Patents

Literature

191 results about "Polluted atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air pollution is an unwanted change in the quality of earth's atmosphere caused by emission of gases due to burning of fossil fuels, outpouring of ashes and gases from the particulate matter due to soil erosion. Pollen and organic compounds from vegetation and lightening strokes also pollute the atmosphere.

Method for synchronous desulfurization and denitrification of marine vessel exhaust

InactiveCN101822937AShort stayStrong oxidation abilityDispersed particle separationAir quality improvementDecompositionSeawater quality

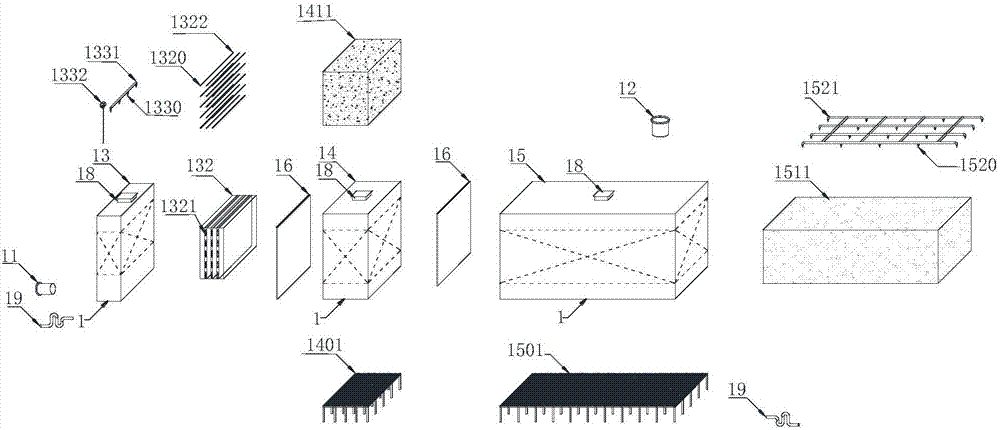

The invention discloses a method for synchronous desulfurization and denitrification of marine vessel exhaust, which belongs to the field of the air pollution control and the marine vessel exhaust emission control. In the method, exhaust passes through a spray humidification and cooling zone, an ozone decomposition and free radical oxidation zone and a seawater washing zone in sequence, thereby realizing synchronous desulfurization and denitrification. The spray humidification and cooling zone which consists of a small seawater pump, an exhaust humidification and cooling pipeline and a spray nozzle can humidify and cool the exhaust; the ozone decomposition and free radical oxidation zone which consists of an ozone decomposition and free radical oxidation device, an ultraviolet lamp and an ozone generator can rapidly convert SO2 and NO into hydroxyl acid and nitric acid through hydroxyl and the like; and the seawater washing zone which consists of a seawater washing tower, a filler and a large seawater pump can convert the hydroxyl acid and the nitric acid into sulfate and nitrate and discharge the exhaust and washing water meeting standards. The synchronous desulfurization and denitrification system formed through the invention has the advantages that the size is small, no seawater quality restoration system and raw material storage and transportation are needed, the products can be directly discharged into the sea, and the like.

Owner:WUHAN TEXTILE UNIV

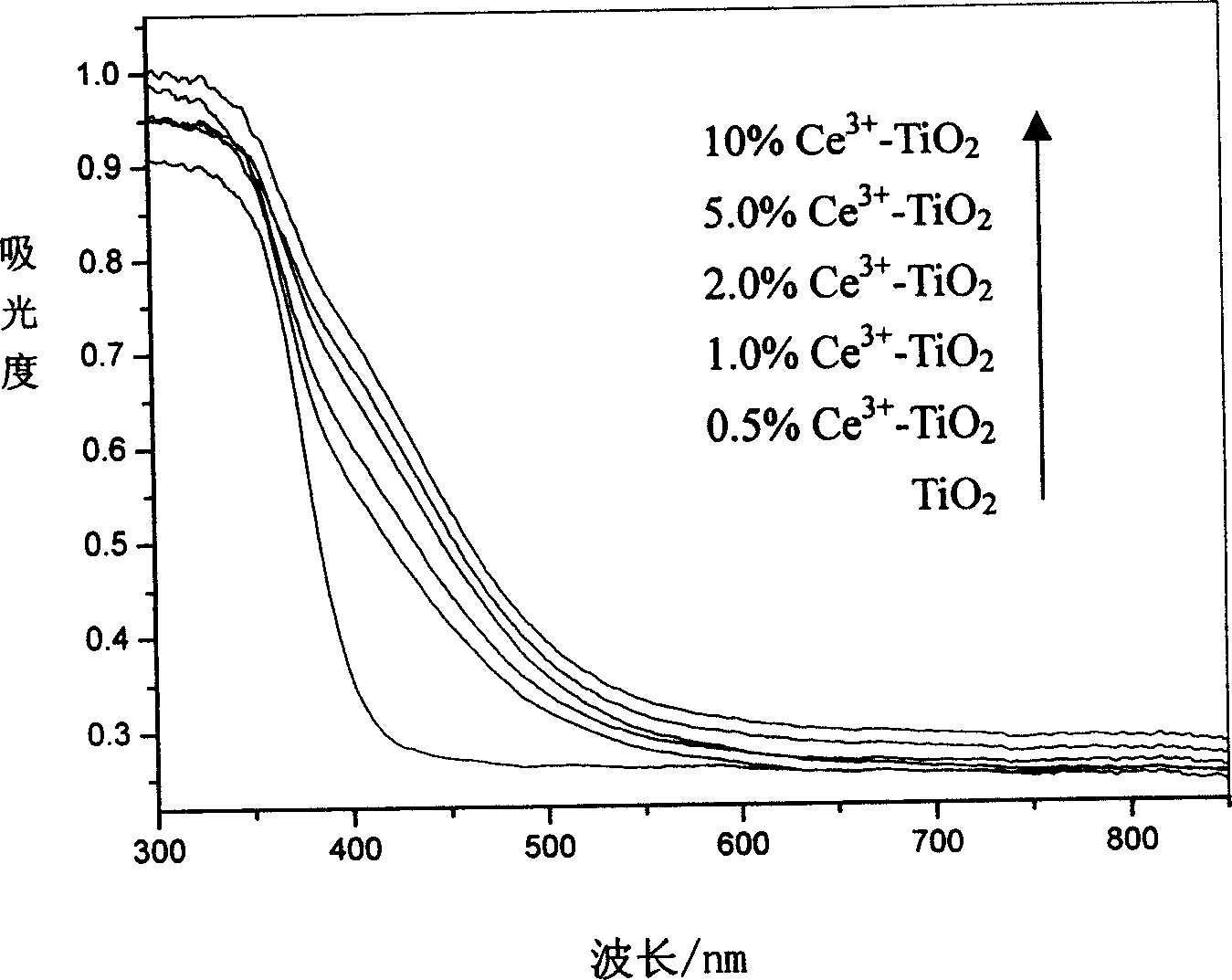

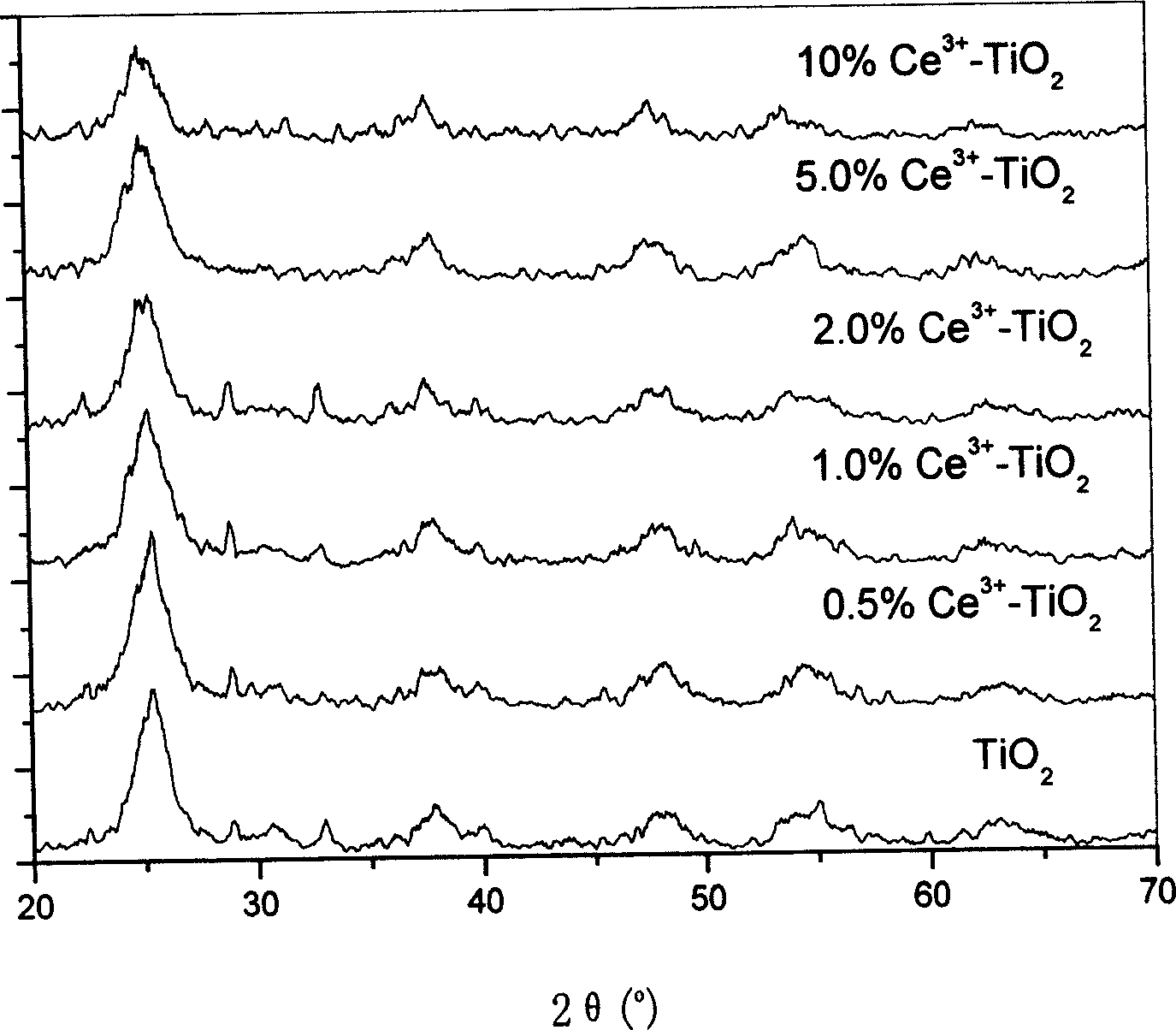

Preparation method of visible light photoactivated octahedrite type titanium oxide colloidal sols

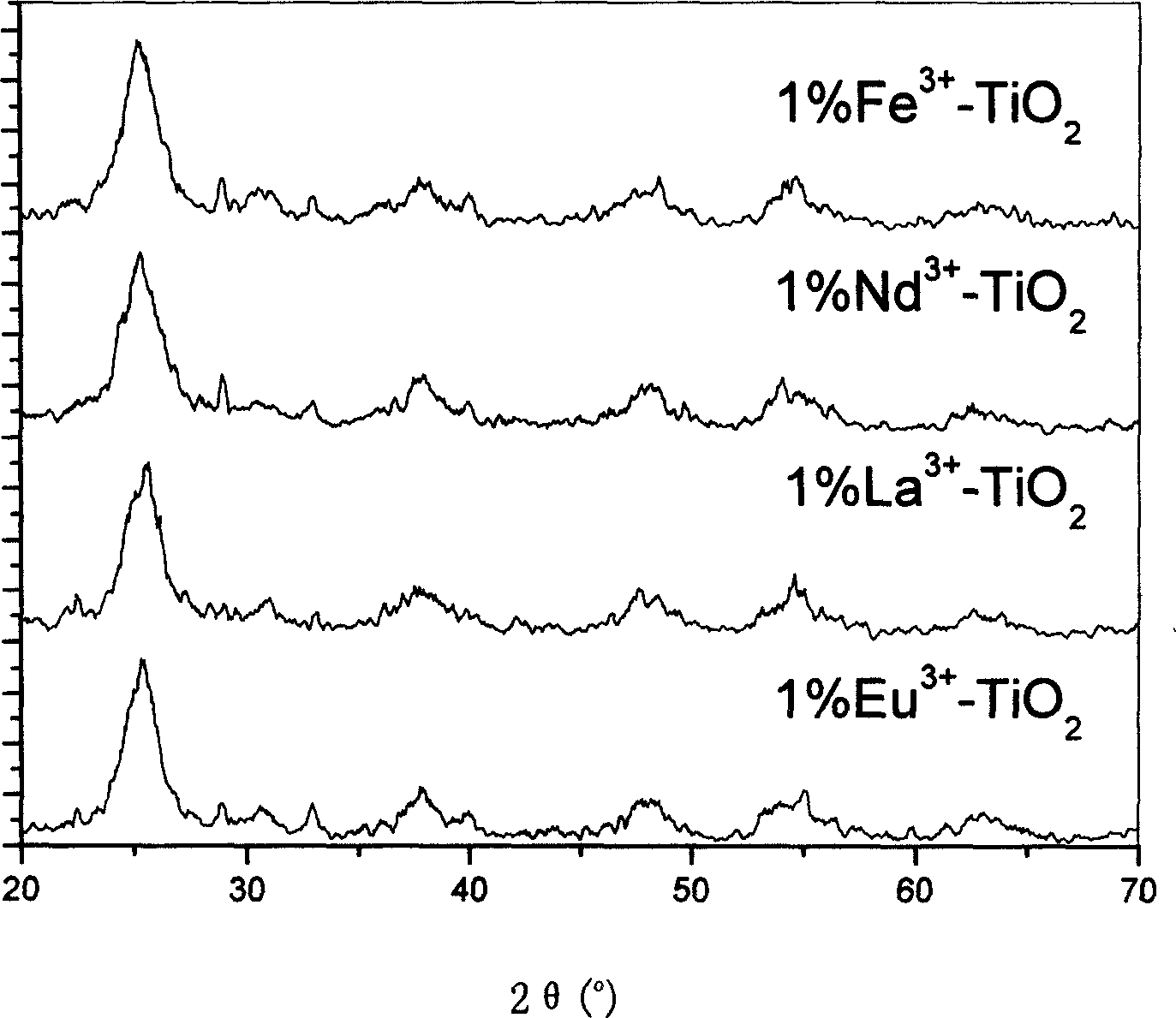

The present invention relates to the preparation process of TiO2 sol with relatively high visible light activity. TiO2 sol has high dispersivity, homogeneous granularity and other advantages, and may be modified via adding RE or other transition metals to alter its energy band structure and to form photocatalytic TiO2 material capable of being excited with visible light. The present invention has improved technological process of preparing TiO2 sol, and through synthesis at low temperature and normal pressure and doping with RE or other transition metals, TiO2 sol with greatly raised visible light activity is prepared. The present invention may be applied in processing polluted atmosphere, purifying indoor air, sterilizing indoor air, sterilizing crop, etc. and has important application foreground.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

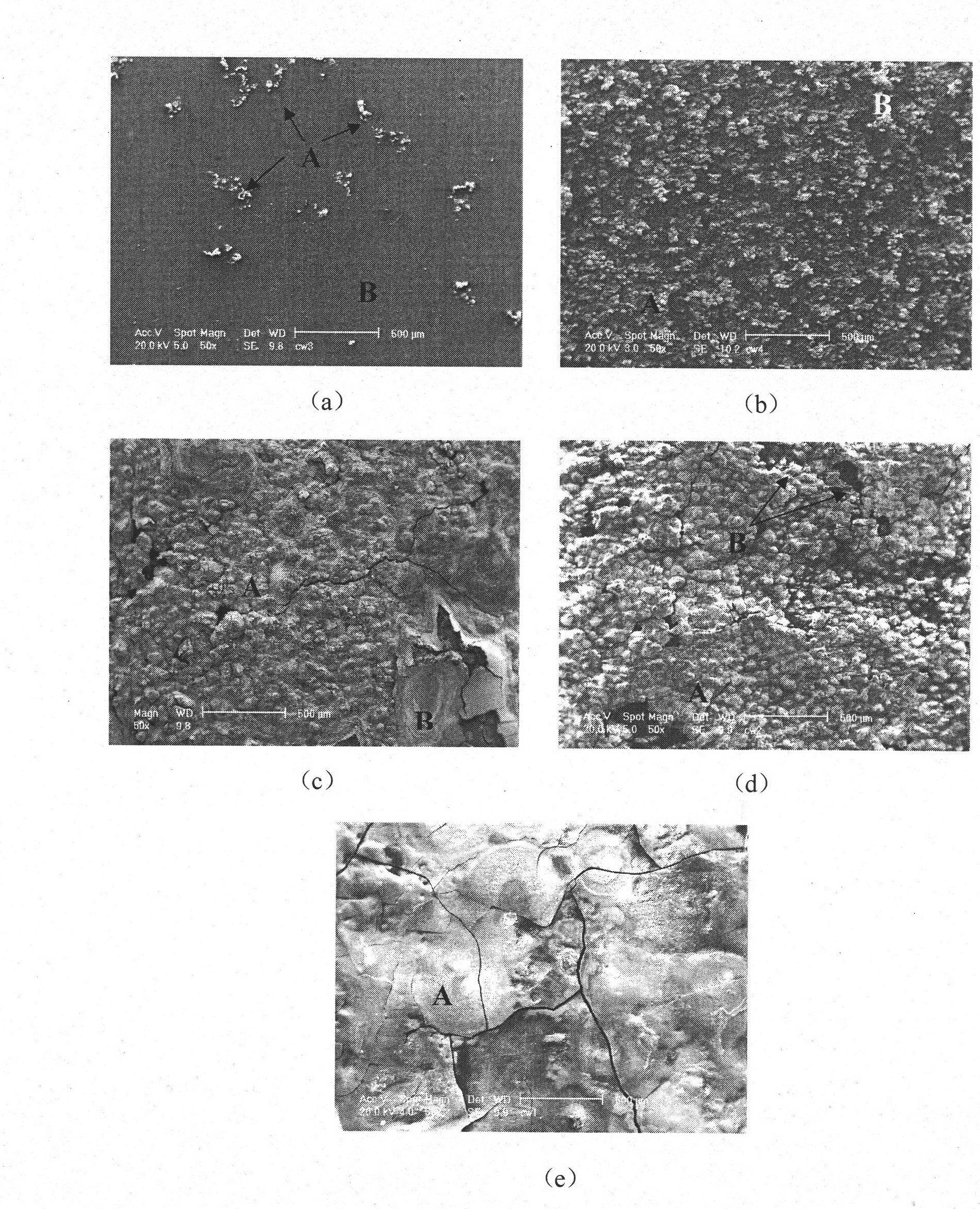

High-performance hot-rolled H profile steel resisting atmosphere corrosion and preparation method thereof

