Manufacturing method for personalized bracket for repairing of center plane across mandibular defect

A central plane and manufacturing method technology, applied in the direction of bone implants, etc., can solve the problems of irreparable, fast absorption and unable to provide good mechanical support, so as to promote and guide bone growth, good stress structure, and good bone growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better explain the present invention, the present invention will be further explained below in combination with specific embodiments.

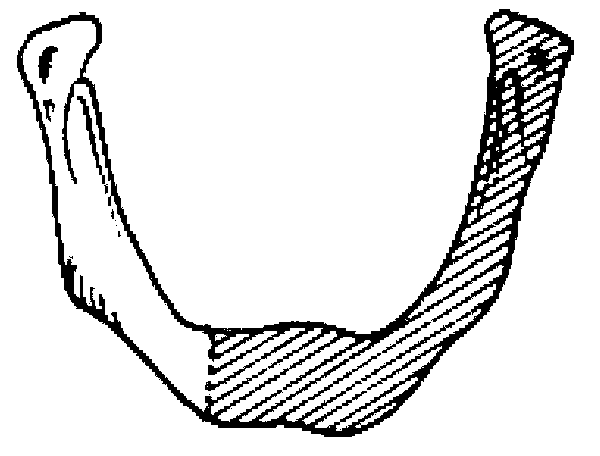

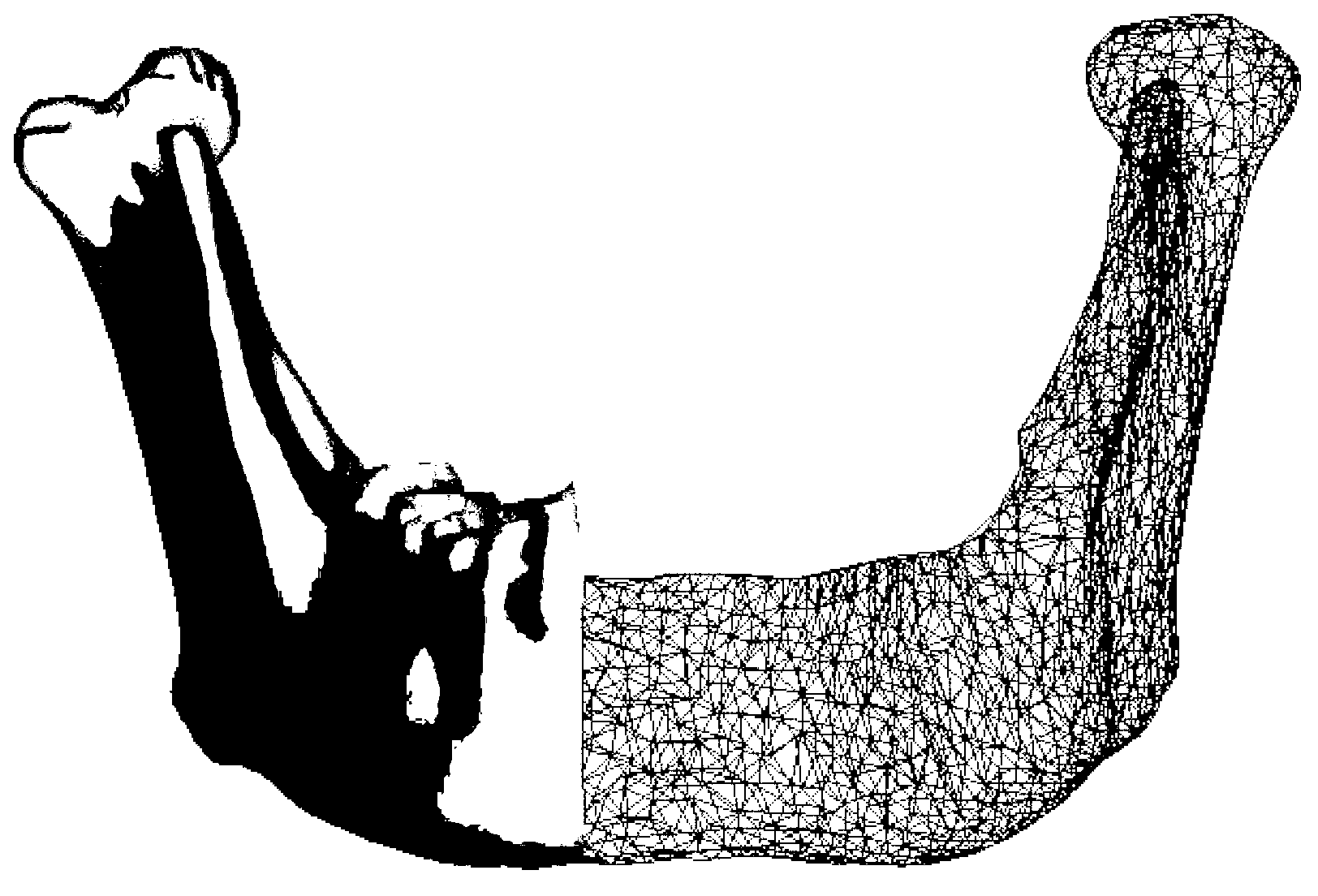

[0033] like figure 1 As shown, the defect is located from the mandibular right incisor to the left mandibular ramus and condyle, with a size of about 8-10cm.

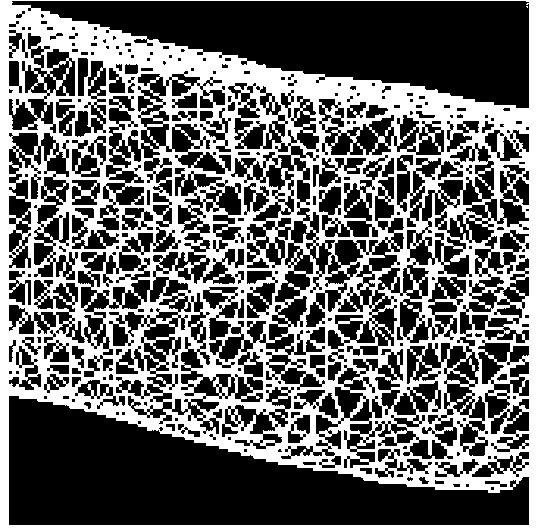

[0034] Firstly, perform spiral CT scanning on the mandibular defect: the MX-8000 spiral CT produced by Philips Company is used for scanning, the scanning plane is parallel to the orbito-auricular plane, and the scanning range is from the upper orbital edge to the lower edge of the mandible to obtain the patient's original cross-section image. Then use the 3D visualization technology and the 3D reconstruction software 3DMSR (3-Dimensional Medicine Surface Rendering) independently written by Jima Fei Company to carry out 3D reconstruction of these discrete data, transform it into an image with an intuitive three-dimensional effect, and obtain the mandible in STL format...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com