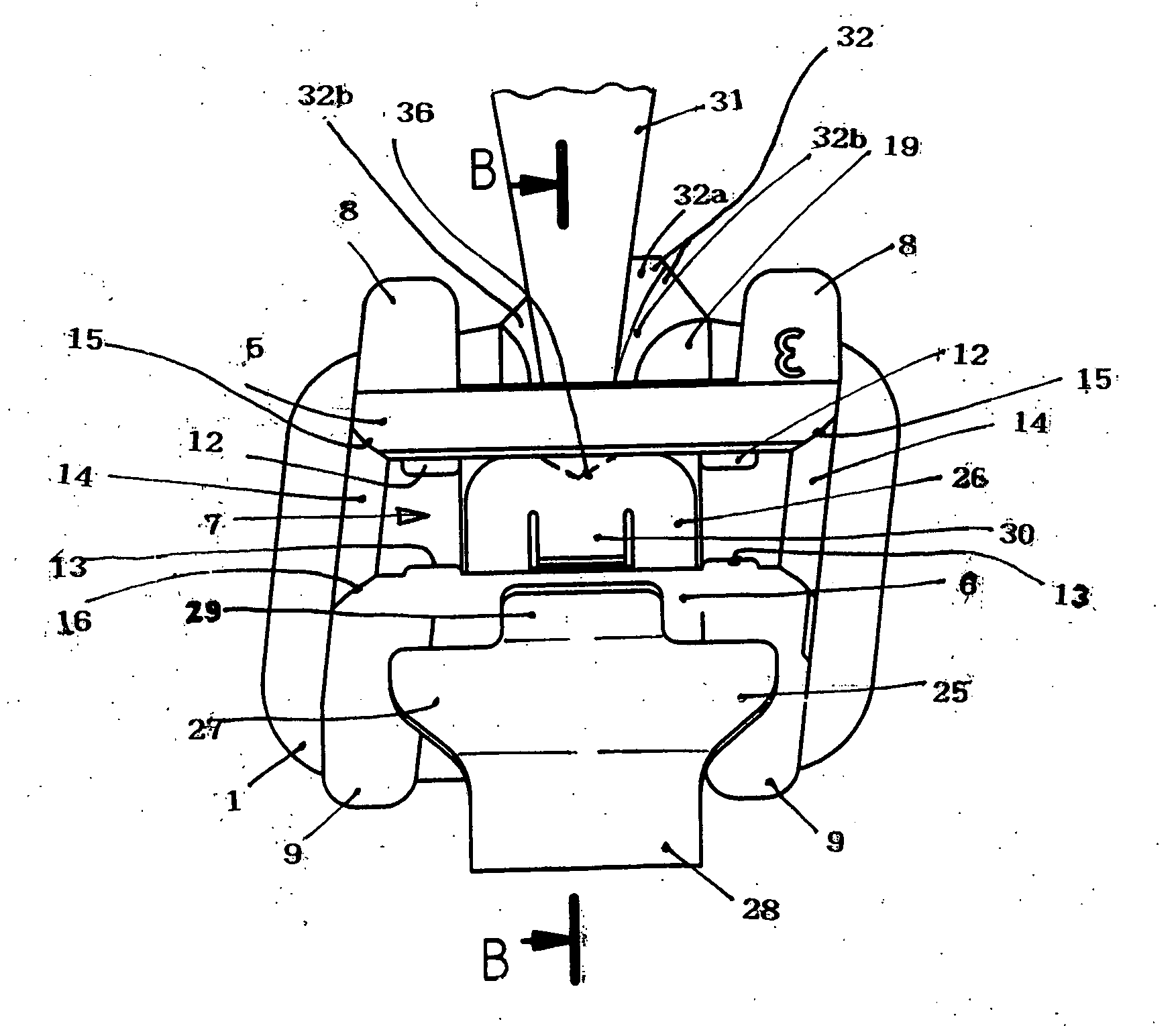

Self-ligating bracket for use in orthodontics

The invention is a self-ligating bracket for use in orthodontics having a base (1); a support (4) arranged on the base (1); an occlusal wall (6) with at least one occlusal ligature wing (9) extending from the support (4); a gingival wall (5) with at least one gingival ligature wing (8) extending from the support (4); a slot (7) separating the occlusal wall (6) and the gingival wall (5) one from the other and extending continuously in the mesial-to-distal direction; a second slot (18) which extends continuously through the support (4) in the gingival-to-occlusal direction, and which is limited by a lingual surface (19) and by a labial surface (6a); and a resilient clip (25) having a labial leg (27) and a lingual leg (26) that are connected one to the other by an occlusal section (28); the lingual leg (26) being received in the second slot (18) and being arranged for displacement in the slot in the gingival-to-occlusal direction between a closed position in which the labial leg (27) extends into a recess (24) in the gingival wall (5) and an open position of the clip (25) in which the tip of the labial leg (27) rests on the occlusal wall (6). A tongue (30), directed toward the occlusal wall (6), is cut out from the lingual leg (26) of the clip (25) and is bent off in the labial direction so that an acute angle is enclosed between the tongue and the lingual leg (26) of the clip (25).

Owner:BERNHARD FOERSTER GMBH 75172 PFORZHEIM DE

Capacitive Sensor Array for Dental Occlusion Monitoring

ActiveUS20170265978A1Reduce electromagnetic interactionDentistryForce measurementGraphicsSensor array

The invention relates to devices, systems and methods exploiting capacitive means for monitoring and analysing teeth-related parameters in a subject, such as the dental occlusion profile and / or the load / force applied upon clenching. The device comprises a body such as a bite fork or bite splint, capacitive sensor(s) incorporated within a soft substrate reversibly deformable once bitten by a subject and a micro-controller unit. The teeth contact points and forces applied upon occlusion are measured via the sensors, delivered to and re-elaborated by the micro-controller unit and possibly sent and visualized in a graphical / numerical fashion on e.g. a display screen.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

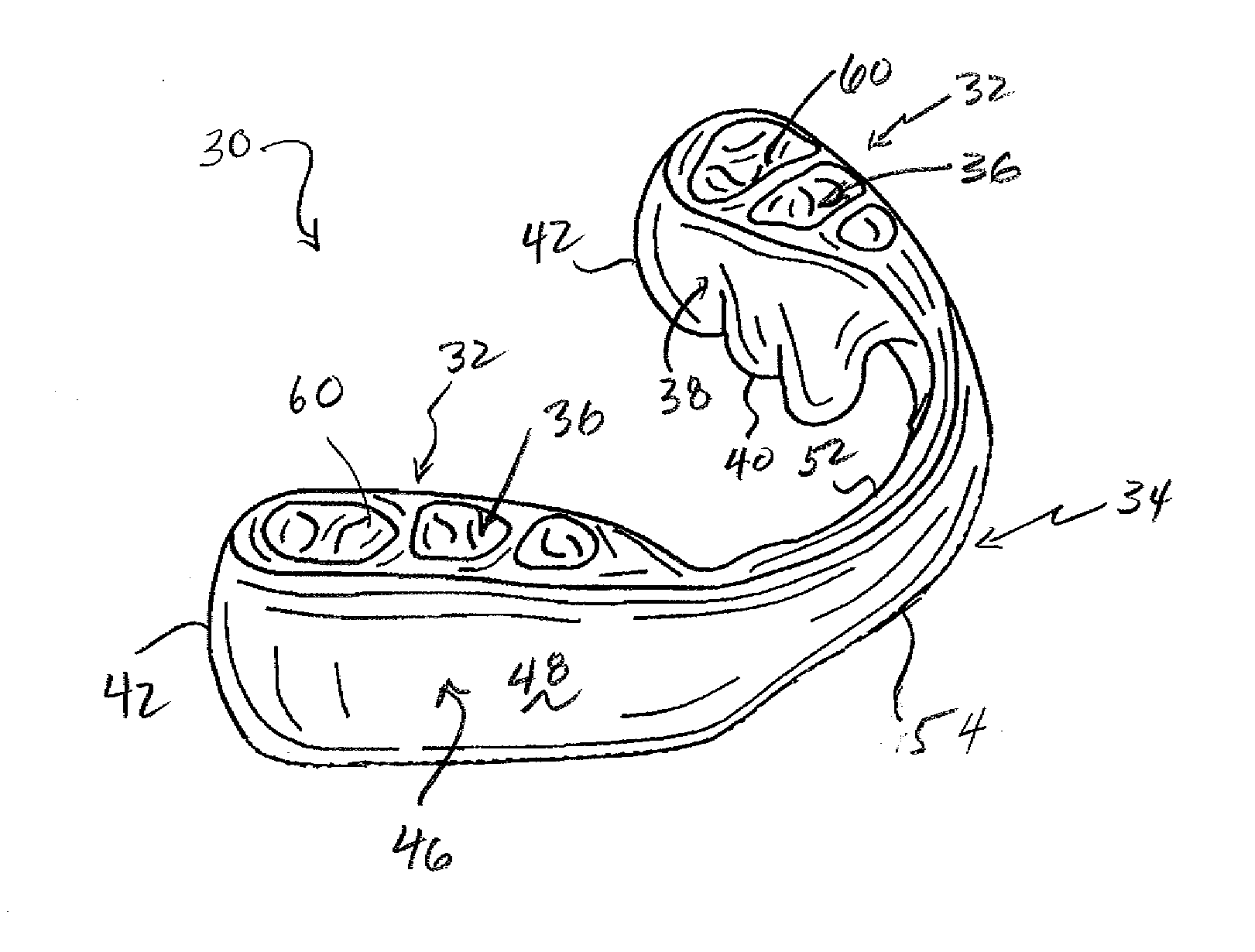

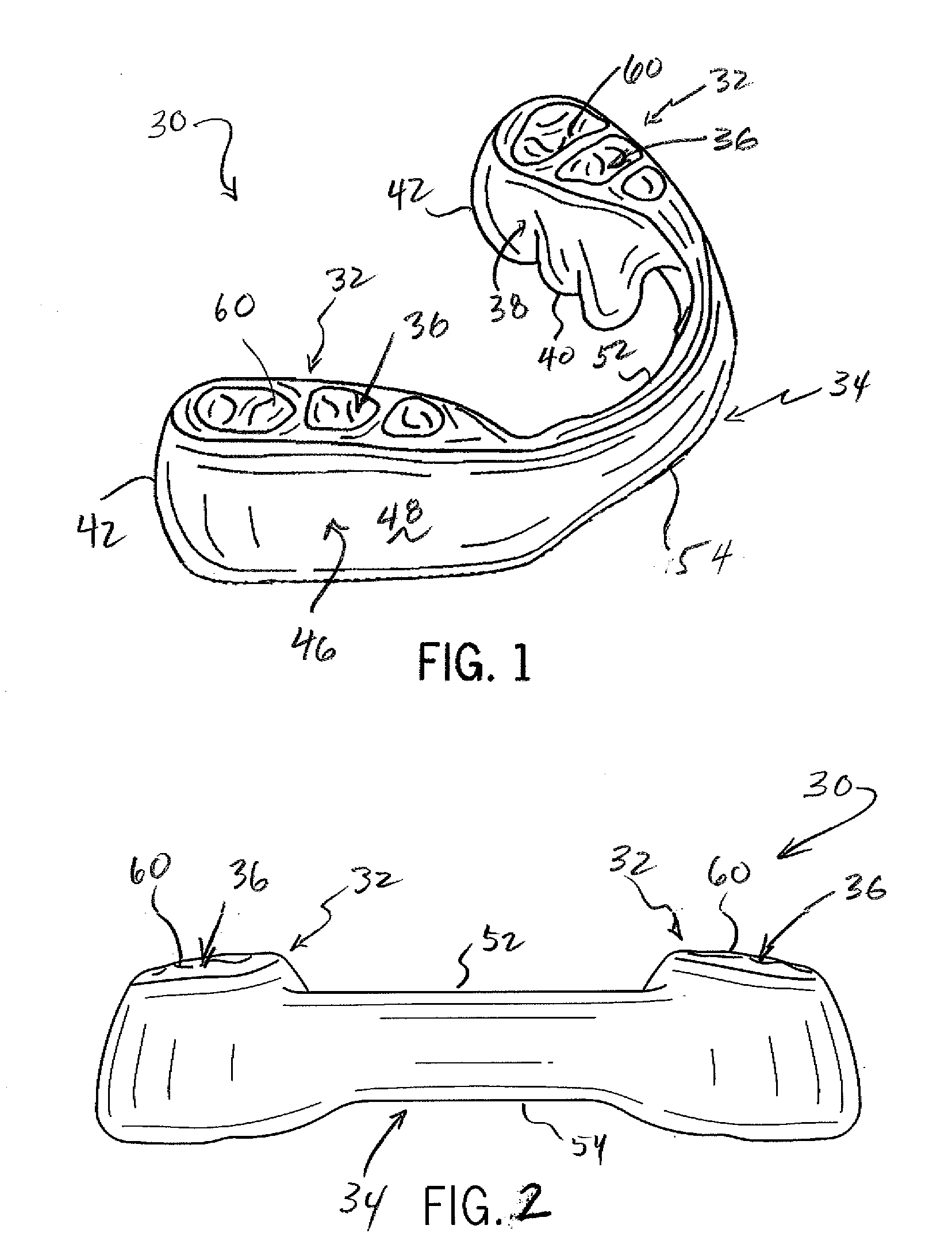

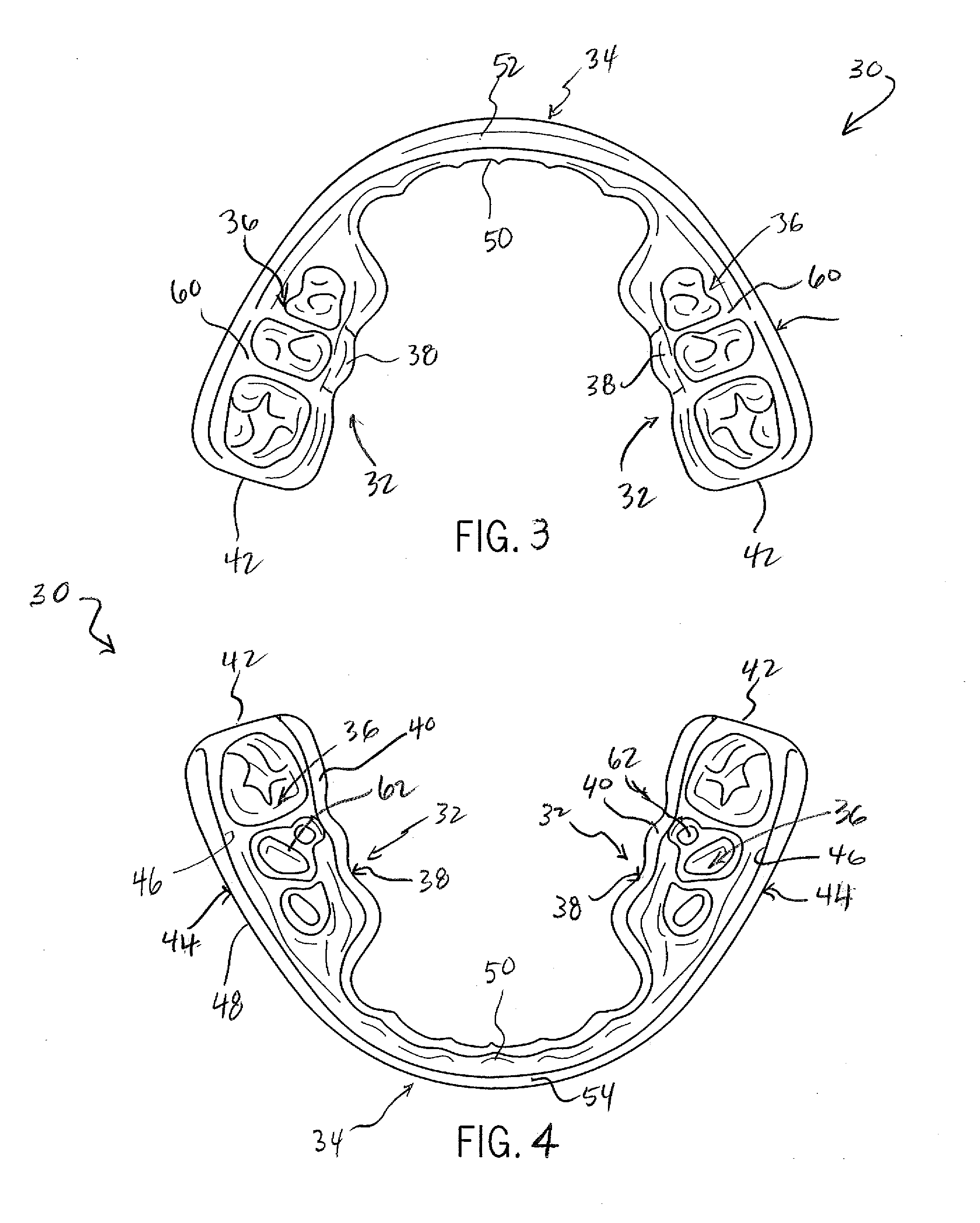

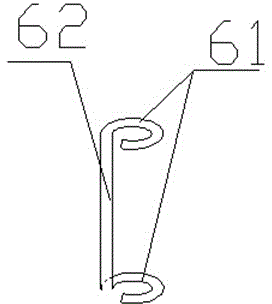

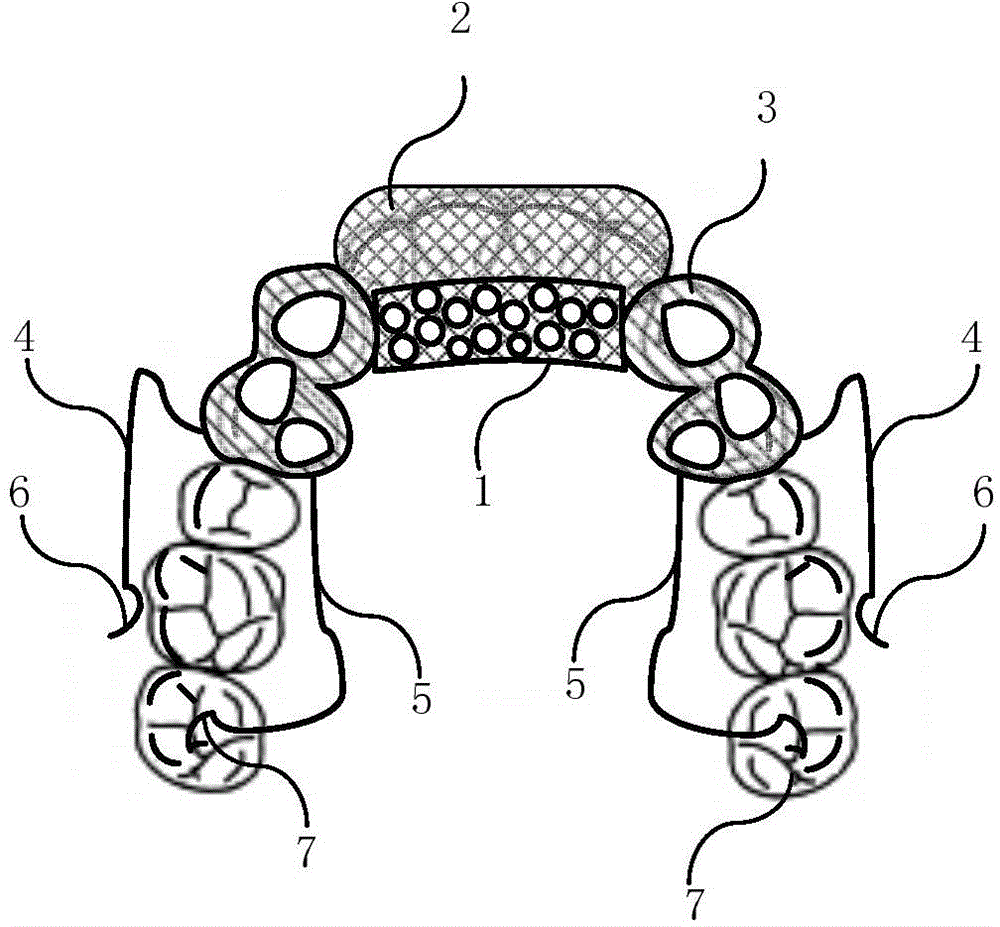

Dental occlusion correcting system

InactiveUS8932054B1Safe and easy-to-use and expeditious processEasy to correctArch wiresBracketsDental patientsDental malocclusion