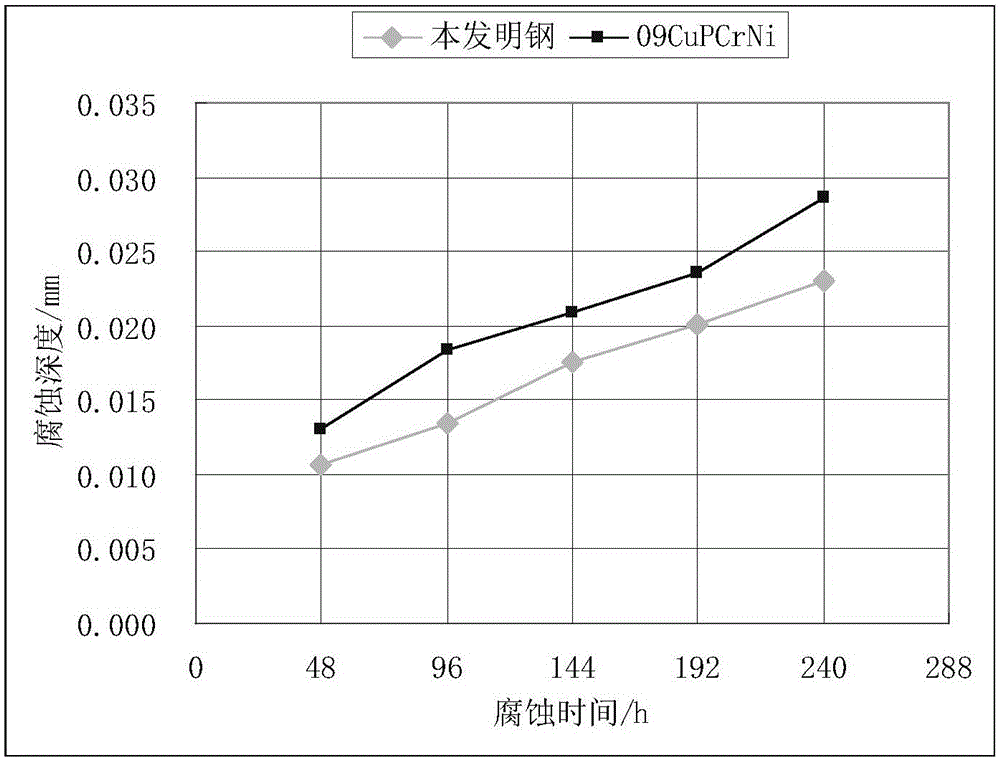

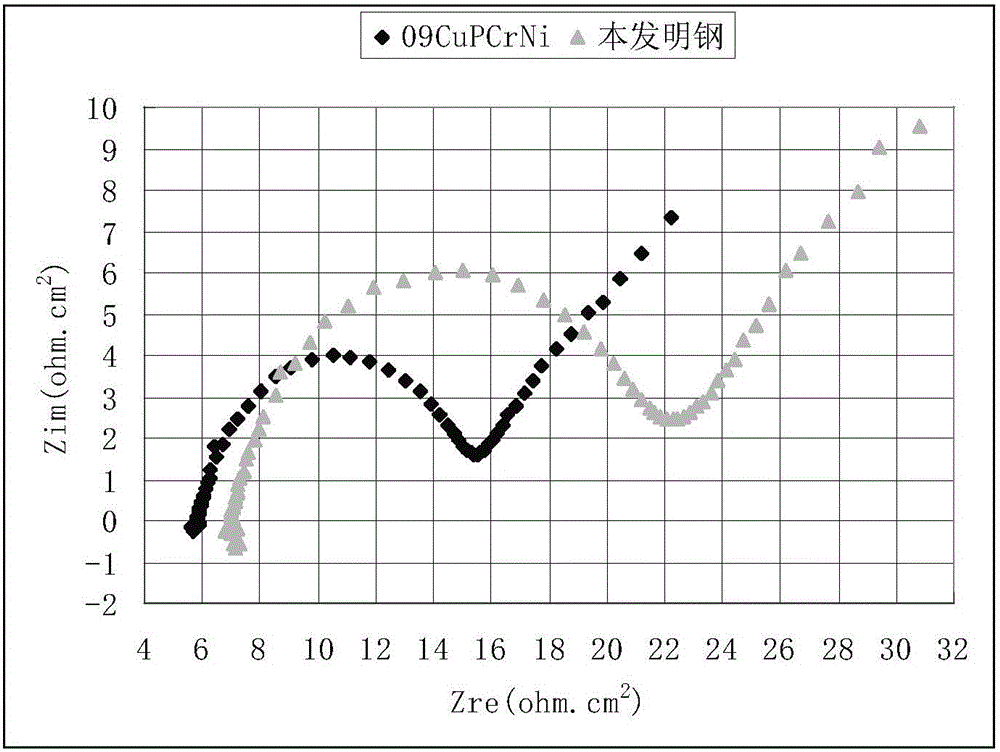

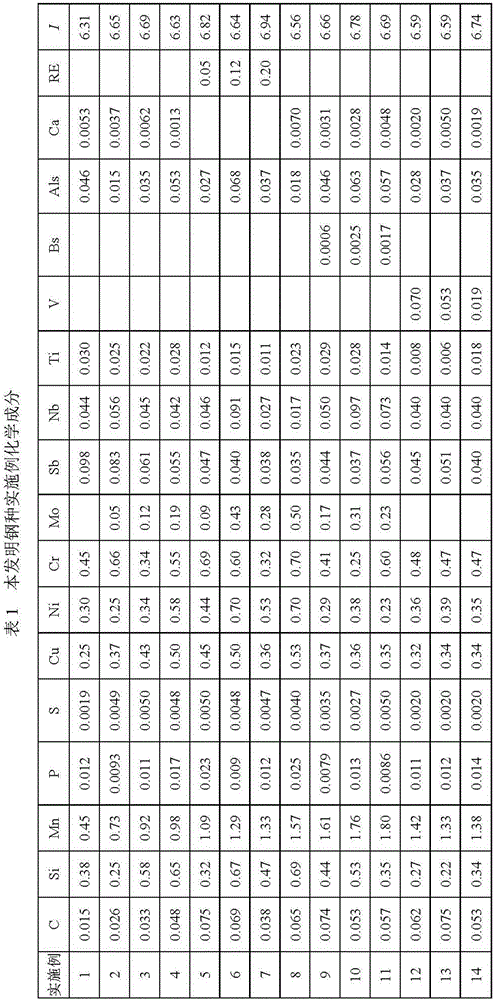

The invention aims to solve the defects of welding and strength performances in traditional weather-resistant H profile steel, and provides high-performance hot-rolled H profile steel resisting atmosphere corrosion and a preparation method thereof. The H profile steel comprises the following chemical components: C, Si, Mn, Cr, Cu, Ni, Mo, Sb, Als, not more than 0.025% of P, not more than 0.010% of S, not more than 0.0080% of N, Bs, Nb, Ti, V, Ca, and the balance of Fe and inevitable impurities; and the required atmosphere corrosion resisting index I is not less than 6.30. The preparation method is to perform air cooling or rapid cooling for a forging blank of the components after secondary rolling. The product reduces the carbon content, adds the microalloying elements of Nb and Ti, adds Ni, Mo, Cu and Cr, and also adds Sb to greatly improve the corrosion resistance in industrial-polluted atmosphere environment containing such higher pollutants as SO2; the steel structure of the product mainly adopts ferrite and ferrite+bainite; and the product has the yield strength of 235-500 MPa grade, is excellent in toughness and plasticity, is excellent in industrial-polluted atmosphere environment corrosion resistance, and can be used without coating in the industrial-polluted atmosphere environment.

Owner:蒋南宁

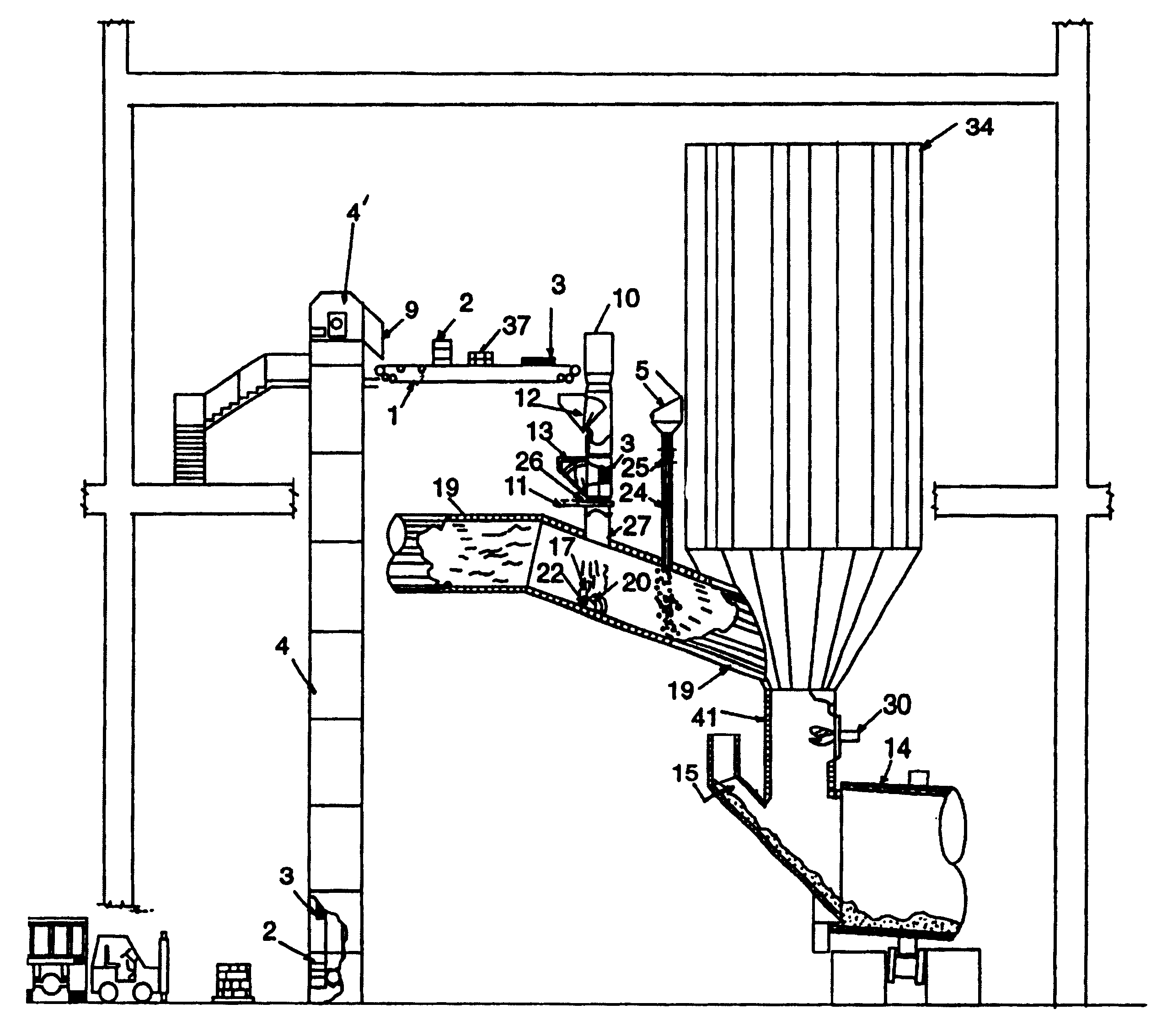

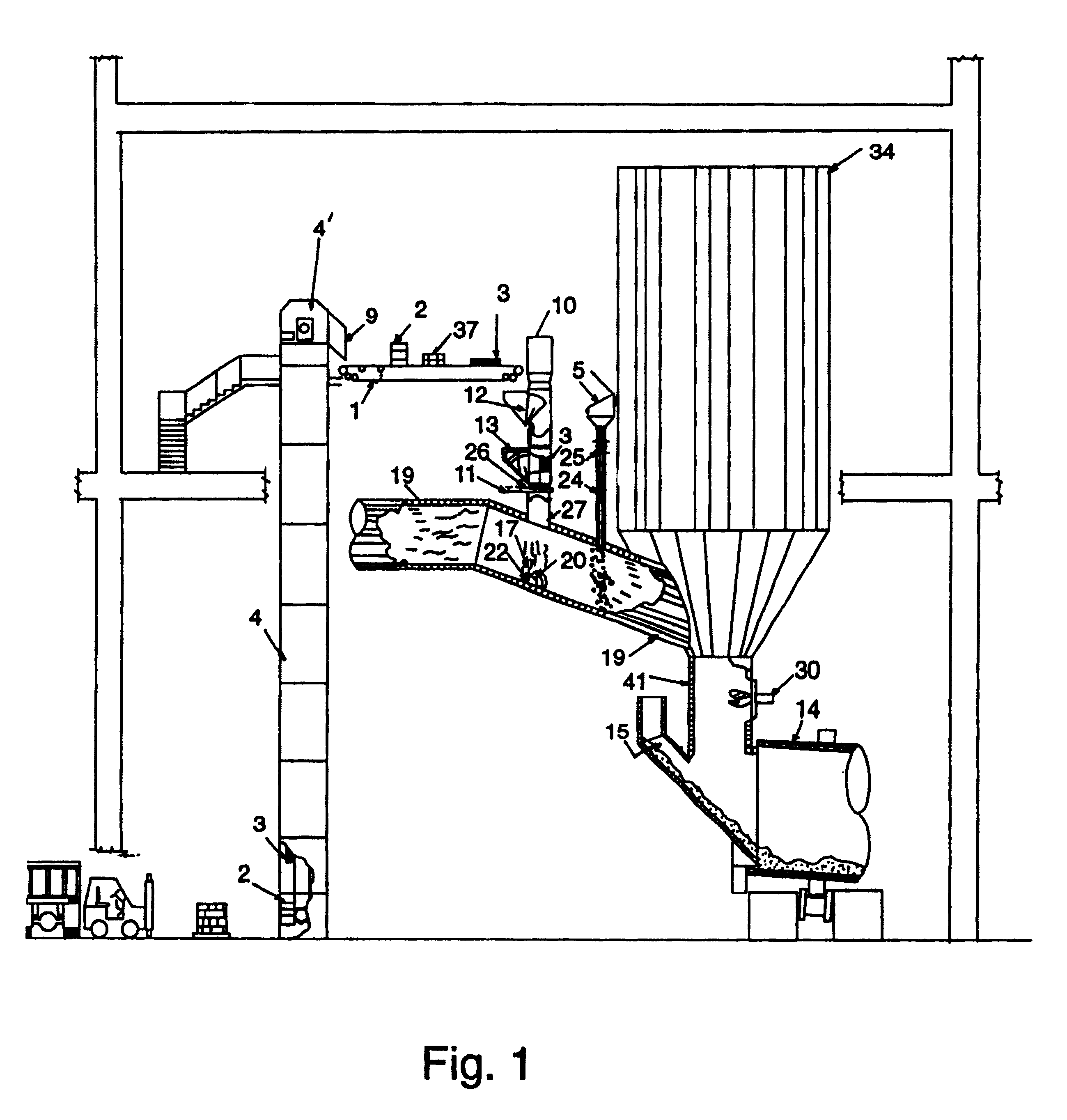

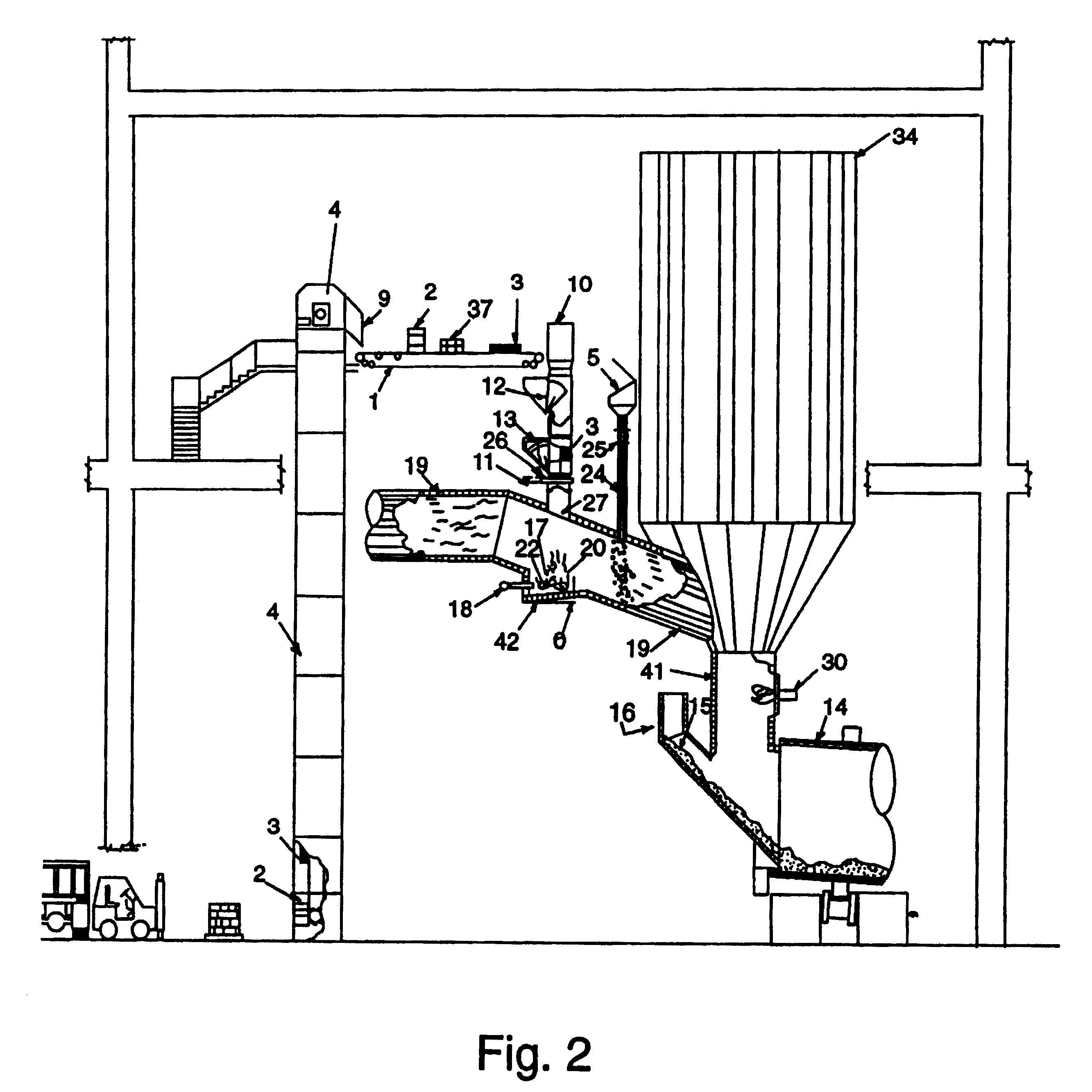

Method and apparatus for recovering energy from wastes by combustion in industrial furnaces

InactiveUS6470812B1Efficient energy recoveryEffective recoveryBranding equipmentMechanical apparatusWastewaterAtmospheric pollution

Method and apparatus to recover energy from waste by means of combustion of such waste in industrial furnaces, particularly of the rotary type, that has an external calciner, feeding such waste into the tertiary air duct of the calciner and burning the waste inside the duct itself, to efficiently make use of the energy produced by such combustion, as a contribution of the total cost of fuel necessary to operate the industrial furnace. The method and apparatus permit the elimination of hazardous wastes that are efficiently disassociated when burned sufficiently to produce effluents that are typically non-toxic, producing greatly reduced or even no atmospheric pollution nor environmental damage.

Owner:CEMEX DE C V

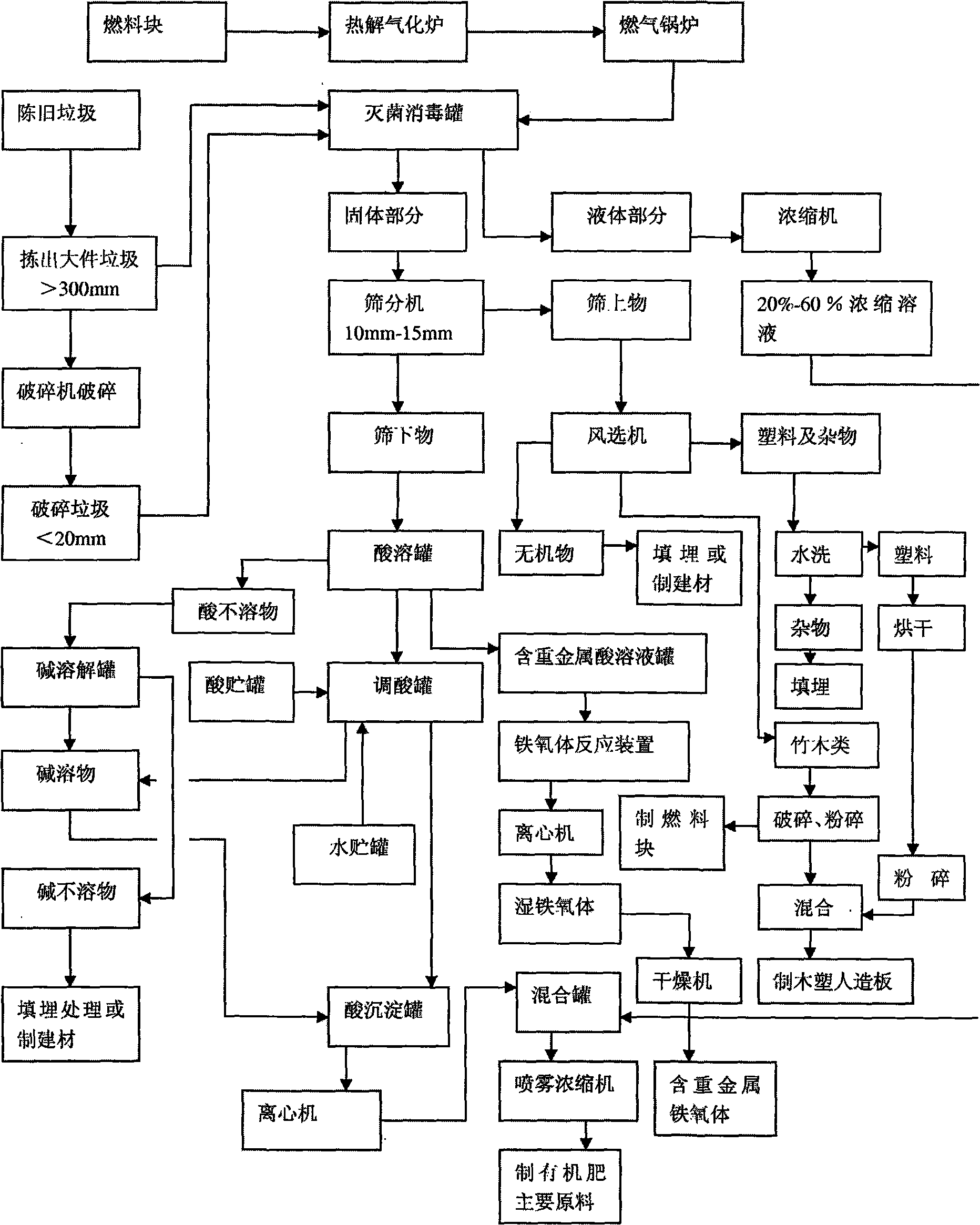

Reclamation processing method for poor garbage

InactiveCN101314163AEliminate pollutionAvoid flammable and explosive hazardsSolid waste disposalPlastic recyclingLiquid wasteEcological environment

The invention provides a completely innocent and utmost resource treatment method for old garbage, which comprises the following steps that: a wood-plastic man-made board is produced after pretreatments such as disinfection, sterilization, screening and air separation of waste bamboo wood and plastics; and septic soil and concentrated waste liquid are prepared into a main raw material of high-quality organic fertilizer. The method used to treat the old garbage has the advantages that: 1. the method eliminates foul odor, foreign odor, and pollution to the environment which are produced by the prior treatment of the old garbage, and avoids the problems of greenhouse pollution and heavy metal pollution as well as flammability and explosibility due to produced inflammable gas when the old garbage is added with fresh organic matters and is prepared into compost through secondary fermentation; 2. the method avoids the atmospheric pollution produced by incineration treatment, particularly dioxin pollution; 3. the method can reclaim and reuse useful substances in the old garbage to the utmost extent, and produces good social benefit, economic benefit and ecological environment benefit.

