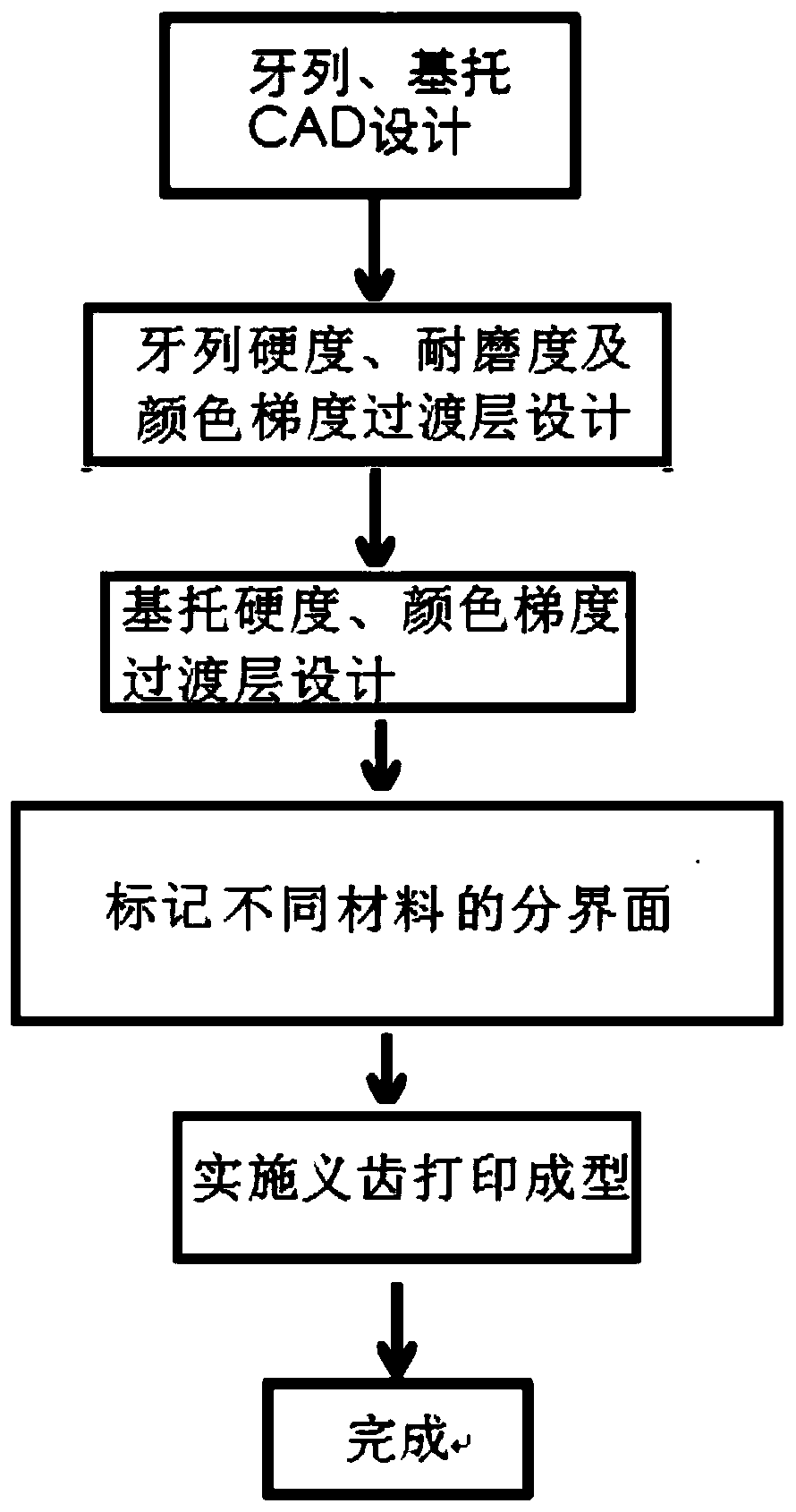

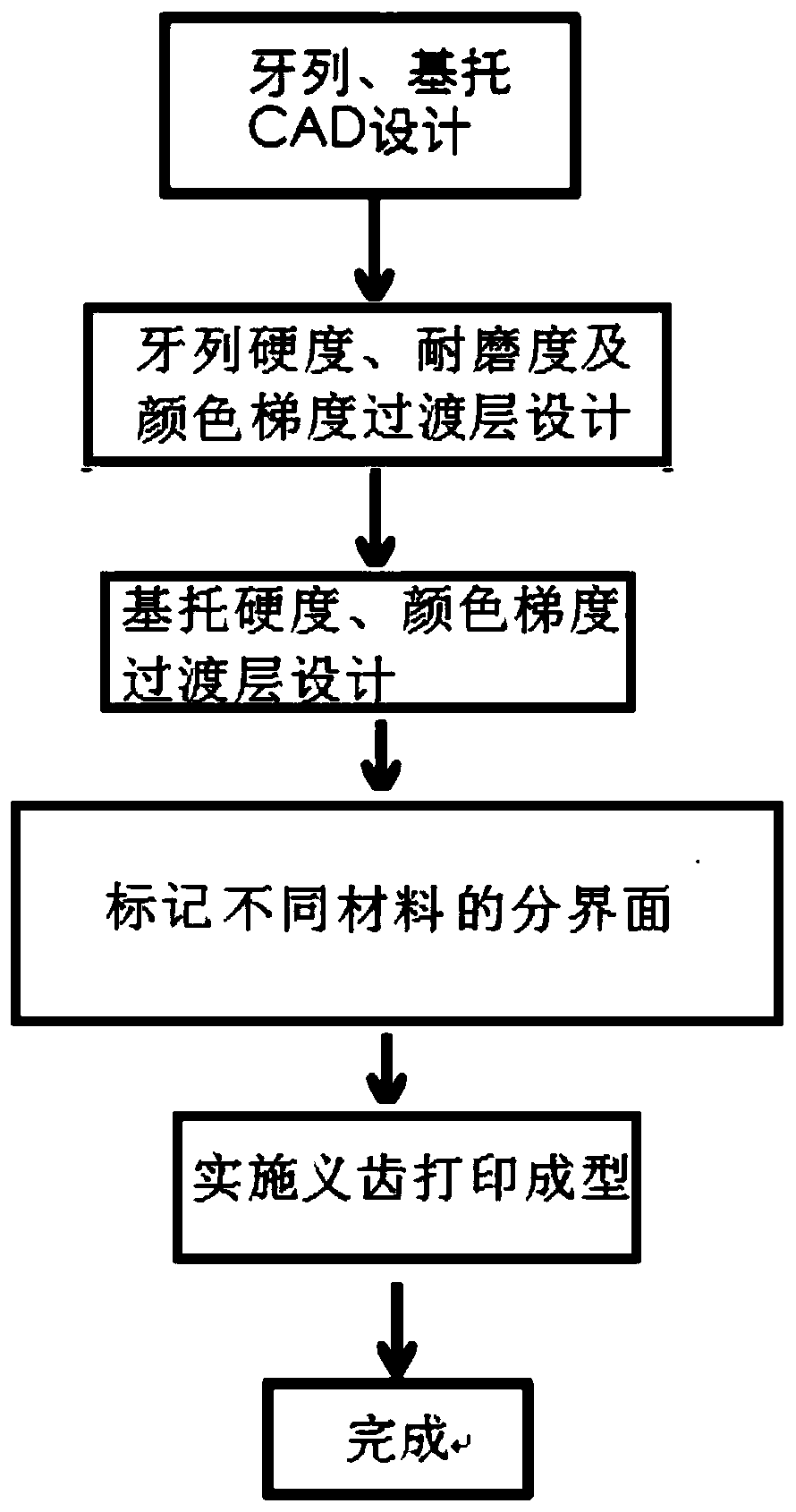

Mechanical and aesthetic gradient false tooth integrated design and 3D printing method

A 3D printing and denture technology, applied in 3D object support structures, metal processing equipment, household components, etc., can solve the problems of unable to solve the individual requirements of denture mechanics, unable to simplify the production procedures, etc., to improve the wear resistance and simplify the production. effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0026] Such as dentition: 1) The first layer has the highest hardness and is used for the occlusal surface. It uses ceramic fillers, PMMA with a mass ratio of 70-85%, the color is A1, and the translucency is 50%. The second layer has lower hardness and uses Pure PMMA, the color is A2, and the translucency is 30%; the third layer has the same hardness as the second layer, which is also pure PMMA, but the color is A3, and the translucency is 10%.

[0027] Gums: The first layer is pink in color; the second layer is red.

[0028] The PMMA material wires include base material wires and artificial tooth material wires. The base material wires are gingival pink, and the artificial tooth material wires are tooth white. They are divided into multiple types according to the chroma, saturation, and lightness of the color of the material wires. According to the clinical colorimetric results, different types of bases and artificial tooth material filaments can be individually selected and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com