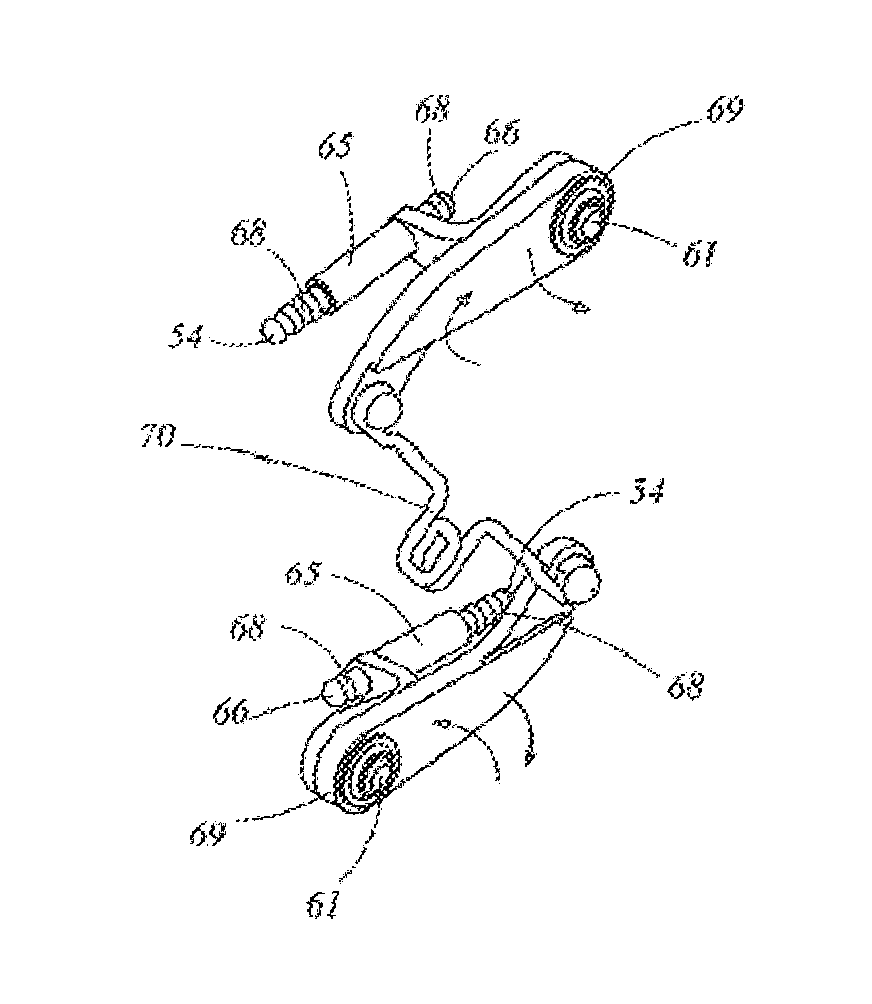

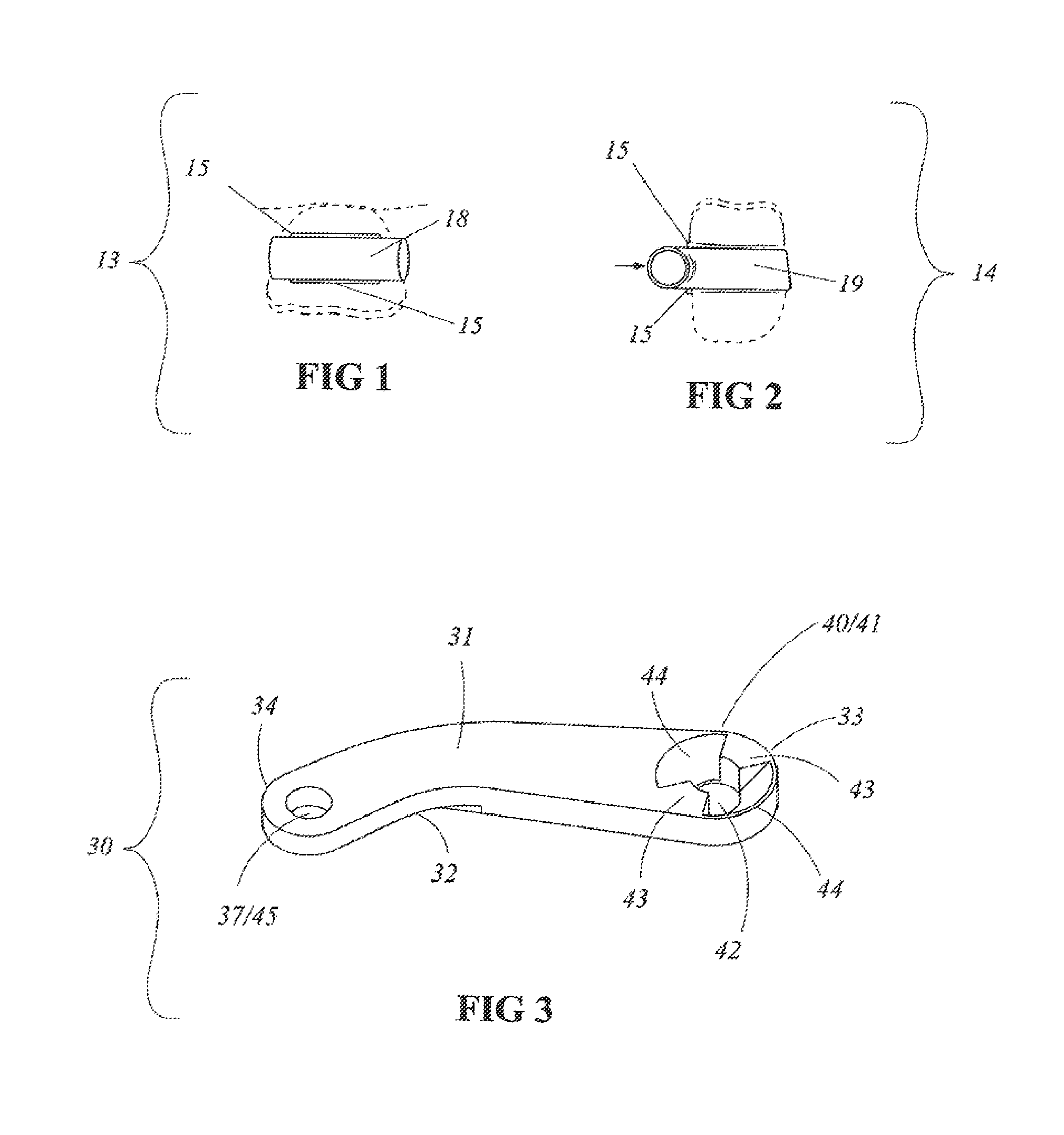

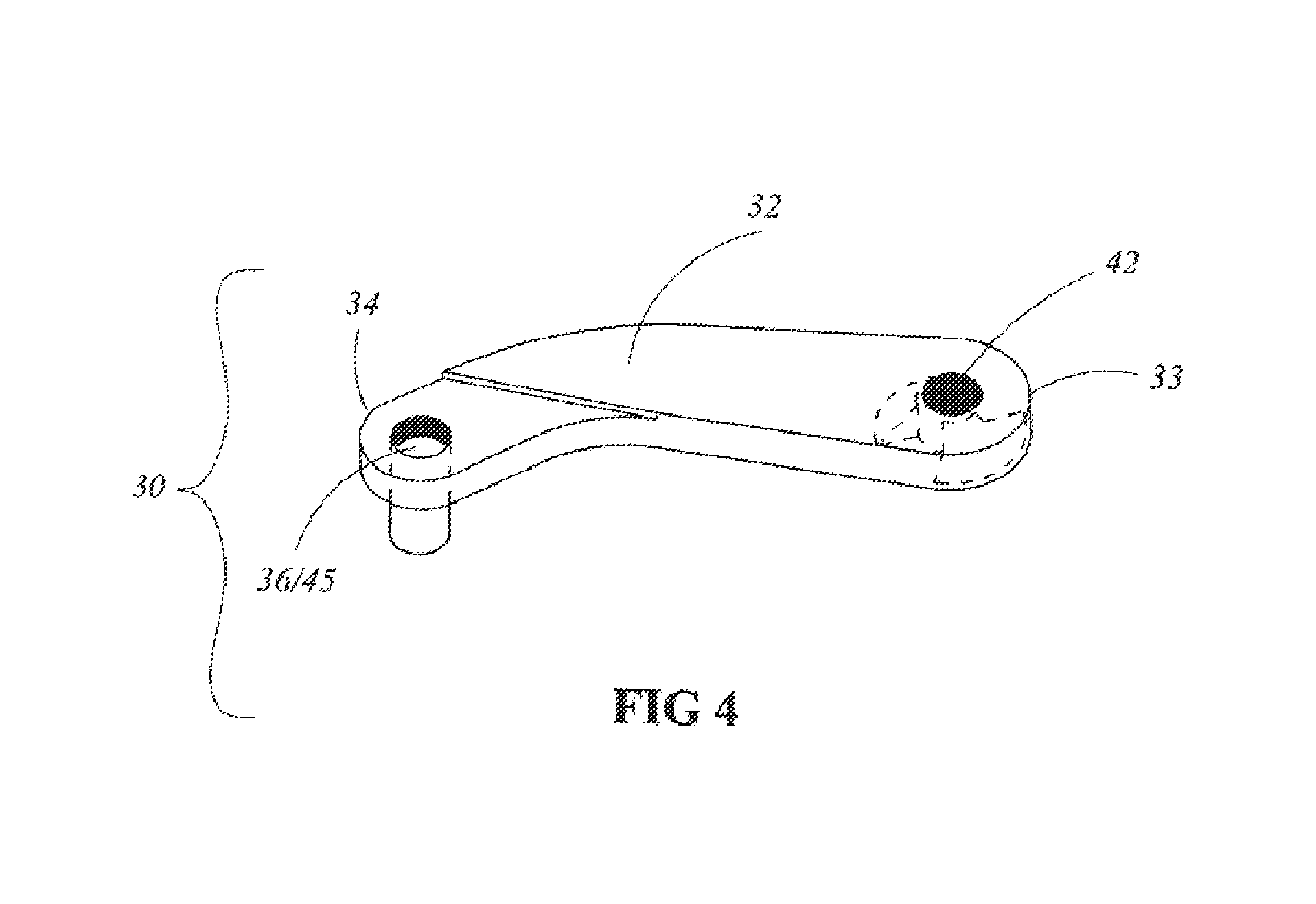

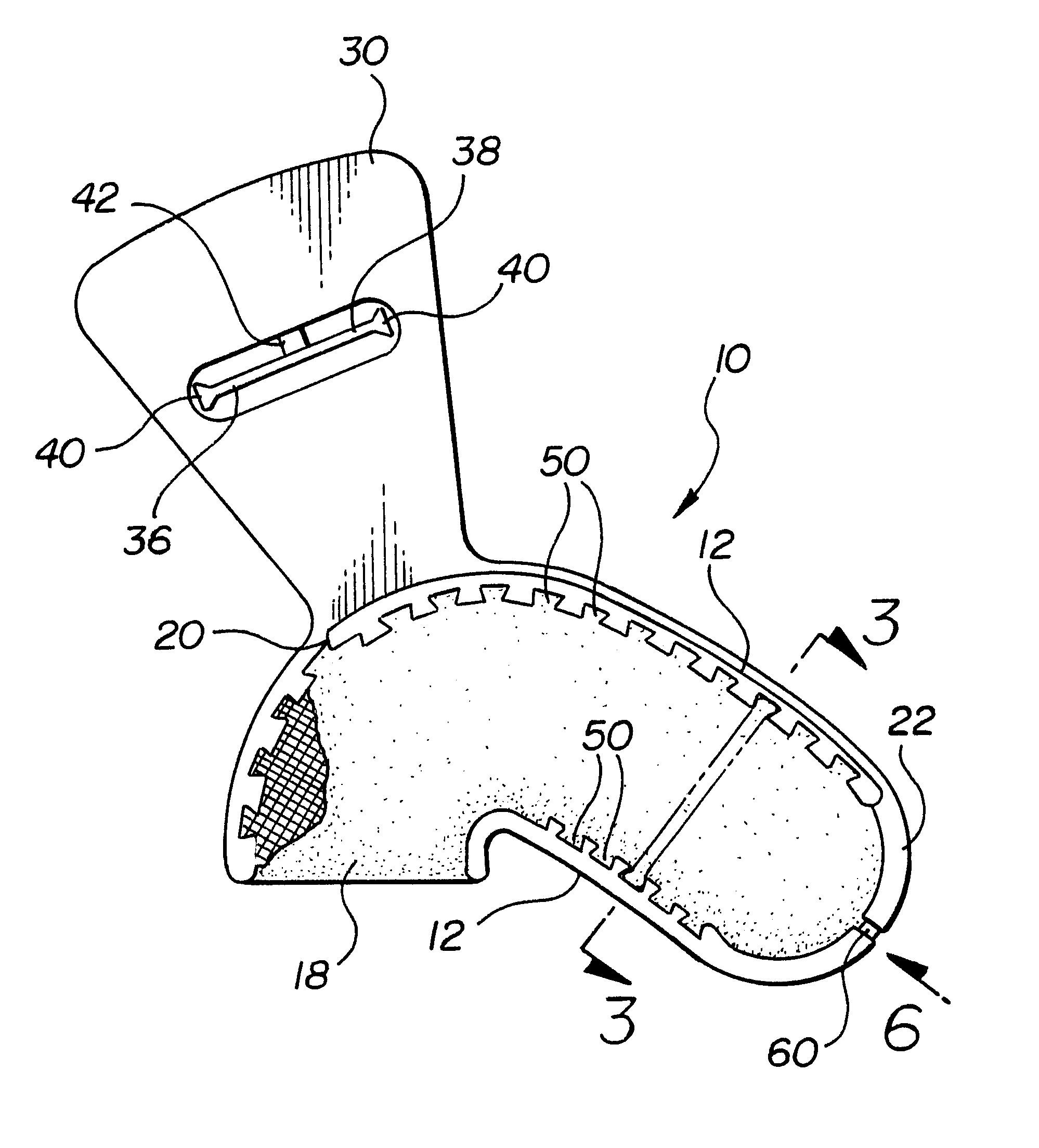

A dental occlusion correcting system (DOCS) that is designed to simplify and expedite the correction of Class II dental malocclusions. The DOCS (10) includes a set of upper and lower molar attachment structures (13,14), attached respectively to a person's upper molar and lower molar, a set of upper and lower loosely attached linkages (11,12), and a force module (70). Each of the loosely attached linkages (11,12) includes a link pivitor (50) and a link base (30) which are rotatably connected together through a system of gears and stops and rotational sections (43,44,58,59). The upper and lower loosely attached linkages are connected together, on the same side of a patient's dentition, by a force module. The force module produces upward-backward and downward-forward compression force, commensurate with the force required by a specific dental patient.

Owner:FAREL ROSENBERG LIVING TRUST

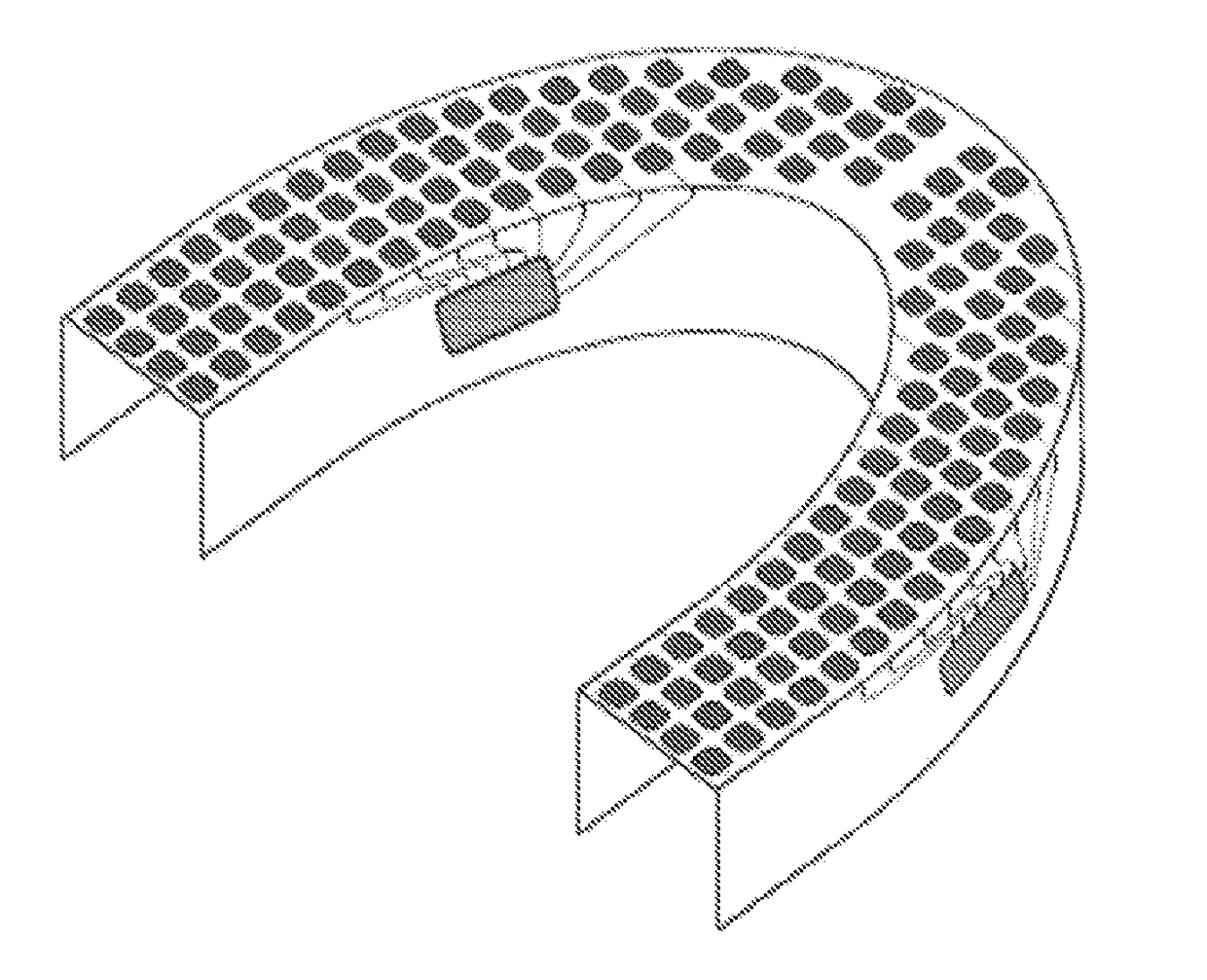

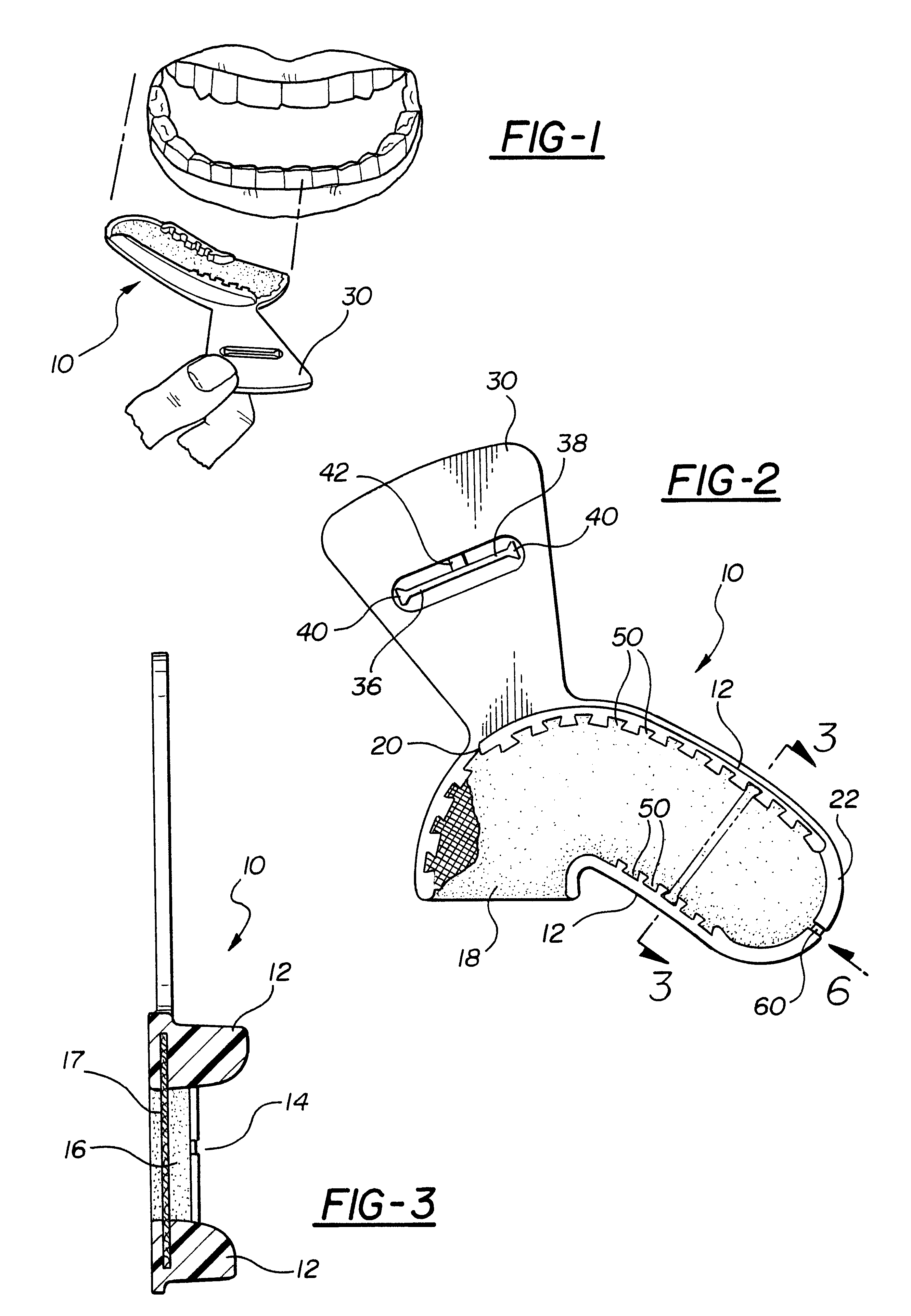

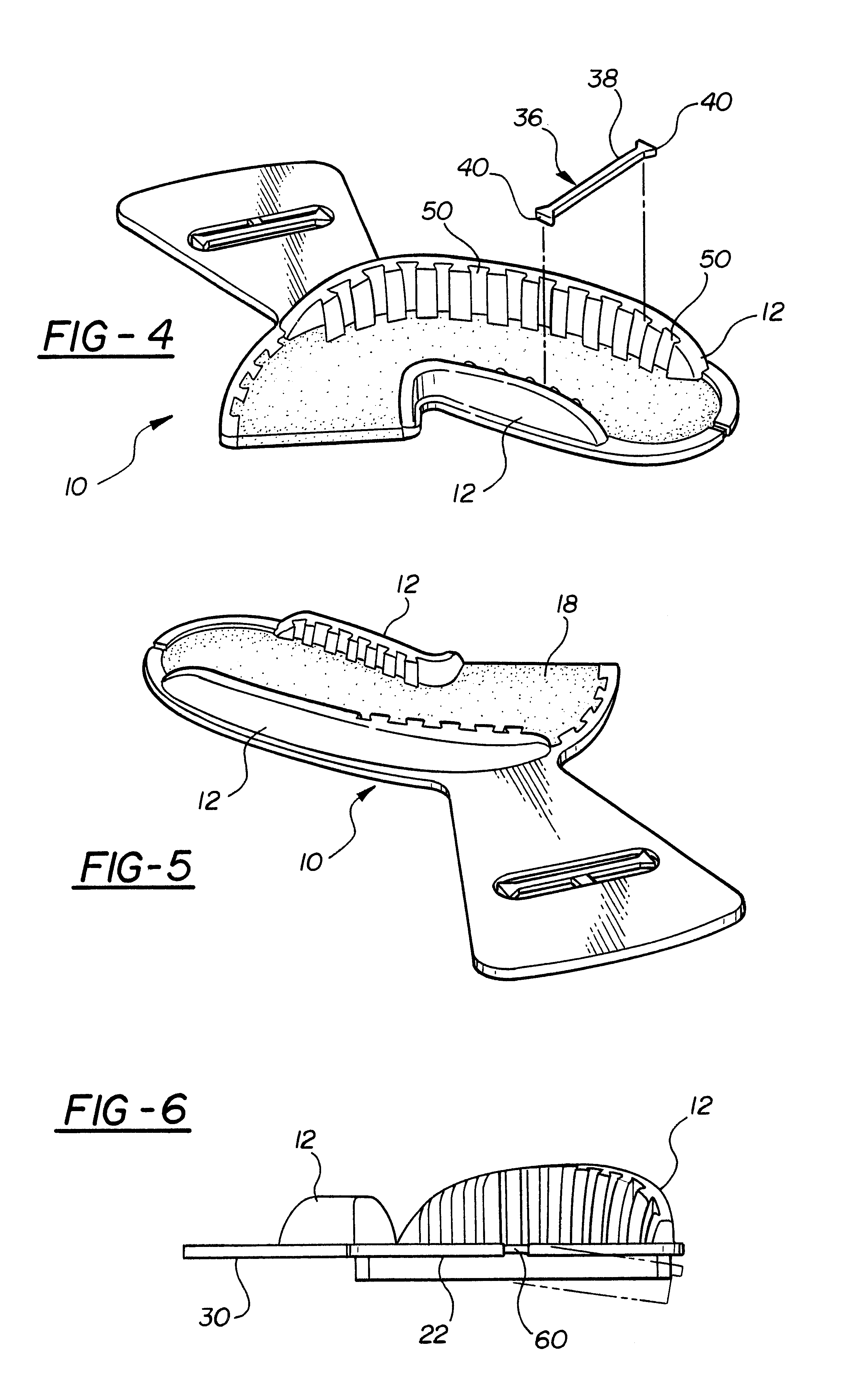

Dental impression tray

InactiveUS6450808B1Well formedReduce the cross-sectional areaImpression capsEngineeringDental occlusion

A dental impression tray having a pair of spaced and outwardly flared sidewalls with a layer of material, such as gauze, netting, plastic or the like, or a rigid material, extending perpendicularly between the sidewalls. The sidewalls, furthermore, are dimensioned to extend substantially a one-half arch of a dental occlusion. The layer of material, however, extends outwardly from one end of the sidewalls so that the layer extends substantially a three-quarters of an arch of a dental occlusion. The dental impression tray is easily convertible between a one-half arch and a three-quarters arch of a dental occlusion by selectively removing the outwardly extending portion of the layer material. Additionally, a frame connects the sidewalls together while a notch in the frame enables the sidewalls to deflect upon occlusion and remain in a deflected position. Optionally, the sidewalls are eliminated.