Owner:费爱民 +2

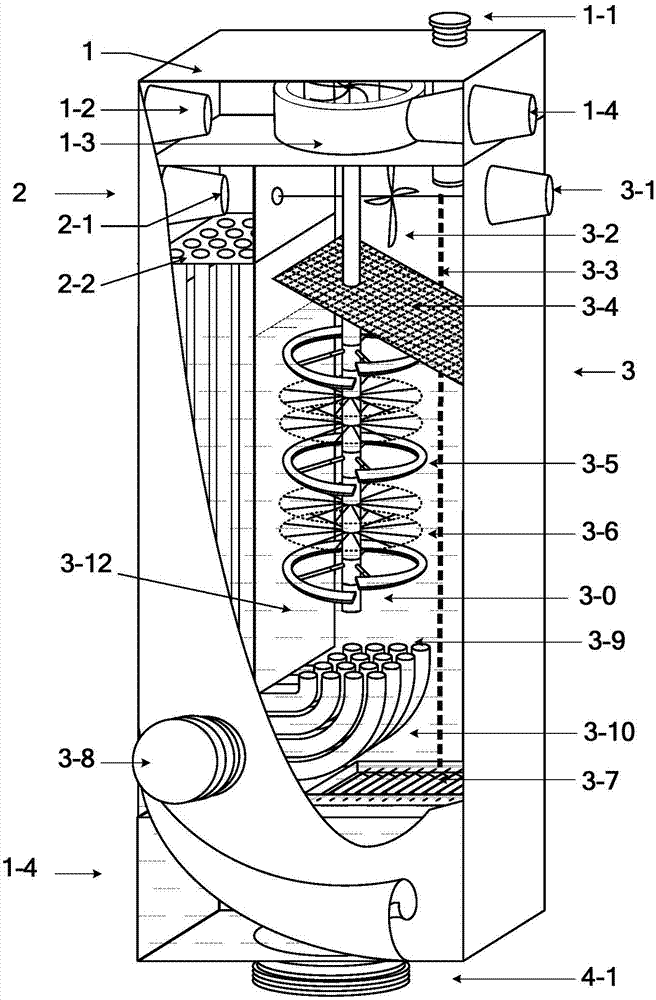

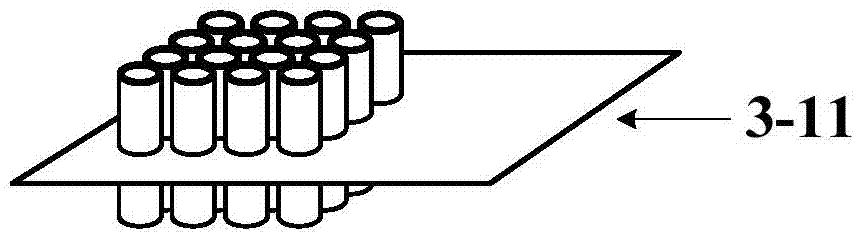

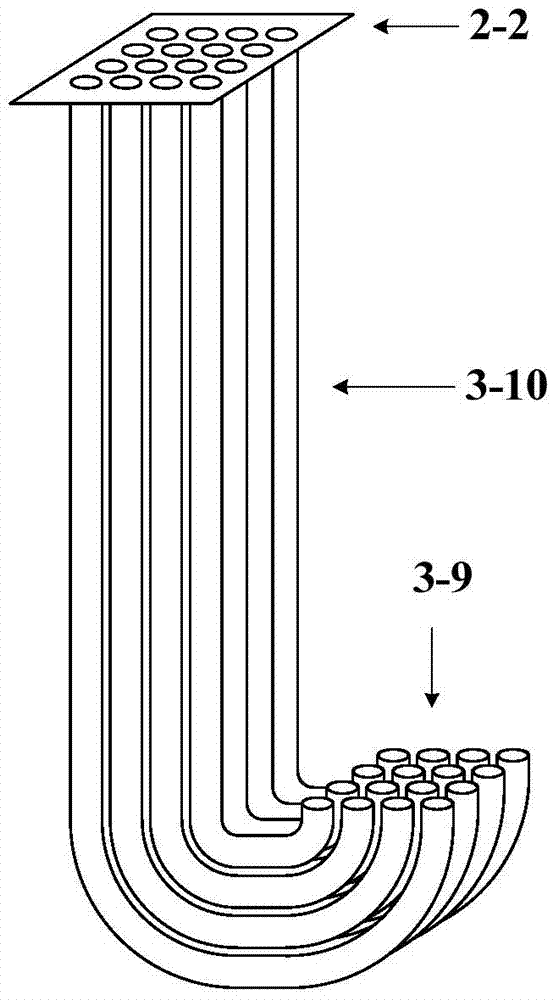

Device for eliminating haze and atmospheric pollutant

ActiveCN103933832AExtra running costEasy to useHuman health protectionUsing liquid separation agentSorbentCapillary Tubing

The invention discloses a device for eliminating haze and atmospheric pollutants. Appropriately preheated atmosphere with pollutants flows through a capillary tube array and is introduced into a liquid adsorbent, the pollutants in the atmosphere inside formed bubbles are adsorbed or dissolved by the surface of the liquid inside the bubble, and then atmosphere purification is achieved. The purification is applicable to atmospheric suspended grains of various diameters, and pm2.5 purification can be thoroughly achieved. To enhance the purification effect and the use convenience, the device is provided with function components such as a stirring rod with a bubble cutting steel wire and a spiral belt, and a waste liquid sucking chamber. The device can be separately used and can be also used with other devises in series. The device can be mounted on various carrying tools such as a vehicle, and due to the position change, the haze cleaning places can be changed at appropriate time, and the movement airflow of the carrying tool can be used as the power for eliminating the haze. The device can be used for purifying air at fixed points. When the device is used together with dust cleaning equipment, pm2.5 purification in polluted enterprises can be achieved. With special liquid adsorbent, the device can be used in special purification and professional equipment.

Owner:石博天

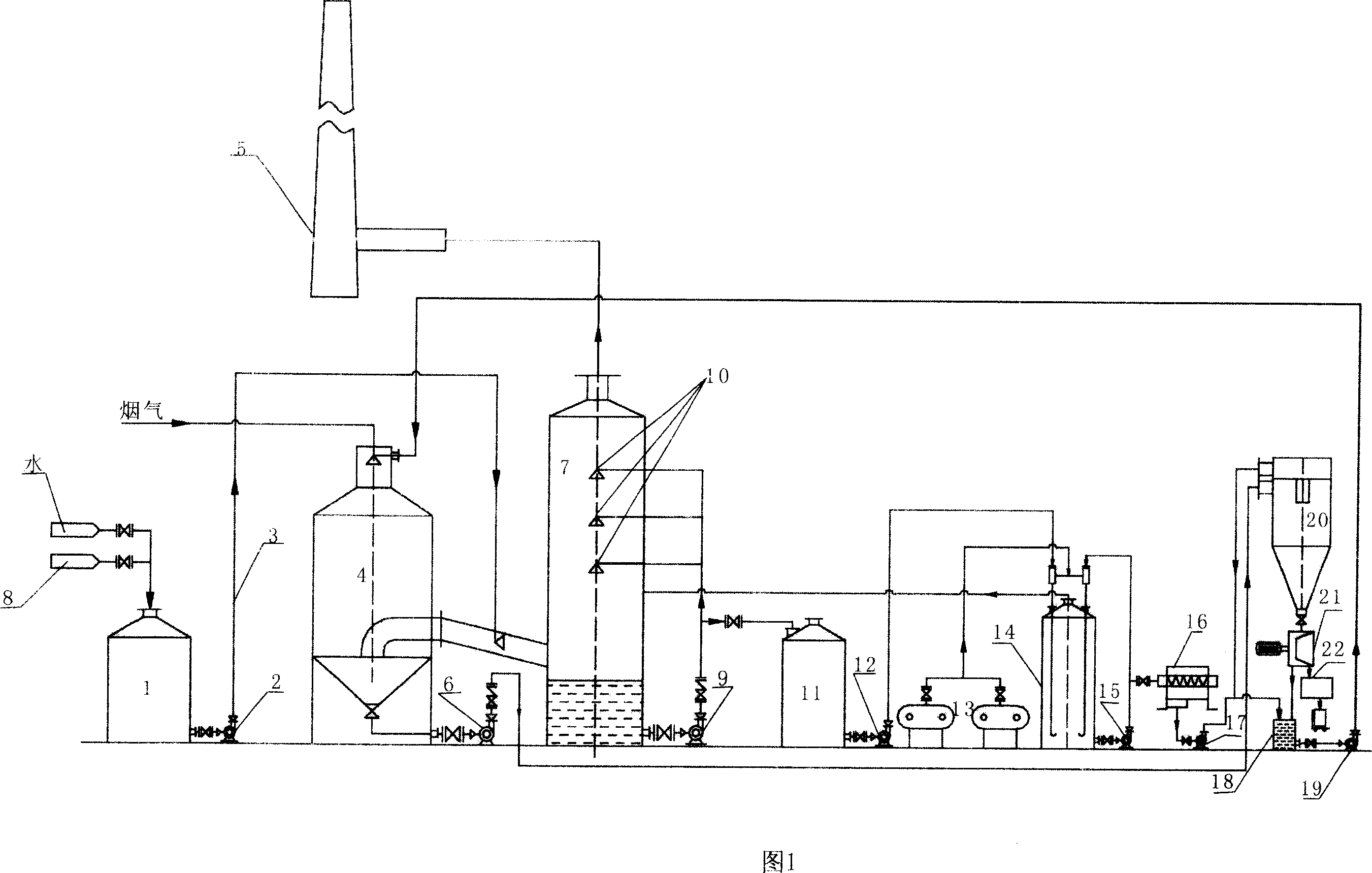

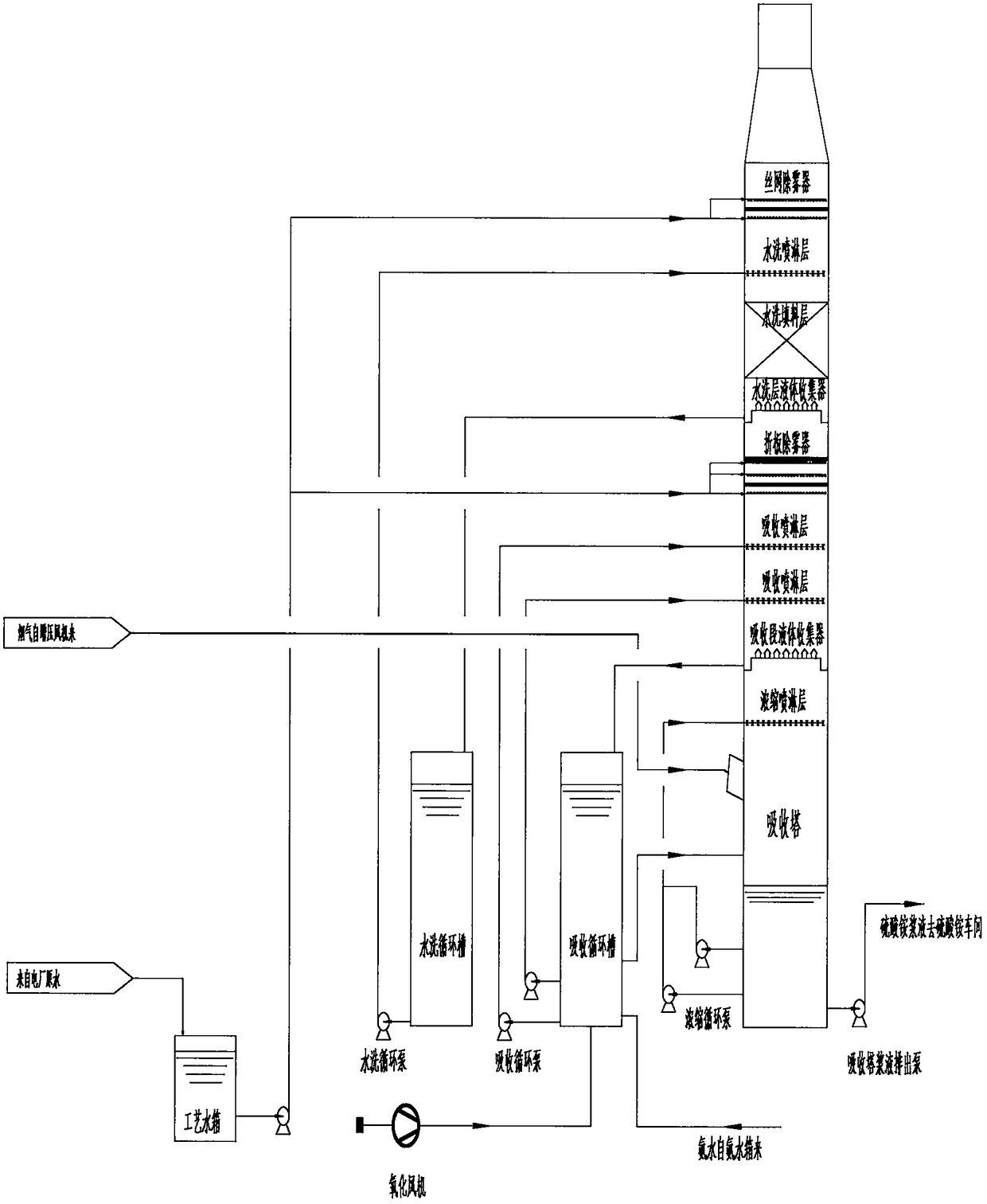

Low-consumption high-quality ammonium sulfate fertilizer recovery wet ammonia process desulfurizing technology

InactiveCN101143291ALow recycling comprehensive operating costConsiderable "positive benefit"Dispersed particle separationWastewaterNitrogen

The invention relates to a desulphurization and denitrogenation technology for controlling air pollution in environmental protection field. The invention is designed aiming at the problem of high production cost of reclaiming ammonium sulfate fertilizer and low quality of the reclaimed ammonium sulfate product by using the existing ammonia-fertilizer desulphurization technology, and the problem of that the half dry typed ammonia desulphurization technology can cause a secondary pollution to the environment. The invention provides a wet typed ammonia desulphurization technology of reclaiming ammonium sulfate fertilizer with low energy consumption and high quality. The invention adopts ammonia water as a desulfurizer. The ammonium sulfite, which is made after the gas is fully processed two-grade desulphurization, is processed two-grade oxidation outside the tower. The ammonium sulfite is fully reacted and formed ammonium sulfate, and the produced ammonium sulfate solution is contacted exchanged heat with high temperature gas, which reduces the gas temperature, and at the same time, the ammonium sulfate solution is condensed, and consequently, through which greatly saves the cost of evaporating, drying and making the ammonium sulfate fertilizer, and so the technical proposal of the invention not only can reclaim high quality ammonium sulfate product, but also has low reclaiming cost, and at the same time the purified gas can reach discharge standard without a secondary pollution like waste water etc.

Owner:史选增

Method used for detecting atmospheric heavy metal pollutants based on laser-induced-breakdown spectroscopy

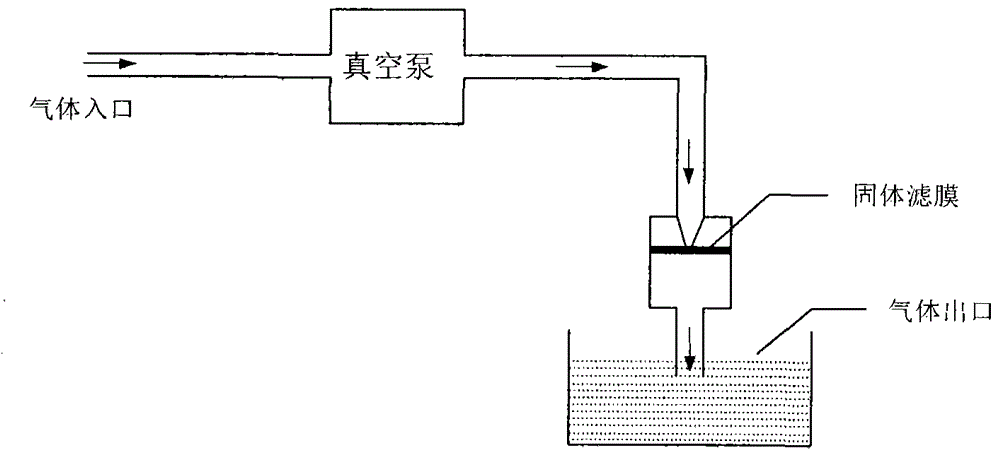

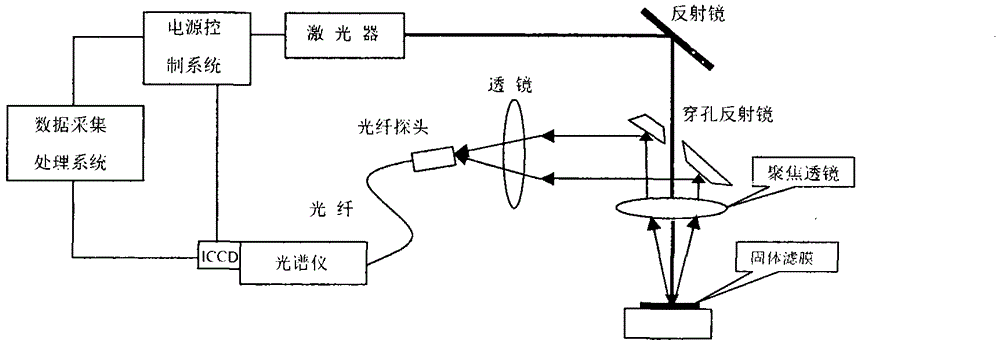

InactiveCN103954592AGuaranteed accuracyGuaranteed stabilityAnalysis by material excitationParticulatesFiltration

The invention discloses a method used for detecting atmospheric heavy metal pollutants based on laser-induced-breakdown spectroscopy. According to the method, a vacuum pump is used for sample collection of atmosphere containing suspended particulate matters; a filtration device provided with a solid filter membrane is used for absorbing the suspended particulate matters in the atmosphere so as to form a relatively stable aerosol deposition layer on the solid filter membrane; the aerosol deposition layer comprises a plurality of solid particles and liquid particles suspended in the atmosphere; breakdown of the aerosol deposition layer on the solid filter membrane is realized via laser beam induction, and distribution and content information of heavy metal elements in atmospheric particulate pollutants is obtained via analysis on aerosol plasma spectrum signals. The method is capable of changing gas detection to solid detection, increasing emission intensity of laser plasma spectrums, prolonging plasma spectrum emission time, and increasing detection limit of heavy metal elements in the atmospheric particulate pollutants, and is suitable for analysis and detection of a plurality of heavy metal elements in gaseous states in the samples.

Owner:郭锐 +1

Disinfecting and purifying agent for environment atmospheric membrane method and environment atmospheric disinfection and purification method

InactiveCN104258656AHigh mechanical strengthImprove mechanical stabilityElectrostatic separationUsing liquid separation agentMembrane methodPurification methods

The invention discloses a disinfecting and purifying agent for environment atmospheric membrane method and an environment atmospheric disinfection and purification method. The disinfecting and purifying agent is composed of the following components in percentage by weight: 2 to 25% of disinfecting agent, 20 to 60% of film forming agent, and 20 to 60% of foaming agent. The invention further provides an environment atmospheric disinfecting and purifying method. The resources of raw materials are wide, the raw materials are easy to process, the disinfecting and purifying agent is effective and economic, normal people can use the agent to cope with environment atmospheric disastrous pollution in time, the environment atmospheric disaster can be resolved by the agent, and a convenient and feasible technical scheme is especially provided for eliminating environment atmospheric dangerous dust pollution and possible atmospheric biochemical pollution.

