Manufacturing method of repositioning biteplate for treating temporal-mandibular joint disc recoverable forward displacement and repositioning biteplate

A technology for temporomandibular joints and manufacturing methods, which is applied in the fields of processing and manufacturing, manufacturing auxiliary devices, and medical science. Simple and convenient effects to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The manufacturing method of the repositioning occlusal splint for treating the repositionable anterior displacement of the temporomandibular joint disc of the present invention comprises the following steps:

[0048] (1) The patient opens the mouth normally, let the patient protrude the mandible and close the mouth, find the position of the mandibular condyle when the mandible is protruding and in contact with the teeth, record and fix the position;

[0049] Among them, the determination of the position of the mandibular condyle is that when the patient opens his mouth, after the bilateral or unilateral mandibular joints pop and the mouth reaches the maximum, the mandible protrudes forward and closes the mouth to the position where the upper and lower incisal edges or cusps touch in a point-like manner. Open the mouth and close the mouth again and reciprocate the mandibular protruding position. After the bilateral or unilateral mandibular joints do not appear popping sou...

Embodiment 2

[0061] The manufacturing method of the occlusal splint for treating temporomandibular joint disc displacement of the present invention comprises the following steps:

[0062] (1) The patient opens the mouth normally, let the patient protrude the mandible and close the mouth, find the position of the mandibular condyle when the mandible is protruding and in contact with the teeth, record and fix the position;

[0063] Among them, the position of the mandibular condyle is determined when the patient’s mandible is protruded, and after bilateral or unilateral mandibular joints have popping sounds and reach the maximum, the mandible is protruded and closed to the position where the incisal edges of the upper and lower anterior teeth are opposite, and the mouth is opened and closed again. Reciprocate the mandibular protruding position. After the bilateral or unilateral mandibular joints do not appear popping sound, if it still occurs, continue to protrude and adjust the mandibular po...

Embodiment 3

[0076] The accompanying drawing is only a structural diagram, and those skilled in the art can obtain a structural diagram that meets clinical needs by combining the accompanying drawings and clinical practice.