Owner:ADVANTAGE DENTAL PRODS

Performance Enhancing Bite Regulator and Method of Custom Fitting Same

Owner:P3 ATHLETICS INC TRADING AS PX3 SPORTS SCI

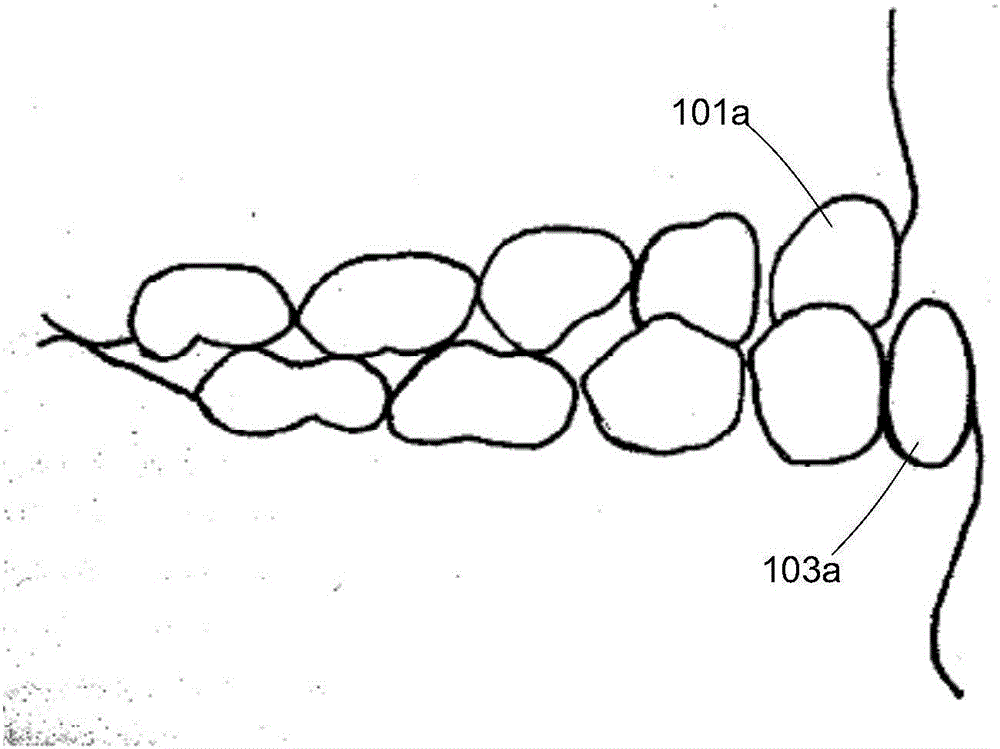

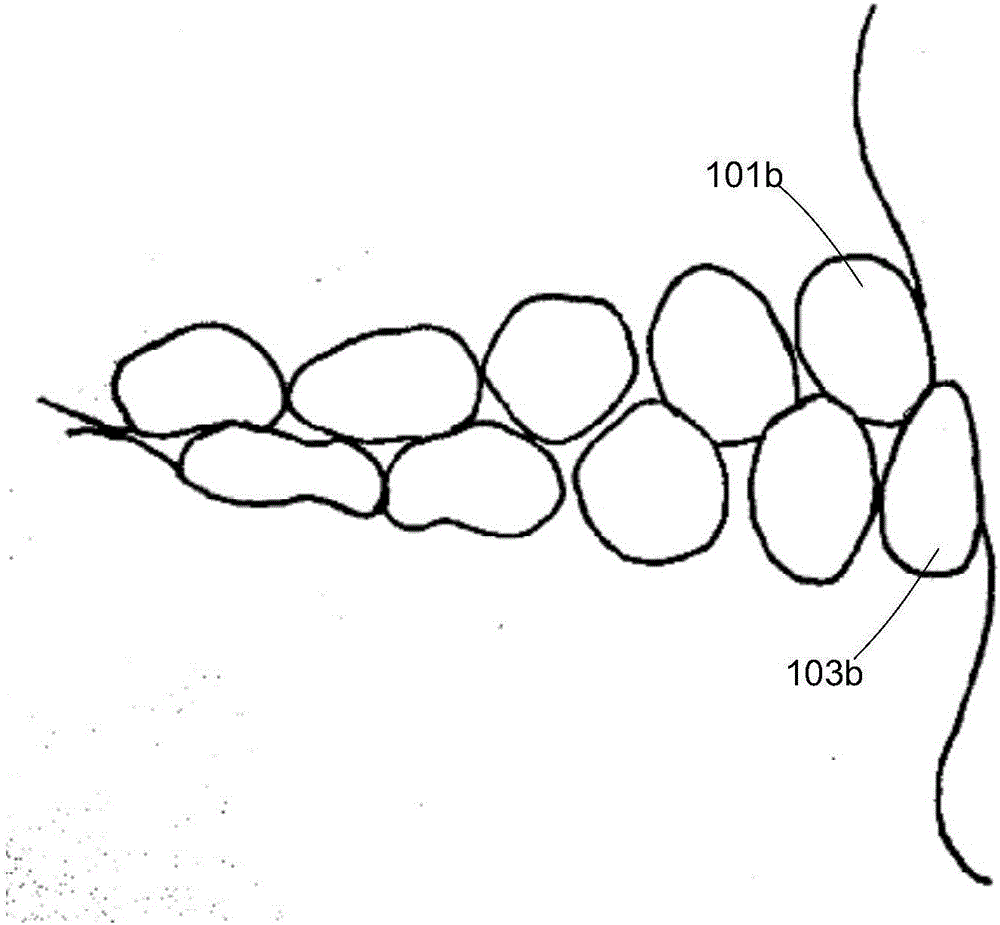

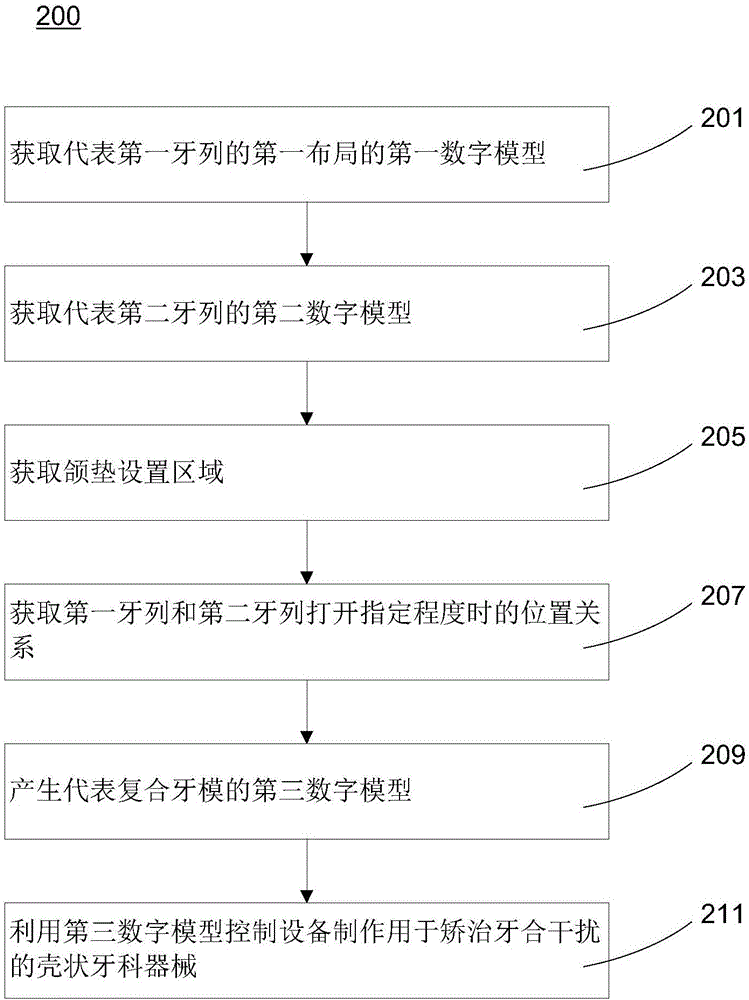

Shell-shaped dental instrument for correcting occlusal interference

The invention provides a shell-shaped dental instrument for correcting occlusal interference. The shell-shaped dental instrument takes the shape of an integral shell, and comprises a cavity, wherein the cavity is used for accommodating multiple teeth of a first tooth row; jaw pillows are formed in a convex manner in the opposite jaw direction in an area between canine teeth and molar teeth; the jaw pillows are used for opening the first tooth row and an opposite jaw tooth row to a sufficient extent, and then front teeth of the opposite jaw tooth row can be relieved from hindering adjustment of front teeth of the first tooth row; the cavity takes a geometrical shape for repositioning the multiple teeth to second arrangement from first arrangement; and the positions of the front teeth of the second arrangement are different from that of the first arrangement.

Owner:SICHUAN UNIV

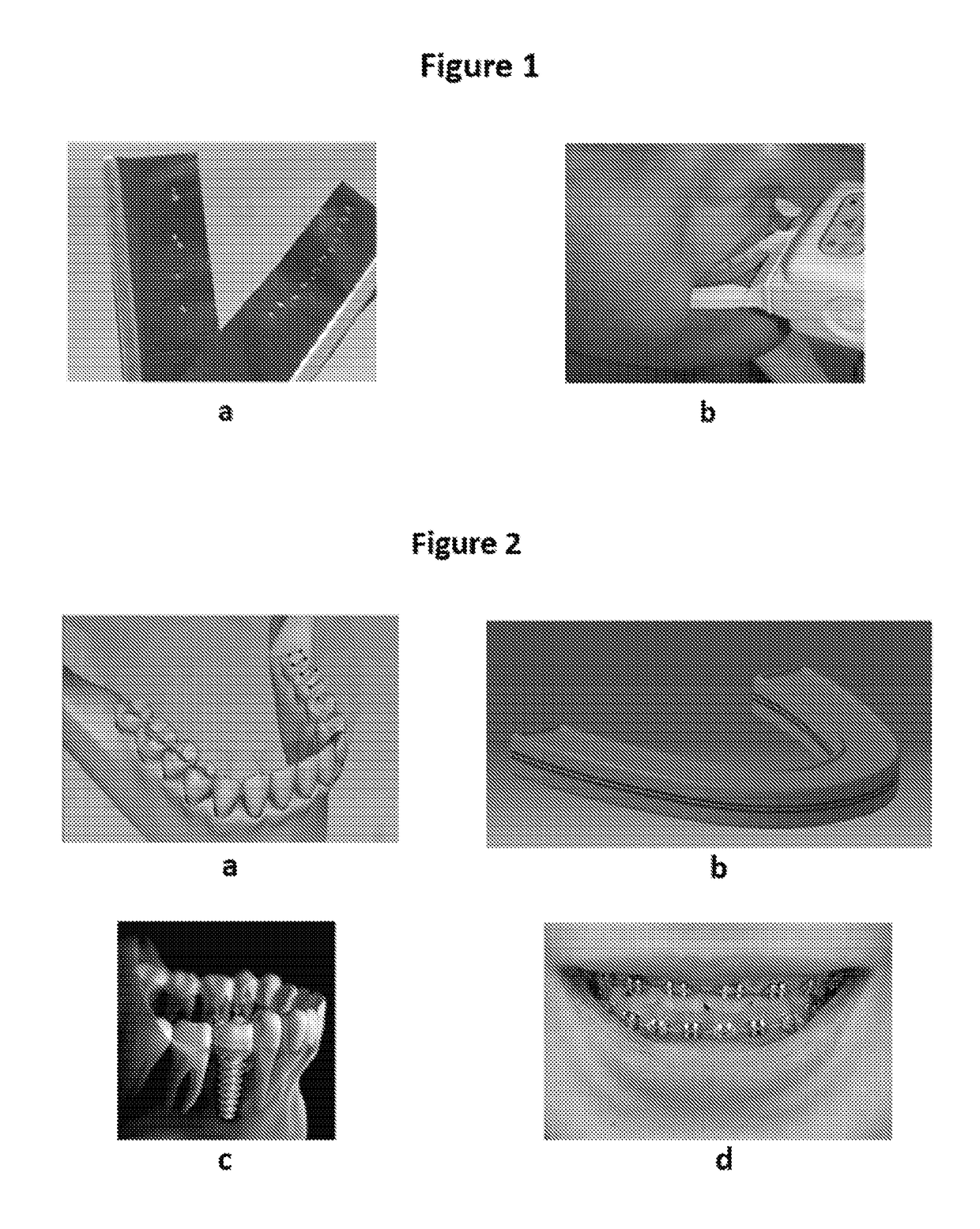

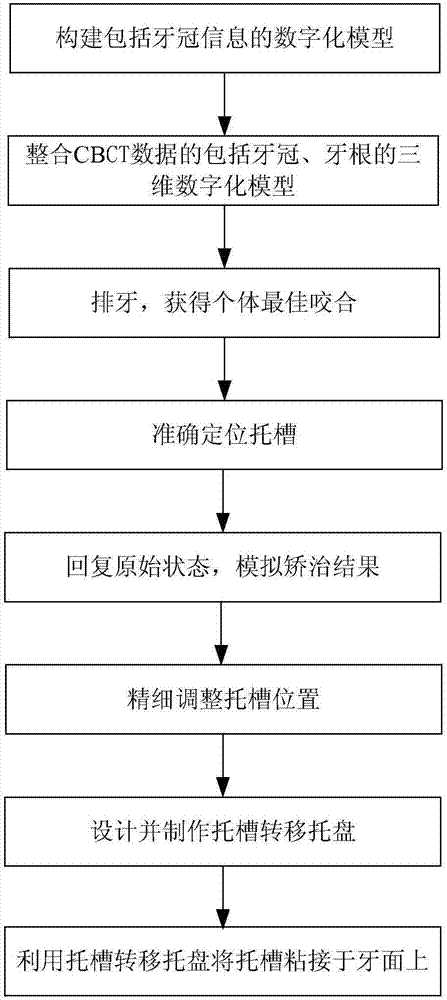

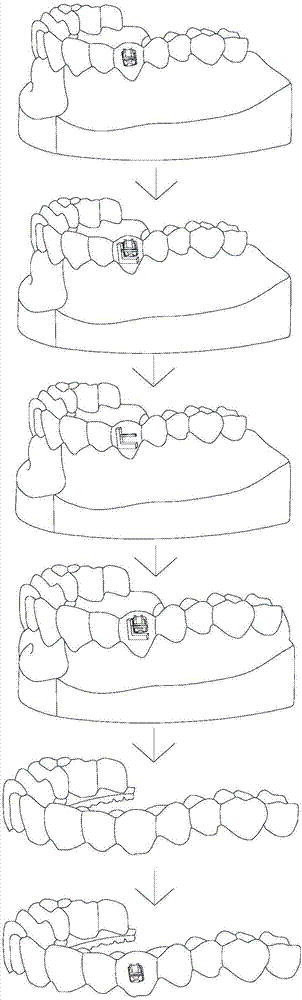

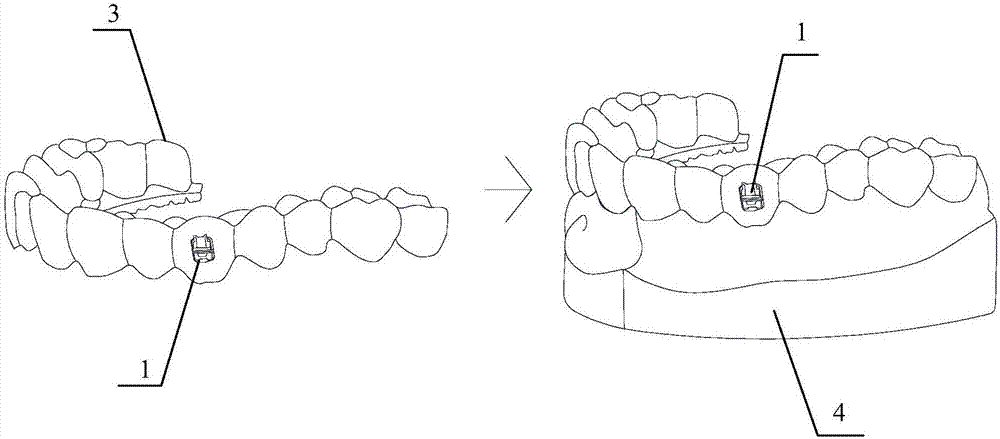

Indirect bonding method of goal-directed localization orthodontic bracket

InactiveCN106880414AAvoid complicated laboratory operation stepsGuaranteed to be locatedBracketsClinical efficacyCurative effect

The invention discloses an indirect bonding method of a goal-directed localization orthodontic bracket. The indirect bonding method comprises the following steps: on the basis of a three-dimensional digital occlusion model, implementing a teeth arrangement test until reaching six Andrews normal occlusion standards; precisely localizing a virtual bracket on the three-dimensional digital model that dentition is completely aligned and kept flat, and simulating an orthodontic result by virtue of professional orthodontic software; assessing the orthodontic result, optimizing bracket localization in accordance with the orthodontic result, designing a bracket transfer tray, and processing the bracket transfer tray by virtue of a 3D printing technology and a vacuum pressed film technology; and arranging a real bracket on the bracket transfer tray, and bonding the bracket to a dental face by virtue of the bracket transfer tray. According to the method, an internationally recognized clinical curative effect assessment standard, which is directed by the result, is adopted for the first time, with a purpose of offering a new way for solving the problem on bracket precise localization by virtue of an orthodontic indirect bonding technology.

Owner:四川安特信医疗科技有限责任公司

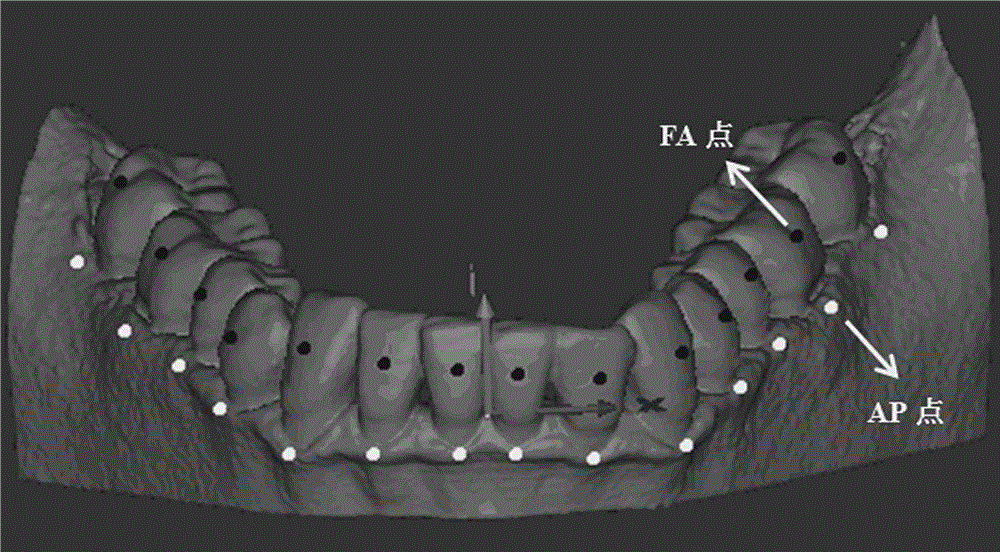

Method for measuring transverse and longitudinal inclinations of teeth

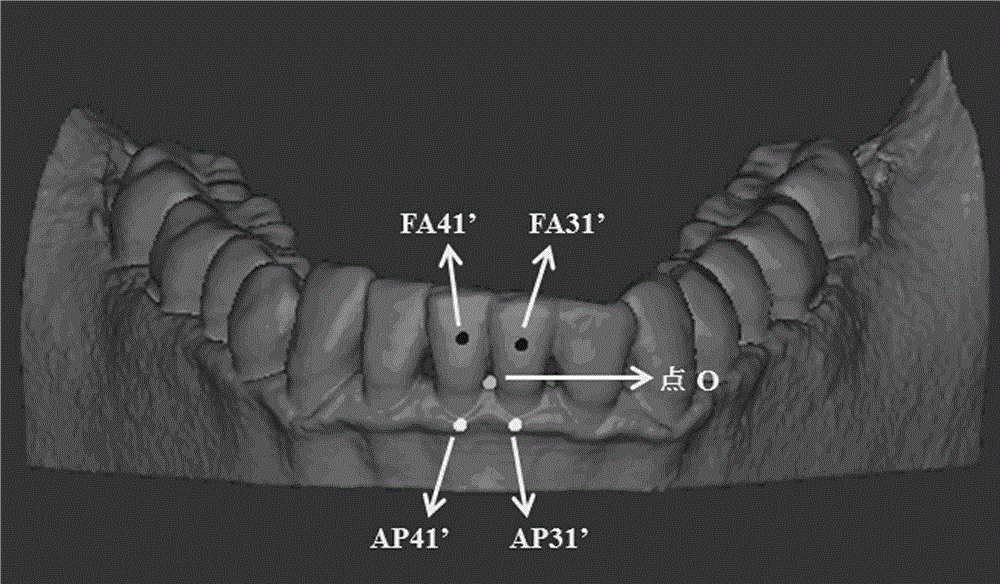

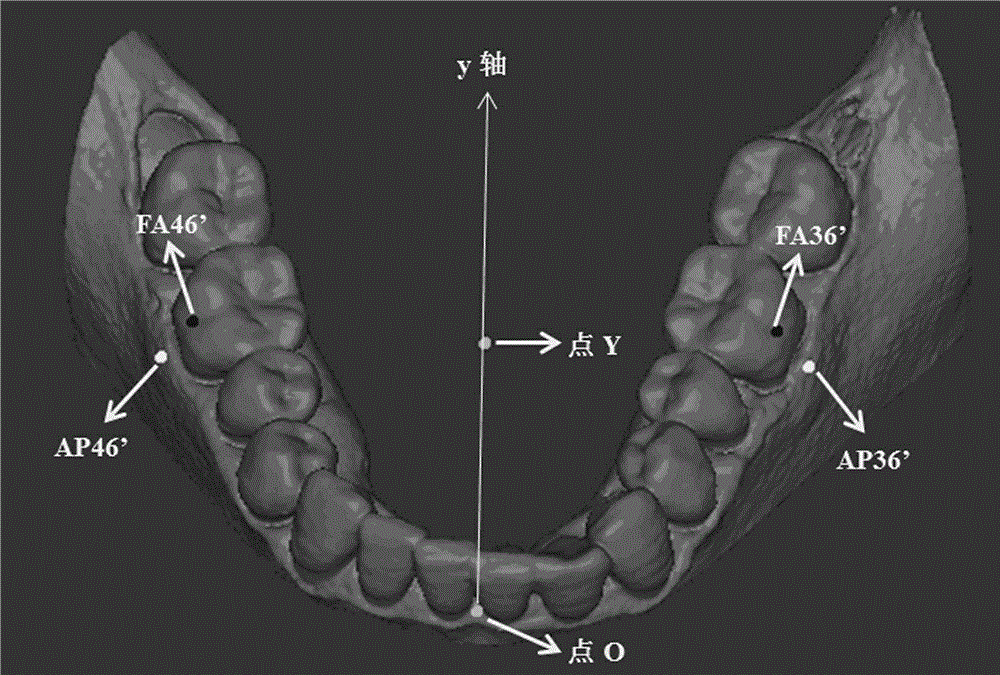

ActiveCN105030364AAccurate locationHigh accuracy of resultsDentistryRadiation diagnostics for dentistryDimensional simulationModel reconstruction

A method for measuring transverse and longitudinal inclinations of teeth includes the steps of 1, performing three-dimensional simulation model reconstruction; 2, selecting reference points, for a simulation model, drawing dental arch reference points FA and basal bone reference points AP at incisor teeth and first molars in left and right lower jaws in the simulation model, respectively; 3, establishing a coordinate system, defining a midpoint among four points FA31', AP31', FA41' and AP41' as an origin O of the coordinate system, defining a midpoint among four points FA36', AP36', FA46' and AP46' as a point Y, defining a line OY as an axis y, using a plane formed by a mesial contact point connecting to the incisor teeth in the lower jaw and mesial buccal cusps of the left and right first molars, as a plane xy, namely an occlusal plane; and 4, measuring transverse and longitudinal inclinations of teeth. The method has the advantages that observation is direct, detection is convenient and results are accurate.

Owner:SOUTHERN MEDICAL UNIVERSITY

Multiple bite configurations

Disclosed is a method of digitally designing a dental component for a patient, wherein the method comprises: - obtaining a 3D representation of the patient's upper jaw; - obtaining a 3D representation of the patient's lower jaw; - obtaining at least a first 3D representation of a first bite configuration of the patient's jaws in a first occlusion and a second 3D representation of a second bite configuration of the patient's jaws in a second occlusion different from the first occlusion; - digitally determining a occlusal contact movement of the patient's jaws relative to each other based on the at least first 3D representation, the second 3D representation and contact between the patient's upper jaw and lower jaw; and - digitally designing the dental component based on the occlusal contact movement of the patient's jaw relative to each other.

