Testing method for simulating corrosion process of carbon steel in atmospheric environment with different ultraviolet radiation intensities

A technology of atmospheric environment and test method, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of insufficient rigor and achieve the effect of increasing authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

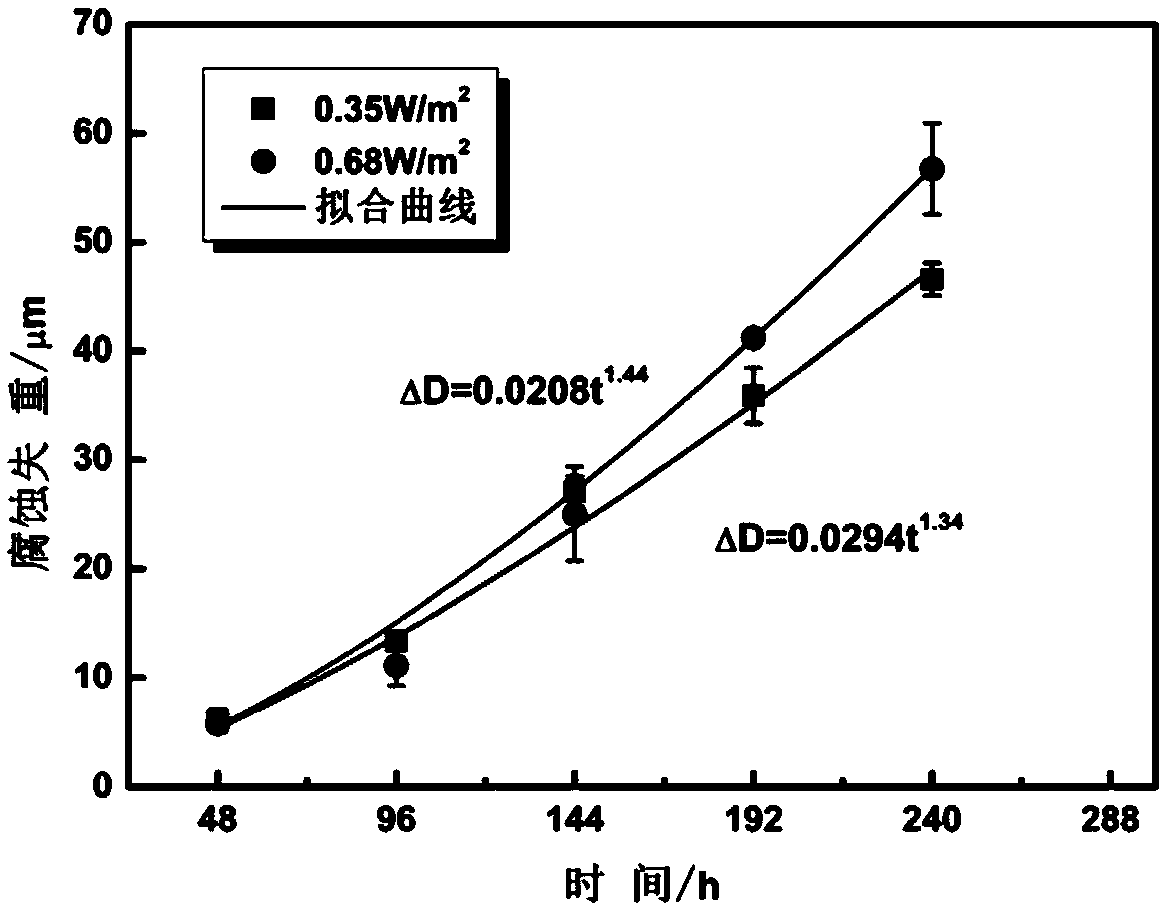

[0019] The influence of different ultraviolet radiation doses on the corrosion behavior of carbon steel in simulated South China Sea atmospheric environment. The test material is carbon steel, and its composition is shown in Table 1.