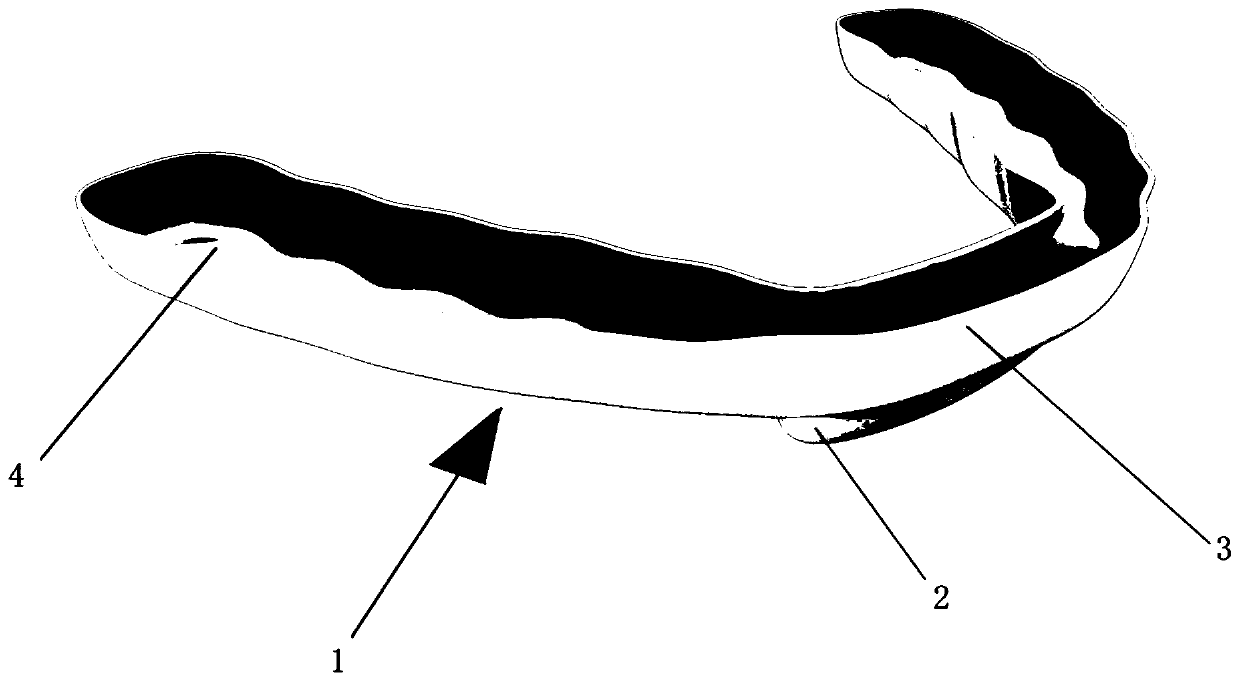

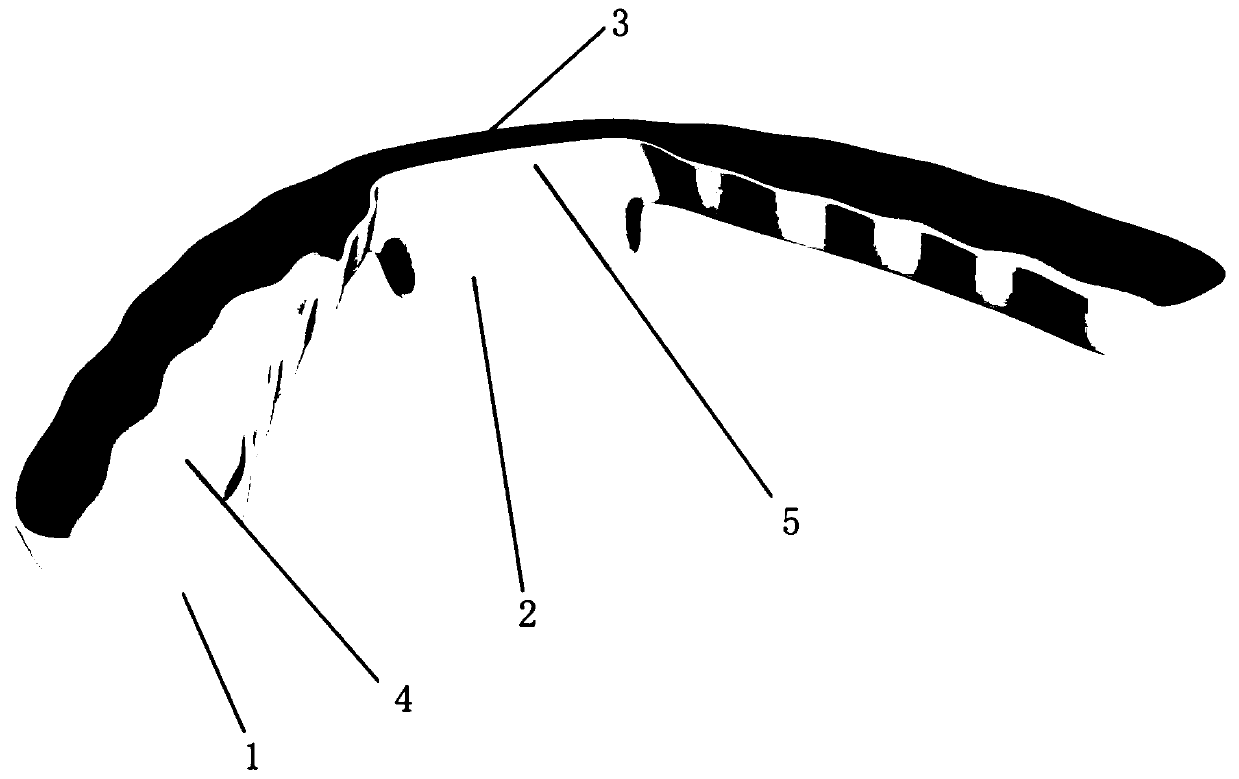

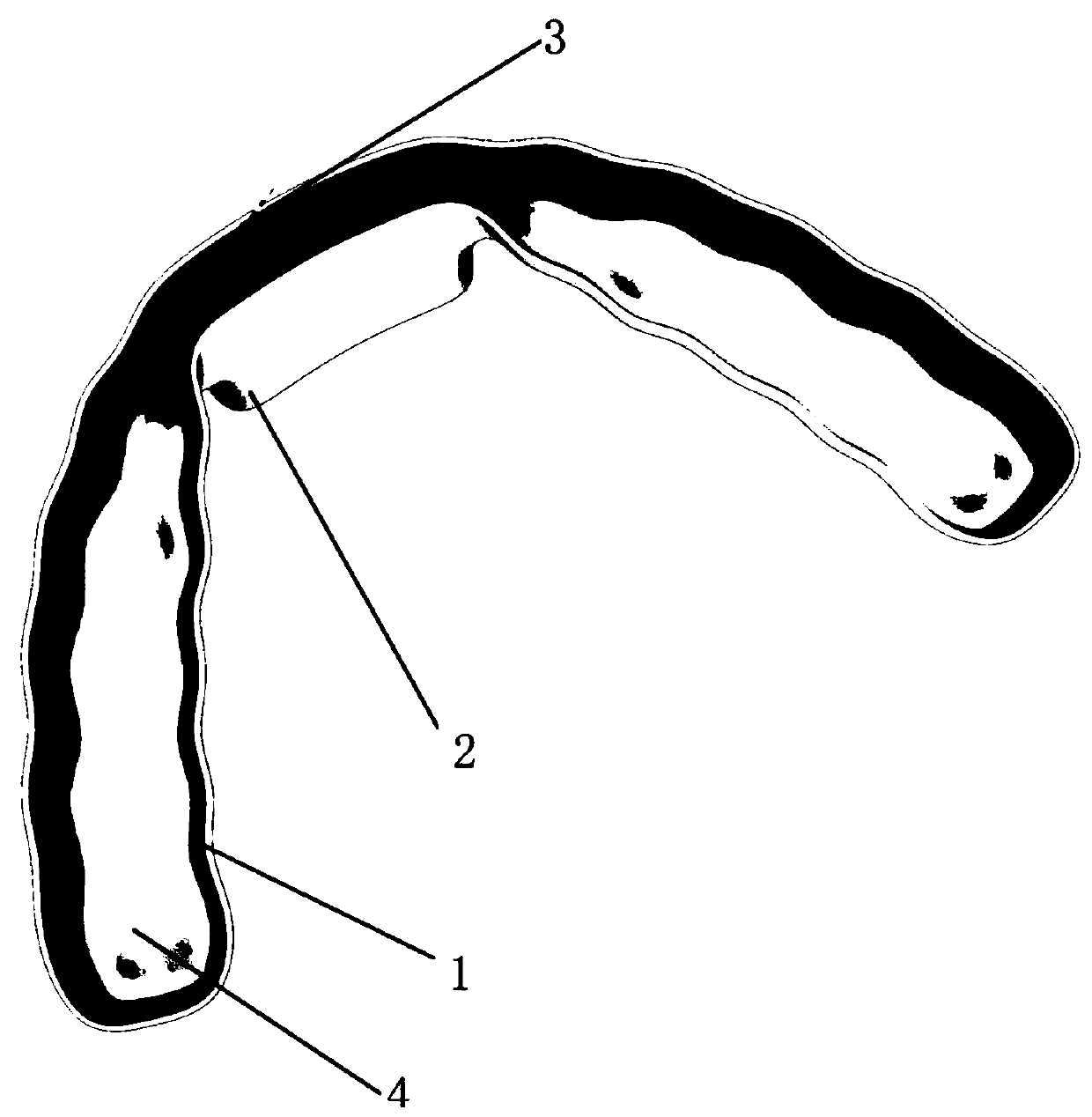

[0077] As shown in the figure, the repositioning occlusal splint for the treatment of the repositionable anterior displacement of the temporomandibular joint disc of the present invention includes 2 pairs of continuous symmetrical molar occlusal sleeves 1 that coincide with the upper dentition, and dental occlusal sleeves 1 on both sides. Connected by the connecting plate, tooth placement holes 4 are correspondingly set in the occlusal sleeve, the connecting plate is arranged on the inner and outer sides, and the shape of the inner connecting plate and the outer connecting plate is consistent with the inner and outer sides of the upper jaw or the top of the upper dentition. The shape of the inner bottom surface of 1 is consistent with the bottom surface of the teeth of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com