Owner:3SHAPE AS

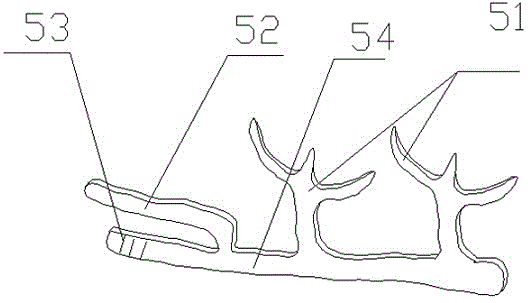

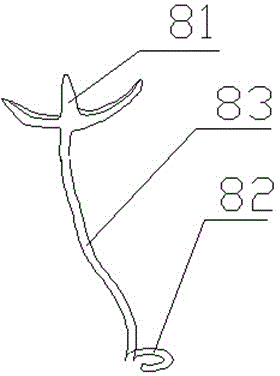

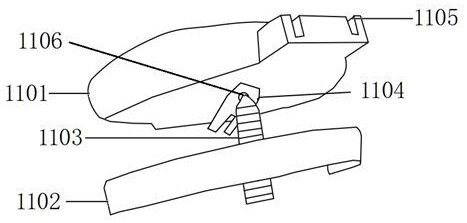

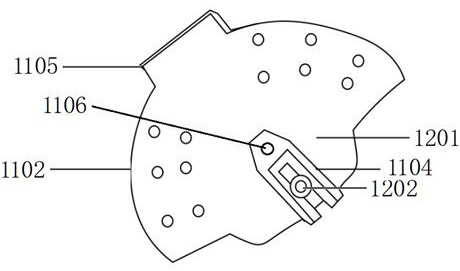

Traction device for mandibular impacted wisdom teeth

InactiveCN104622590AFlexible direction adjustmentAchieve separationOthrodonticsEngineeringDental occlusion

The invention provides a traction device for mandibular impacted wisdom teeth, which relates to the field of orthodontics. The device comprises a bracket, a first retention part, a second retention part and a traction part, wherein the bracket is used for being fixed on the lingual sides of mandibular first and second molars on the same side of a mandibular impacted wisdom tooth, the first retention part is used for being fixed on the crown side of the mandibular impacted wisdom tooth, the second retention part is used for being fixed on the buccal side of the mandibular impacted wisdom tooth, and the two ends of the traction part are respectively connected with the bracket and the first retention part; and the bracket comprises a rod-shaped main body, connecting heads, a connecting rod and a cross rod, the connecting heads are respectively arranged at the positions on the rod-shaped main body and corresponding to the mandibular first and second molars, a groove and the cross rod are arranged at the positions on the rod-shaped main body and corresponding to the mandibular impacted wisdom tooth, the cross rod and the rod-shaped main body are parallel to each other and are located on the occlusion side of the rod-shaped main body, and the cross rod is connected with the rod-shaped main body by the connecting rod. The traction device provided by the invention can flexibly adjust the traction direction of an impacted wisdom tooth, and effectively draw the impacted wisdom tooth to separate from an alveolar nerve canal in a relatively short period of time so as to facilitate subsequent tooth extraction treatment.

Owner:SHANGHAI XUHUI DISTRICT DENTAL CENT

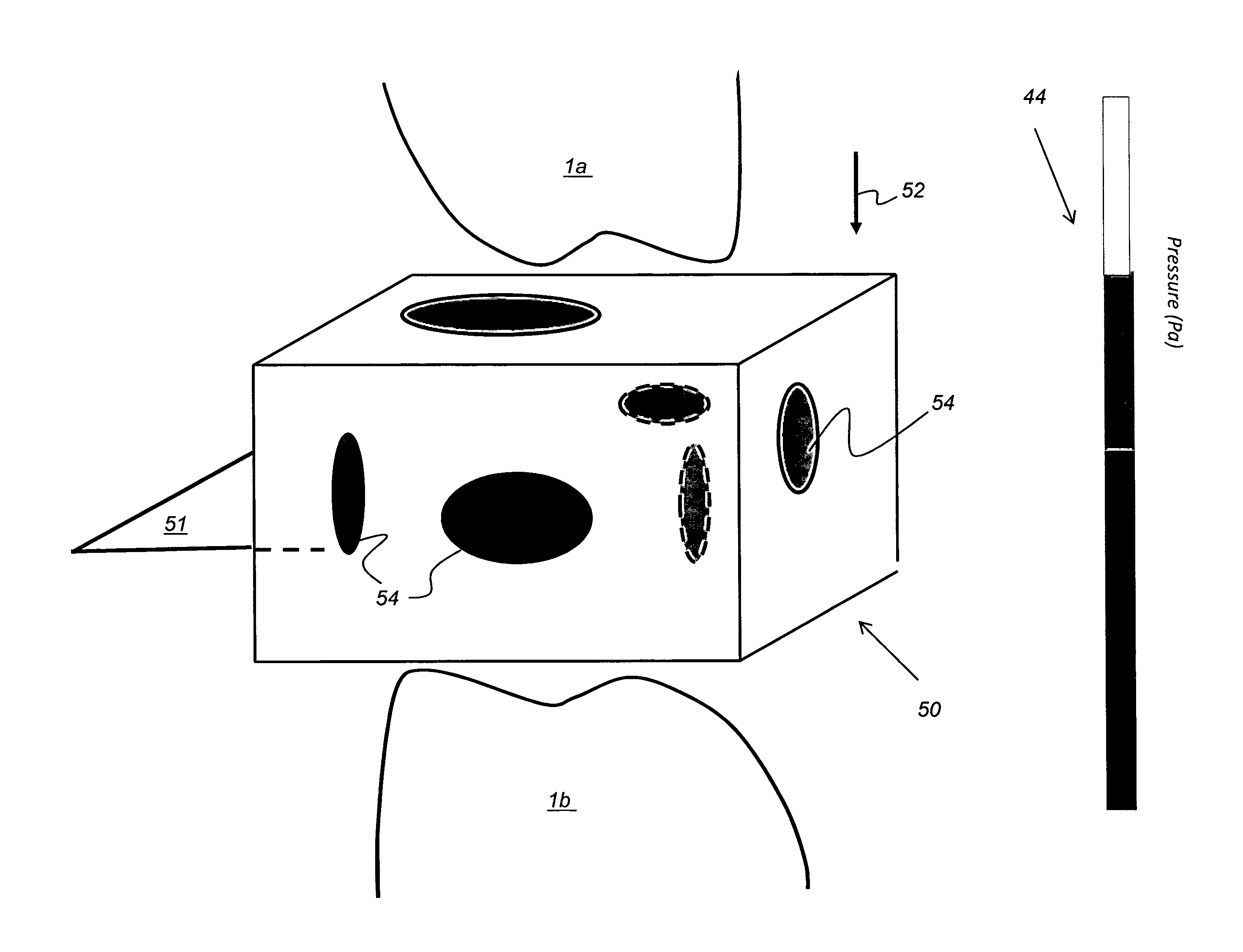

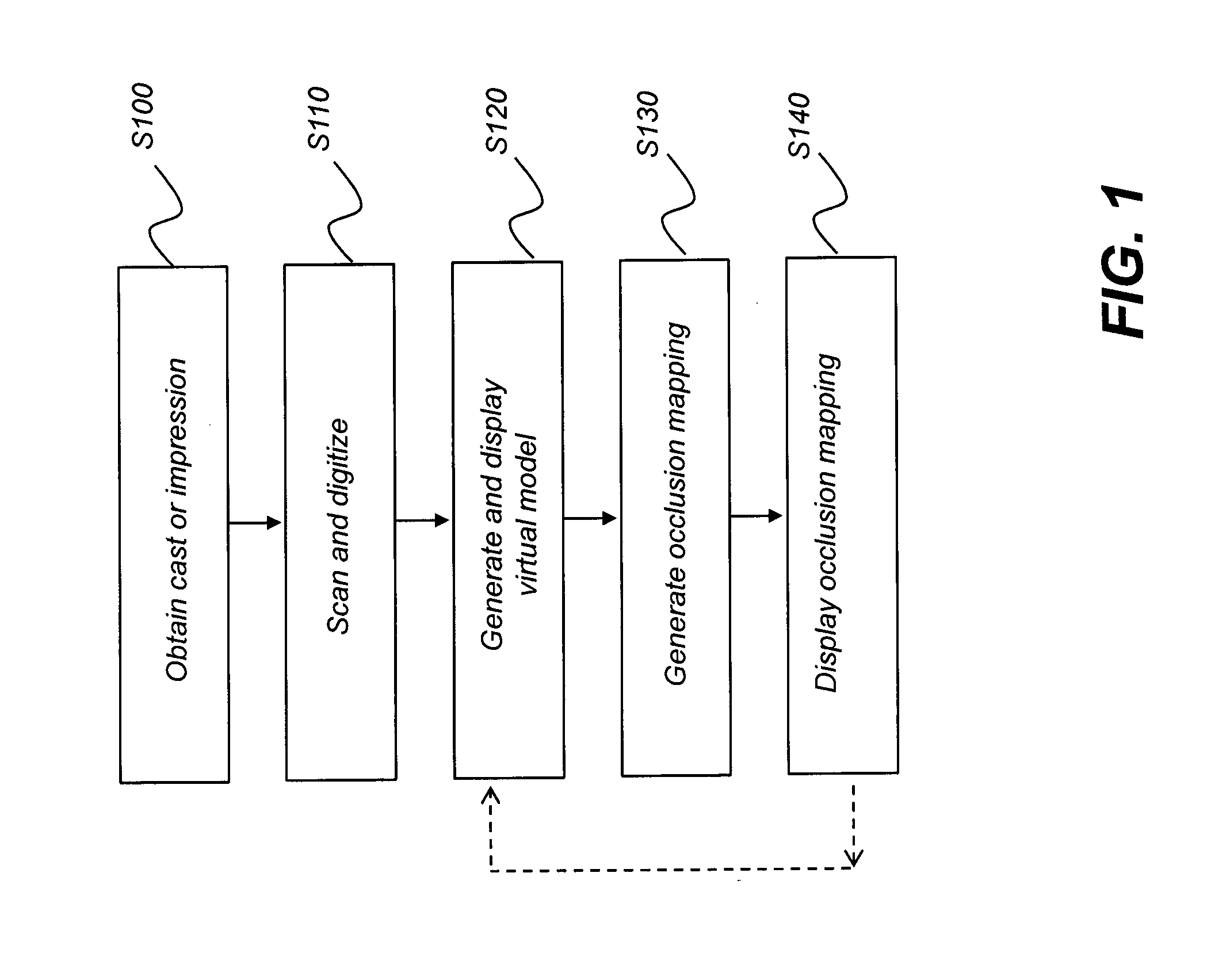

Occlusion mapping using elastic foam modeling

A method for generating a mapping of dental occlusion generates a three-dimensional model of the patient's teeth (la, according to acquired image data. The maxillary and mandibular arches are positioned in opposition in the generated model of the patient's teeth and a meal model (50) generated having characteristics of a foam material. A pressure field distribution for the generated meal model is calculated for one or more pairs of opposed teeth (1a, 1b) from the generated three-dimensional model of the patient's teeth. The calculated pressure field distribution (54) can be displayed.

Owner:TROPHY SAS

Orthodontics treatment device

InactiveCN105832431ASimple and fast operationGuaranteed to press in verticallyOthrodonticsCuspid toothMaxillary incisor

The invention relates to the technical field of orthodontics, and discloses an orthodontics treatment device. The device comprises a lingual-side cast web plate wore on maxillary incisors, a plane guide plate arranged on the surface of the cast web plate, and combination cast crowns connected to two ends of the cast web plate, wherein each combination cast crown contains maxillary ipsilateral cuspid teeth and a first front premolar. A buccal-side hook connection bar and a lingual-side (occlusal) rest connecting rod extend out of each combination cast crown. The hook connection bar is connected to a lowering hook, which is arranged in the buccal-side center of to-be-lowered maxillary molars. The (occlusal) rest connecting rod is connected to an (occlusal) rest, which is arranged on rear molars of the to-be-lowered maxillary molars. Through the orthodontics treatment device, occlusion can be opened and elongated maxillary incisors are lowered at the same time, and the problem of multiple staggered occlusion is solved. The device is beneficial for saving curative time and cost and relieving wound suffered by patients during a therapeutic process.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

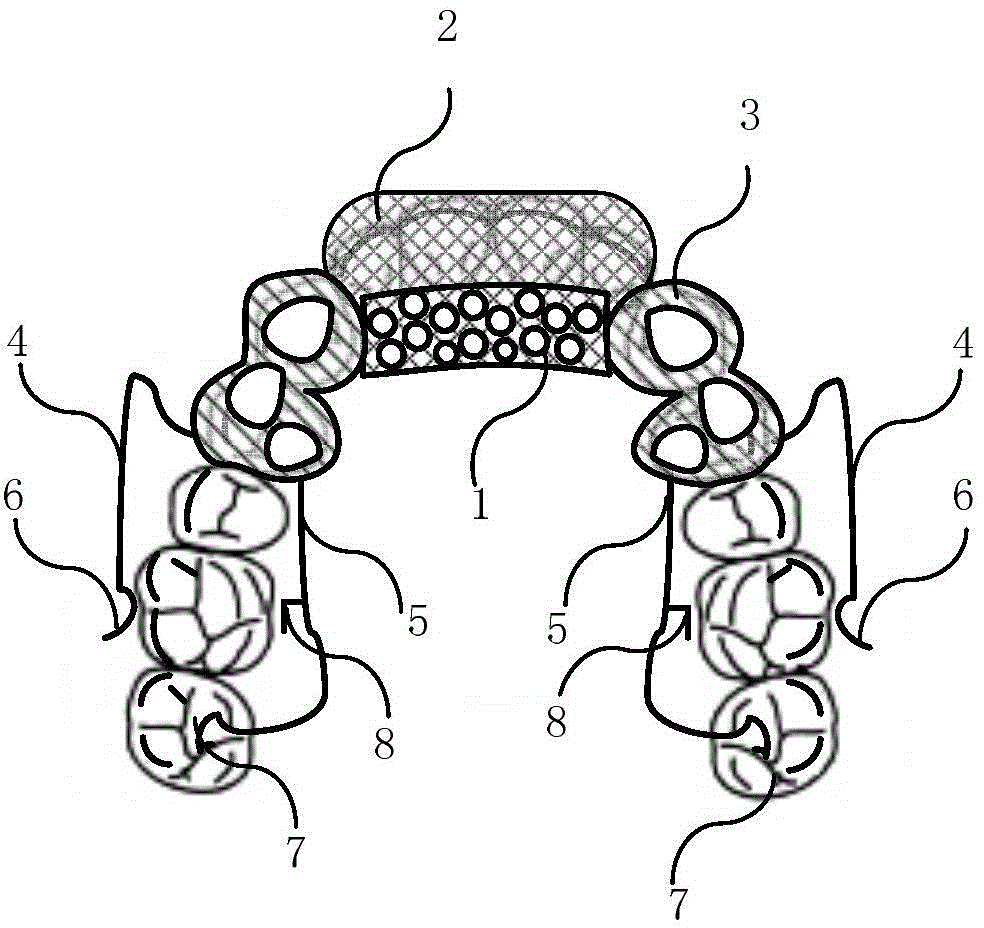

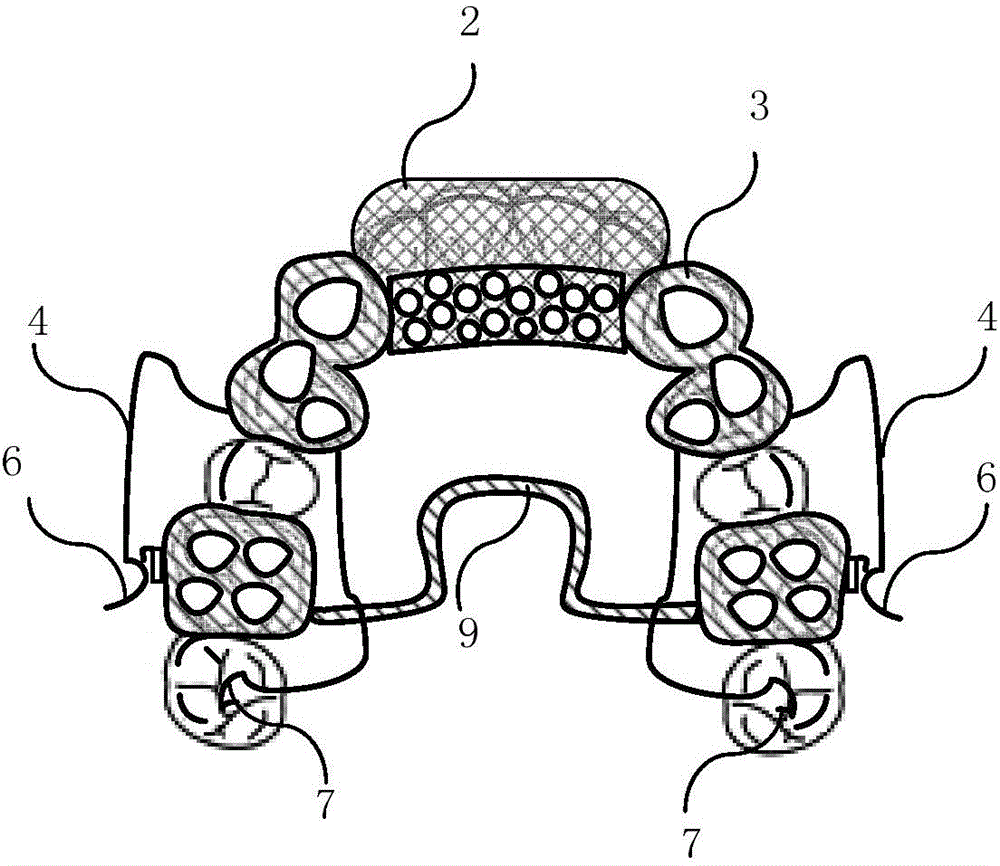

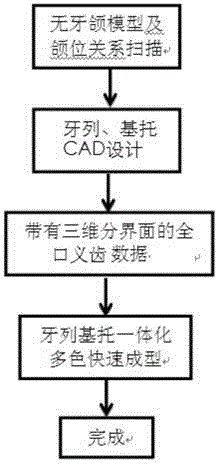

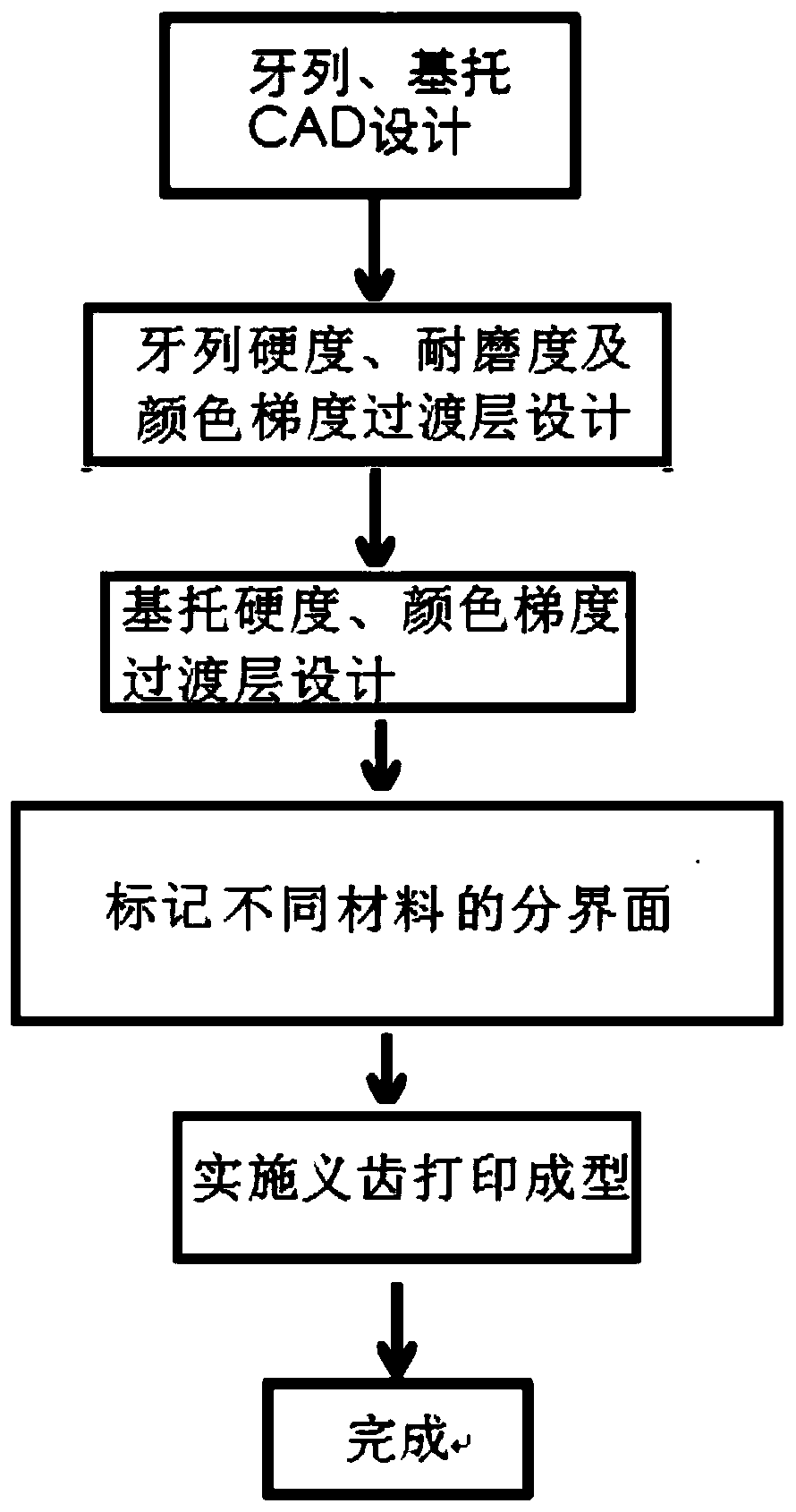

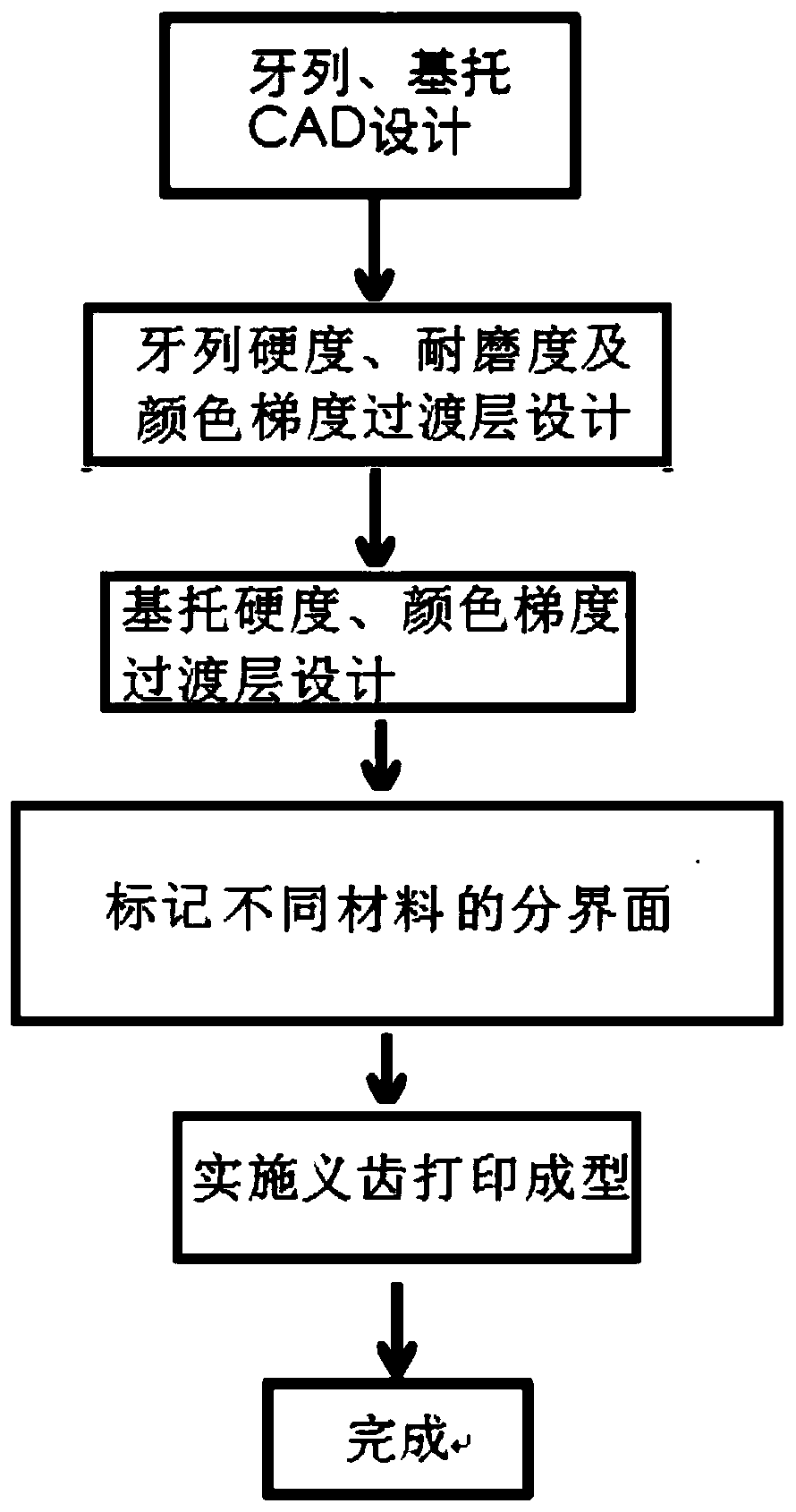

An integrated rapid prototyping method for a multicolor resin denture restoration