Owner:尹无忌

Air flue soot dust granule visual sense sampling system and monitoring method

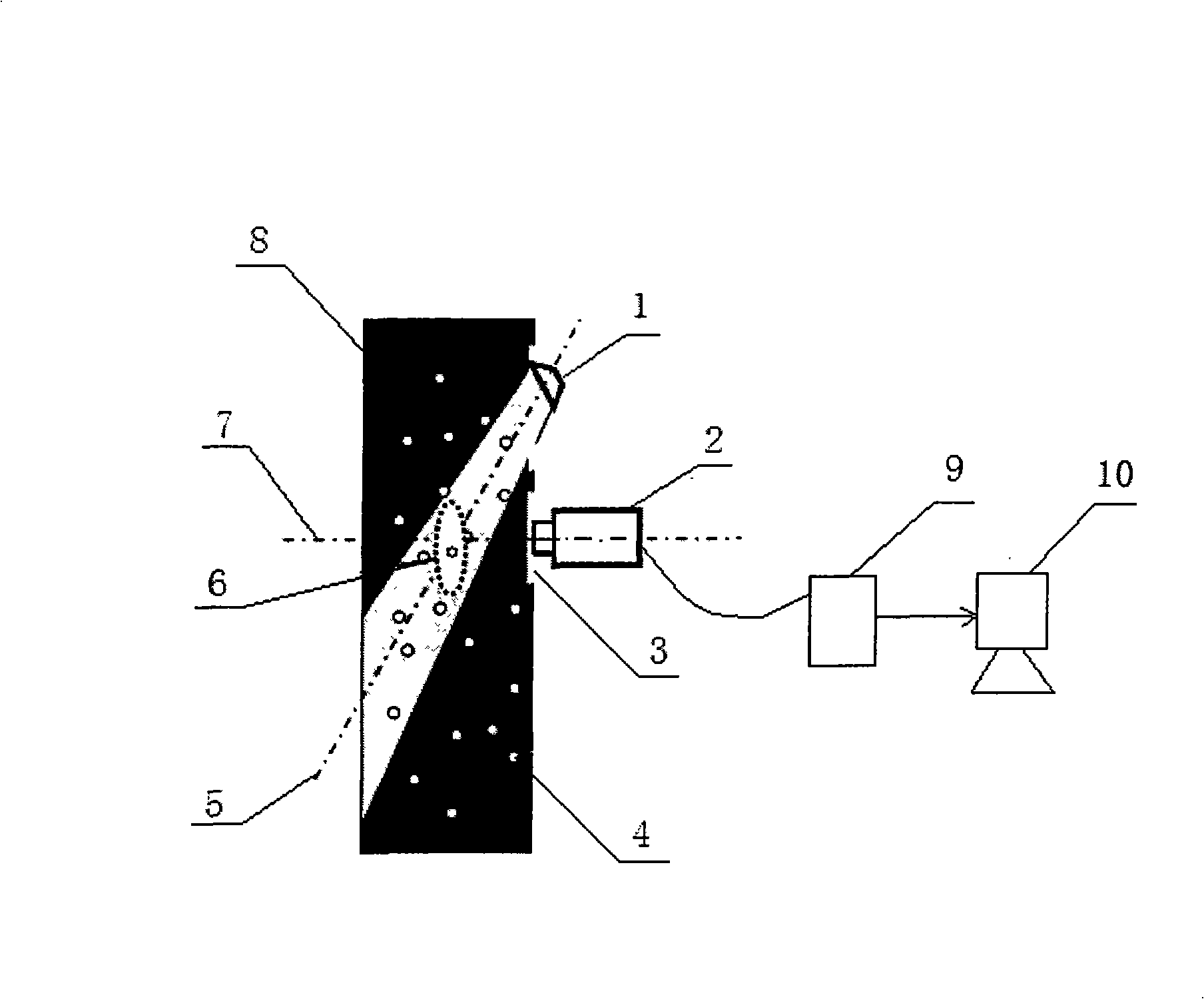

InactiveCN101308081ARealize online real-time detectionMaterial analysis by optical meansAlarmsFlue gasAtmospheric air

The invention relates to a flue dust particle vision sampling system and a monitoring method thereof, wherein, an image sensor and an illumination light source are arranged at the port of a flue gas discharge channel of a flue reflecting conditions of dust particles discharged to the air, and the image sensor acquires the flue dust image information in the flue and enters a computer for processing data through an acquisition card, so the system can realize the on-line real-time detection to flue gas discharge and provide the powerful gist for controlling the atmospheric pollution.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Fume desulfurizing process with enhancement lime method

ActiveCN1923339AIncrease profitImproves pH buffering capacityDispersed particle separationSulfurSlurry

The invention relates to a method for desulfurising smoke, especially a strengthen limestone smoke desulfurising method. Wherein, it comprises adding limestone and additive into reactor, to be mixed and reacted with water to generate adsorption slurry; inputting slurry into adsorption tower; the sulfur smoke enters into tower to react with slurry; the purified smoke is discharge outside the tower; the slurry with sulfur dioxide will be discharged at the bottom of tower to be recycled. The invention can improve desulfurising efficiency at 5-10% and improve the absorber utilization at 1-10%.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Low-moisture coke quenching and waste heat utilizing device

InactiveCN103759544AReduce pollutionReduce wasteCoke quenchingEnergy inputHigh pressure waterWater circulation

The invention discloses a low-moisture coke quenching and waste heat utilizing device. The low-moisture coke quenching and waste heat utilizing device comprises a coke quenching car, a coke quenching tower, a high-pressure water channel, a waste heat boiler, a steam heat accumulator, a condensing steam turbine, a generator and the like and is characterized in that the high-pressure water channel, the coke quenching tower, the waste heat boiler, the steam heat accumulator and the condensing steam turbine form a water circulation system. The low-moisture coke quenching and waste heat utilizing device respectively integrates low-moisture coke quenching, coke quenching stabilization and dry-method coke quenching, water for coke quenching is saved, the coke quenching effect is good, and atmospheric pollution and heat energy waste are reduced. The device is simple in structure, low in invest cost, convenient to transport, capable of continuously working and good in economical efficiency.

Owner:HENAN SHENGSHI ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

Fume desulfurizing process with enhancement limestone method

ActiveCN1923338AIncrease profitImproves pH buffering capacityDispersed particle separationSulfurSlurry

The invention relates to a method for desulfurising smoke, especially a strengthen limestone smoke desulfurising method. Wherein, it comprises adding limestone and additive into reactor, to be mixed and reacted with water to generate adsorption slurry; inputting slurry into adsorption tower; the sulfur smoke enters into tower to react with slurry; the purified smoke is discharge outside the tower; the slurry with sulfur dioxide will be discharged at the bottom of tower to be recycled. The invention can improve desulfurising efficiency at 5-10% and improve the absorber utilization at 1-10%.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

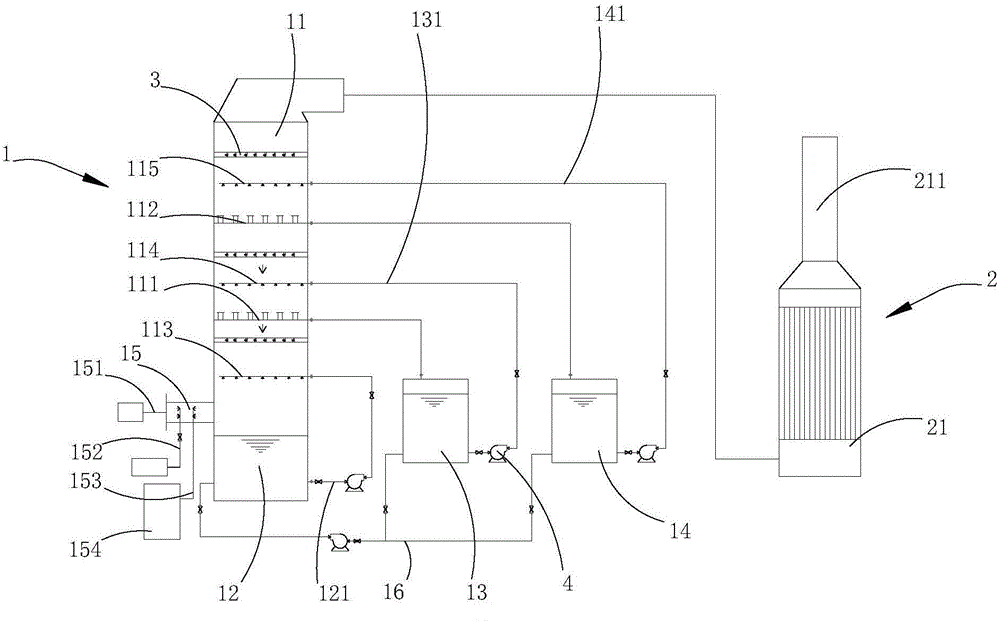

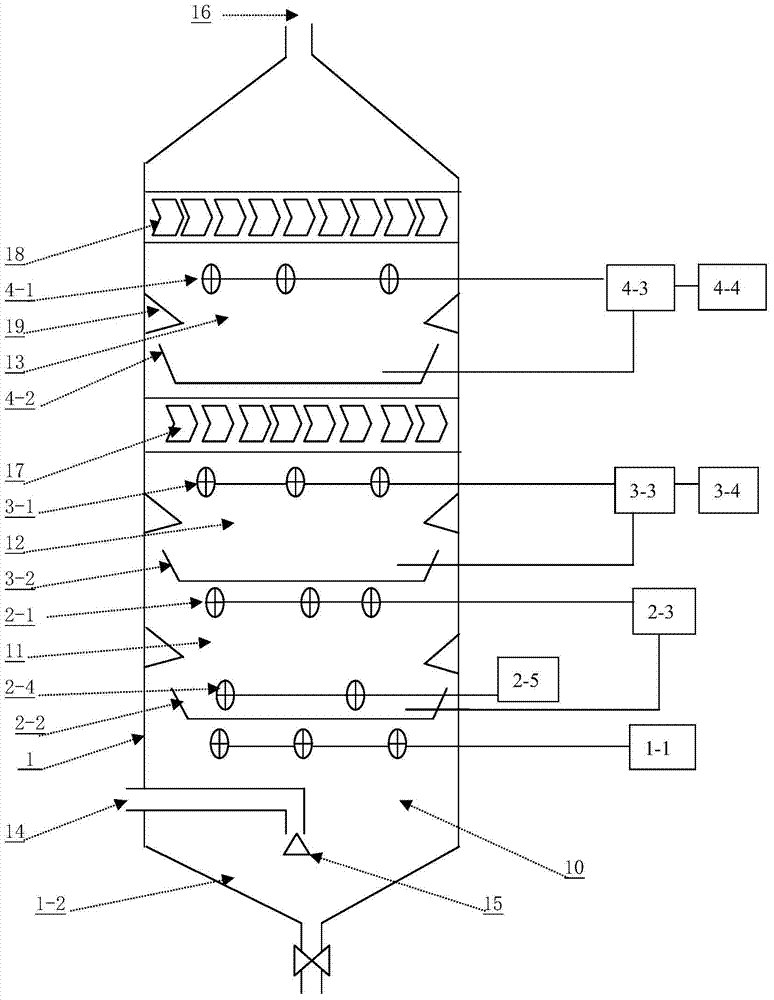

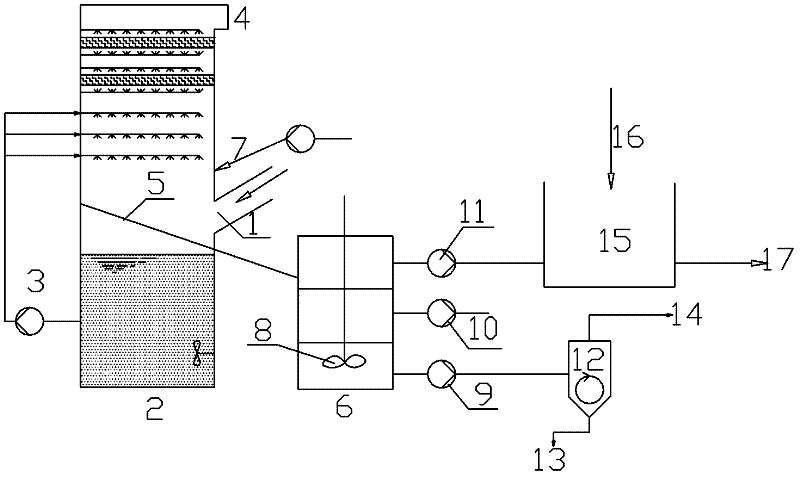

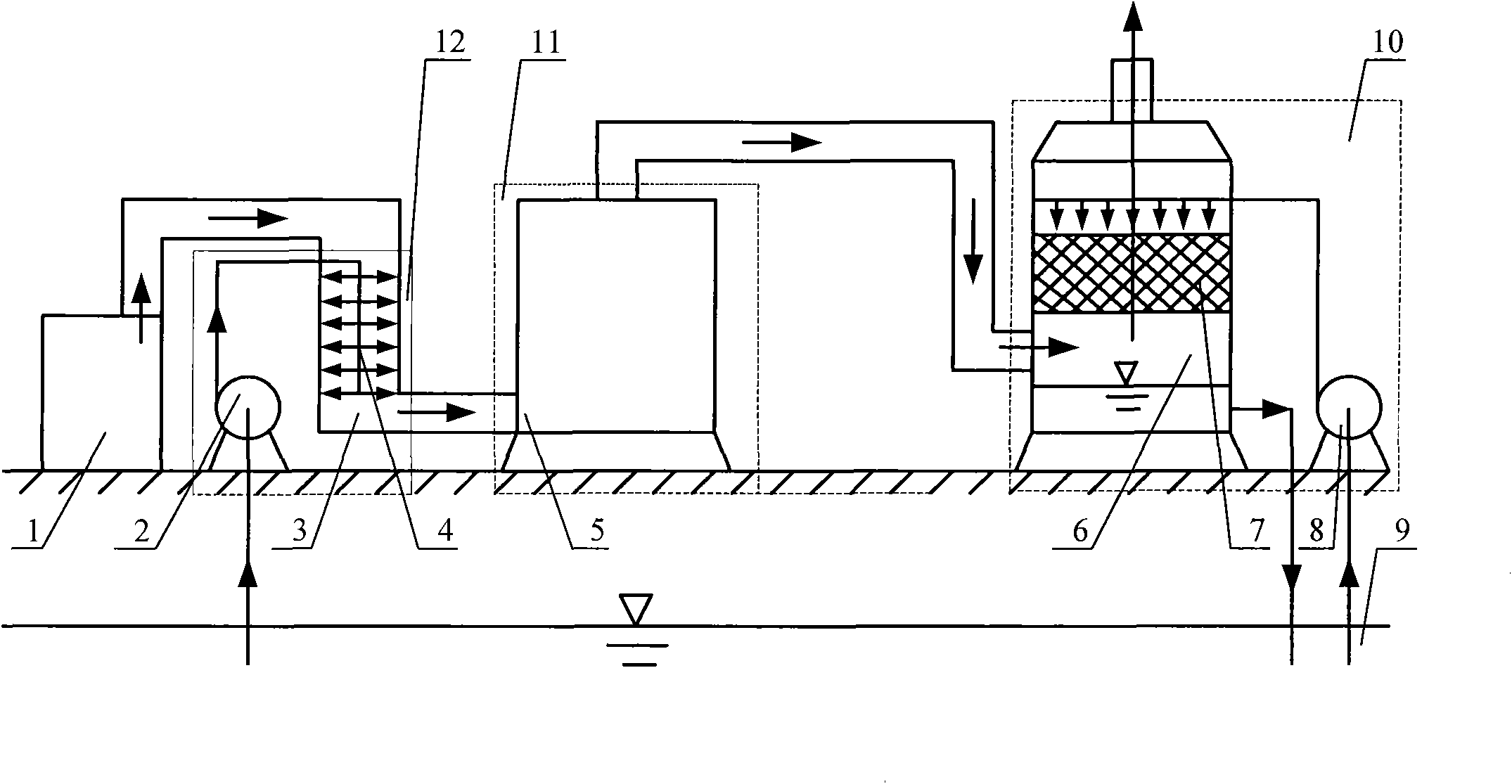

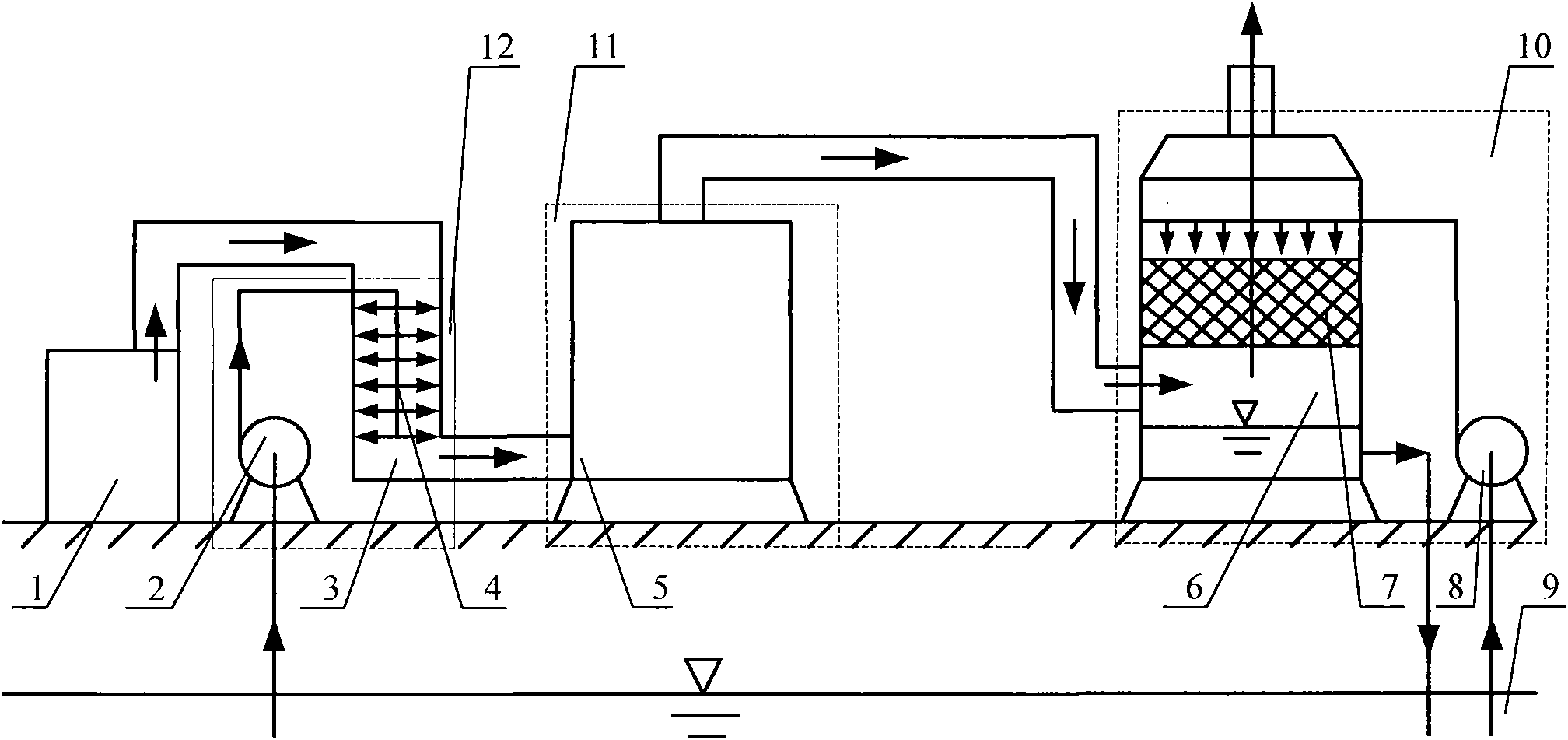

Industrial flue gas desulfurization/denitrification/dedusting integrated technique and device

InactiveCN104826476AReduce concentrationAlleviate white smoke phenomenonDispersed particle separationEmission standardIntegrated devices

The invention relates to air pollution control, and provides an industrial flue gas desulfurization / denitrification / dedusting integrated technique. Ozone and ammonia water are adopted to form the technique composed of at least three circulating spray stages in the spray tower, thereby synchronously removing nitrogen and sulfur compounds in the flue gas. The invention also provides an industrial flue gas desulfurization / denitrification / dedusting integrated device which is applied to the technique. In the technique, the ozone with strong oxidizing property is utilized to convert nitrogen monoxide in the flue gas into nitrogen dioxide, and the spray tower is divided into at least three stages to perform the circulating spray by using the ammonia water. The whole technical process has very high utilization ratio for ammonia water, and can synchronously implement desulfurization and denitrification at higher efficiency. The flue gas carries the solution with very low concentration, can not generate the phenomenon of white smoke, and can completely satisfy the national discharge standard. The device applied to the technique has the advantages of simpler structure, smaller occupied area and lower investment cost.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Method for removing mercury from flue gas

InactiveCN101496980AMeet the needs of mercury removalSimple structureDispersed particle separationSorbentSmall footprint

The invention discloses a method for demercuration of smoke gas. A mercury sorbent is filled in a reaction vessel by a feed distribution device; boiler smoke gas at a temperature of between 50 and 400 DEG C and the mercury sorbent of the reaction vessel are mixed and stirred to form a reaction bed layer so that the smoke gas and the mercury sorbent are in violet turbulent motion; purified smoke gas is pressurized and discharged by a chimney; the method adopts a simple adsorption and separation device; the device has a simple structure, occupies small area and has low manufacturing and mounting cost; a process flow is simple, occupies small area and has low investment and operating cost; the removing rate of mercury is more than 90 percent; the removing rate of dust is more than 95 percent; the method can be suitable for requirement of demercuration of smoke gas in a coal-fired power plant, is environment-friendly, economic, practical and suitable for promoting industry and forming scale production capacity, thereby being applicable to emergent requirement of promoting a task of atmospheric pollution treatment; modified active carbon used by the method can be applicable to wide temperature range of the smoke gas and can be arranged before or after denitration of the smoke gas or desulphurization of the smoke gas; and an arrangement mode is relatively flexible.

