Test method for stimulating corrosion process of low-alloy steel in atmospheric environment in salt lake

A low-alloy steel, atmospheric environment technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

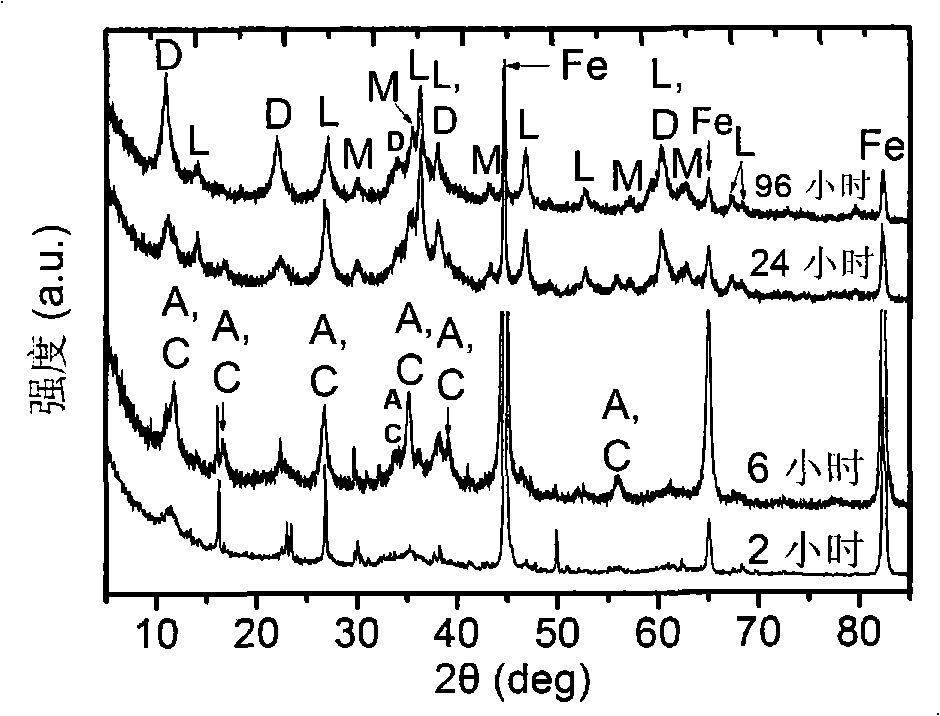

[0033] The test material is the above-mentioned Corten A weathering steel, and the saline lake water diluted 20 times with distilled water is used as the corrosion medium, and the cycle is repeated every 20 minutes in the order of "dipping→drying→wetting", among which: dipping at 40°C for 2min; drying at 50°C 15min; wet at 40°C, 3min; test time is 6 hours. The rust layer on the surface of the sample contains a large amount of foreign elements such as Cl and Mg. From figure 1 It can be seen from the X-ray diffraction spectrum of the corrosion products in the medium that the rust layer is mainly composed of β-FeOOH, Fe 8 (O,OH) 16 Cl 1.3 and γ-FeOOH; Among them, A: β-FeOOH; L: γ-FeOOH; M: Fe 3 o 4 ; C: Fe 8 (O,OH) 16 Cl 1.3 ; D: Mg 4 Fe(OH) 8 OCl·xH 2 O.