InactiveCN105581849ARealize one-time digital processing and formingSimplify work intensityArtificial teethYarnNumerical control

The invention relates to an integrated rapid prototyping method for a multicolor resin denture restoration. The method includes steps of scanning a plaster model of an edentulous jaw and an (occlusion) rest of a patient, building an (occlusion) plane and tooth arranging lines, arranging lower and upper teeth, completing dentition CAD data, completing rest CAD data, introducing denture CAD data into bundled software of numerical control machining equipment, setting color layers distinguished by color type numbers at the normal direction of the (occlusion) plane according to clinical colorimetric results with each of the layers representing one color, labeling beginning and end planes of each of the color layers at the normal direction of the (occlusion) plane with the planes being adopted as interfaces for changing material yarn with different colors, and performing multicolor complete denture prototyping through applying the numerical control machining equipment, the bundled software of the equipment and the PMMA material yarn, thus completing manufacturing of a complete denture. The method simplifies manufacturing steps, meets artistic requirements of multi-layer color of complete dentures and achieves accurate prototyping.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

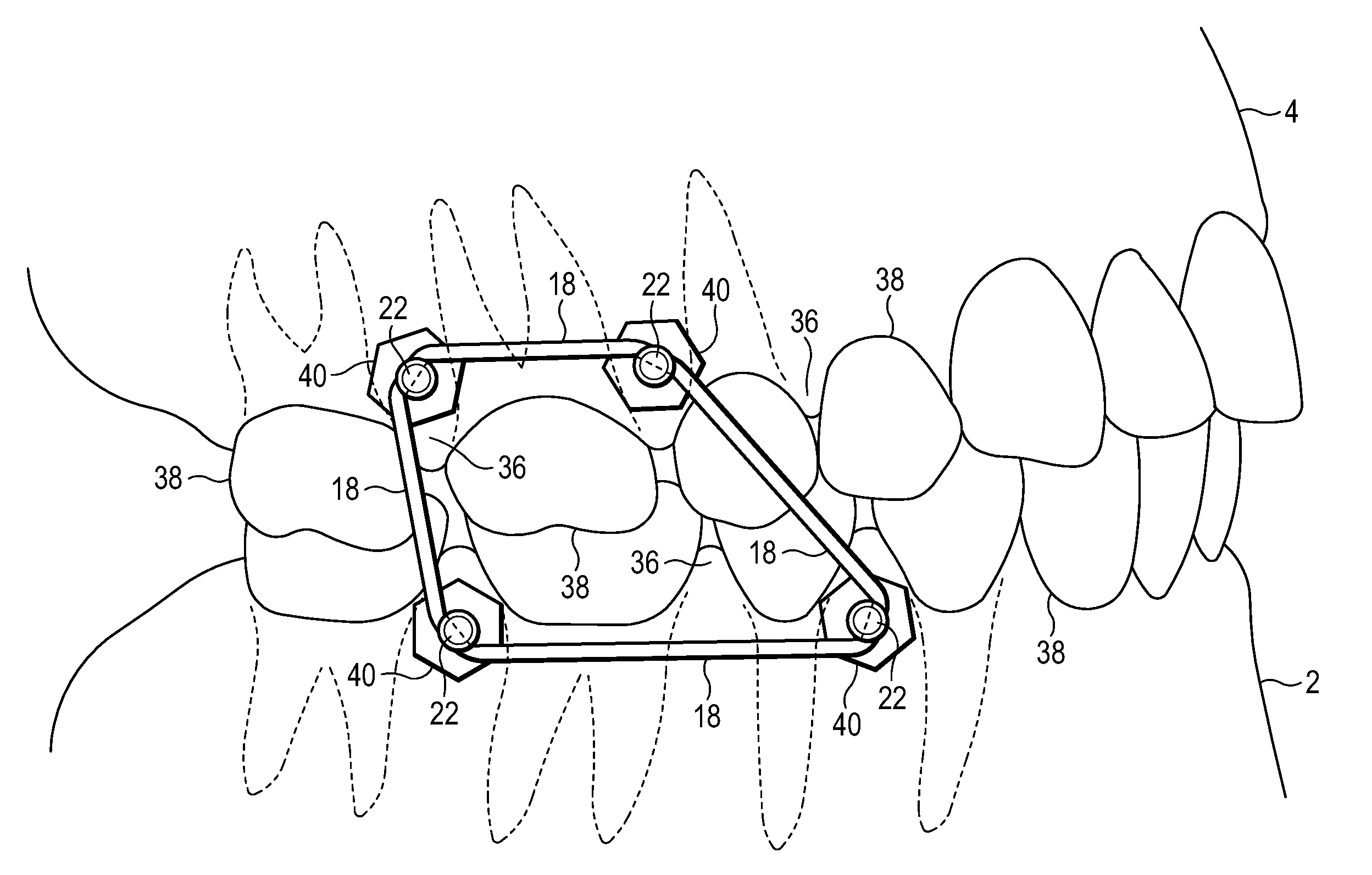

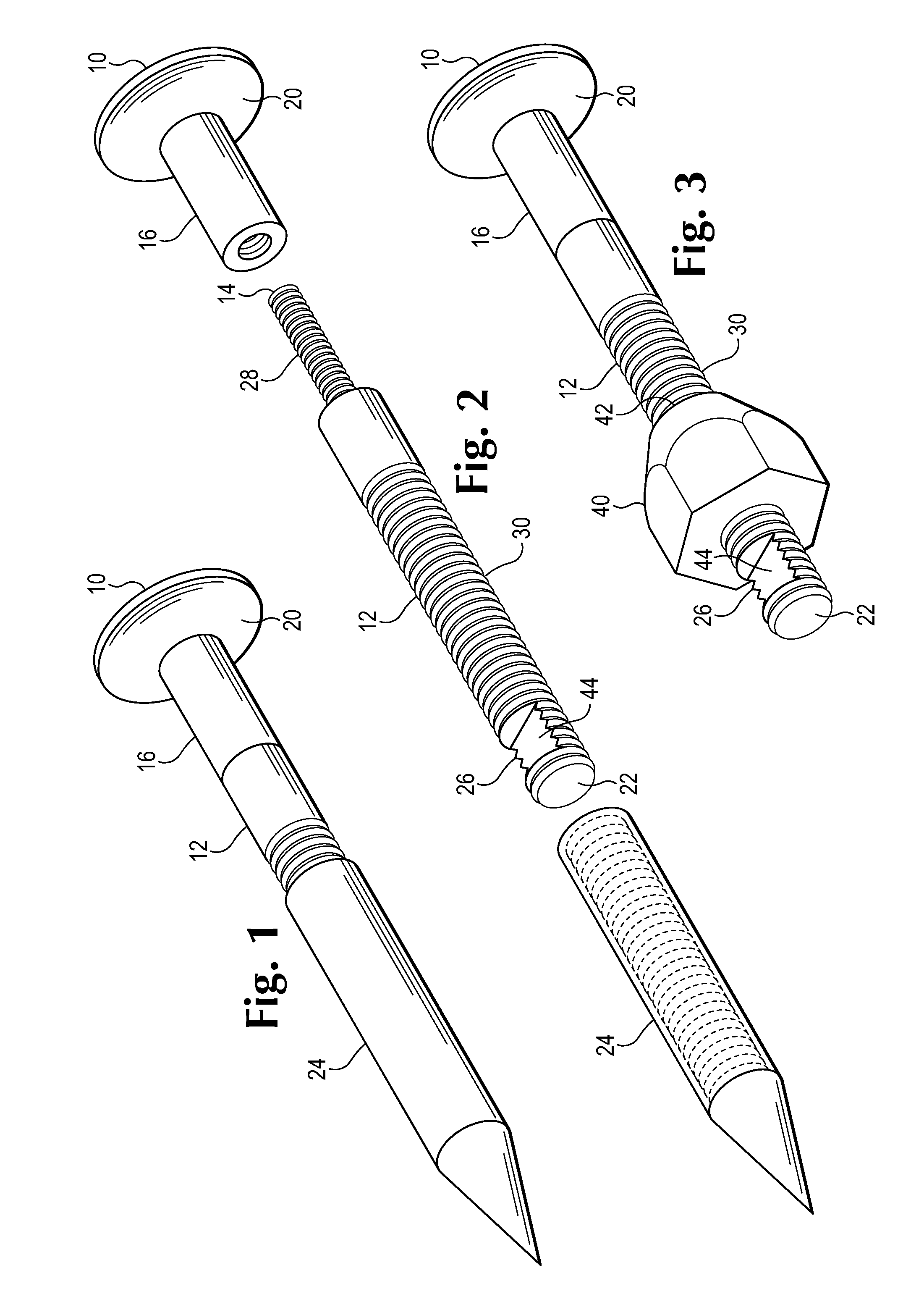

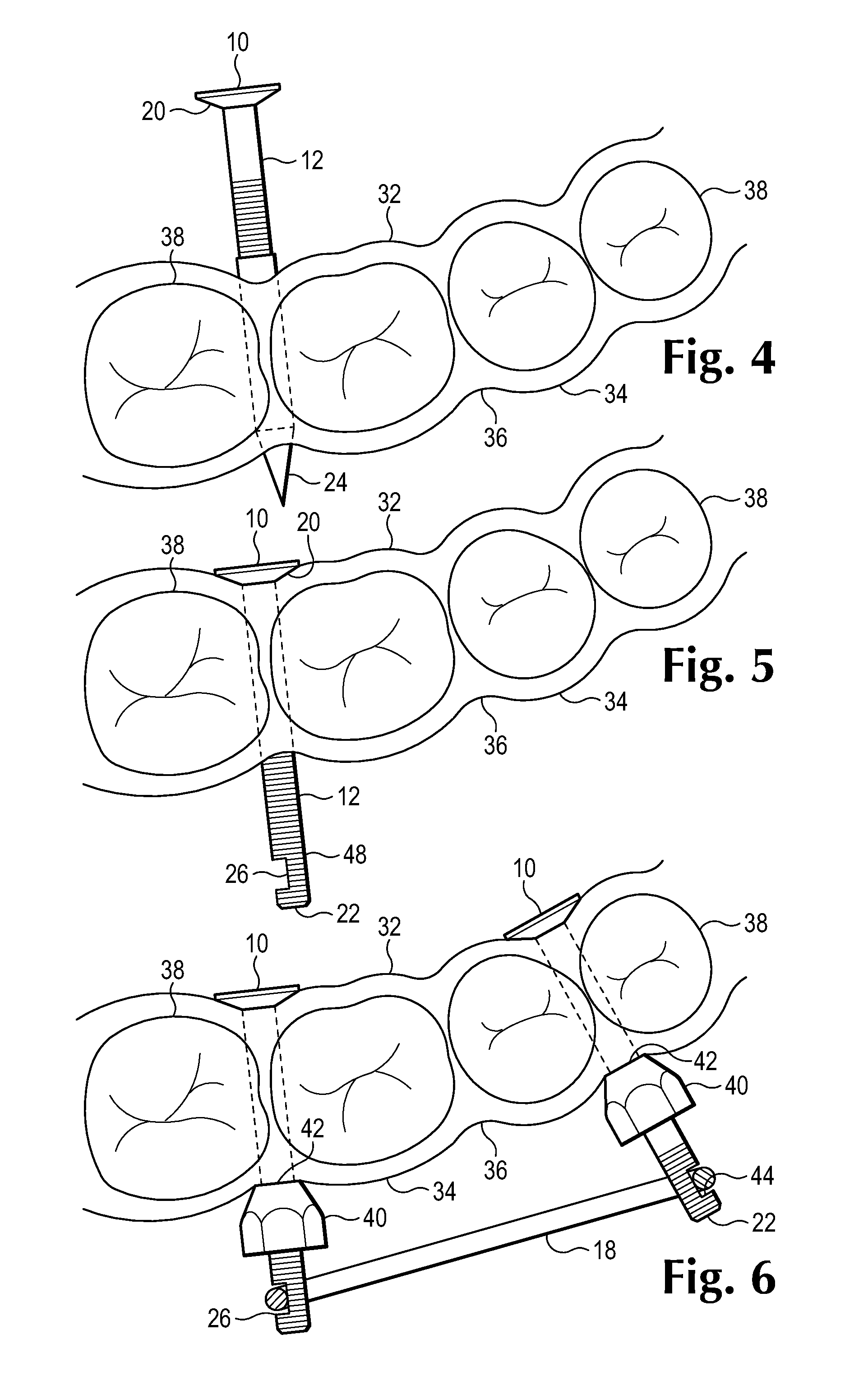

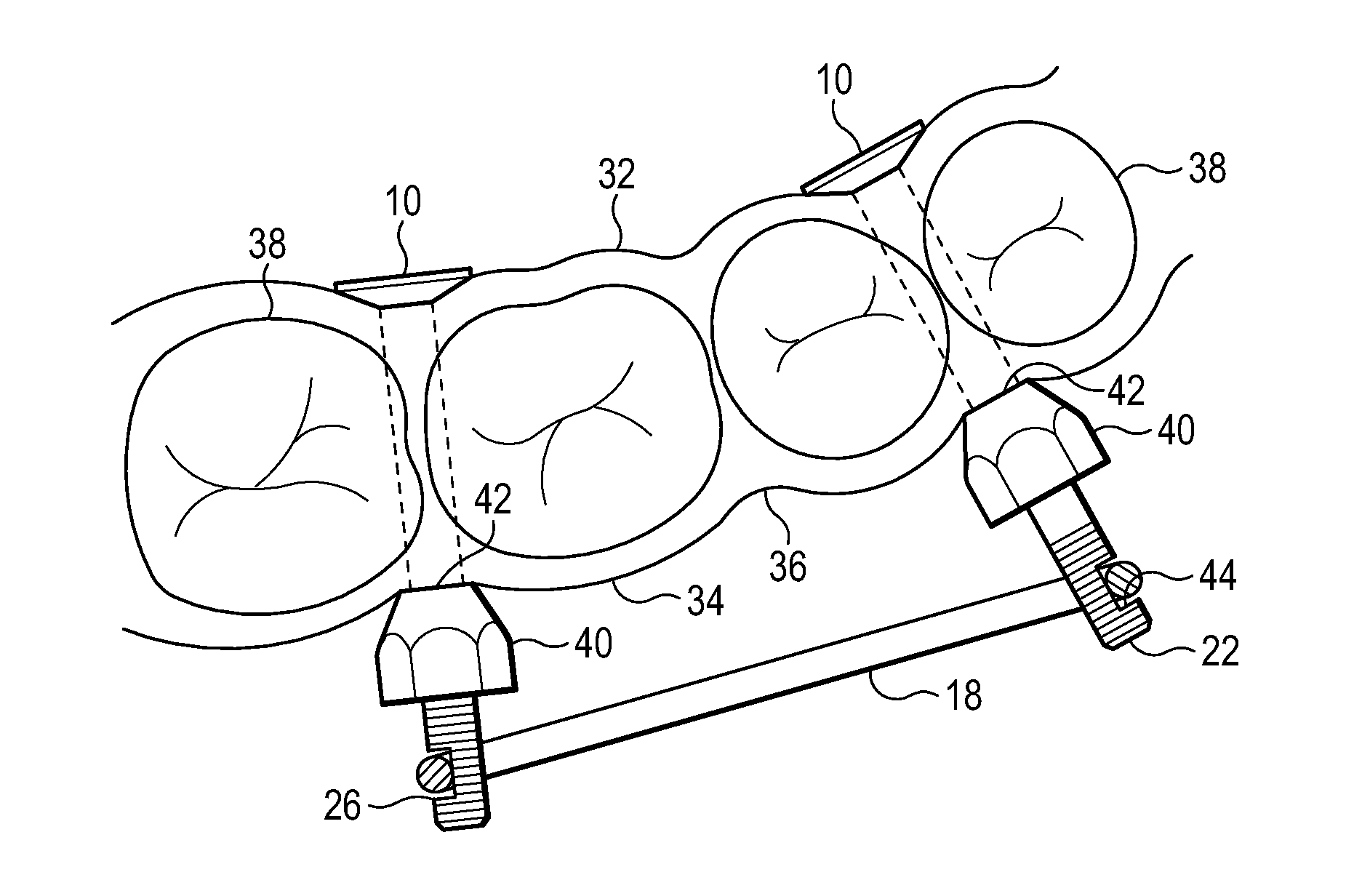

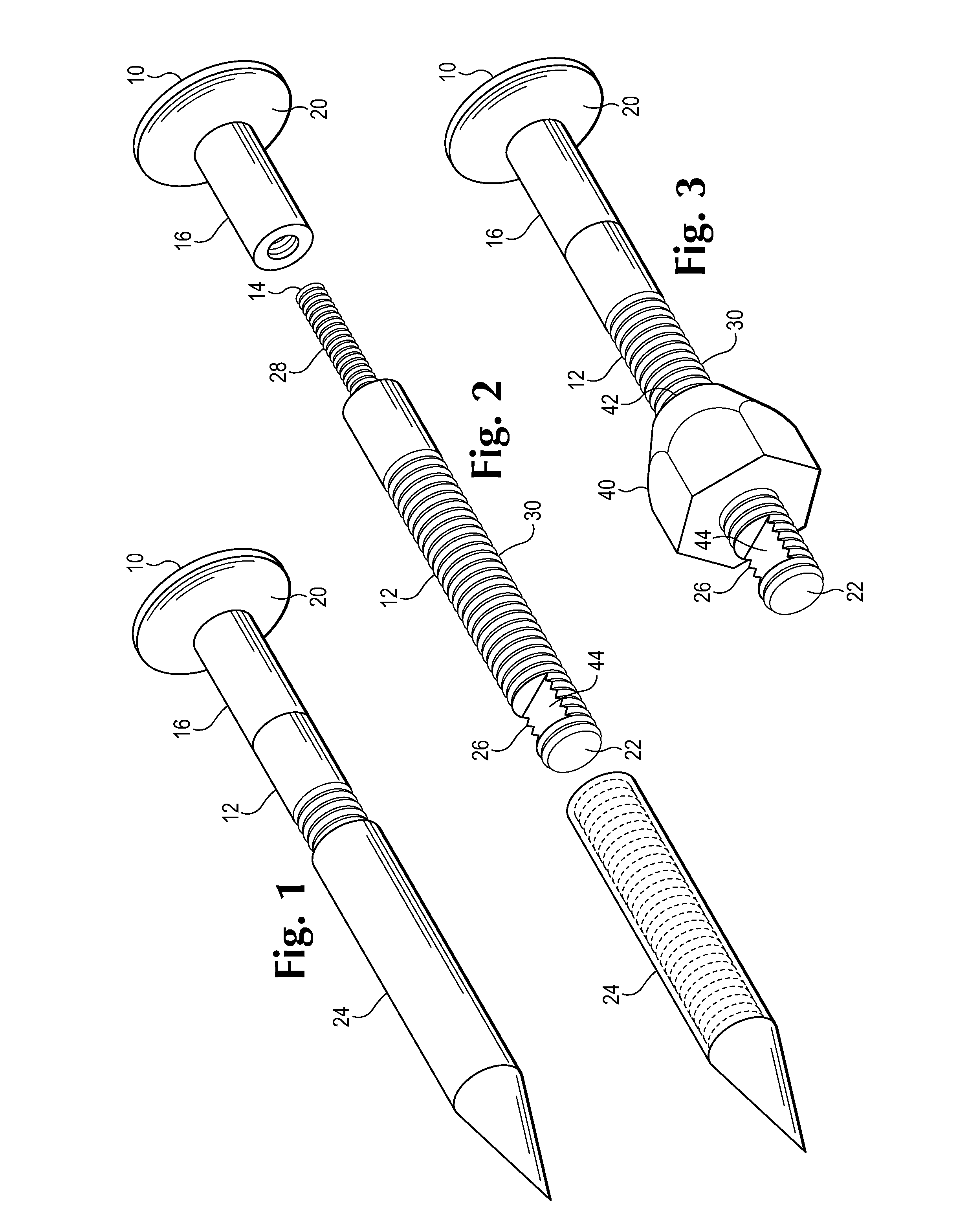

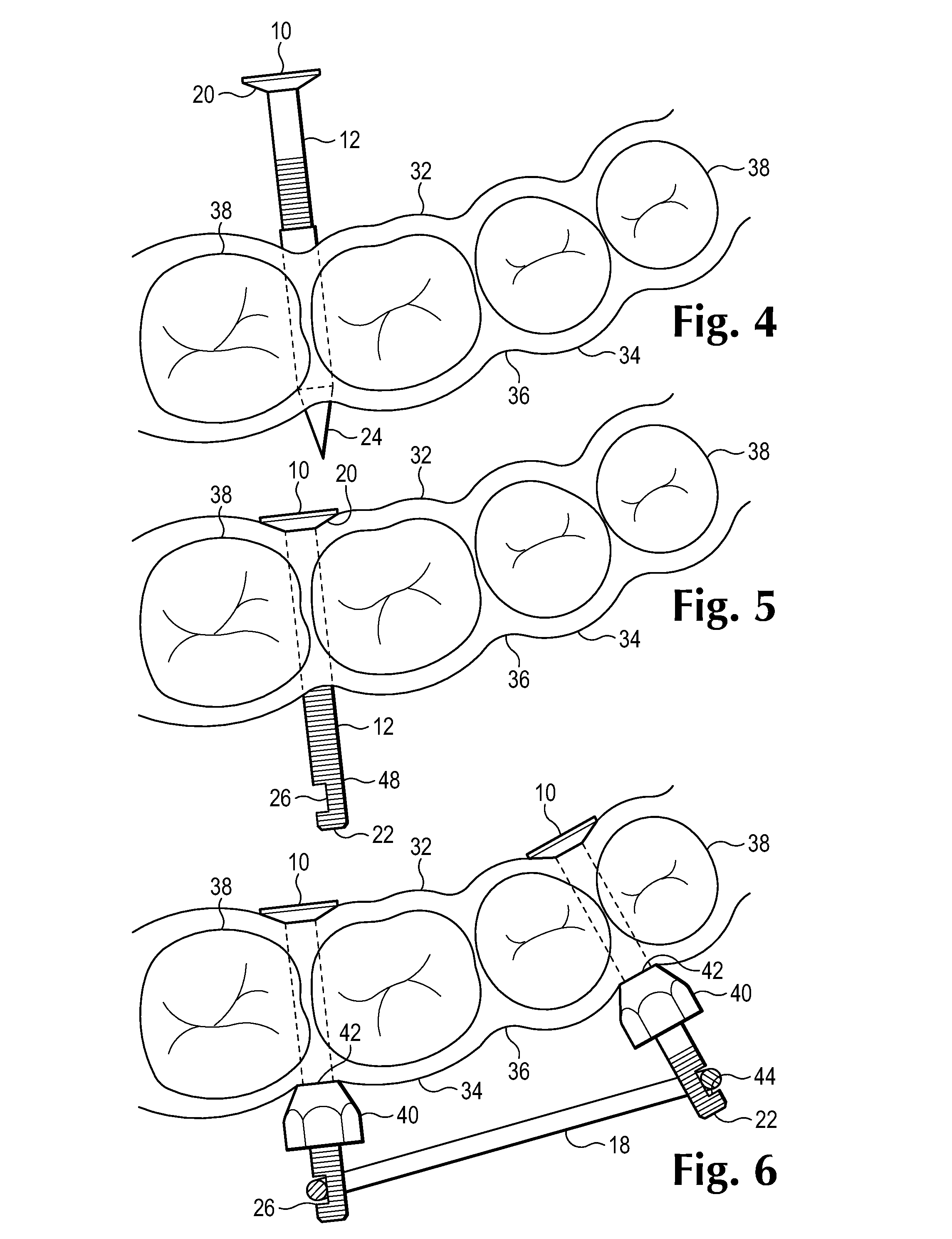

Method and apparatus for maxillo-mandibular fixation

Apparatus and method of use which can be used to immobilize maxilla and mandible in dental occlusion utilizing the tissue of the interdental space.