Owner:CHONGQING UNIV +1

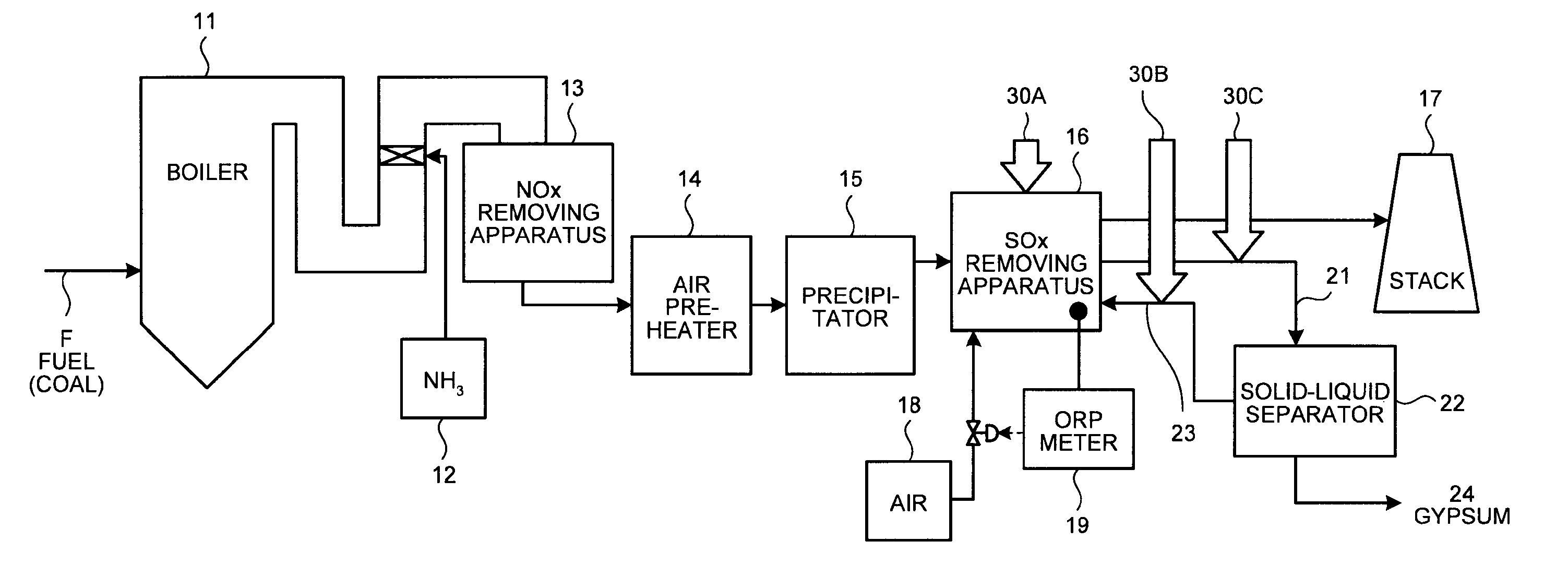

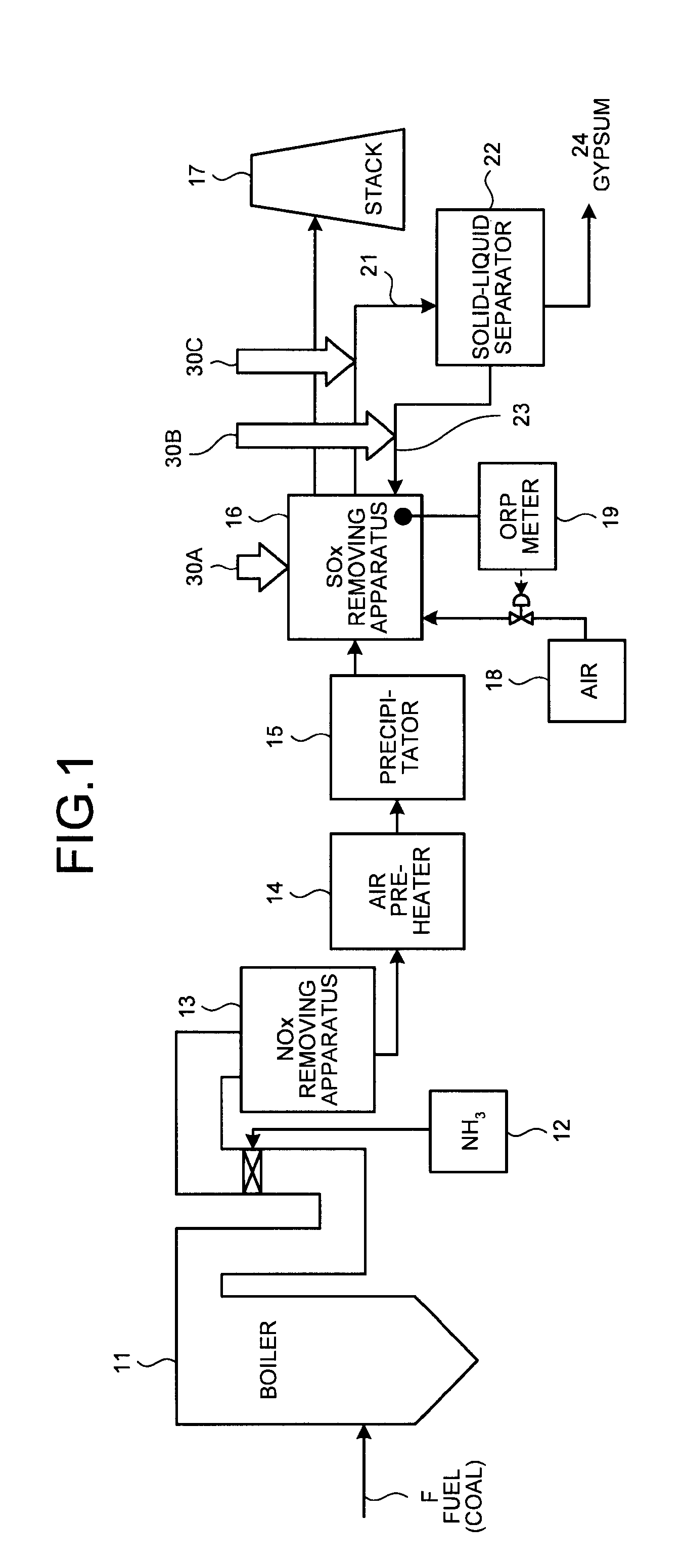

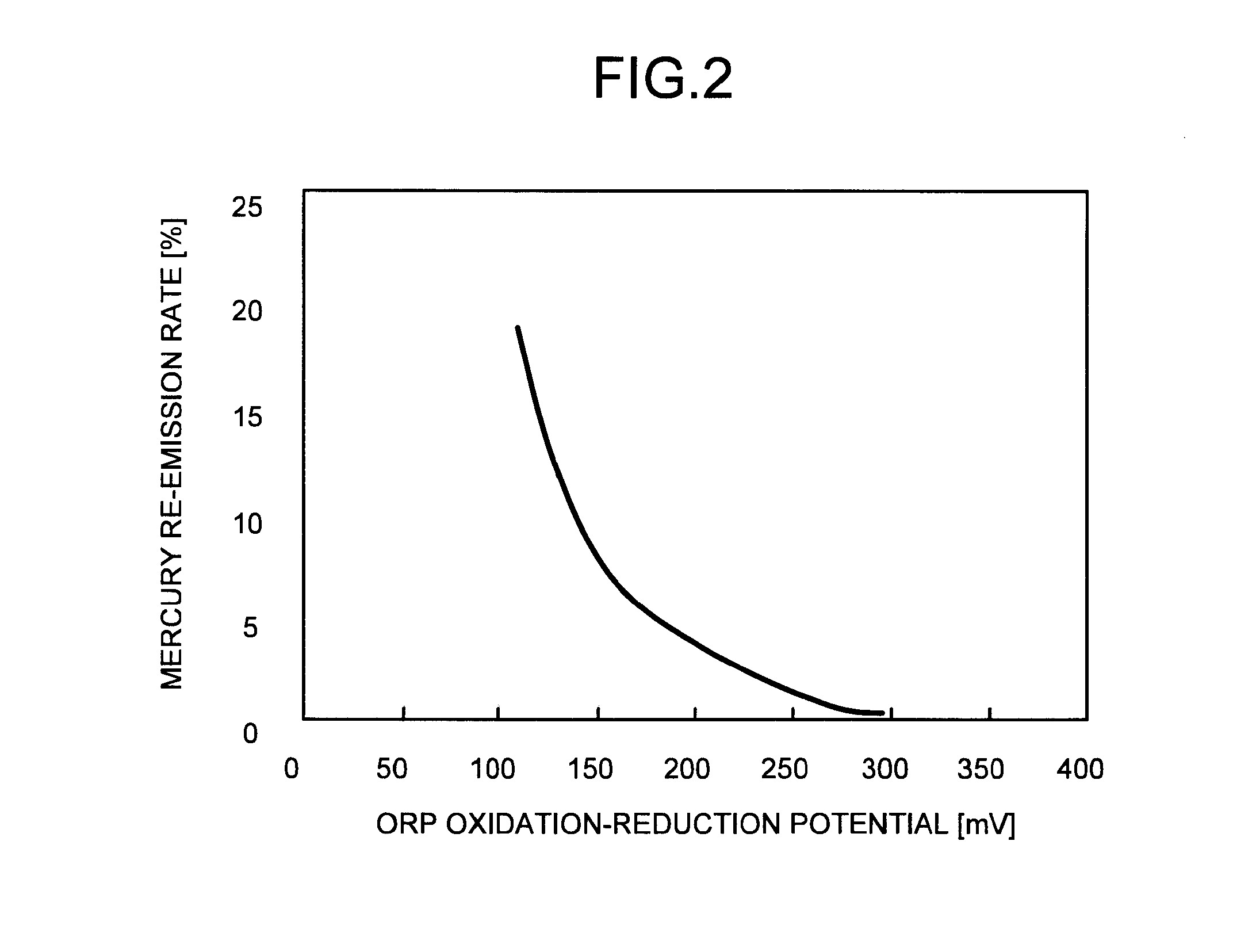

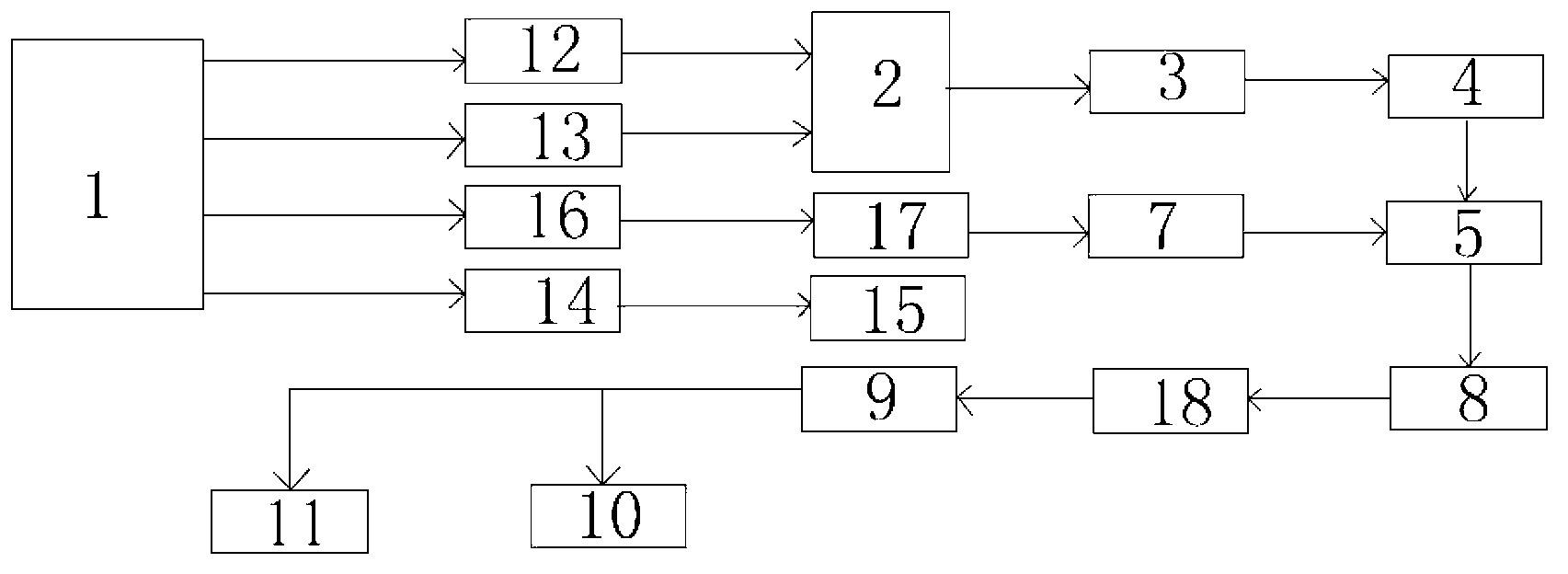

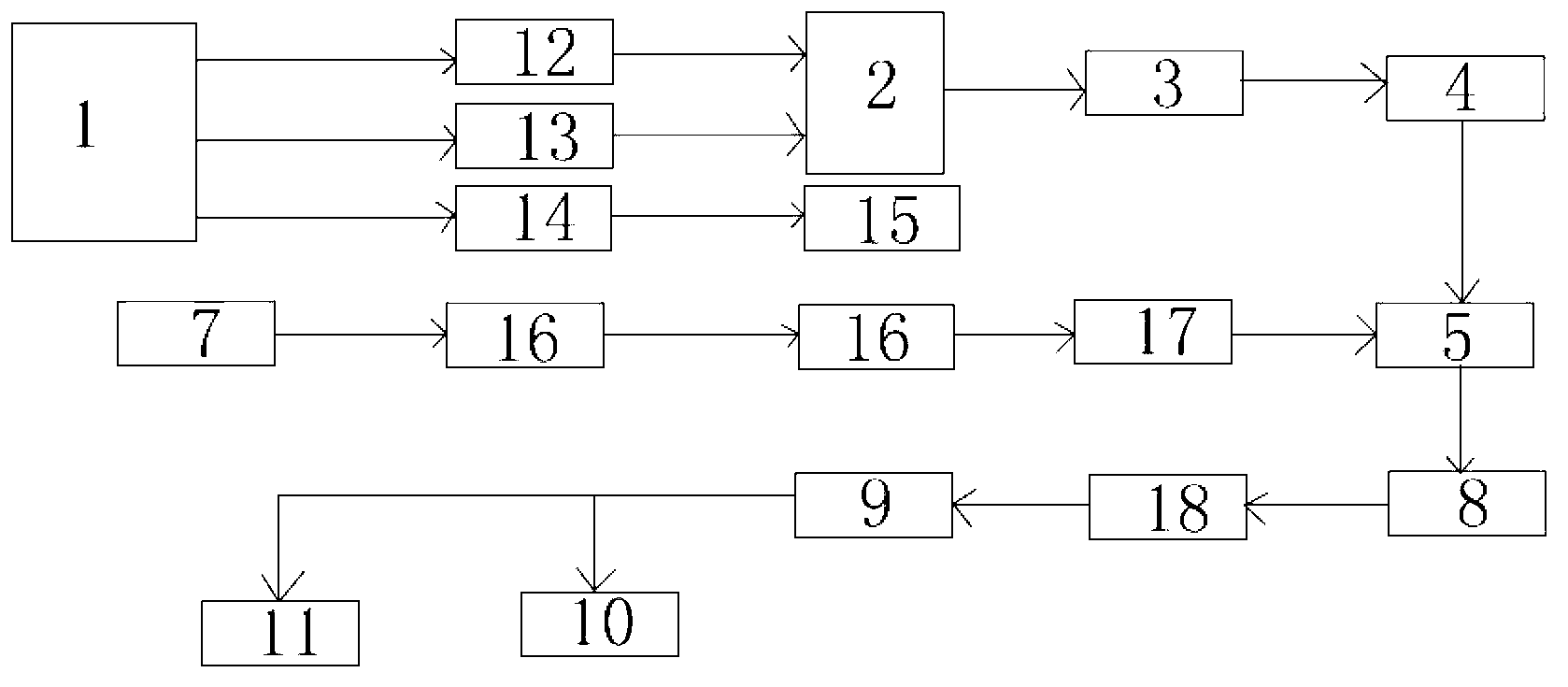

Air pollution control system and method for coal combustion boiler

InactiveUS20100284878A1Smooth connectionEasy to fixCombination devicesGas treatmentAir preheaterParticulates

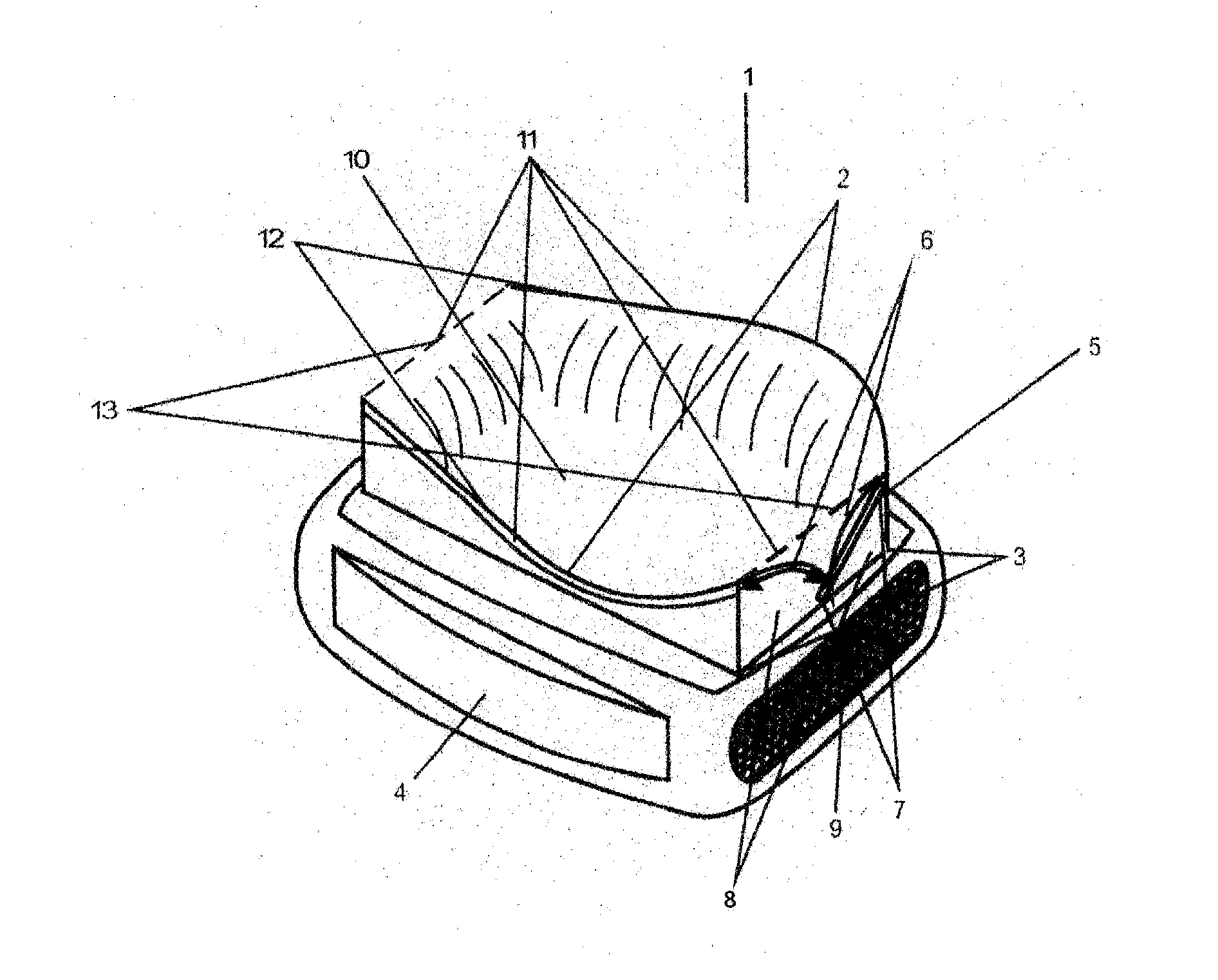

An air pollution control system for a coal combustion boiler according to the present invention includes: a NOx removing apparatus (13) that removes nitrogen oxide contained in flue gas emitted from this coal combustion boiler (11) by adding ammonia (12) thereto, an air pre-heater (14) that recovers heat in the gas after the nitrogen oxide is removed, a precipitator (15) that reduces particulates from the gas after the heat is recovered, a gas-liquid contact type SOx removing apparatus (16) that removes sulfur oxide by way of a limestone-gypsum method and reduces mercury oxide in the gas after the particulates are reduced, and a stack (17) that releases purified gas after the sulfur and the mercury are reduced, where an oxidant is added to limestone-gypsum containing slurry (21) in or extracted from the SOx removing apparatus (16).

