Accelerated testing apparatus for simulation of corrosion by industrially polluted atmosphere

A technology that pollutes the atmosphere and accelerates the test. It is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., which can solve problems such as corrosion, achieve good reproducibility, and increase the use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

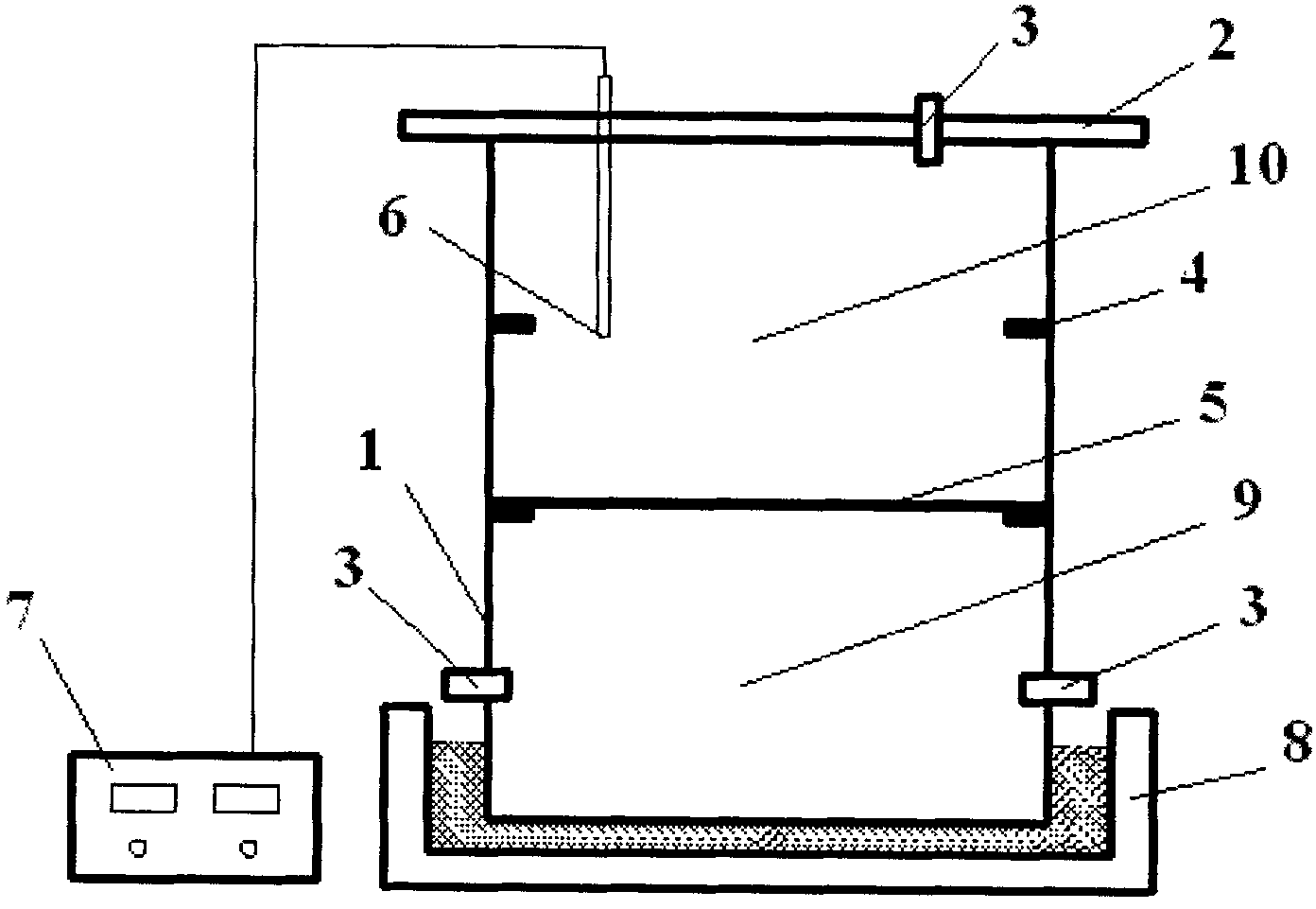

[0026] Such as figure 1 As shown, the accelerated test device for simulating industrial pollution atmospheric corrosion of the present invention mainly includes: reaction box 1, case cover 2, intake and exhaust pipe 3, sample rack 4, sample tray 5, temperature and humidity monitoring probe 6, temperature and humidity meter Display monitor 7, temperature control device 8, atmosphere generating chamber 9, corrosion chamber 10, etc., the specific structure is as follows:

[0027] The inner cavity of the reaction box 1 is divided into upper and lower chambers, the upper chamber is an accelerated corrosion chamber 10 , and the lower chamber is an atmosphere generating chamber 9 . A box cover 2 is movably installed on the top of the reaction box 1, and an inlet and exhaust pipe 3 and a temperature and humidity monitoring probe 6 are inserted into the box cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com