Owner:STUPAK HOWARD D

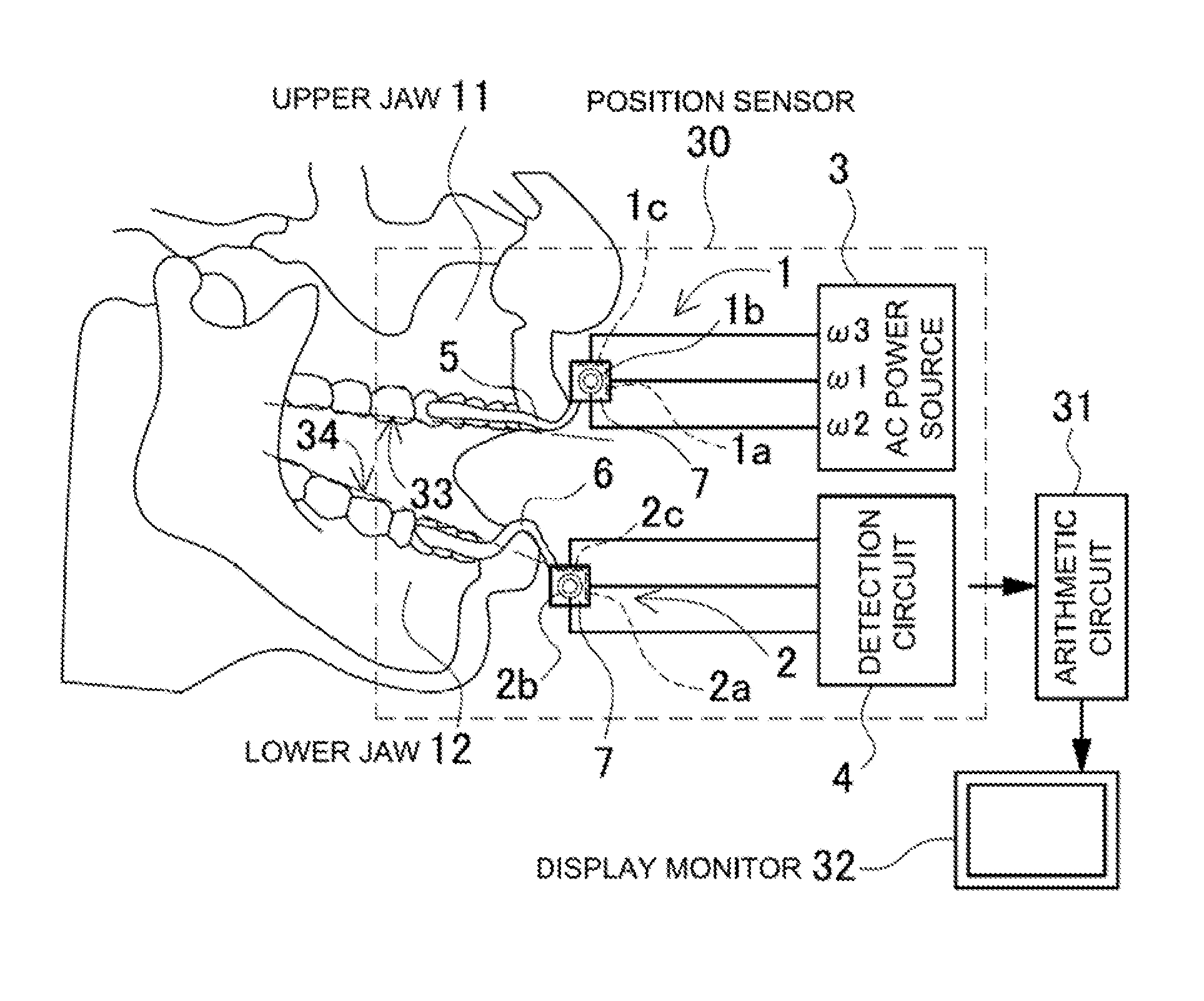

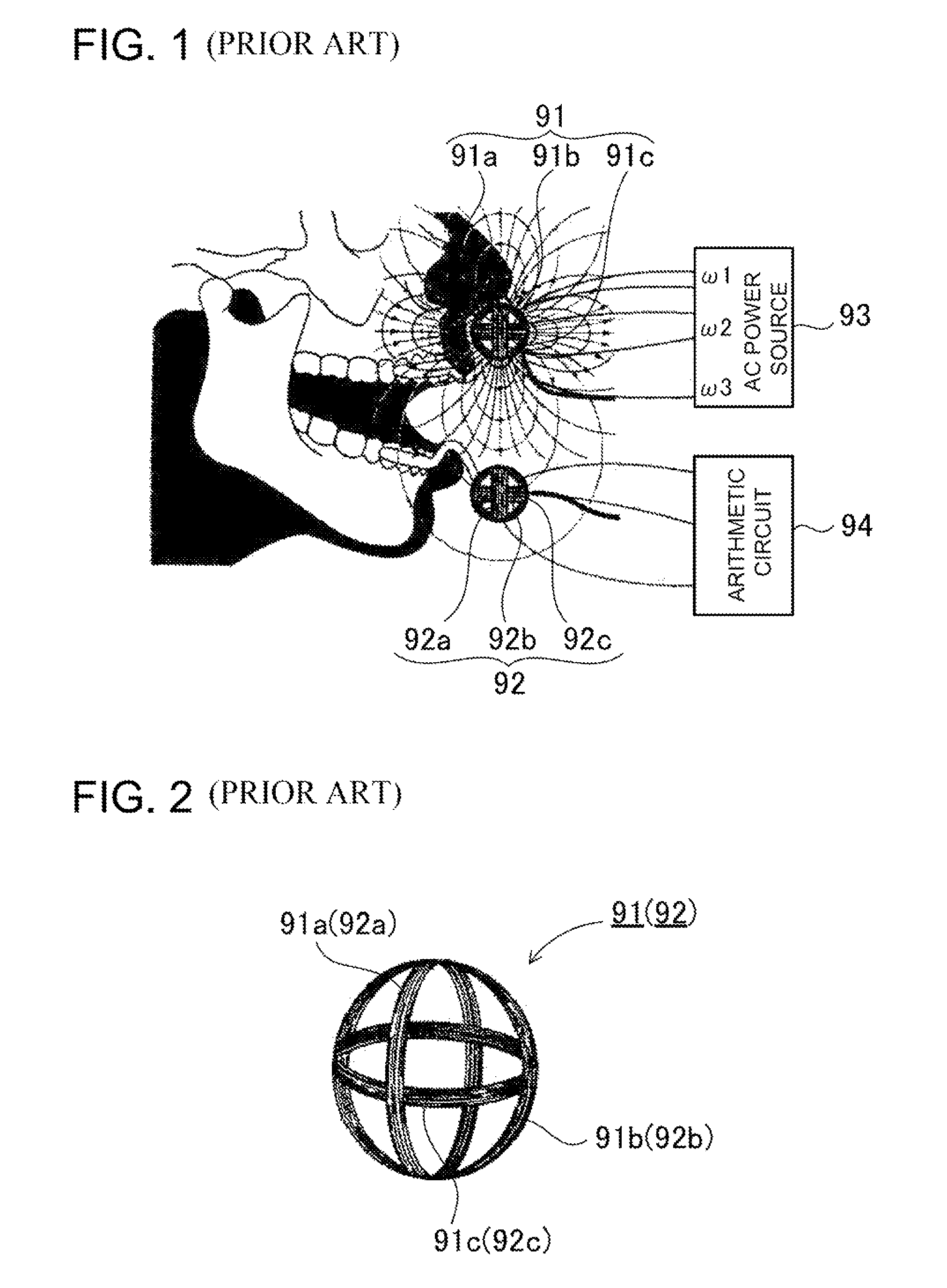

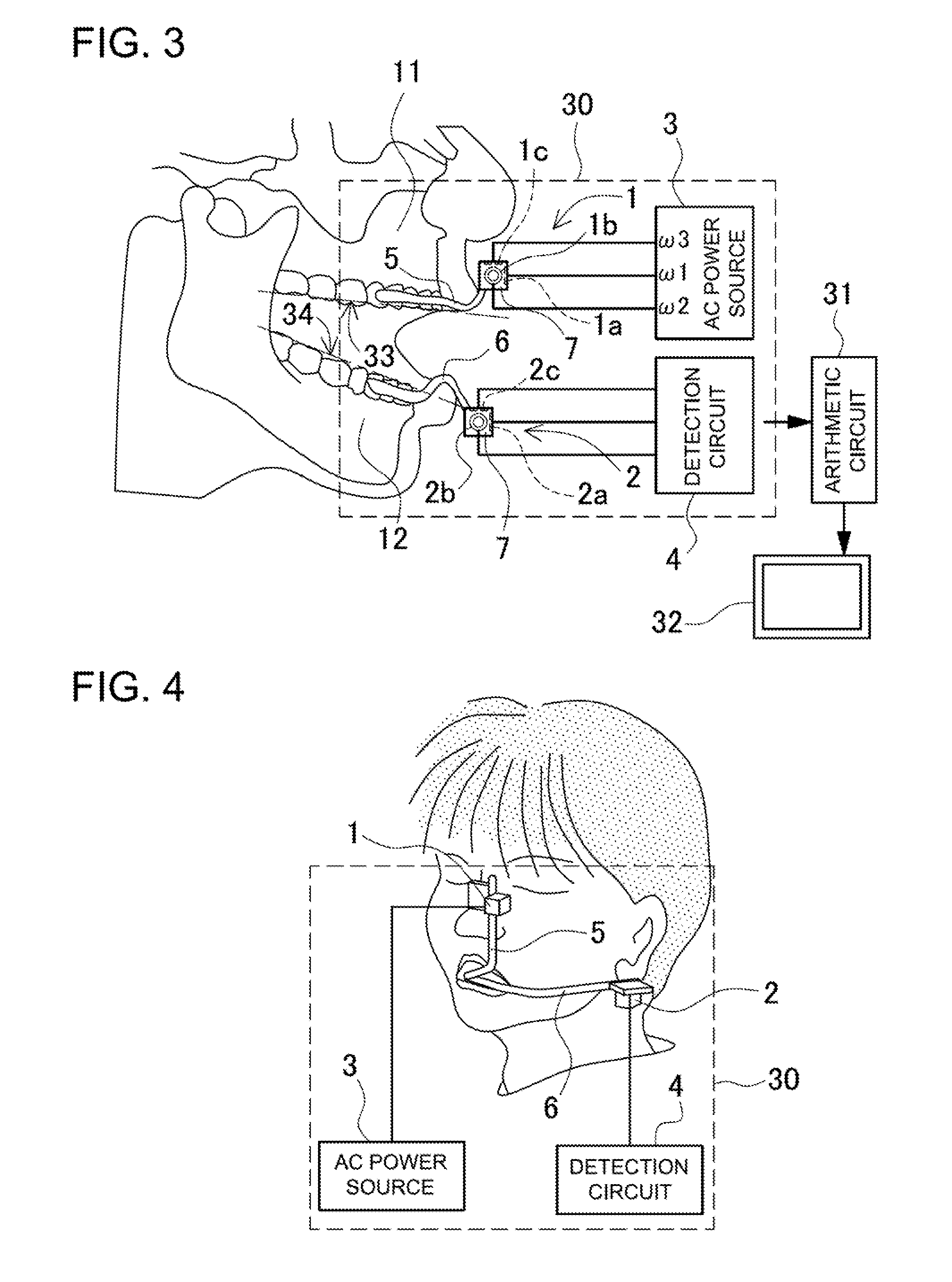

Apparatus for measuring dental occlusion

An apparatus for measuring a dental occlusion includes: a position sensor (30) for detecting a position and posture of a lower jaw (12) relative to an upper jaw (11) and; an arithmetic circuit (31) for computing a posture relative to a translation distance in a state of occlusal contact. The computation is derived from the position and posture of the lower jaw (12) relative to the upper jaw (11) detected by the position sensor (30). The apparatus also includes a display monitor (32) for displaying the posture relative to the translation distance computed by the arithmetic circuit (31).

Owner:SHOFU INC +1

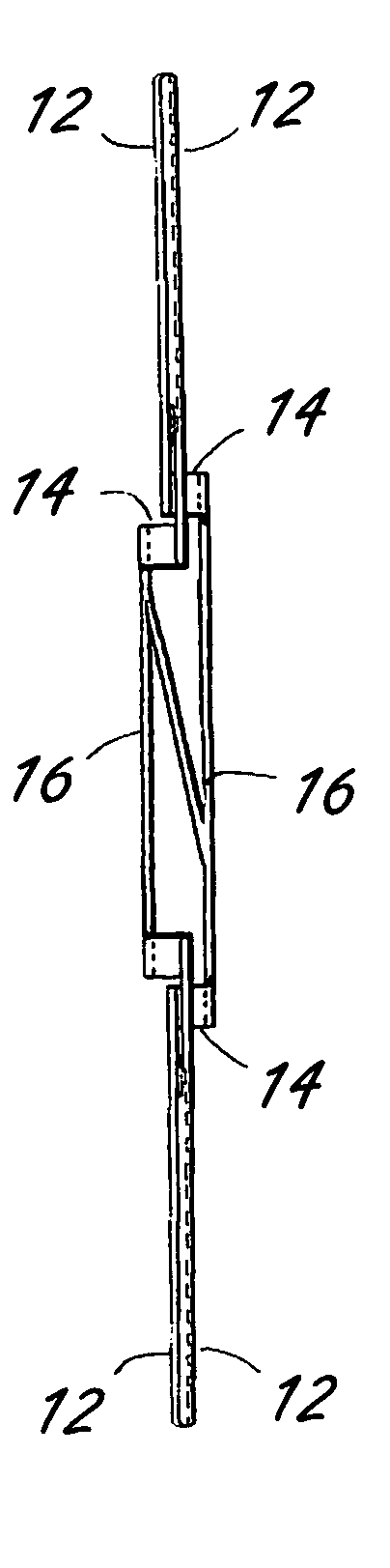

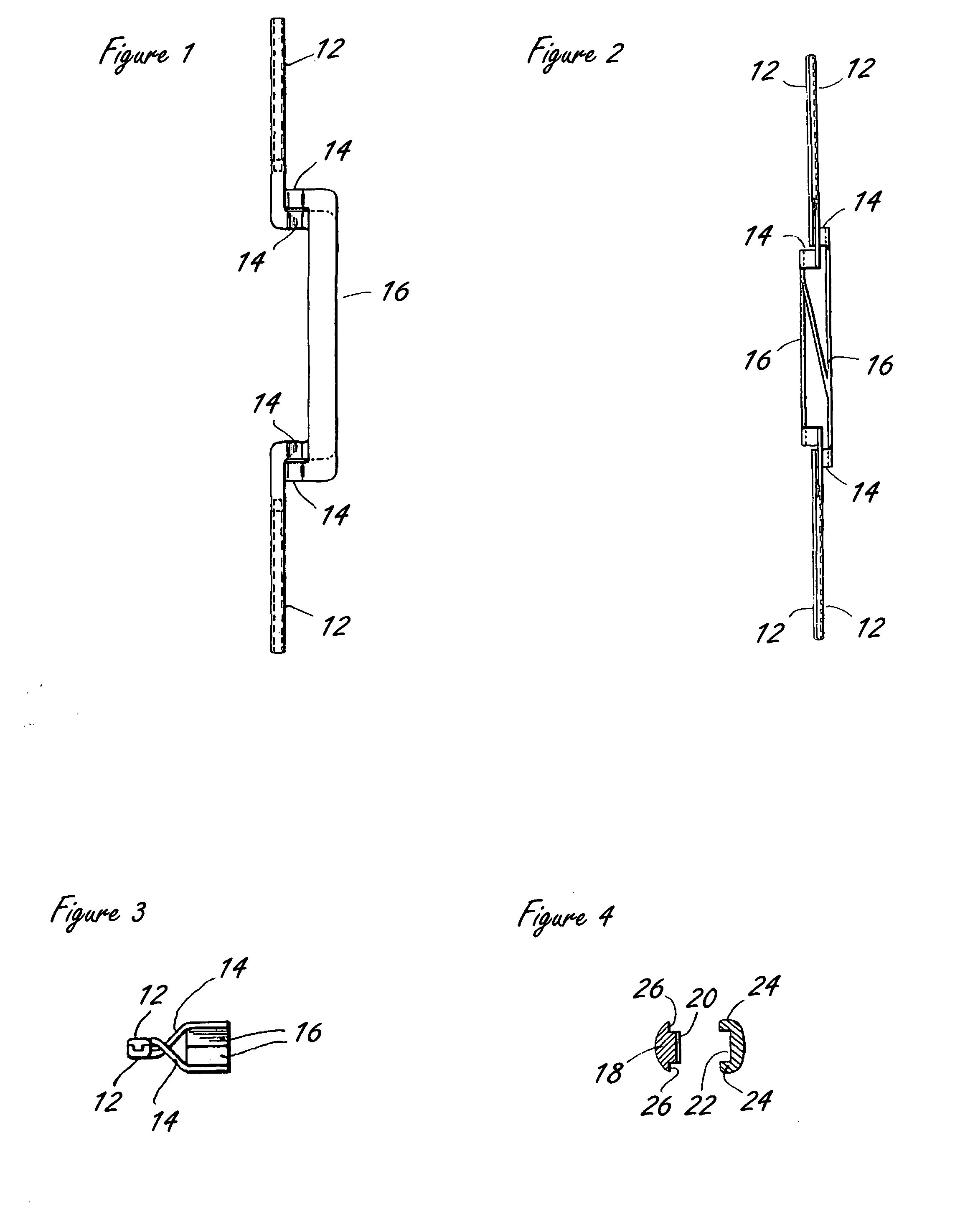

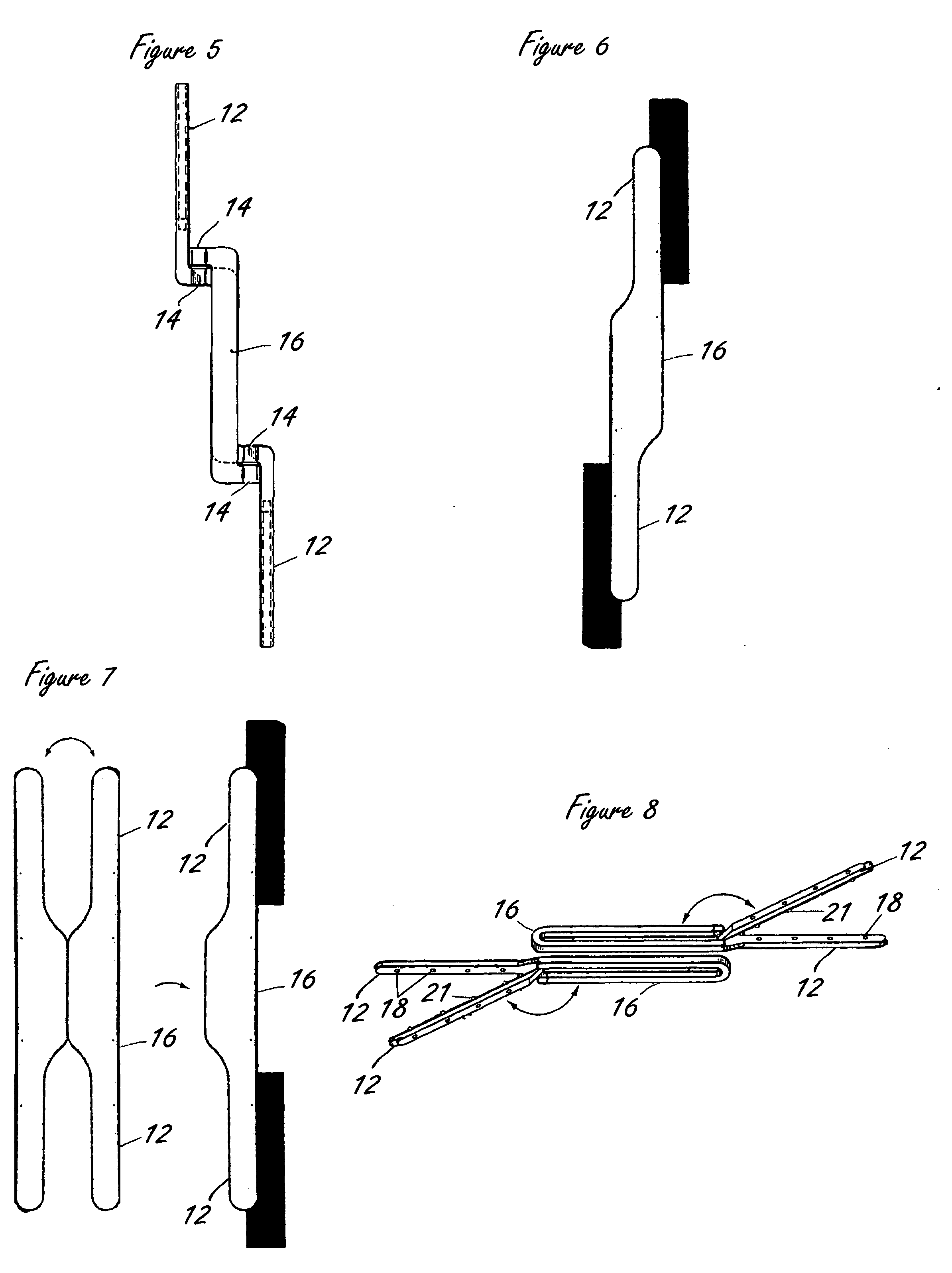

Double sided dental articulating paper forceps

ABSTRACT: A double sided dental articulating paper forceps that has two pairs of opposed jaws (12) which hold articulating paper or gauze, one on each end of the appliance, extending from interconnected arms (16) and intermediate arms (14), allowing the quick drying and marking of the dental occlusion with one instrument as well as allowing the marking of the dental occlusion with two separate articulating paper colors in one instrument.

Owner:HAHN CHRISTIAN WOLFRAM

Method and apparatus for maxillo-mandibular fixation

Apparatus and method of use which can be used to immobilize maxilla and mandible in dental occlusion utilizing the tissue of the interdental space.

Owner:STUPAK HOWARD D

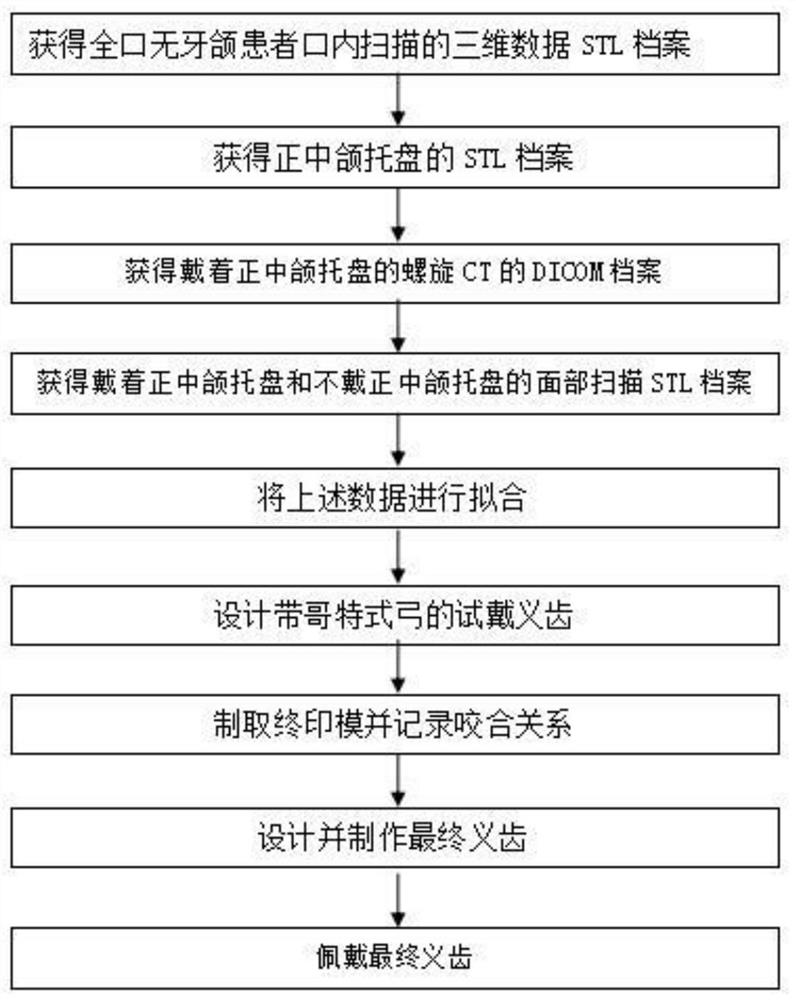

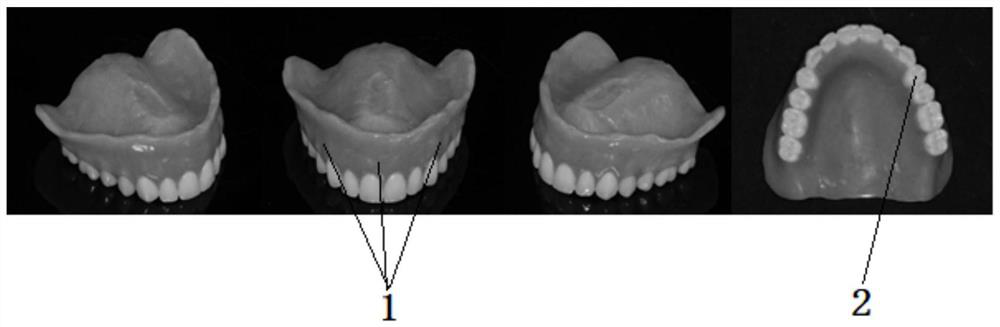

Full-process digital manufacturing method of complete dentures

ActiveCN112535545AImprove try-in effectHigh strengthImpression capsArtificial teethAnatomical structuresEntire mouth

The invention provides a full-process digital manufacturing method of complete dentures. The full-process digital manufacturing method comprises the following steps: acquiring an STL file of three-dimensional data by intraoral scanning of a patient with complete edentulous jaw; putting the median occlusal tray into the mouth, recording the morphology of the mucous membrane surface of the upper jawand the lower jaw and the relative position relation of the upper jaw to the lower jaw, obtaining an STL file of three-dimensional data of the median occlusal tray by scanning; and obtaining a DICOMfile about spiral CT or CBCT of the edentulous jaw patient wearing the median occlusal tray. The full-process digital manufacturing method of the present invention has the advantages as follows: 1, athree-dimensional space about maxillofacial region of the patient is constructed by fitting four digital files, and the occlusal plane in which the patient tries on the dentures and morphology and position of the anterior teeth are set with reference of the anatomical structure of the maxillofacial region of the patient, thereby improving the try-on effect of the dentures; 2, a final impression scanning and copying technology is utilized to accurately manufacture the morphology of a final denture base; and 3, a base plate and a artificial dentition are obtained by adhering the separately cut resin discs with different colors and high strength through adhesive, thereby achieving high cutting precision, high strength of the resin discs and good wear resistance of the artificial teeth.