Owner:MITSUBISHI HEAVY IND LTD

Flue gas desulfurization technology with effect of ultra-clean emission

InactiveCN108067091AHigh desulfurization rateLow running costCombination devicesAmmonium sulfatesAir contaminantSulfate

The invention discloses an ultra-clean emission technology for removing ammonia sulfate chemical fertilizer as an SO2 byproduct in flue gas, and belongs to a desulfurization and denitrification technology for air contaminant treatment in the field of environmental protection. According to the technology, ammonia is taken as a desulfurizing agent, high-temperature flue gas is cooled to 50-70 DEG Cthrough a concentration section of an absorption tower and then enters an absorption section of the absorption tower, an absorption liquid in the absorption section is subjected to a reaction with SO2in the flue gas to finish the desulfurization process, the absorption liquid obtained after the reaction flows to an absorption circulating tank automatically, the absorption liquid in the absorptioncirculating tank is subjected to a reaction with ammonia, ammonium sulfite is generated, part of ammonium sulfite is taken as the absorption liquid to return to the absorption section, part of ammonium sulfite is oxidized into ammonium sulfate, an ammonium sulfate solution is sent to the concentration section to exchange heat with the flue gas, ammonium sulfate crystals are separated out, a suspension containing the ammonium sulfate crystals is subjected to swirling flow treatment and filtered, solids are dried to be a finished product, and a liquid returns to the concentration section; the desulfurized flue gas passes through a folded plate type demister and then enters a desulfurized flue gas deep purification section at the upper part of the absorption tower for treatment, and accordingly, the flue gas meets the ultra-clean emission standard.

Owner:九美科技有限公司 +1

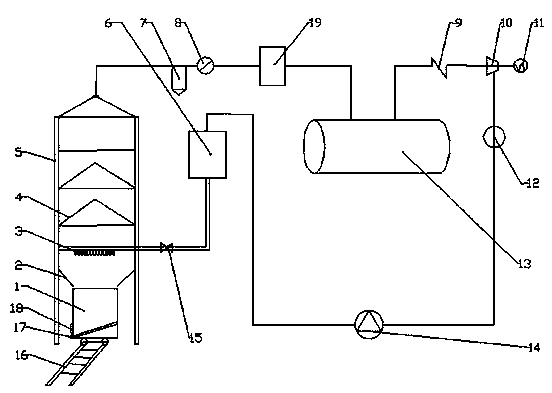

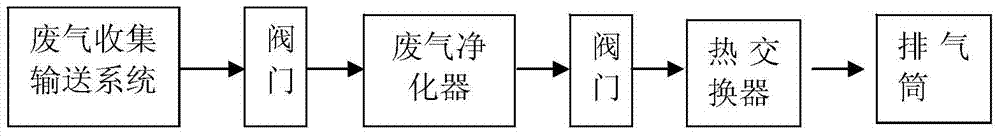

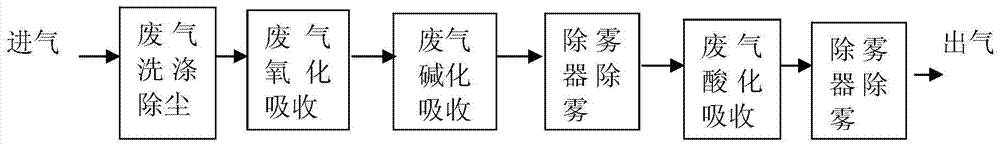

Waste gas treatment device

InactiveCN103657306ASolve pollutionSimple structureUsing liquid separation agentFlue gasAtmospheric pollution

The invention relates to a waste gas treatment device, which comprises a waste gas purifier and a waste gas collection and exhaust system. A waste gas washing and dust removing area, a waste gas oxidization absorbing area, a waste gas alkalization absorbing area, a first demister, a waste gas acidification absorbing area and a second demister are sequentially arranged in the waste gas purifier from bottom to top. A tap water spray device and a dust and waste water collection cone tank are arranged in the waste gas washing and dust removing area. A waste gas oxidization absorbing component is arranged in the waste gas oxidization absorbing area. A waste gas alkalization absorbing component is arranged in the waste gas alkalization absorbing area. A waste gas acidification absorbing component is arranged in the waste gas acidification absorbing area. A heat exchanger is arranged at the front of a flue gas exhaust pipe. The waste gas treatment device has the advantages that the waste gas with higher dust concentration can be effectively purified, various organic, inorganic, acidic and alkali waste gas can be effectively treated, and the problem of atmospheric pollution caused by waste gas sources in factory workshops, garbage stations and the like is solved.

Owner:CHANGZHOU UNIV

Dynamic adsorption-type toxic gas detection device

InactiveCN103175763AThe detection basis is stableThe test result is accuratePermeability/surface area analysisAbsorption filterElectron

The invention discloses a dynamic adsorption toxic gas detection device. According to the invention, compressed air is delivered into one of the gas inlets of a gas mixer through an air purifier, a gas humidity regulator, an electronic thermometer / hygrometer, and a gas flowmeter; an outlet of a toxic gas source communicates with a second one of the gas inlets of the gas mixer. The gas outlet of the gas mixer communicates with a gas inlet of a toxic gas concentration detector and a gas inlet of a toxic gas absorption filter. The outlet of the toxic gas absorption filter is connected with a penetration concentration detector. The gas humidity regulator, the electronic thermometer / hygrometer, and the gas flowmeter form an air flow rate and air humidity regulation circuit. The toxic gas concentration detector, the toxic gas absorption filter, and the penetration concentration detector form a dynamic absorption and toxic gas detection circuit. The device provided by the invention has the advantages of simple structure, convenient operation, and precise detection data. With a waste absorption device, pollution to the atmosphere and harm to operators caused by residual toxic gas are avoided.

Owner:广州市高坚劳保用品有限公司

Method for measuring air pollutant emission amount of coal burned at bungalows

The invention relates to a method for measuring the air pollutant emission amount of coal burned at bungalows. The method includes the following steps that satellite data are processed, residential bungalow information is extracted in a remote sensing mode, the area of residential bungalows is refined, and the amount of the coal burned at the bungalows, pollutant emission factors of the coal burned at the bungalows and the pollutant emission amount of the burned coal are calculated. The method has the advantages that the ground monitoring and satellite remote sensing technology is used fully to obtain the area and space distribution of the bungalows at an area to be measured, on the basis, calculation is conducted on the amount of the coal burned at the bungalows and the emission amount of main pollutants, and the method is beneficial exploration and innovation of air pollution surface source remote sensing monitoring operation and provides a scientific basis for air pollution reduction.

Owner:BEIJING MUNICIPAL ENVIRONMENTAL MONITORING CENT

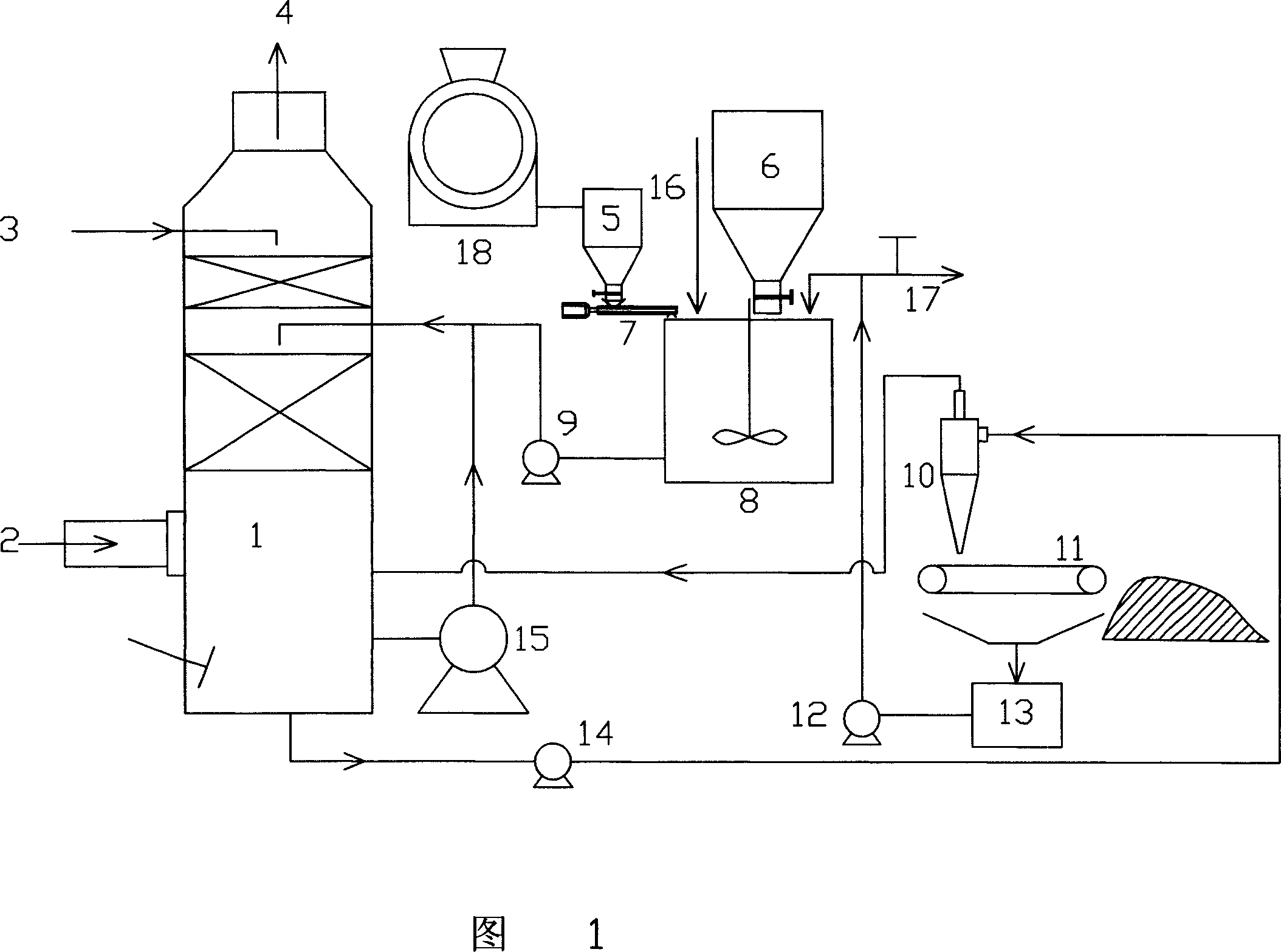

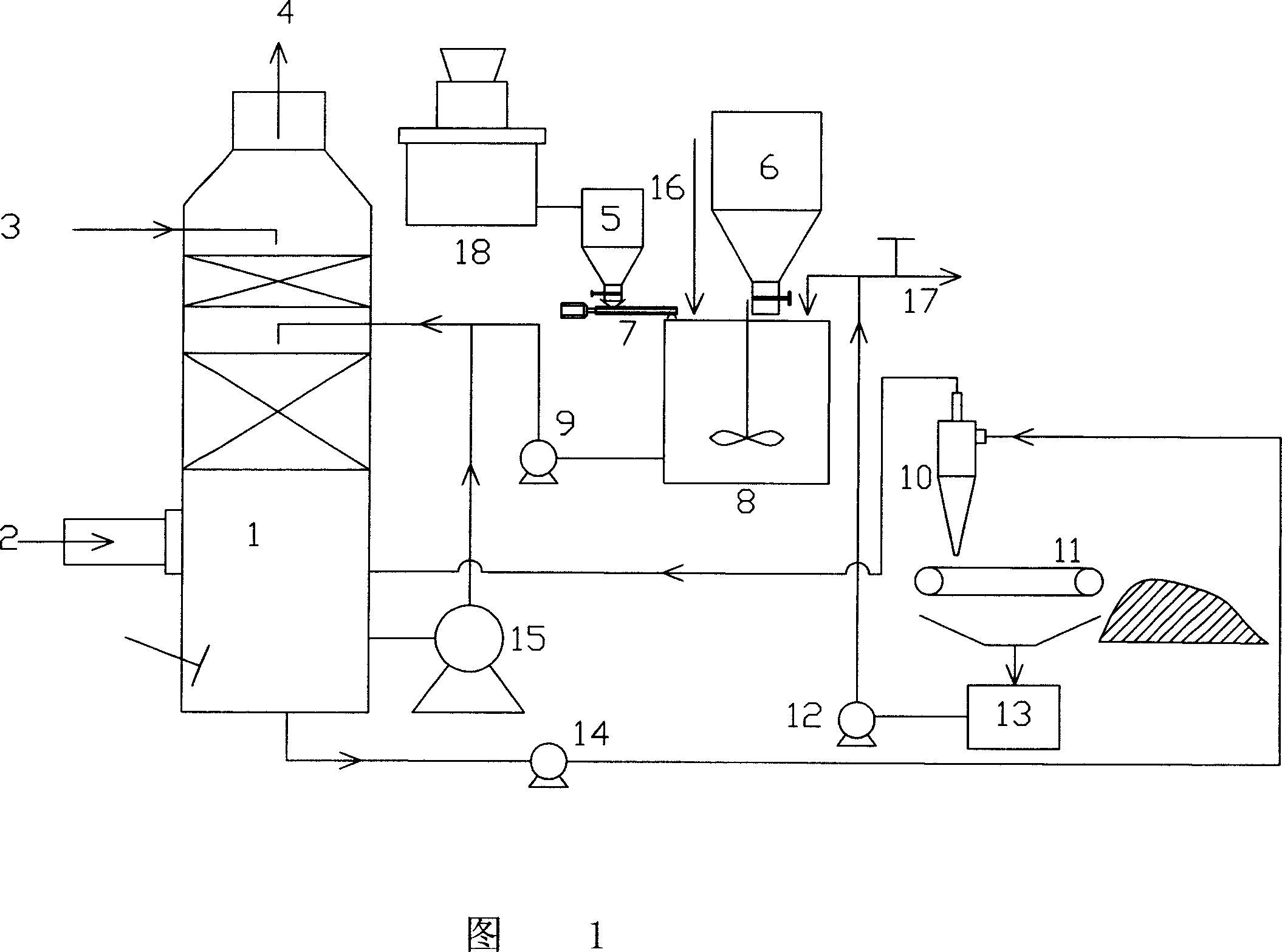

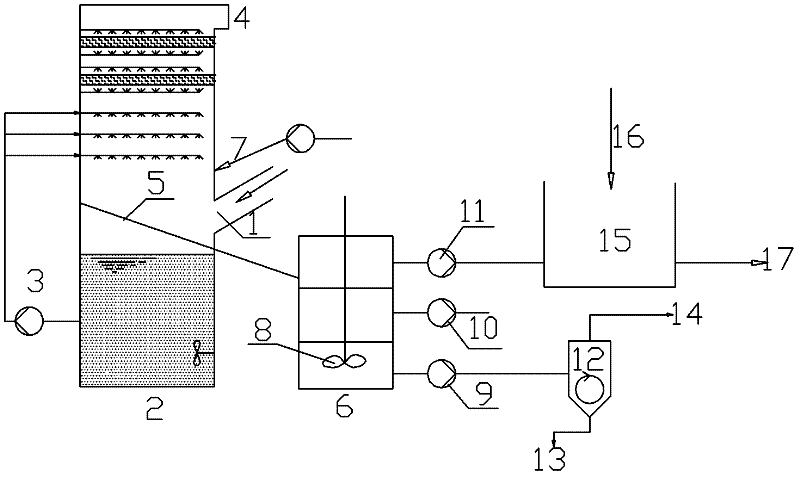

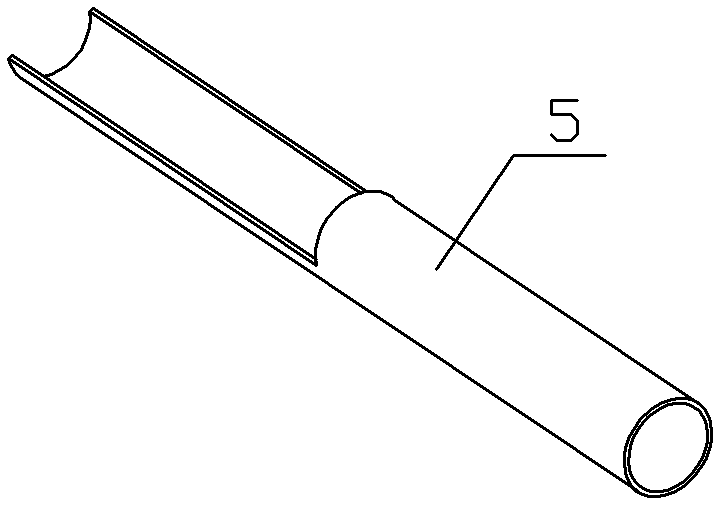

Process and device for flue gas wet desulphurization using carbide slag or white clay as desulfurizing agent

The invention discloses a process and device for flue gas wet desulphurization by using carbide slag or white clay as desulfurizing agent, and belongs to the field of air pollution control. The wet desulphurization device comprises an absorption tower, a slurry pool and gypsum dehydration equipment, wherein a demisting layer, a spraying layer, a flue gas absorbing zone and a slurry tank are arranged in sequence from up down inside the absorption tower; the flue gas absorbing zone is provided with a flue gas inlet; the wet desulphurization device further comprises a separation tank in which a stirrer is arranged; the separation tank is communicated with the absorption tower through a drainage tube; the drainage tube is positioned below the flue gas inlet; the inlet end of the drainage tube is inclined upward and extends into the flue gas absorbing zone; a notch is formed at the part of the drainage tube in the flue gas absorbing zone and in parallel to the axial line of the drainage tube and forms an upward-opening recess; the lower part of the separation tank is communicated with the gypsum dehydration equipment; and the upper part of the separation tank is communicated with the slurry pool. The device is applied to flue gas wet desulphurization. The gypsum slurry is pretreated before dehydration, so that the gypsum layer separates from the solution layer and the colloidal substance layer, which increases the purity of gypsum, reduces the water content of gypsum and improves the quality of gypsum.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

