Image recognition and processing system on automatic tracking dispensing equipment

An automatic tracking and image recognition technology, applied in the fields of intelligent manufacturing, equipment automation, and fluid control, can solve the problems of inability to meet the production line of small batches, multiple batches, and multiple types of product production scenarios, poor flexibility, time-consuming and labor-intensive, etc. Achieve the effect of improving production efficiency, equipment reuse rate, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

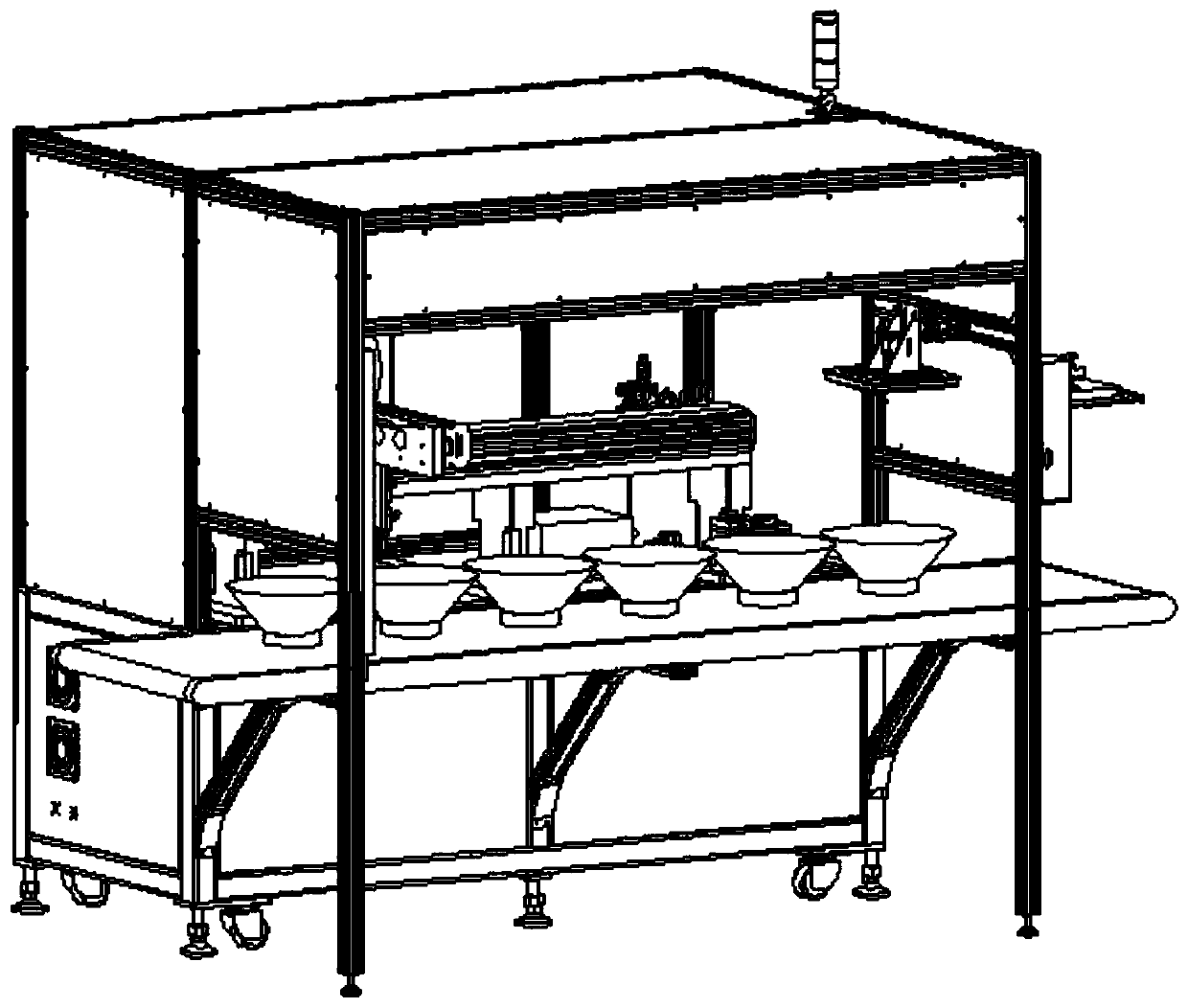

[0039] A preferred embodiment of this program

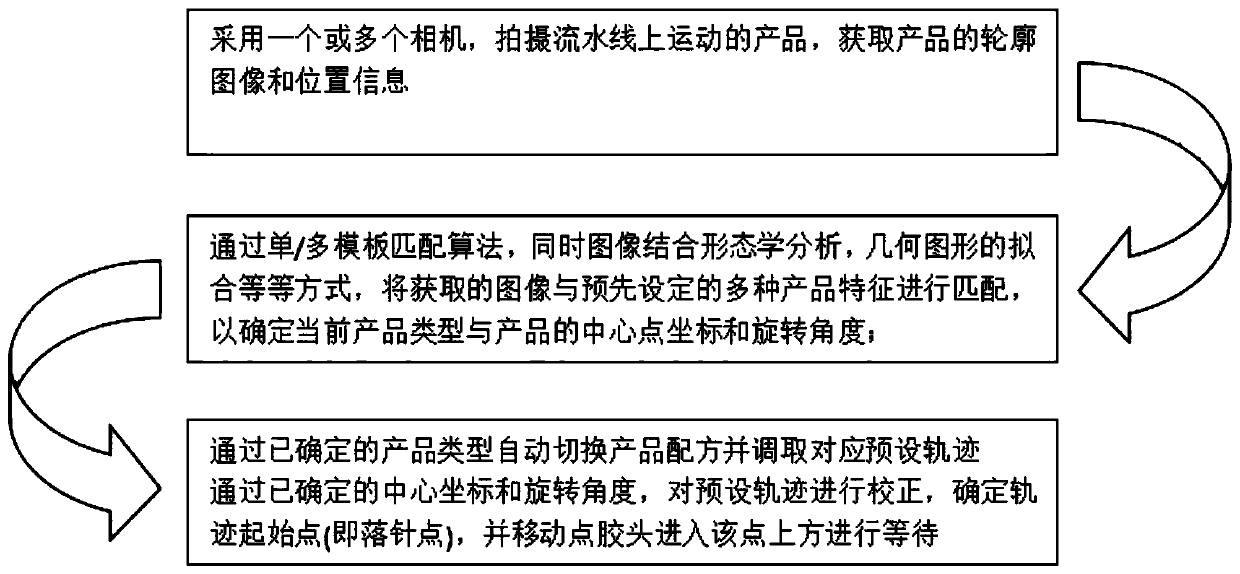

[0040] image acquisition

[0041] One or more cameras are used to shoot the products moving on the assembly line, obtain the profile images of the incoming materials and record the position information. Generally, a combination of 2D camera and 3D line laser scanning is used to fit the shape of the material through 2D images and 3D contours.

[0042] The specific process of image acquisition consists of two sub-steps:

[0043] A. Build a suitable optical system, select a suitable light source combination and installation angle according to the characteristics of the incoming material and the background environment, and select a suitable high-resolution camera lens (this model uses an 8mm wide-angle lens to obtain a large field of view of 400*400mm Range), adjust the appropriate camera parameters (exposure value, gain value, etc.) to obtain a high-quality original image with uniform brightness;

[0044] B. Distortion correction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com