Test method for simulating corrosion course of low alloy steel under marine industrial atmospheric environment

A low-alloy steel and atmospheric environment technology, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The test material is the above-mentioned low-alloy steel P265GH, and a certain concentration ratio of NaCl and NaHSO is prepared in advance. 3 solution, the solvent is distilled water and absolute ethanol mixed at a volume ratio of 1:1. In the present embodiment, calculate the concentration of the prepared solution according to the following formula:

[0042] C NaHSO3 =S×R SO3 × M NaHSO3 ×k / (V×M SO3 ) (1)

[0043] C NaCl =S×R Cl × M NaCl ×k / (V×M Cl ) (2)

[0044] in:

[0045] The surface area of a single surface of the sample S = 2.4cm × 2.0cm = 4.80cm 2 ;

[0046] Amplification factor k=10, unit is d (day);

[0047] The volume V of the salt solution taken by the micro-sampler = 10×10 -3 mL;

[0048] The sulfation rate R of the actual atmosphere in the simulated area SO3=1.154mg / 100cm 2 d(day);

[0049] The sedimentation rate R of sea salt particles in the simulated area Cl =0.079mg / 100cm 2 d(day);

[0050] m NaHSO3 , M SO3 , M NaCl...

Embodiment 2

[0054] The test material is the above-mentioned low-alloy steel P265GH, and a certain concentration ratio of NaCl and NaHSO is prepared in advance. 3 solution, the solvent is distilled water and absolute ethanol mixed at a volume ratio of 1:1. In this example, NaHSO 3 The concentrations of NaCl and NaCl are the same as in Example 1, being 72mg / mL and 6.24mg / mL respectively.

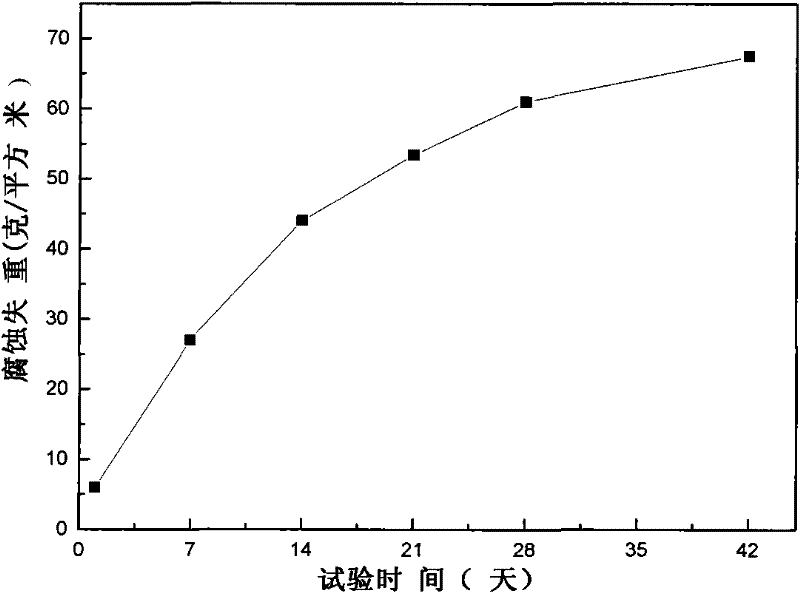

[0055] Use a micropipette to take 10 μL of the solution and apply it evenly on both surfaces of the sample, and then dry it slowly with a hair dryer. Cycle once every 24 hours according to the sequence of "wet→dry", in which: the test temperature is 30°C, the wet and dry processes are both 12h, the relative humidity of the wet and dry processes are 80% and 10% respectively, and the test time is 1, 7 , 14, 28, 42 days. From image 3 It can be seen from the curve of simulated corrosion weight loss versus time in the simulation test that the corrosion weight loss of the simulated test is in line with the...

