Middle jaw tray, using method and manufacturing method applied to digital complete denture

A tray and mandibular technology, applied in the field of denture manufacturing devices, can solve the problems of inaccuracy, difficulty in measuring the relationship between the central jaw and the occlusal plane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

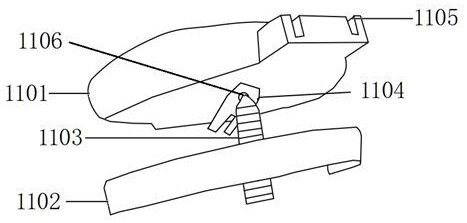

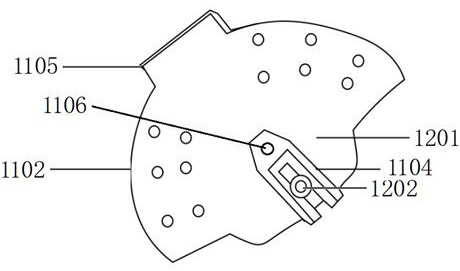

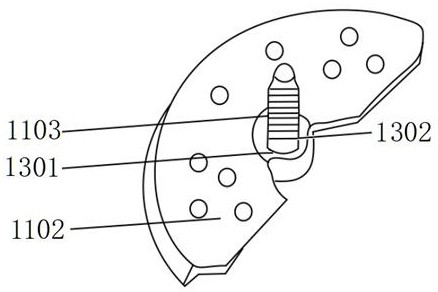

[0103] Such as Figure 1-3 As shown, a centric jaw tray includes an upper jaw tray 1101, a lower jaw tray 1102, an occlusal positioning pin 1103, an occlusal locator 1104, and an external interface 1105. 1201 is equipped with an occlusal locator 1104 through a set screw 1202, and the lower jaw tray 1102 is connected to the occlusal locator 1104 through an occlusal positioning pin 1103;

[0104] The external interface 1105 is arranged on the front end of the upper jaw tray 1101, and the external interface 1105 is connected to the handle interface 1401 or the facebow interface 1501;

[0105] Such as Figure 4 As shown, one end of the handle interface 1401 can be inserted into the external interface 1105 and fixed, and the other end of the handle interface 1401 clamps the middle end of the face bow ruler 1402, and the face bow ruler 1402 is parallel to the occlusal plane plate 1201;

[0106] Such as Figure 5 As shown, one end of the facebow interface 1501 can be inserted into...

Embodiment 2

[0109] Embodiment 2: A method of using the centric jaw tray, which includes the following steps:

[0110] Step 1: Assemble the upper jaw tray 1101 and the lower jaw tray 1102 into one;

[0111] Step 2: Place silicone rubber on the top surface of the maxillary tray 1101 and the bottom surface of the mandibular tray 1102 and put them into the patient's mouth to obtain the shape of the maxillary alveolar ridge and the shape of the mandibular alveolar ridge;

[0112] Step 3: Install the handle interface 1401 on the external interface 1105, connect the facebow ruler 1402 to the handle interface 1401, make the facebow ruler 1402 parallel to the occlusal plane 1201, and adjust the upper jaw tray 1101 by observing the position of the facebow ruler 1402 The front part of the facebow ruler 1402 is parallel to the pupil line, and the side is parallel to the nasal alar tragus line;

[0113] Step 4: Separate the maxillary tray 1101 from the mandibular tray 1102, insert the tracing needle ...

Embodiment 3

[0115] Example 3, a multifunctional final impression device

[0116] Such as Figure 6-7 As shown, a multi-functional final impression device, which includes a maxillary base 2101, a mandibular base 2102, a maxillary dentition 2201, a mandibular dentition 2202, and an external interface 2103. The bottom of the maxillary base 2101 is provided with matching maxillary teeth The maxillary dentition interface 2104 of row 2201, the top of the mandibular base 2102 is provided with the lower jaw dentition interface 2105 matching the lower jaw dentition 2202;

[0117] Such as Figure 8-9 As shown, the bottom of the maxillary base 2101 is provided with a tracing board interface 2504, the maxillary tracing board 2301 is connected to the tracing board interface 2504 and fixed with the maxillary base 2101, and a locator 2502 is installed on the maxillary tracing board 2301;

[0118] The top of the mandibular base 2102 is provided with a positioning plate interface 2401, the mandibular po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com