[0020] Table 1 Chemical composition of carbon steel

[0021]

[0022] The test conditions are as follows: the seawater retrieved from the South China Sea (see Table 2 for composition) was pre-deposited on the surface of the sample, and after drying, it was cycled every 6 hours according to the sequence of "condensation 2h (wetting)→irradiation 4h (drying)". Deposit the corrosive solution once in 4 cycles to supplement the amount of corrosive medium on the surface of the carbon steel. Cycle process:

[0023] 1) The condensation stage is 40°C, 2h; the irradiation stage is 60°C, 0.35W / m 2 , 4h.

[0024] 2) The condensation stage is 40°C, 2h; the irradiation stage is 60°C, 0.68W / m 2 , 4h.

[0025] The sampling periods are 48, 96, 144, 196 a...

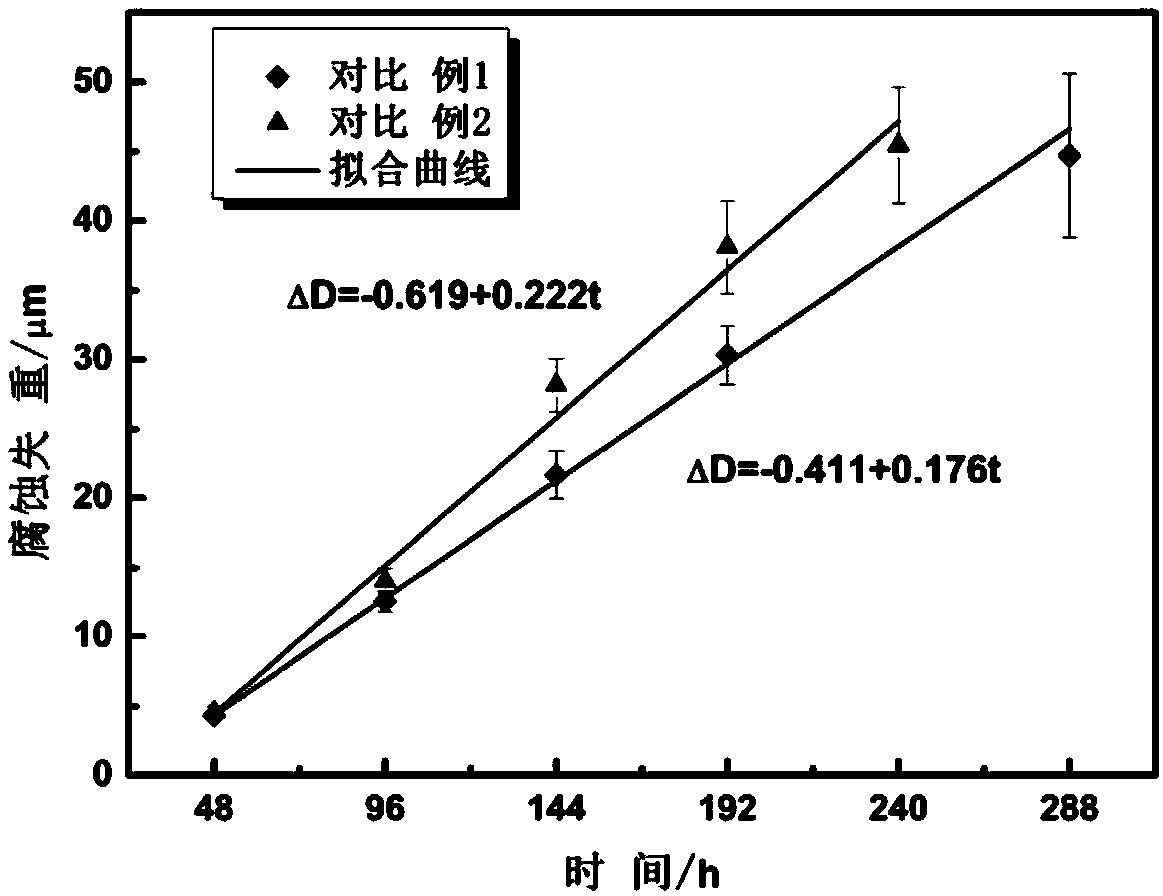

Embodiment 2

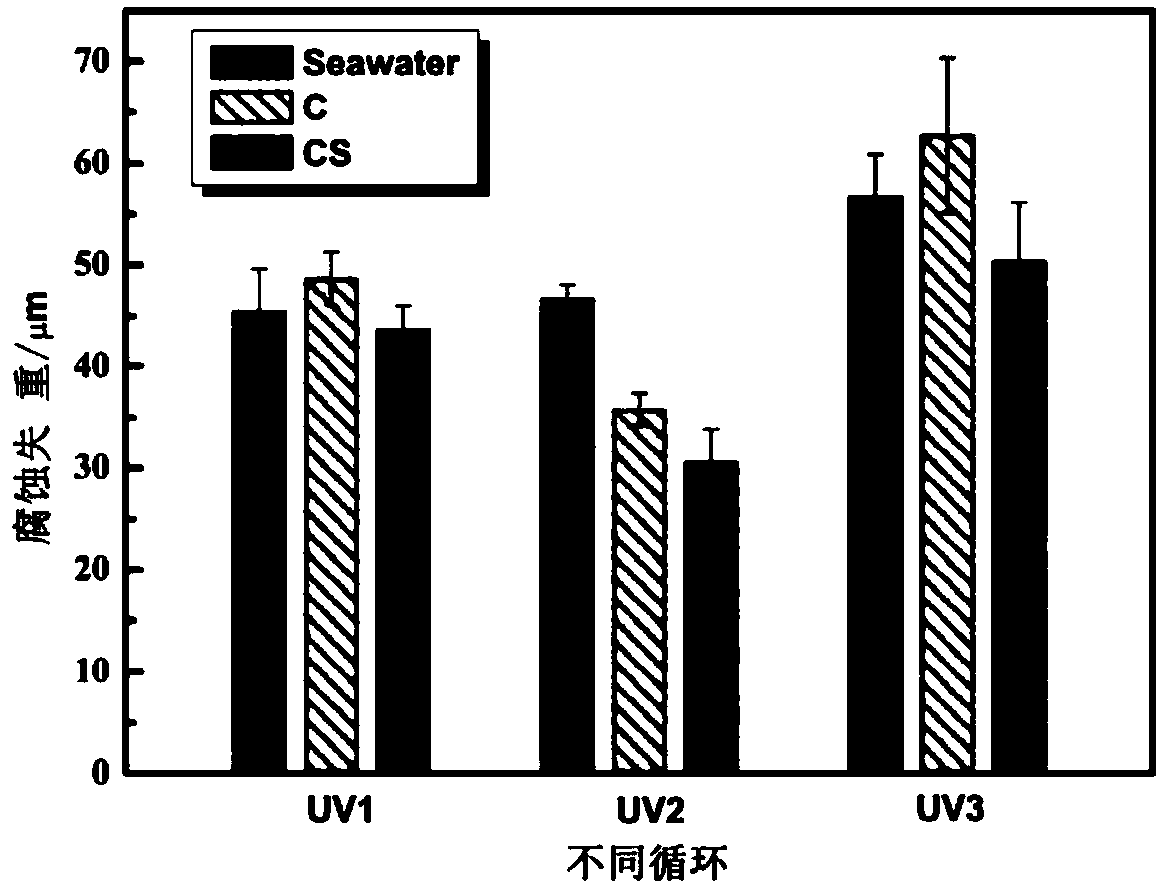

[0034] Simulate the effect of different UV radiation doses on the corrosion behavior of carbon steel in different corrosive media. The test conditions are as follows: 33g / L NaCl solution and 33g / L NaCl+3.2g / L NaCl respectively 2 SO 4 The mixed solution (hereinafter referred to as C and CS respectively, the solution concentration keeps the Cl in the solution - and SO 4 2- Concentrations are consistent with seawater) pre-deposited on the surface of the sample, after drying, cycle every 6 hours in the order of "condensation 2h (wetting)→irradiation 4h (drying)", deposit corrosion solution every 4 cycles, and replenish carbon The amount of corrosive medium on the steel surface. The cycle process is carried out in the following three ways:

[0035] 1) UV1: condensation stage is 40°C, 2h; irradiation stage is 60°C, 0W / m 2 , 4h.

[0036] 2) UV2: condensation stage is 40°C, 2h; irradiation stage is 60°C, 0.35W / m 2 , 4h.

[0037] 3) UV3: condensation stage is 40°C, 2h; irradia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com