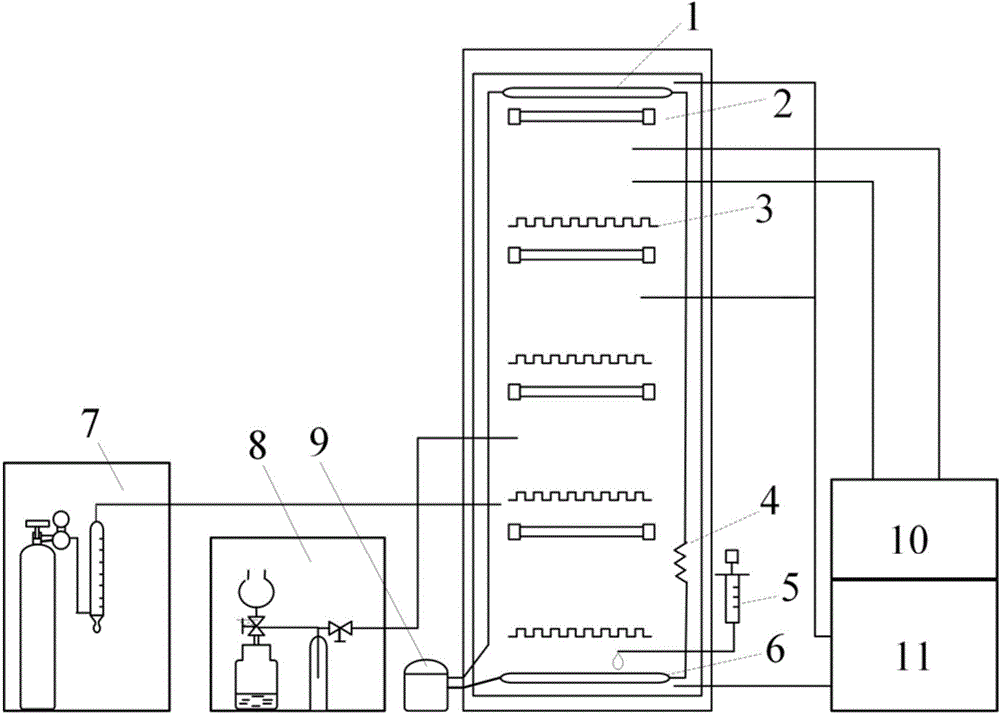

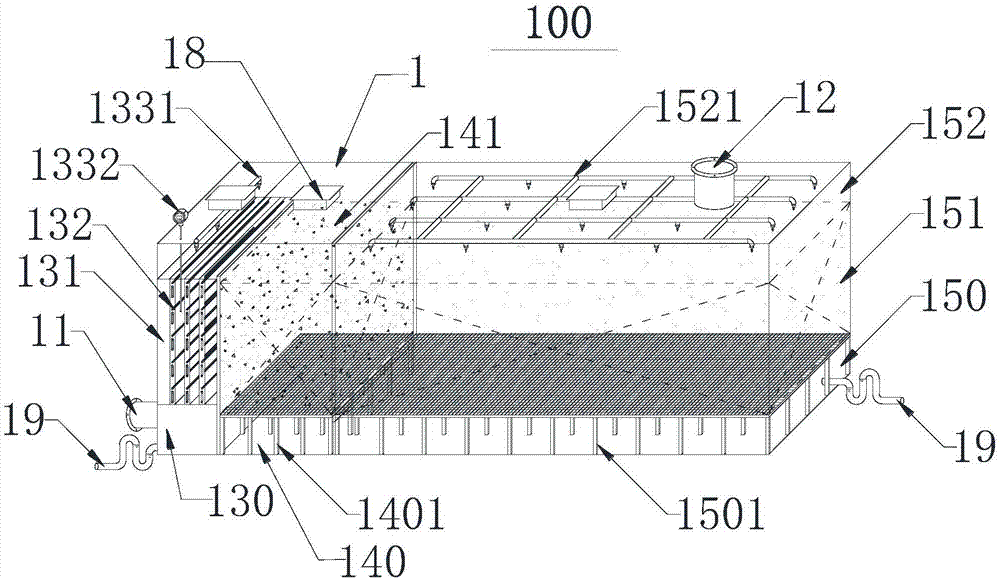

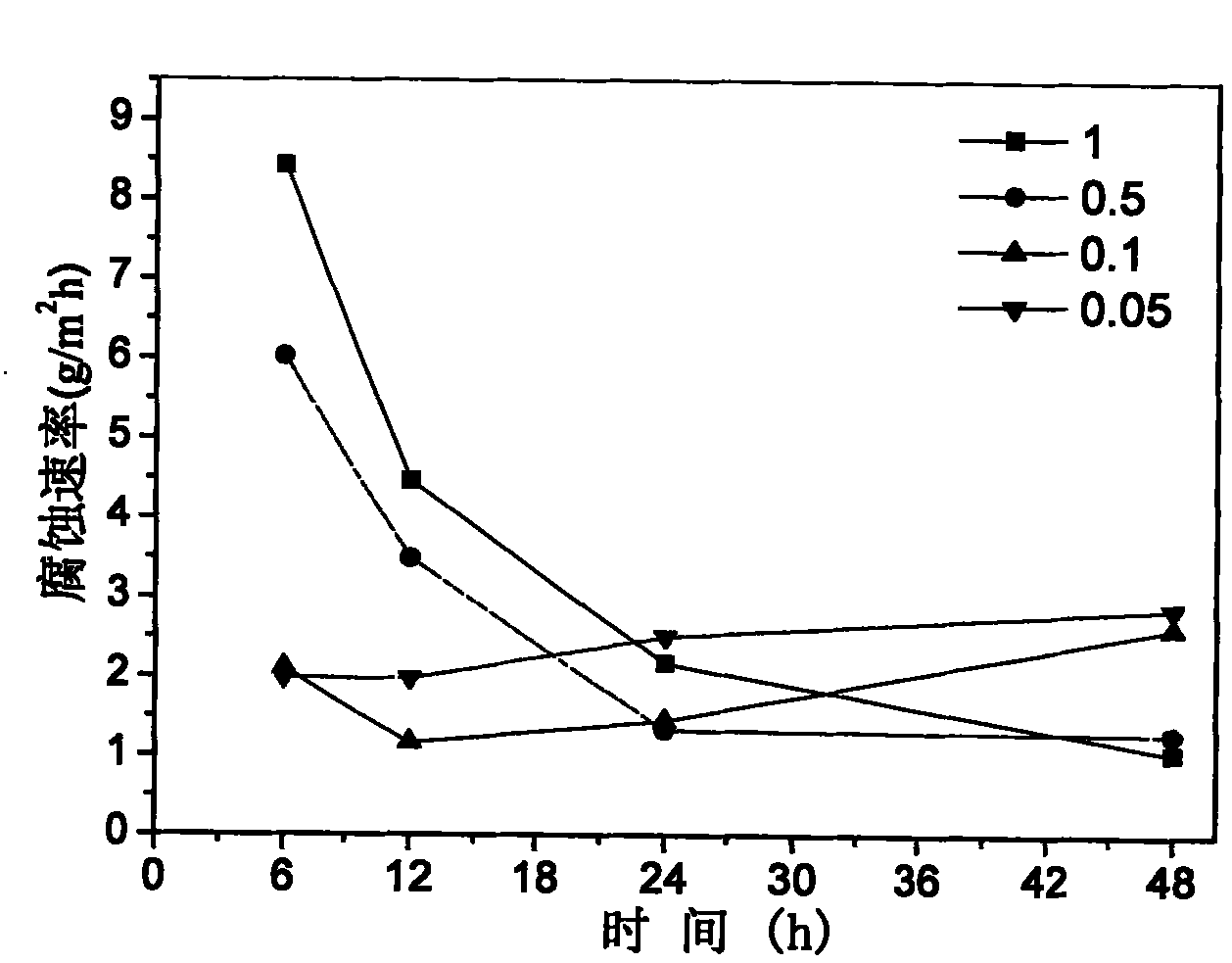

Environment testing box for simulating seriously-polluted atmosphere

ActiveCN104359827AGuaranteed uptimeEasy maintenanceWeather/light/corrosion resistanceWater vaporEngineering

The invention provides an environment testing box for simulating a seriously-polluted atmosphere. The environment testing box comprises a photochemical smoke polluted environment simulation system and a detection system, wherein the photochemical smoke polluted environment simulation system comprises an upper-cold and lower-hot convection generation device, an ultraviolet lamp tube, a heat radiation plate, a carbon dioxide generator, a nitric oxide generator and a water vapor generation device; and the detection system comprises a sample rack, a multi-pipeline infrared gas analyzer and a temperature recorder which are arranged in the box body. Compared with the prior art, a generation condition of photochemical smoke in the seriously-polluted atmosphere can be stably simulated; the environment testing box can be stably operated for a long time, and a long-time corrosion and ageing test can be carried out on a material; a heat pump is used, and heating and refrigeration energy conservation can be realized; and the environment testing box is simple and convenient to maintain.

Owner:SHANGHAI RES INST OF CHEM IND +1

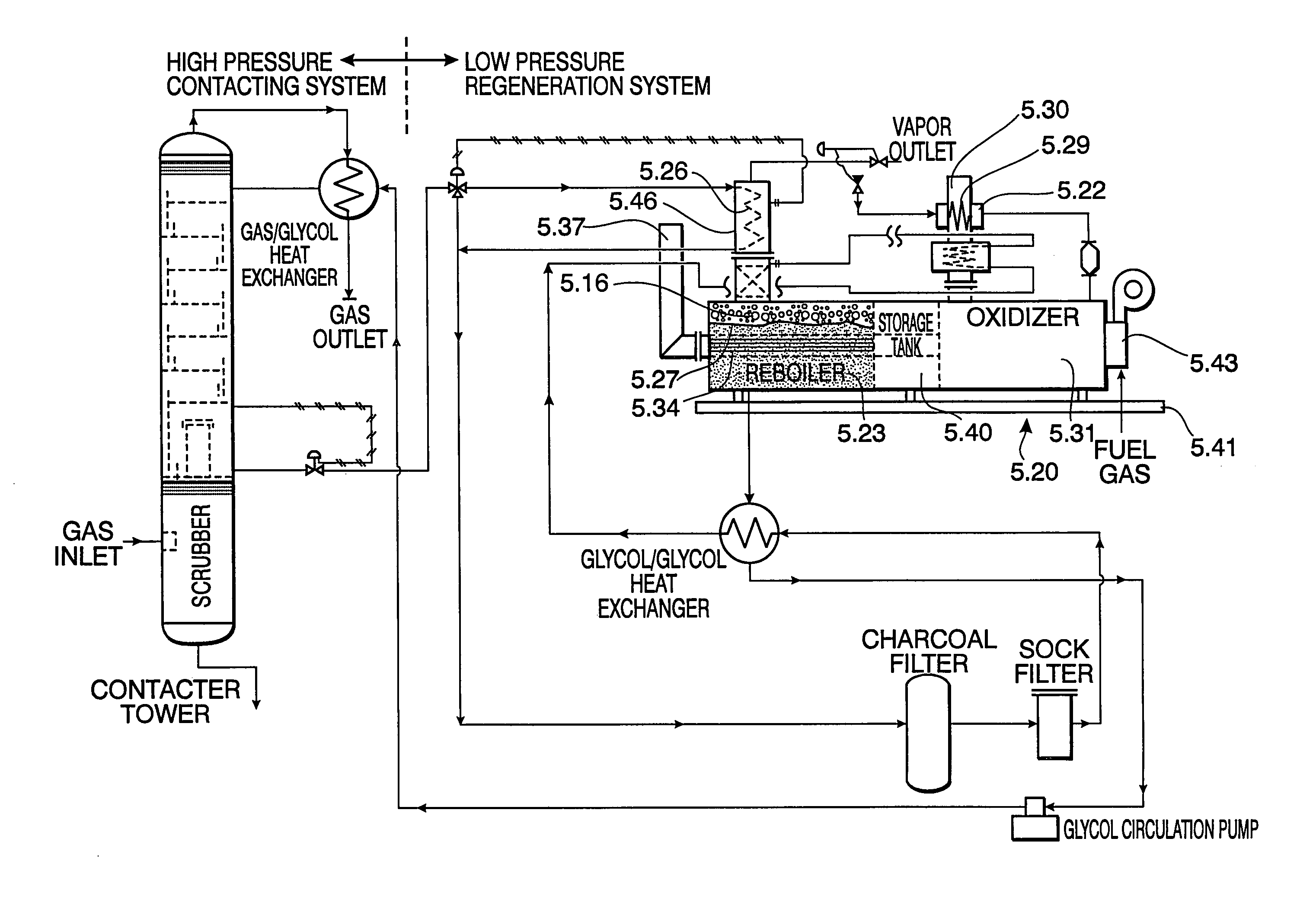

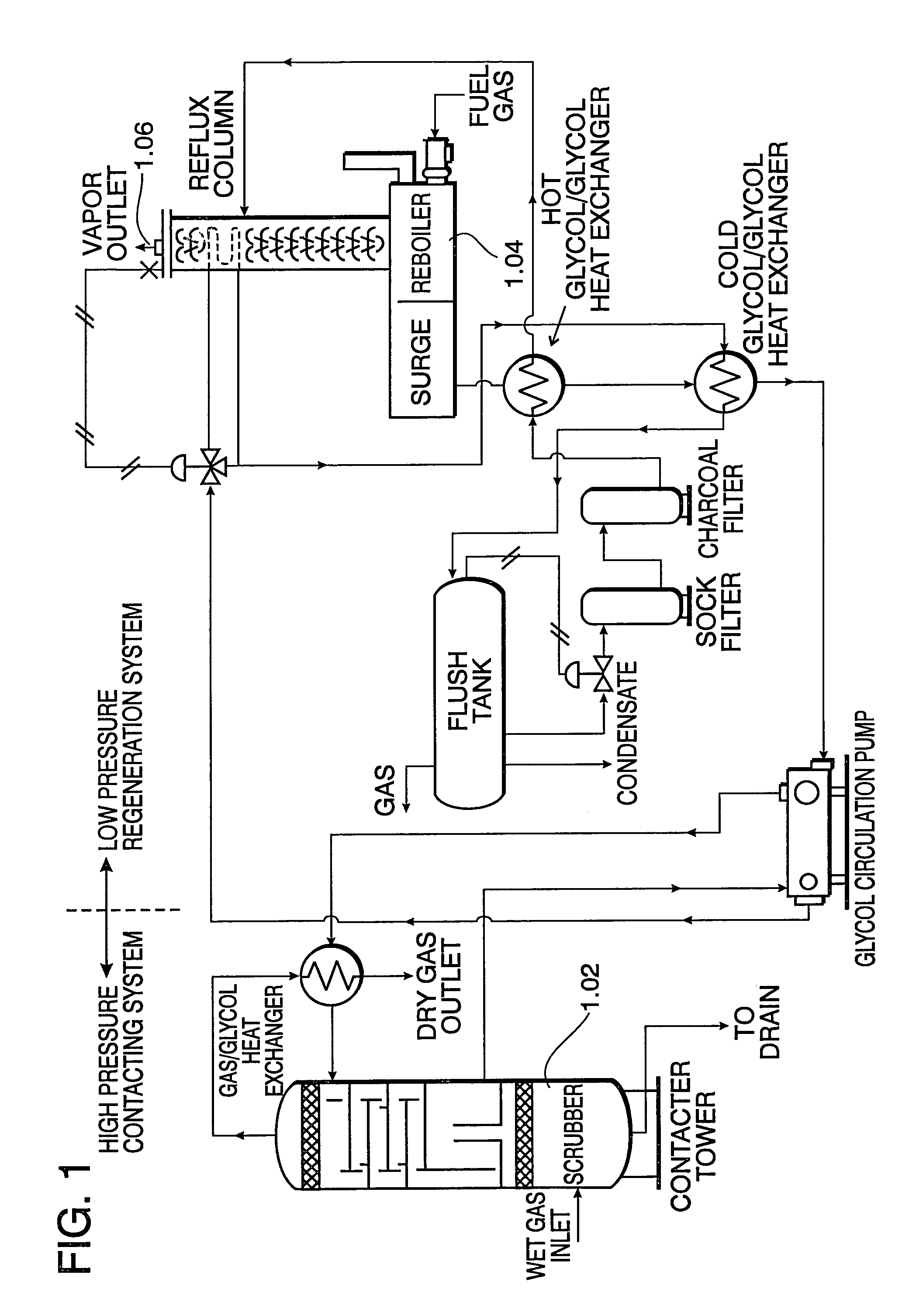

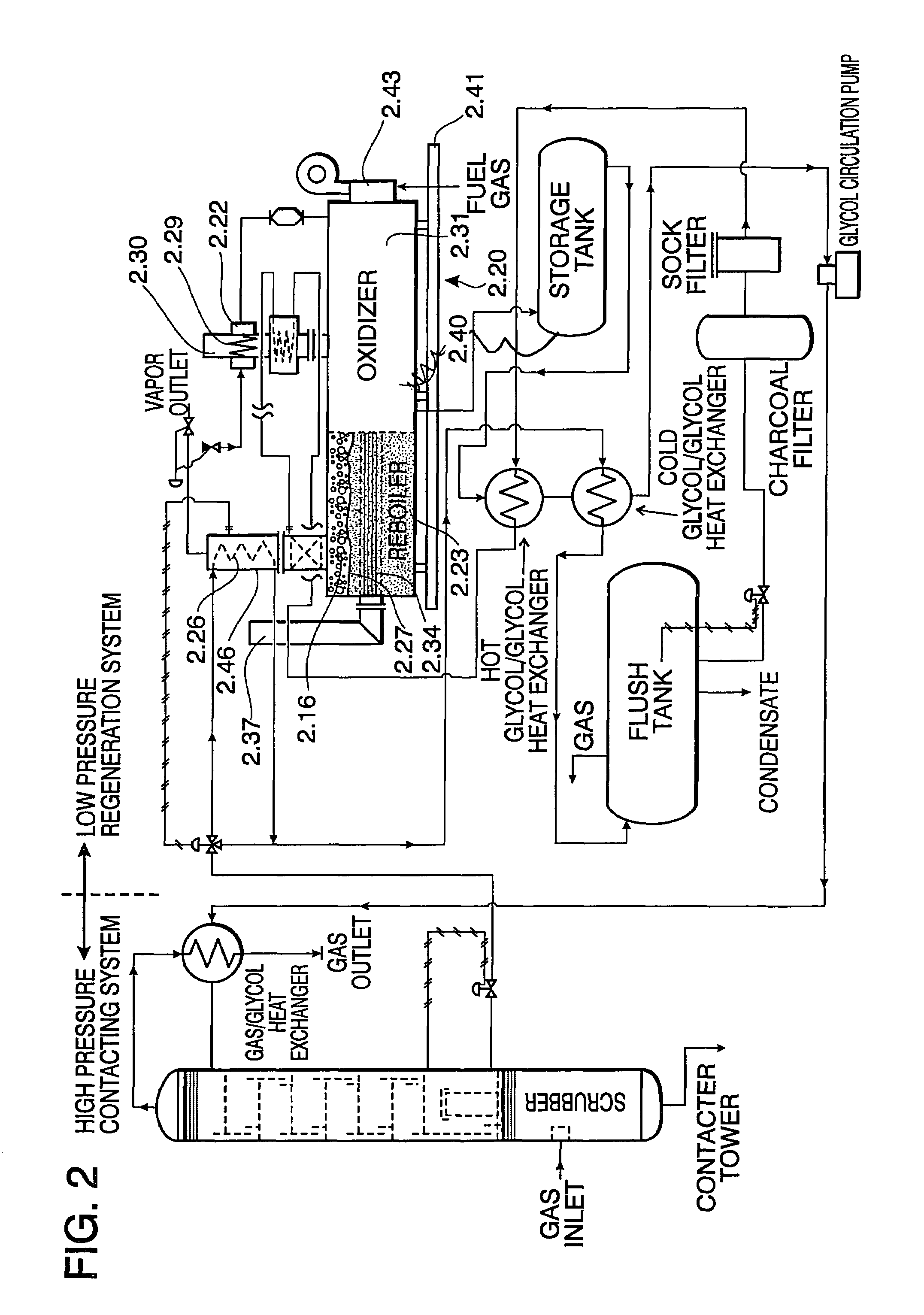

Oxidizing undesired compounds resident within liquid absorbent compounds, reducing atmospheric pollution, regenerating a liquid absorbent and conserving fuel usage associated with reboiler utilization

InactiveUS6964729B1Promote oxidationRetain heatLiquid degasificationOrganic compound preparationCombustion chamberReboiler

An improved method and apparatus for oxidizing undesired compounds residing within a liquid glycol based absorbent wherein the compounds are heated within a reboiler chamber to their boiling point to effectuate production of vaporized effluents. The absorbent's vaporized effluents rise upwardly exiting the reboiler chamber and enter a reflux tower wherein they are partially condensed via a condenser embodied within the interior of the tower. The residual uncondensed effluents are then transported to and first heated via a vaporizer / heat exchanger, thus effectuating the vaporization of any ambient condensed liquids contained within the effluents. The revaporized effluents then enter the invention's thermal oxidizer combustion chamber where they are second heated to a temperature necessary to effectuate destruction of undesirable compounds, such as but not limited to benzene, toluene and xylene. A temperature control throttling mechanism throttles the introduction of supplemental gas as necessary to maintain the temperature necessary to effectuate and maintain destruction of undesirable compounds. The combustion chamber is in fluid communication with a plurality of tubes which pass through the reboiler. The tube bundle generates external tube surface temperatures sufficient to raise a liquid glycol based absorbent in contact therewith to its boiling point. The second heated effluents are then introduced to and through a thermal oxidizer vent stack allowing for the exiting of said effluents. Venting mechanisms located in the invention's still / reflux tower and oxidizer vent stack are controlled in a coordinated manner to ensure temperature consistency of effluents traversing the invention's internal combustion chamber and tube bundle.

Owner:KHOSROWYAR PARVIZ

Method for integrated desulfurization and denitration for marine ship exhaust

InactiveCN101972605AReduce power consumptionReduce volumeDispersed particle separationPlasma generatorSeawater quality

The invention discloses a method for integrated desulfurization and denitration for marine ship exhaust, and belongs to the fields of air pollution control and marine ship exhaust control. The exhaust passes through an atomizing humidification and cooling area, a discharging oxidation area and a seawater washing area in turn to complete the integrated desulfurization and denitration. The exhaust is humidified and cooled by the atomizing humidification and cooling area consisting of a small seawater pump, an exhaust humidifying and cooling pipe and a nozzle; SO2 and NO are converted into sulfuric acid and nitric acid by massive HO2, OH and other oxidative free radicals in the charging oxidation area consisting of a plasma generator; and the sulfuric acid and nitric acid are converted into sulfate and nitrate by the seawater washing area consisting of a seawater washing tower, a filler and a large seawater pump, and the exhaust meeting the standard and washing water are discharged. The integrated desulfurization and denitration system has the advantages of low energy consumption, small volume, low price, no need of a seawater quality restoring system or raw material storage and transportation, direct discharge of products into sea and the like.