Embodiment 3

[0056] Embodiment 3 (comparative example)

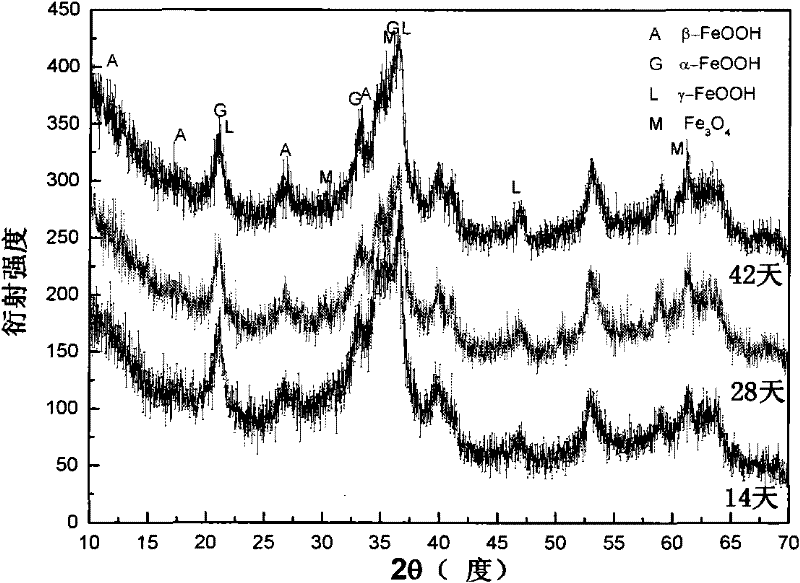

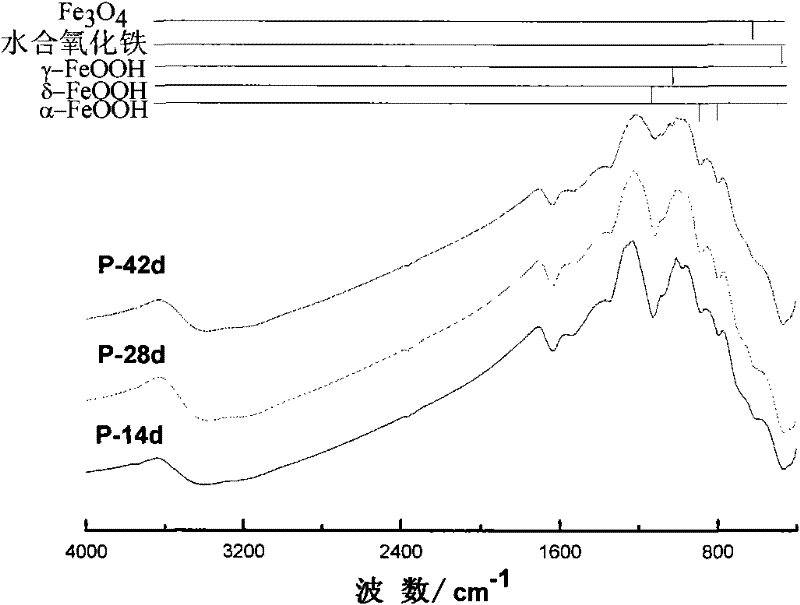

[0057] According to the ISO-4542 standard, the atmospheric exposure test of low alloy steel P265GH was carried out in a coastal area of Liaoning, and the time was 3, 6 and 12 months respectively. From Figure 5 It can be seen that the corrosion weight loss of the samples increases with the increase of exposure time. The X-ray diffraction spectrum of corrosion products shows that the rust layer is mainly composed of β-FeOOH, α-FeOOH and γ-FeOOH ( Figure 4 ). Table 2 shows the comparison of element distribution in the cross-section of the outdoor exposure test for 6 months and the indoor simulation test for 14 days. The rust layer cross-sections all contain foreign elements such as Cl and S.

[0058] Table 2. Comparison of cross-sectional element distribution between outdoor exposure test and indoor simulation test

[0059]

[0060] It can be seen from the examples and comparative examples that the corrosion weight loss of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com