Embodiment 2

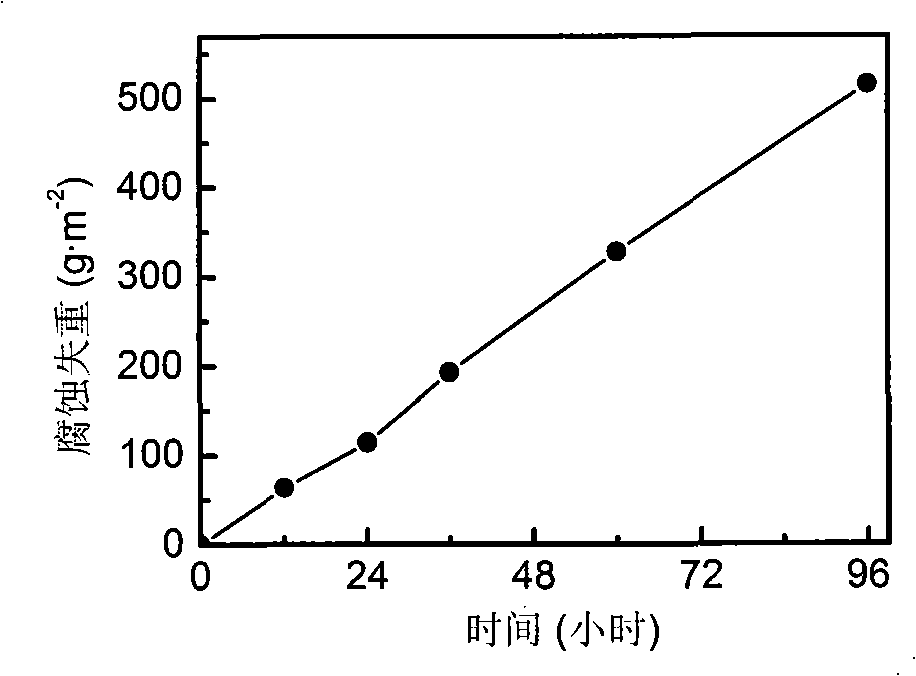

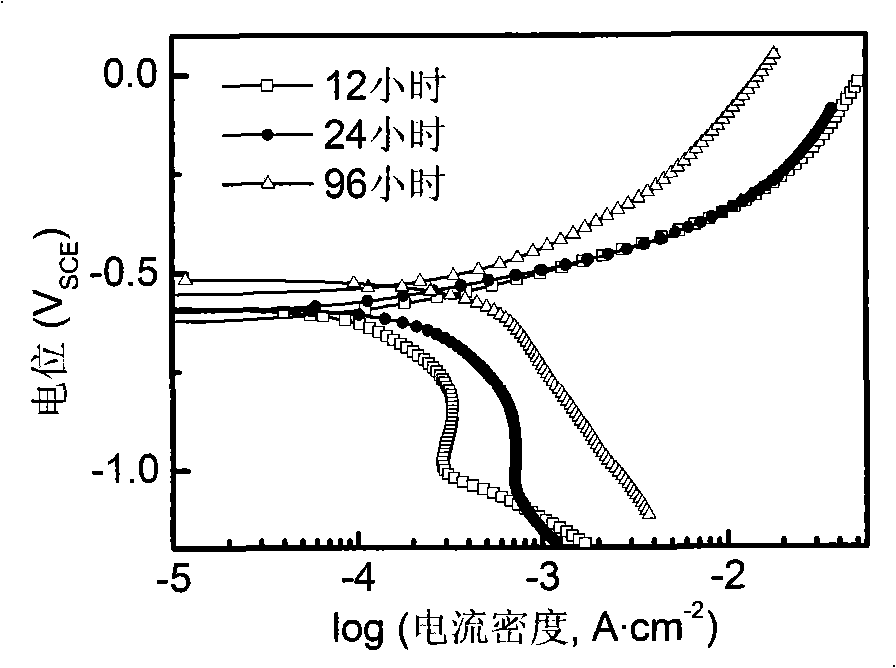

[0035] The test material is the above-mentioned Corten A weathering steel, and the saline lake water diluted 20 times with distilled water is used as the corrosion medium, and the cycle is repeated every 20 minutes in the order of "dipping→drying→wetting", among which: dipping at 40°C for 2min; drying at 50°C 15min; wet at 40°C, 3min; test time is 12 hours. Such as figure 2 As shown, the corrosion amount of the 12-hour sample is 63.32g m -2 . The rust layer contains a large amount of foreign elements such as Cl and Mg. From image 3 It can be seen from the electrochemical polarization curve that the anodic current of the 12-hour sample increases exponentially with the potential. The cathodic current varies little with the increase of potential and is controlled by oxygen diffusion. Rust layer resistance R of the sample R The value is 4.09Ω·cm 2 .

Embodiment 3

[0037] The test material is the above-mentioned Corten A weathering steel, and the saline lake water diluted 20 times with distilled water is used as the corrosion medium, and the cycle is repeated every 20 minutes in the order of "dipping→drying→wetting", among which: dipping at 40°C for 2min; drying at 50°C 15min; wet at 40°C, 3min; test time is 24 hours. From figure 1 It can be seen from the X-ray diffraction spectrum of corrosion products that the rust layer is mainly composed of β-FeOOH, Fe 8 (O,OH) 16 Cl 1.3 , γ-FeOOH, Fe 3 o 4 and Mg 4 Fe(OH) 8 OCl·xH 2 O. Compared with the 6-hour sample, the corrosion product of the 24-hour sample appeared a new phase Fe 3 o 4 and Mg 4 Fe(OH) 8 OCl·xH 2 O. Such as figure 2 As shown, the corrosion amount of the 24-hour sample is 114.06g m -2 . The rust layer contains a large amount of foreign elements such as Cl and Mg. From image 3 From the electrochemical polarization curve, it can be seen that the polarization cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com