Owner:成都橙子思创医疗科技有限公司

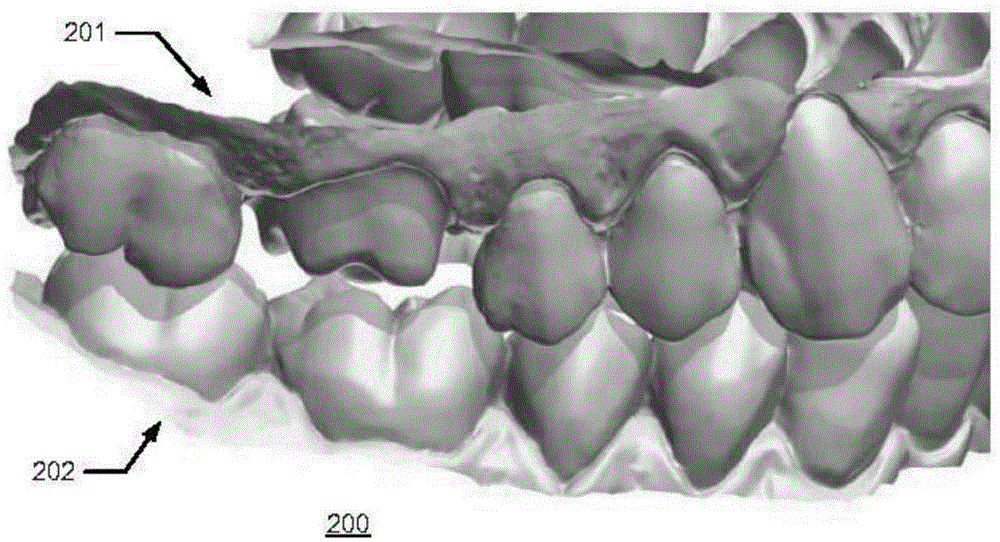

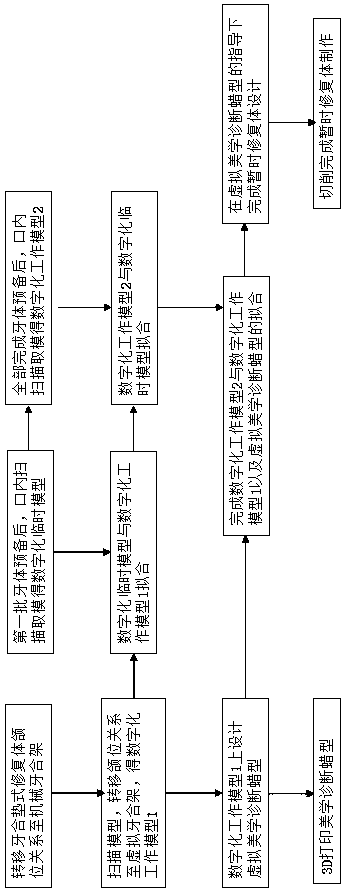

Method for three-dimensional configuration high-efficiency digital optimization after treatment of malocclusion dentitions

ActiveCN109363787APrioritize landscapingImprove the optimization level of functional aestheticsOthrodonticsDental occlusionDigitization

The invention relates to a method for three-dimensional configuration high-efficiency digital optimization after treatment of malocclusion dentitions. The method comprises the following steps: (1) scanning dentitions of normally-occluded upper and lower jaws in batches as standard template data, and establishing a dental arch curve; (2) carrying out three-dimensional scanning on the malocclusion dentition requiring orthodontic treatment as data D1; (3) selecting a set of data from the step (1) as data D2; (4) registering the data D2 to the data D1 with the upper jaw palatal rugae as a common area; (5) extracting the three-dimensional data of the crown and root of each tooth in the data D1, registering the three-dimensional data to the corresponding teeth of the data D2, and generating preliminary preferred result data; (6) adjusting the contact relationship of the mesial and distal of the crown of each tooth, and generating the final preferred result data; and (7) making a female moldafter three-dimensional printing of the preferred result data, and directly presenting an entity of the preferred result in an oral cavity model of a patient. The method can realize the digital orthodontic diagnosis and treatment process and improve the functional aesthetic preference level of an operator.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

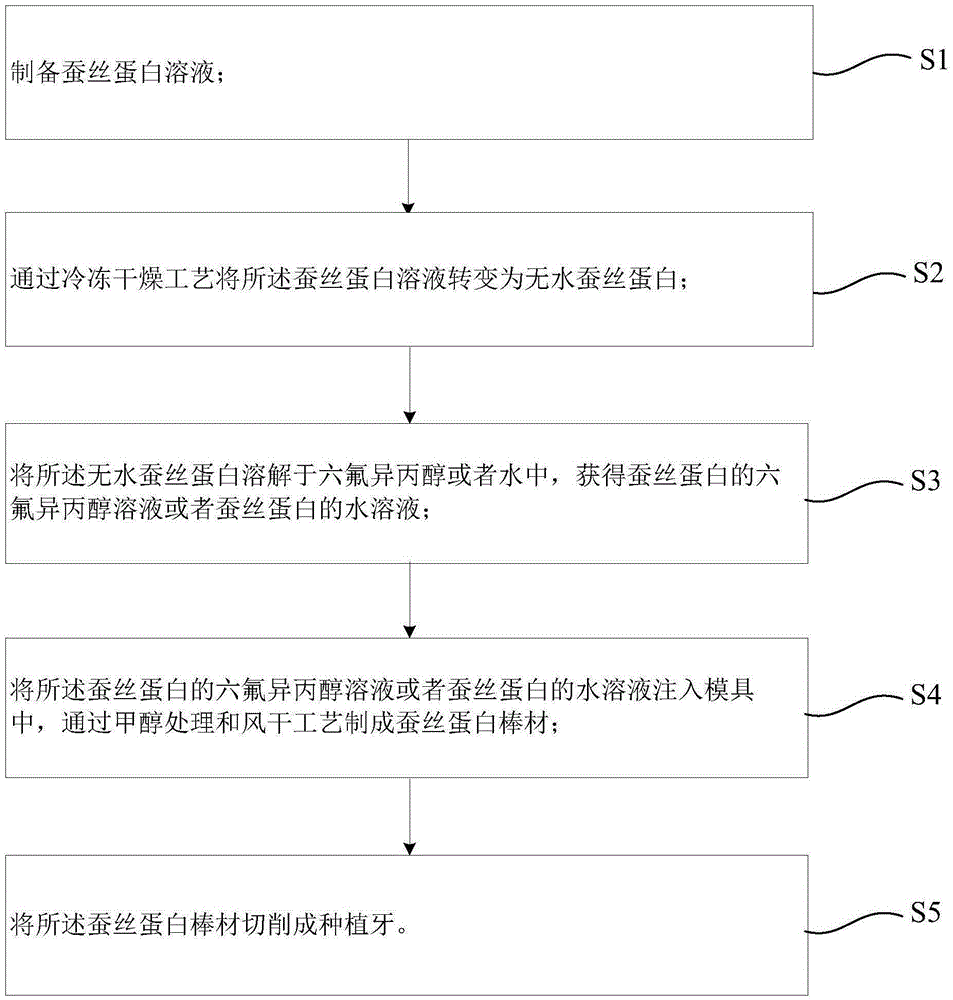

Silk protein dental implant and preparation method thereof

ActiveCN106667595AHigh affinityNo immune rejectionDental implantsImpression capsProtein solutionFreeze-drying

The invention provides a silk protein dental implant and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a silk protein solution; secondly, transforming the silk protein solution into anhydrous silk protein according to a freeze-drying process; thirdly, dissolving an anhydrous silk protein solution into hexafluoroisopropanol to obtain a hexafluoroisopropanol solution of the silk protein; fourthly, injecting the hexafluoroisopropanol solution of the silk protein into the die, and obtaining a silk protein bar by a methanol treatment and air drying process; fifthly, cutting the silk protein bar into the dental implant, and also bonding a high-hardness dental crown on the surface of the dental implant. By controlling preparation parameters of the silk protein solution, and drying and curing parameters and the like as well as doping solid-phase reinforced particles, mechanical properties of silk protein can be controlled and the dental implant which is matched with mechanical parameters of human skeletons and dental occlusion and is well compatible with human biological tissues is obtained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

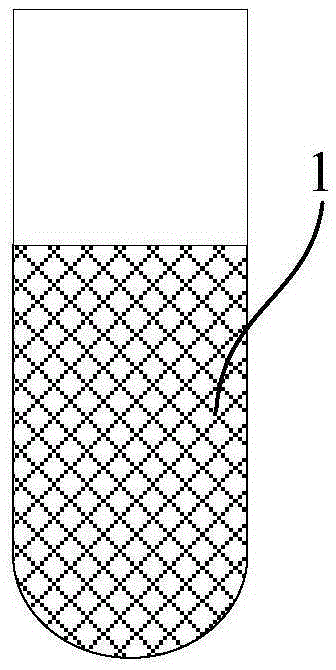

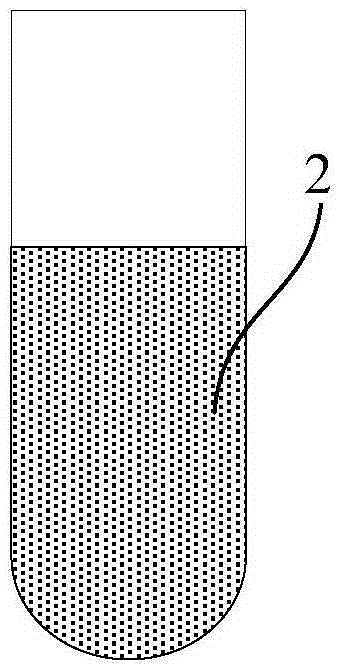

Mechanical and aesthetic gradient false tooth integrated design and 3D printing method

PendingCN111136915AMeet individual requirementsImprove wear resistanceAdditive manufacturing apparatus3D object support structuresNumerical controlSoftware design

The invention relates to a mechanical and aesthetic gradient false tooth integrated design and 3D printing method. The method includes the following steps that a dentition portion and a base plate portion of a false tooth are designed through CAD software; the dentition is divided into 3-5 layers from an occlusal surface to a gingiva, and cross transition layers are arranged between the layers forgradient transition of the hardness, the abrasion resistance and the colors; the base plate is divided into an upper layer and a lower layer from the occlusal surface to the gingiva for gradient transition of the hardness and the colors; color layers distinguished by colors and specifications are set in the normal direction of an occlusal plane according to an individual clinical colorimetric result of teeth of a patient, each layer represents one color, and the start-stop surface of each color layer in the normal direction of the occlusal plane is marked to serve as an interface for replacing different materials; and numerical control machining equipment and bundled software thereof are applied, false tooth printing forming is carried out, and the false tooth is manufactured. The manufacturing process can be simplified, the individual requirements of the mechanical and aesthetic gradient false tooth are met, and precise integrated forming is carried out.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

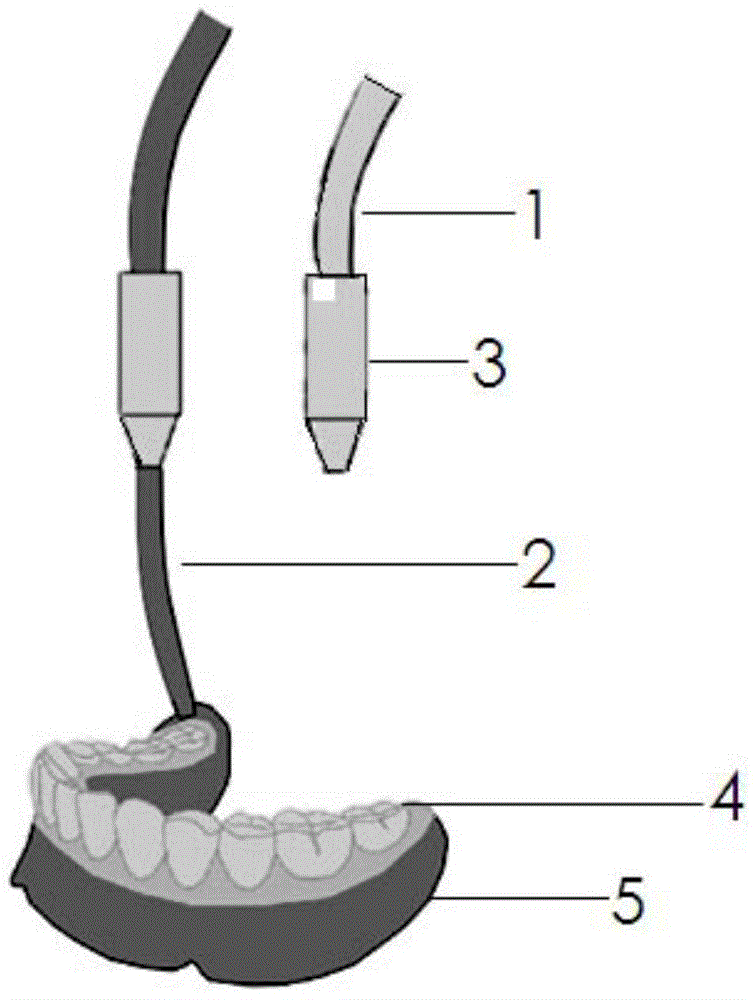

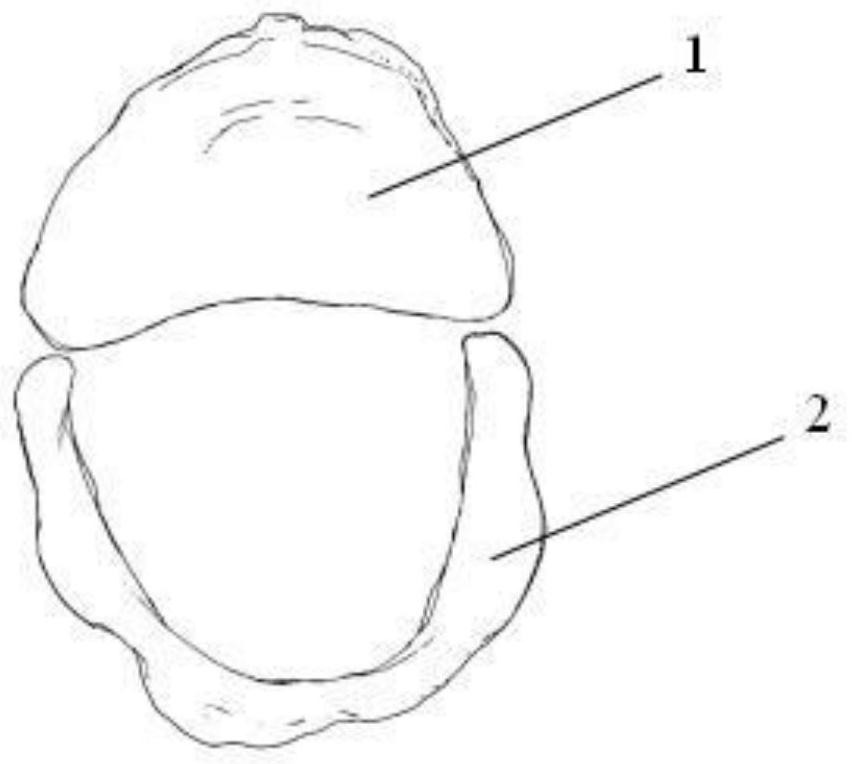

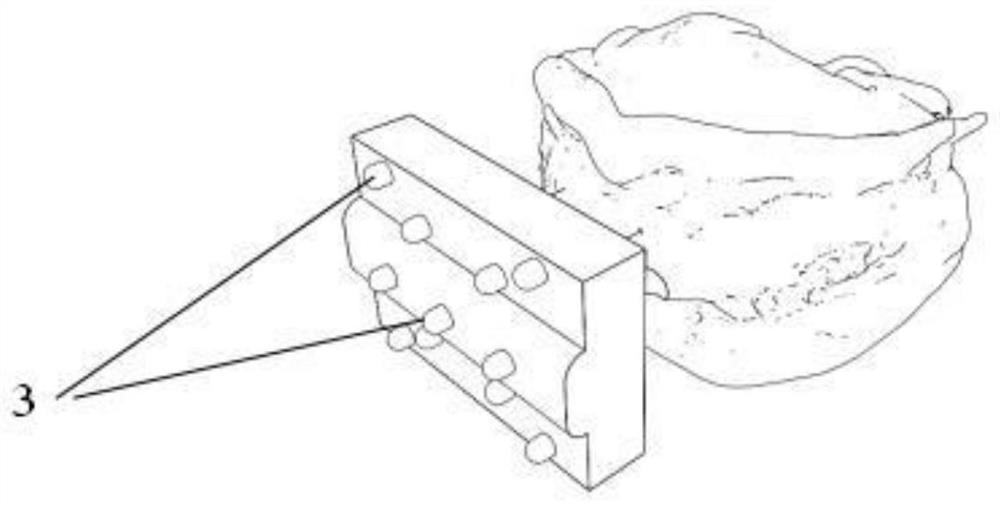

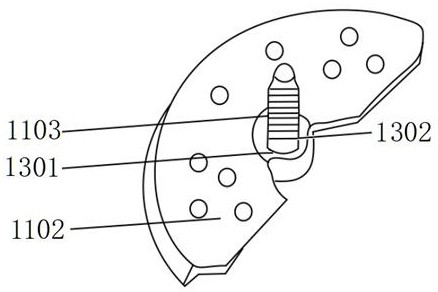

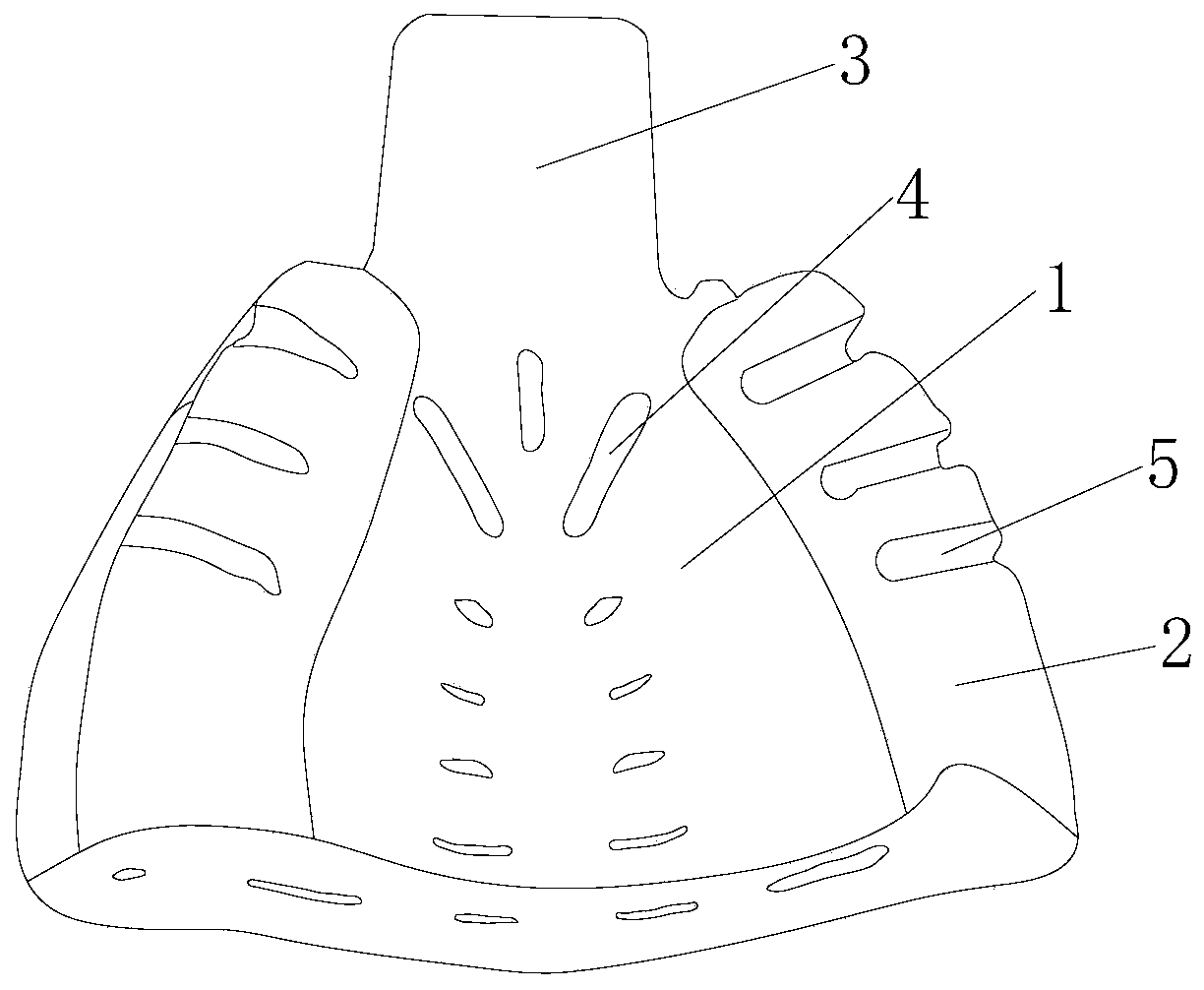

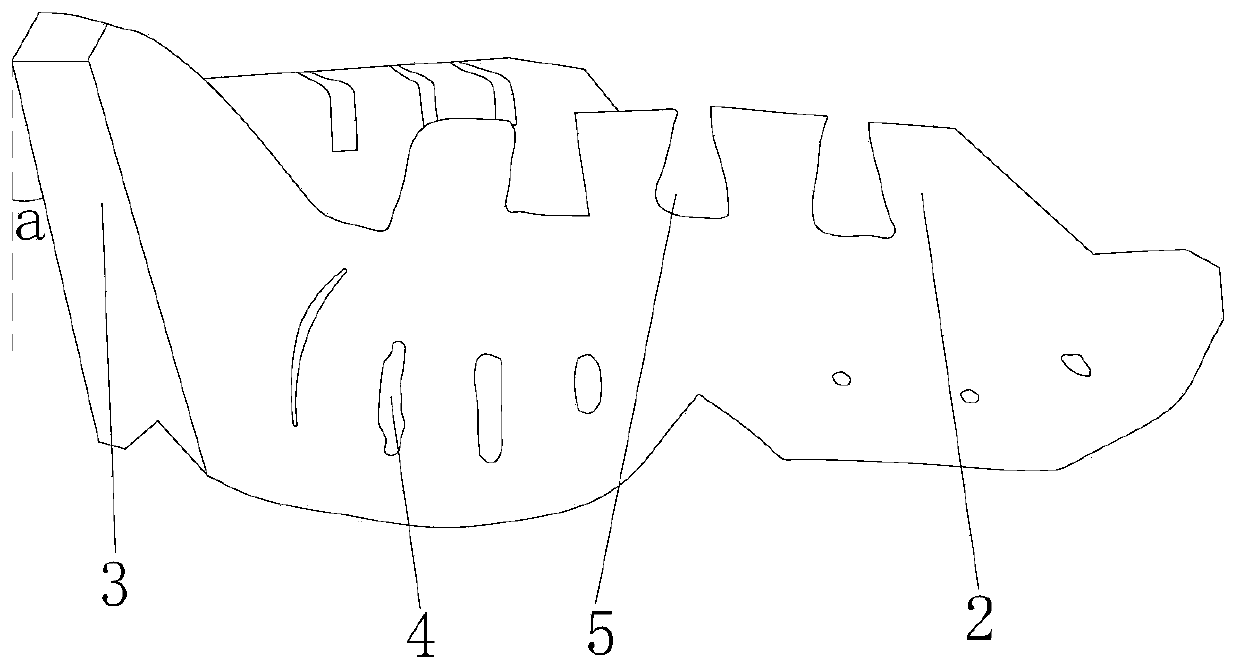

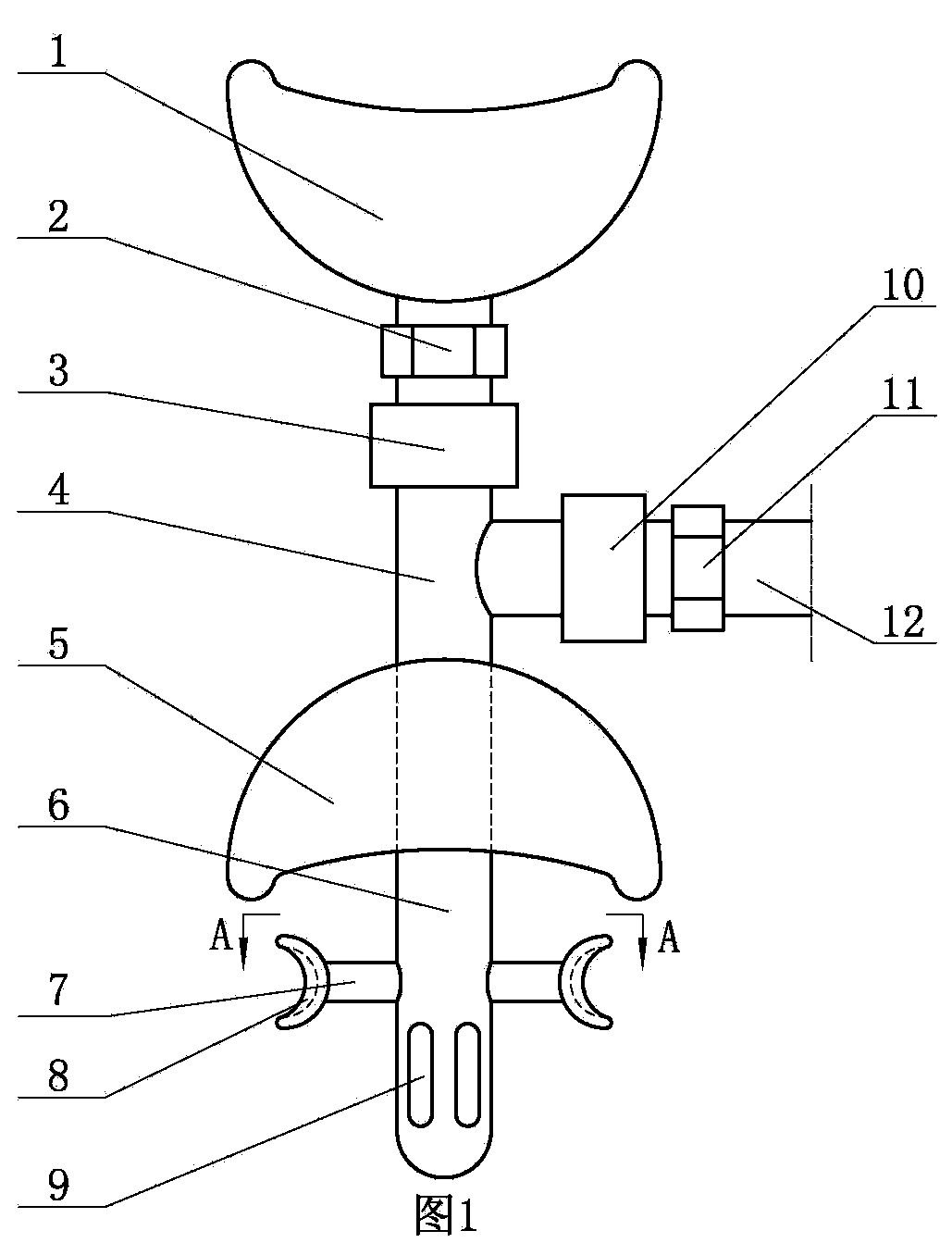

Middle jaw tray, using method and manufacturing method applied to digital complete denture

ActiveCN111743648AReduce the number of referralsEasy to manufactureImpression capsDenturesProsthesis

The invention discloses a middle jaw tray, a using method and a manufacturing method applied to digital complete dentures. The tray comprises an upper jaw tray, a lower jaw tray, an occlusion positioning needle, an occlusion positioner and an external interface, the bottom surface of the upper jaw tray is a occlusal plane plate, the occlusion positioner is arranged on the occlusal plane plate, andthe lower jaw tray is connected with the occlusion positioner through the occlusion positioning needle; an external interface is arranged at the front end of the upper jaw tray and is connected witha handle interface or a face arch interface; one end of the handle connector can be inserted into the outer connector and fixed, the other end of the handle connector clamps the middle end of a face arch ruler, and the face arch ruler is parallel to the occlusal plane plate. One end of the face bow interface can be inserted into the external interface and fixed; by using the tray provided by the invention, a position relationship between the upper jaw and the lower jaw and the occlusal plane can be accurately obtained, and the subsequent prosthesis manufacturing process is simplified while thenumber of times of reexamination of a patient is reduced, so that an occlusion relationship of the final prosthesis is more accurate.

Owner:金鑫 +1

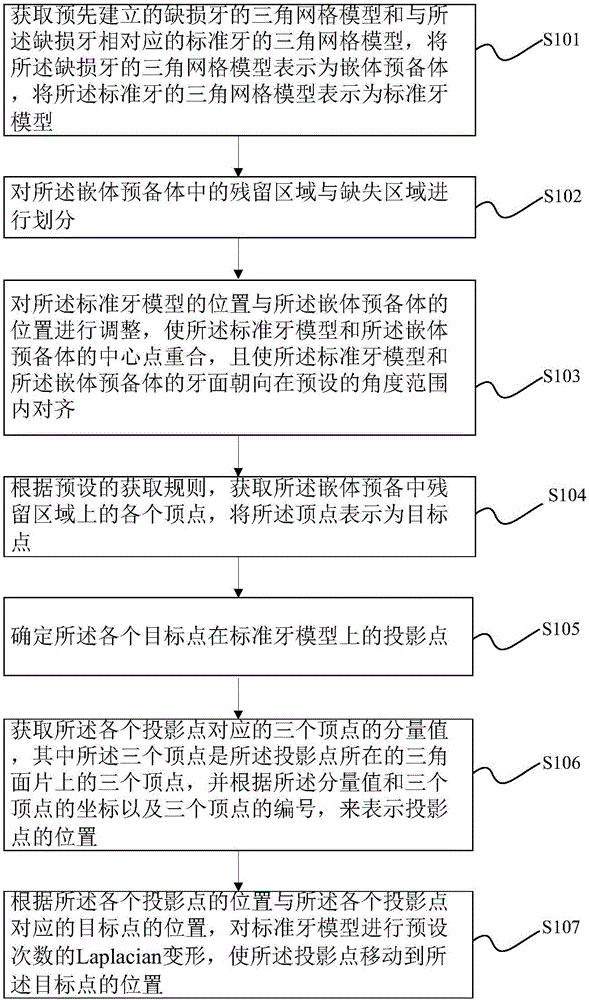

Dental occlusion surface recovering method and system

The invention provides a dental occlusion surface recovering method. The method includes the steps that the vertexes on the residual occlusion surface of an inlay preparation and projection points, on a standard tooth model, of the vertexes are obtained, the projection points are dispersed to the corresponding vertexes, and the projection points are moved to a standard tooth by carrying out Laplacian deformation on the standard tooth so that the standard tooth can be tightly attached to the inlay preparation; as Laplacian deformation is carried out multiple times, model self-crosslinking can be prevented, and moreover key information of fossa, groove, cusp and ridge on the residual occlusion surface is retained.

Owner:GUANGDONG UNIV OF TECH

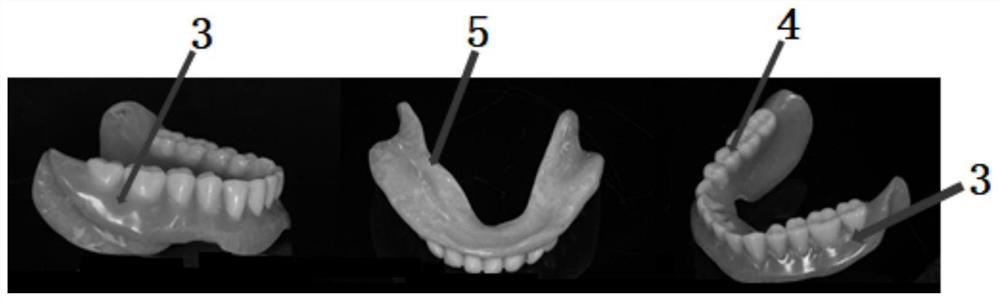

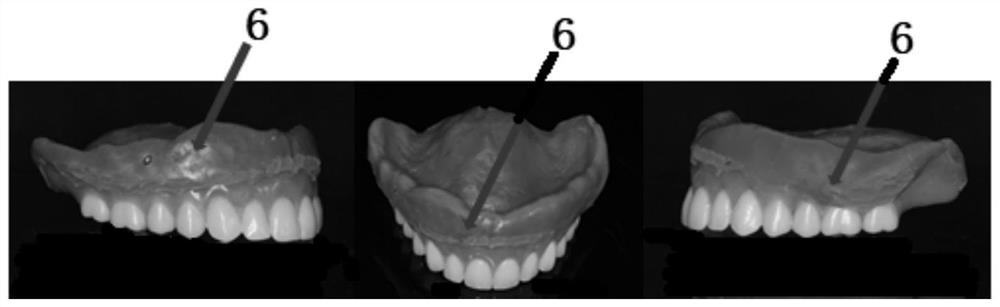

Method for manufacturing complete denture with personalized polished surface by using old denture

ActiveCN113397744AAccurate biteStrong biteImpression capsArtificial teethLower dentitionDental occlusion

The invention discloses a method for manufacturing a complete denture with a personalized polished surface by using an old denture. The method comprises the following specific steps of: preparing an old maxillary denture and an old mandibular denture of a patient; taking the old maxillary denture as an individual tray, and performing final impression preparation and polished surface shaping; taking the old mandibular denture as an individual tray, performing final impression preparation, and performing polished surface shaping at the same time; scanning the maxillary final impression and the mandibular final impression with the personalized polished surface to obtain an STL file; separating dentition from the STL file; cutting the separated upper dentition and lower dentition by using a resin block by using a CAD / CAM method; and resetting the cut dentition into an embedded female die cavity, and performing glue filling injection molding to finish manufacturing of the complete denture. The method disclosed by the invention is accurate and simple in manufacturing, the defect that the personalized polished surface is not fully formed due to direct forming of self-setting resin is overcome, the time of adjusting occlusion during tooth wearing is reduced, and the patient can rapidly adapt to a new complete denture.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Improved complete denture maxillary blank mold tray

The invention belongs to the technical field of dental molding apparatuses, and discloses an improved complete denture maxillary blank mold tray. The blank mold tray comprises a tray base located in the middle and a tray body composed of occlusion banks on the two sides. The positions of the occlusion banks correspond to alveolar ridge crests between the first premolar tooth and the second premolar tooth on the two sides of human teeth respectively. A tray handle connected with the tray base is arranged at one end of the tray body. A plurality of overflow discharge holes are evenly formed in the tray base. The width of the occlusion banks is gradually increased from one end close to the tray handle to the other end. Three fixing grooves are formed in the occlusion banks at intervals. Whenan impression is prepared from the maxillary blank mold tray, the primary occlusion position relation can be prepared; the length and the position of the tray handle cannot interfere with the motionsof an upper lip, operability is high, a patient can hardly be interfered with, a doctor can more easily observe whether the mandible of the patient stretches forwards or not, and the patient is more easy to control.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

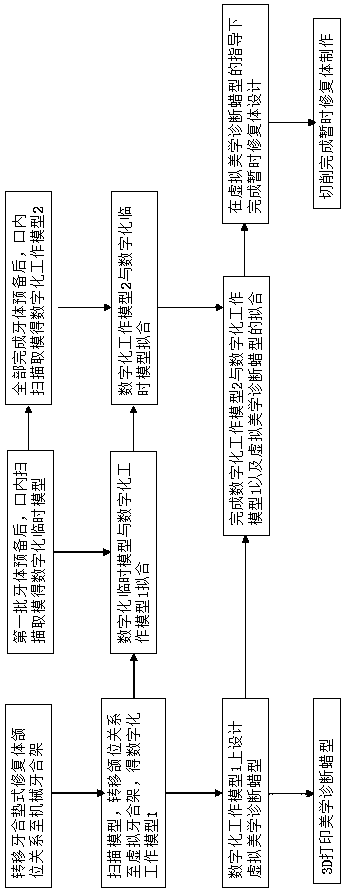

Method for transferring occlusion relationship and form design in dental occlusion reconstruction and restoration

ActiveCN111150507ASimple and accurate operationSave time and costImpression capsDental articulatorsTooth PreparationsDental occlusion

The invention discloses a method for transferring occlusion relationship and form design in dental occlusion reconstruction and restoration, belonging to the technical field of dental occlusion reconstruction and restoration. The method is characterized by comprising the following steps of: a, digitally scanning a model; b, designing a virtual aesthetic diagnosis wax pattern; c, performing 3D printing on the aesthetic diagnosis wax pattern; d, conducting tooth preparation and carrying out digital scanning for formulation of models; e, performing model fitting; and f, completing the design andmanufacturing of a temporary restoration body. According to the invention, data fitting is carried out twice, a working model completing tooth preparation is overlapped and fitted with the virtual aesthetic diagnosis wax pattern, and the jaw position relationship determined by an occlusal pad type restoration body is transferred to the temporary restoration body, so a tissue surface can be tightlyattached to butments after intraoral preparation, repeated relining, adjustment and modification of the temporary restoration body are not needed, and restoration efficiency and restoration precisionare greatly improved.

Owner:SICHUAN UNIV

Breather

InactiveCN103830813AAvoid self-closingEnsure first aid efficiencyRespiratorsEmergency treatmentBreather

Owner:岳安山

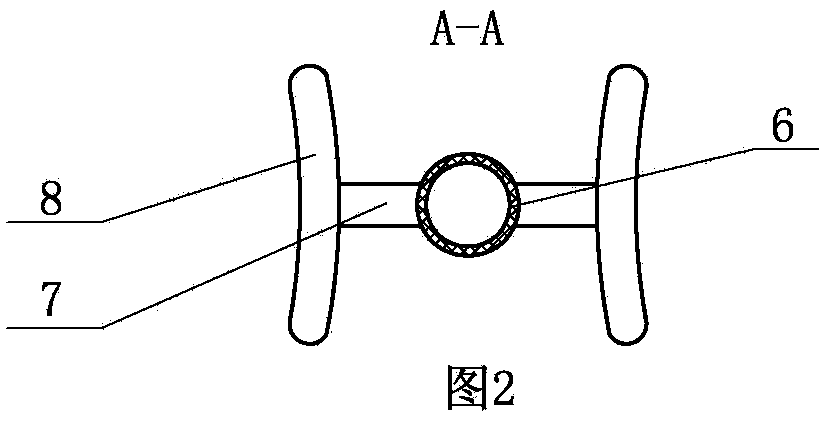

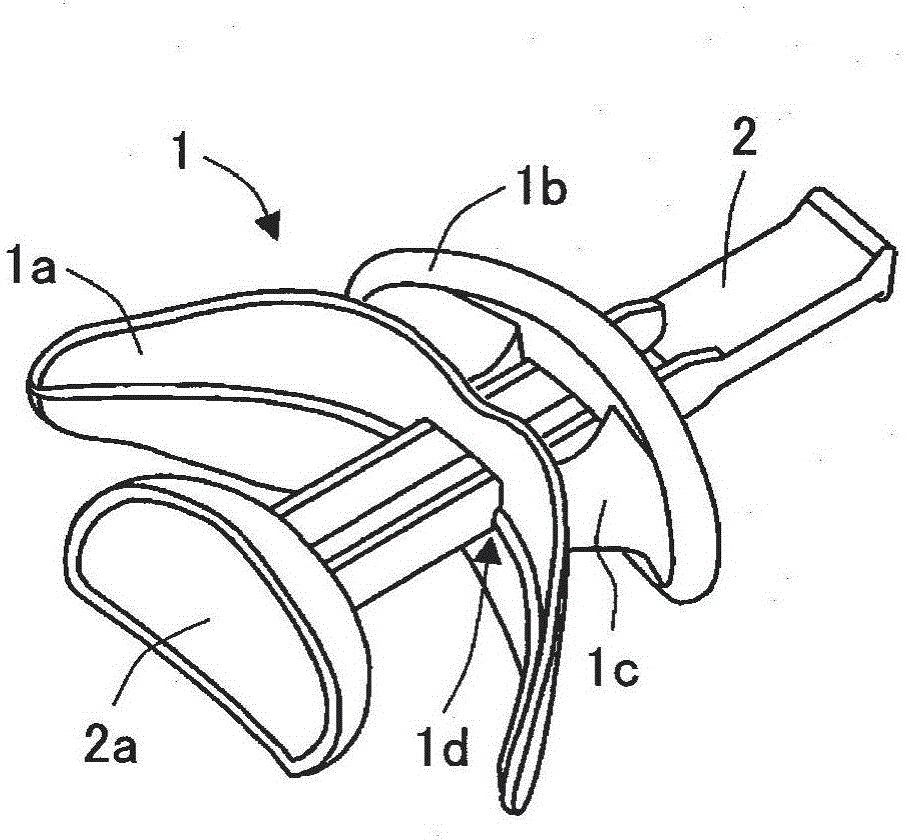

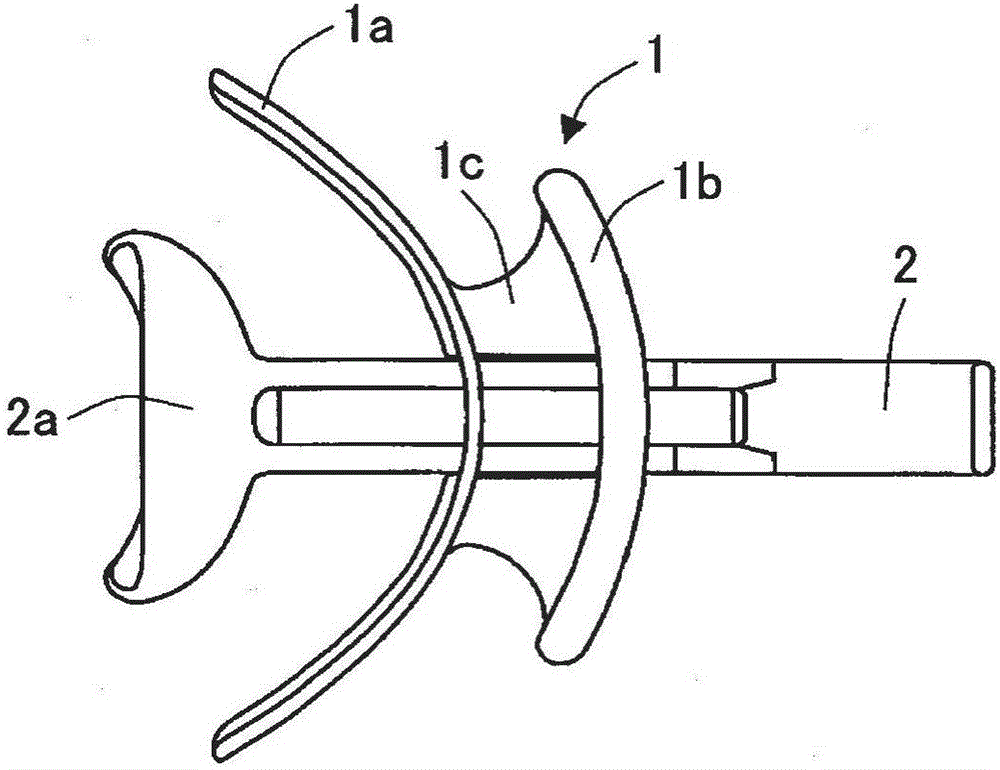

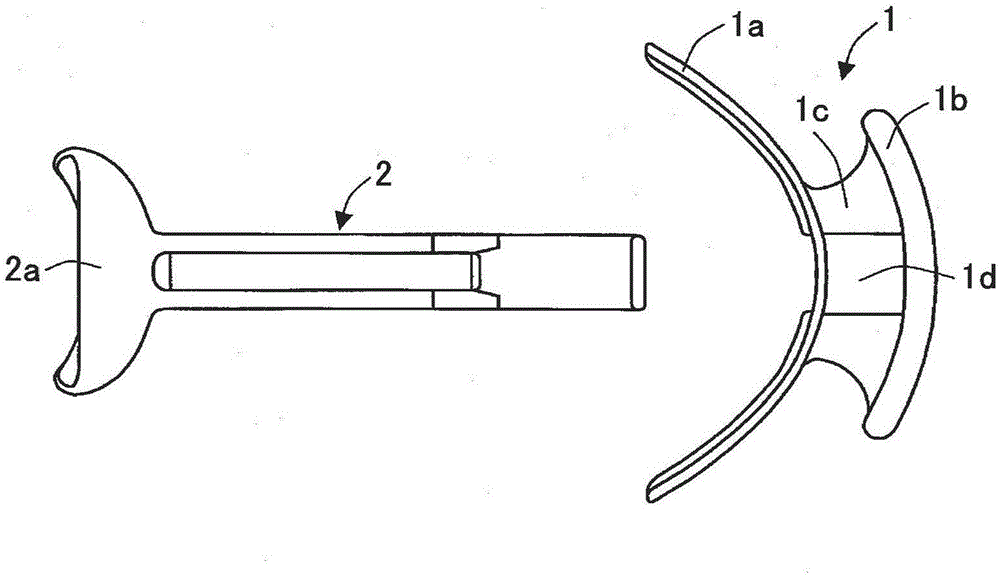

Tool for obtaining dental occlusion in patient with edentulous jaw

In the present invention, a tool for obtaining dental occlusion in a patient with an edentulous jaw is provided with: a main body (1) that has a rear-side curved plate (1a) which is positioned on the buccal side of the maxillary and mandibular residual ridges in the mouth cavity of a patient with an edentulous jaw, a front-side curved plate (1b) which is positioned on the extraoral-side of the upper and lower lips, a joining section (1c) for joining respective vertically intermediate sections of the rear-side curved plate (1a) and the front-side curved plate (1b), and a through hole (1d) formed penetrating through the rear-side curved plate (1a), the front-side curved plate (1b), and the joining section (1c), the main body being positioned and fixed in a state in which each of the upper and lower lips holds the joining section (1c); and an adjusting shaft (2) that is inserted into the through hole (1d) and that has a tongue support section (2a), one end of which projects out to the extraoral-side from the middle of the space between the upper and lower lips, and the other end of which retains the tip of the tongue inside the mouth cavity, the adjusting shaft (2) being for adjusting the position of the tongue support section (2a) and suppressing the movement of the tongue when dental occlusion is being obtained.

Owner:GC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com