Owner:WUHAN TEXTILE UNIV

Organic waste gas treatment device

PendingCN107349767AImprove processing efficiencyImprove the degree of purificationGas treatmentDispersed particle separationCatalytic oxidationOxidation zone

The invention provides an organic waste gas treatment device which comprises a reaction cavity, wherein the reaction cavity is provided with an air inlet and an exhaust port at two ends in the left-right direction respectively, and the reaction cavity is divided into three reaction zones including a photo-oxidation zone, an ozone catalytic oxidation zone and a bio-trickling zone communicated with each other in sequence from the air inlet to the exhaust port. The organic waste gas treatment device for treating organic waste gas by adopting a photo-oxidation and biodegradation coupling method improves the organic waste gas treatment efficiency, realizes deep treatment, avoids the problem that organic small molecular intermediate products with toxicity are produced due to low mineralization degree of organic pollutants when organic waste gas of volatile organic compounds (VOCs) is treated by a single technology, is suitable for treating the organic waste gas of most industrial VOCs, and is beneficial to solving the urgent problem of atmospheric pollution at present in China.

Owner:SHENZHEN POLYTECHNIC

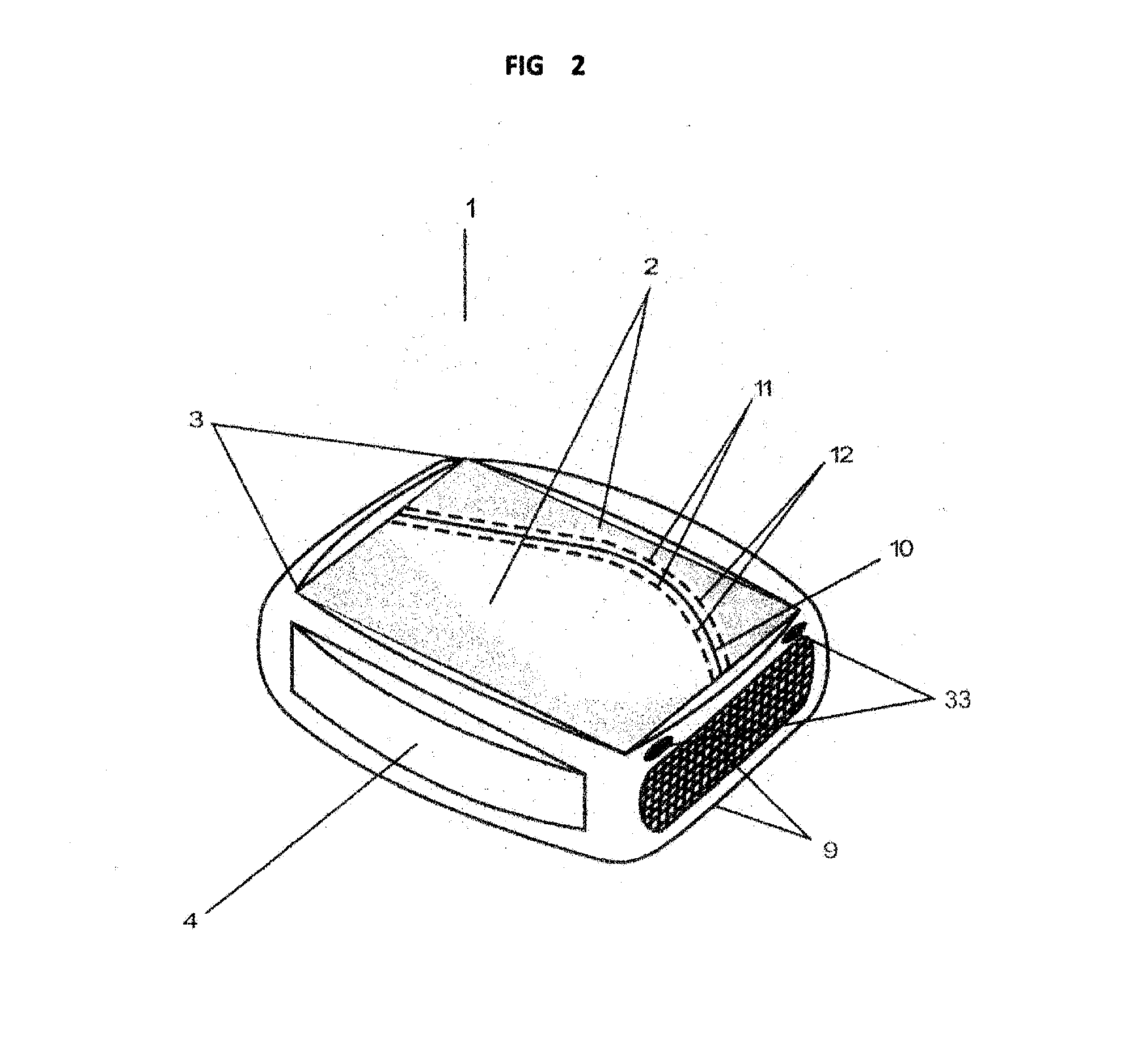

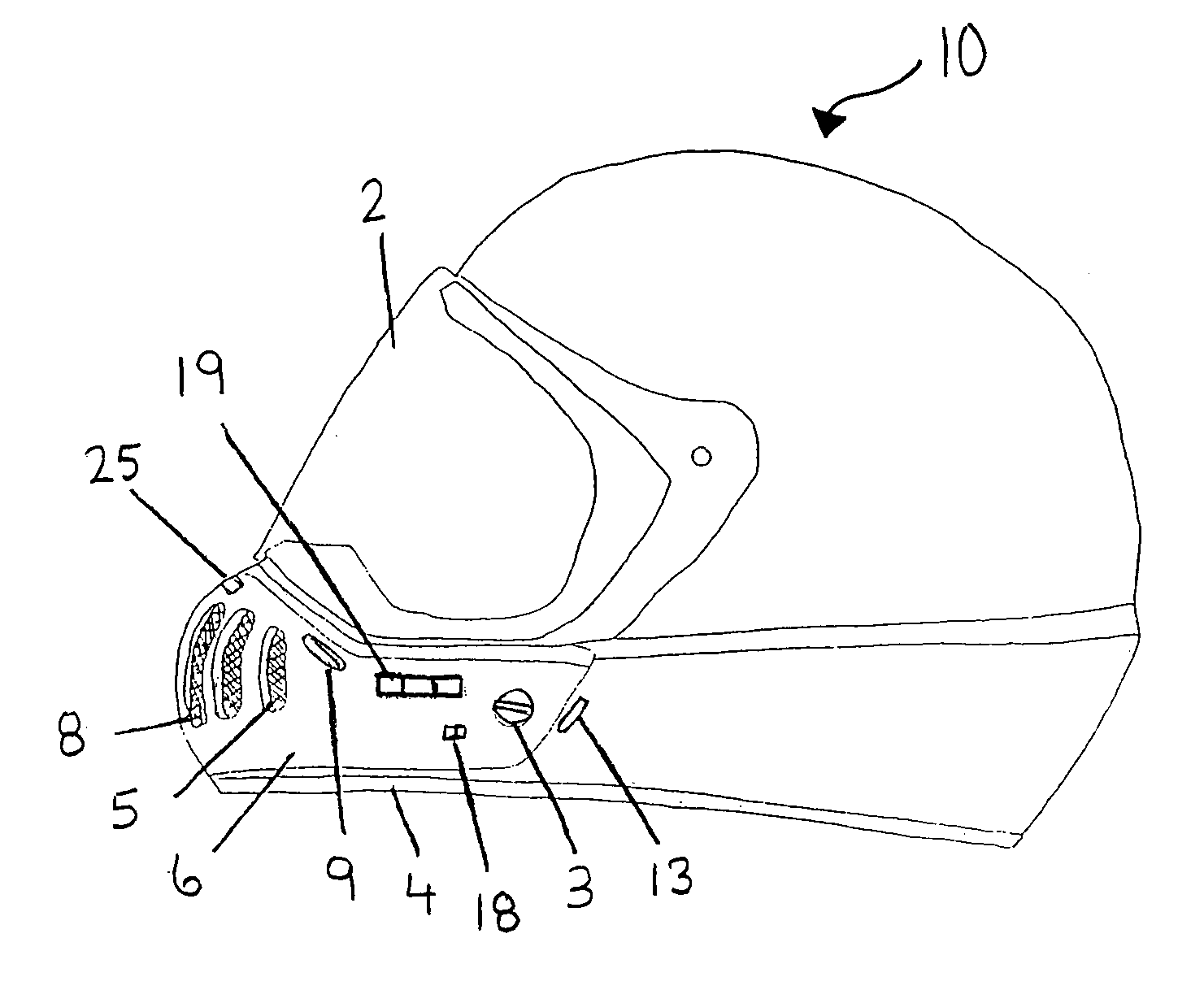

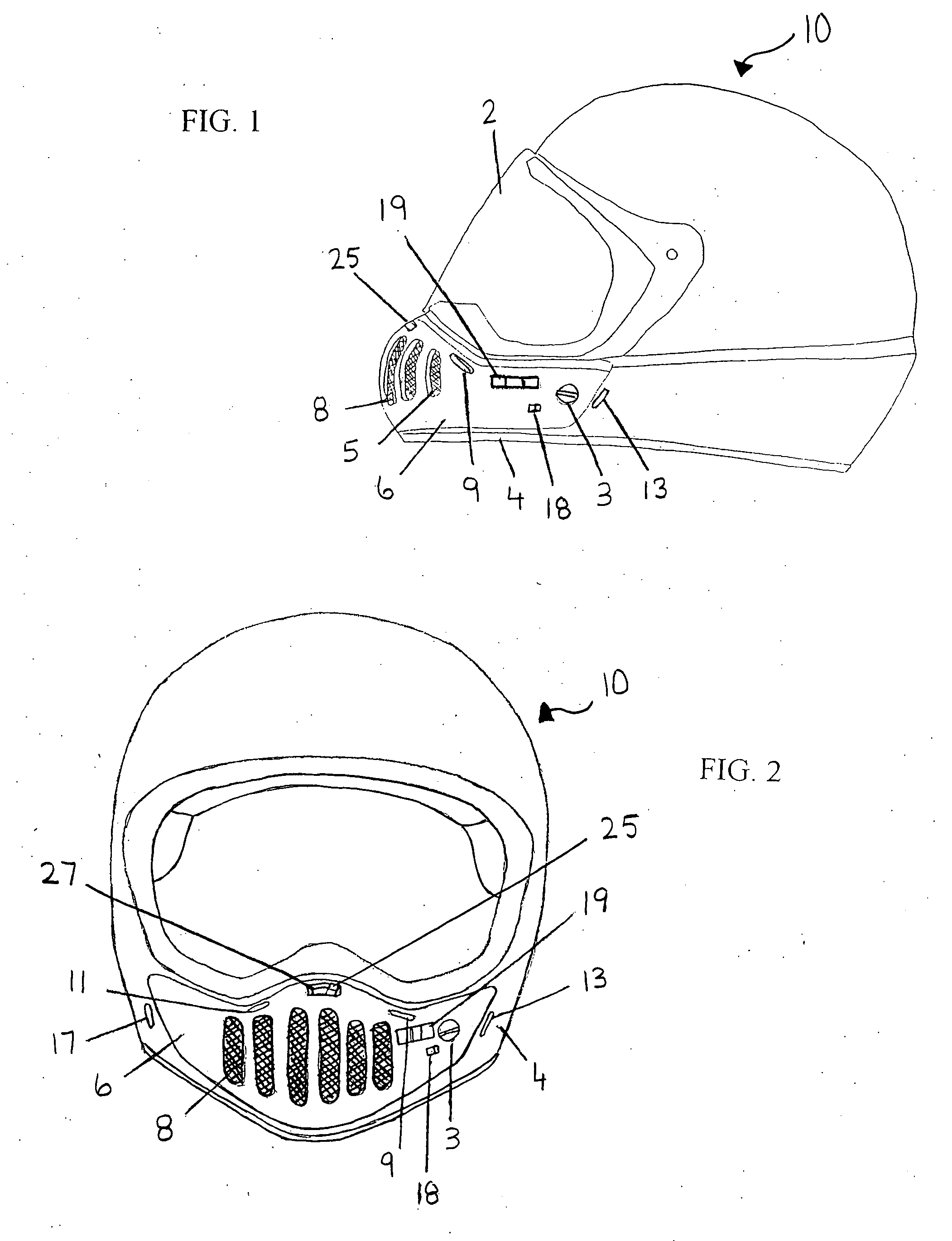

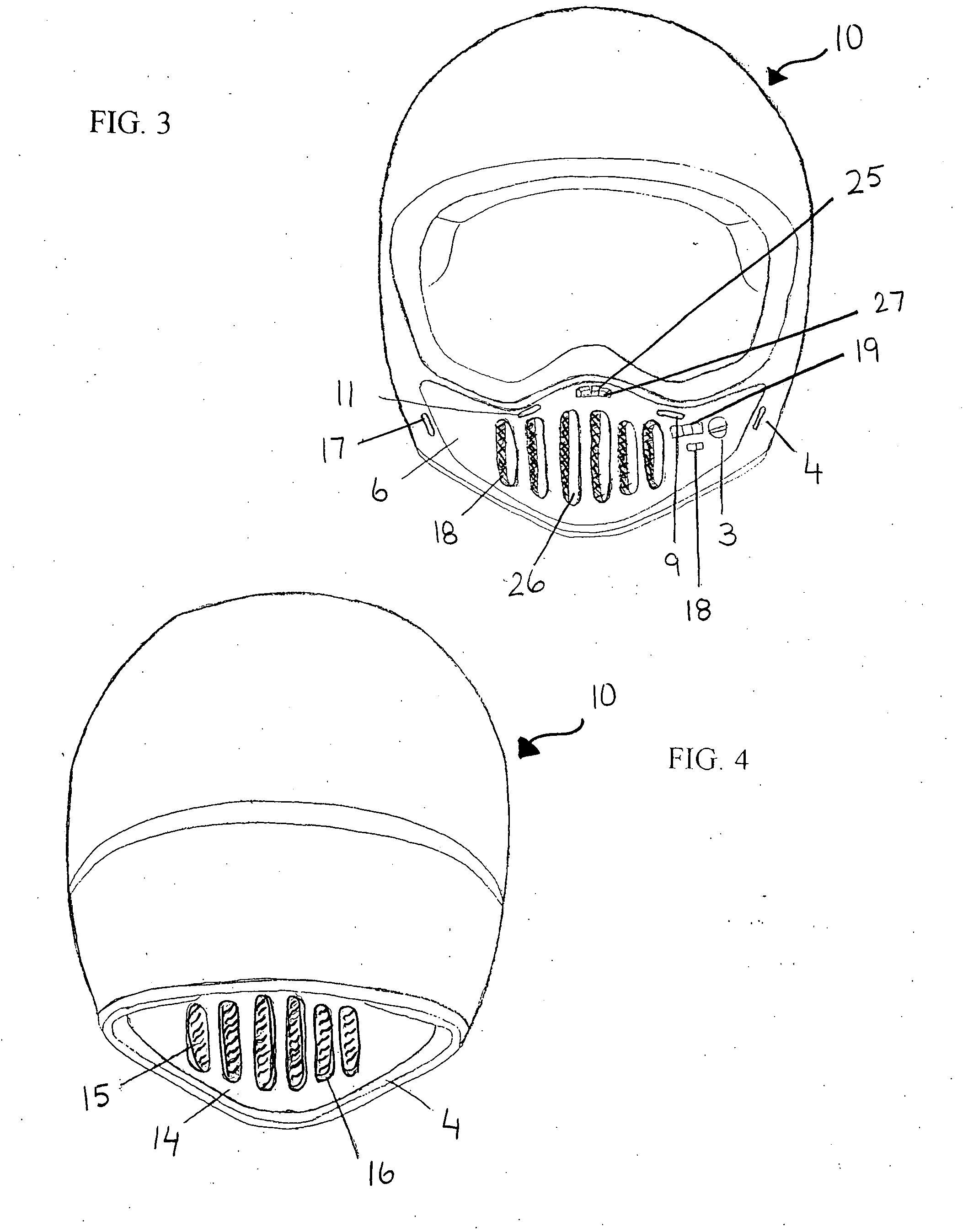

Retractable protective respiratory mask

InactiveUS20140007888A1The process is fast and efficientEasy to carryDiagnosticsBreathing masksNoseToxic material

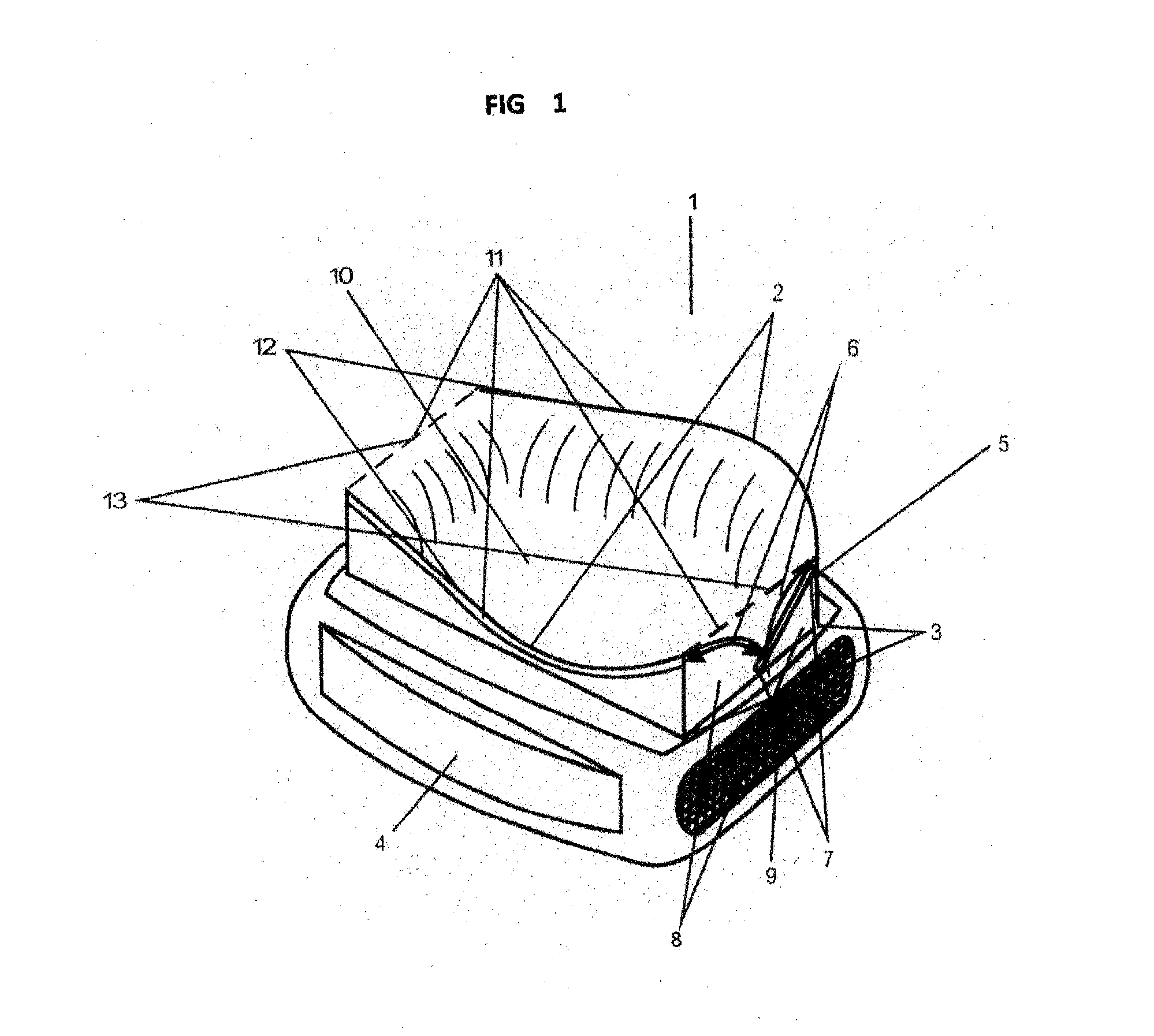

A retractable protective respiratory mask including disposable filters, which protects the respiratory system, covering the nose and mouth during inhalation while breathing in an atmosphere polluted by different agents, such as infectious, virulent, or pathogenic agents, or other toxic substances. The mask also protects non-infected persons from persons infected with a virus, as saliva and sputum expelled when coughing, breathing-out, and / or talking can be deposited inside the mask. The mask can include a collection-container filter, allowing a viral-infected wearer to breathe in a polluted atmosphere, to talk, to cough, to sneeze and / or to deposit saliva and sputum. The mask can be used as any other type of filter mask and / or disposable environmental air mask for industry in general, and also providing protection in rarefied natural atmospheres. The mask can be used as a container or packaging for drugs administered by means of bronchial airways, or as medical or rescue masks.

Owner:POSADA BUITRAGO BARBARA +1

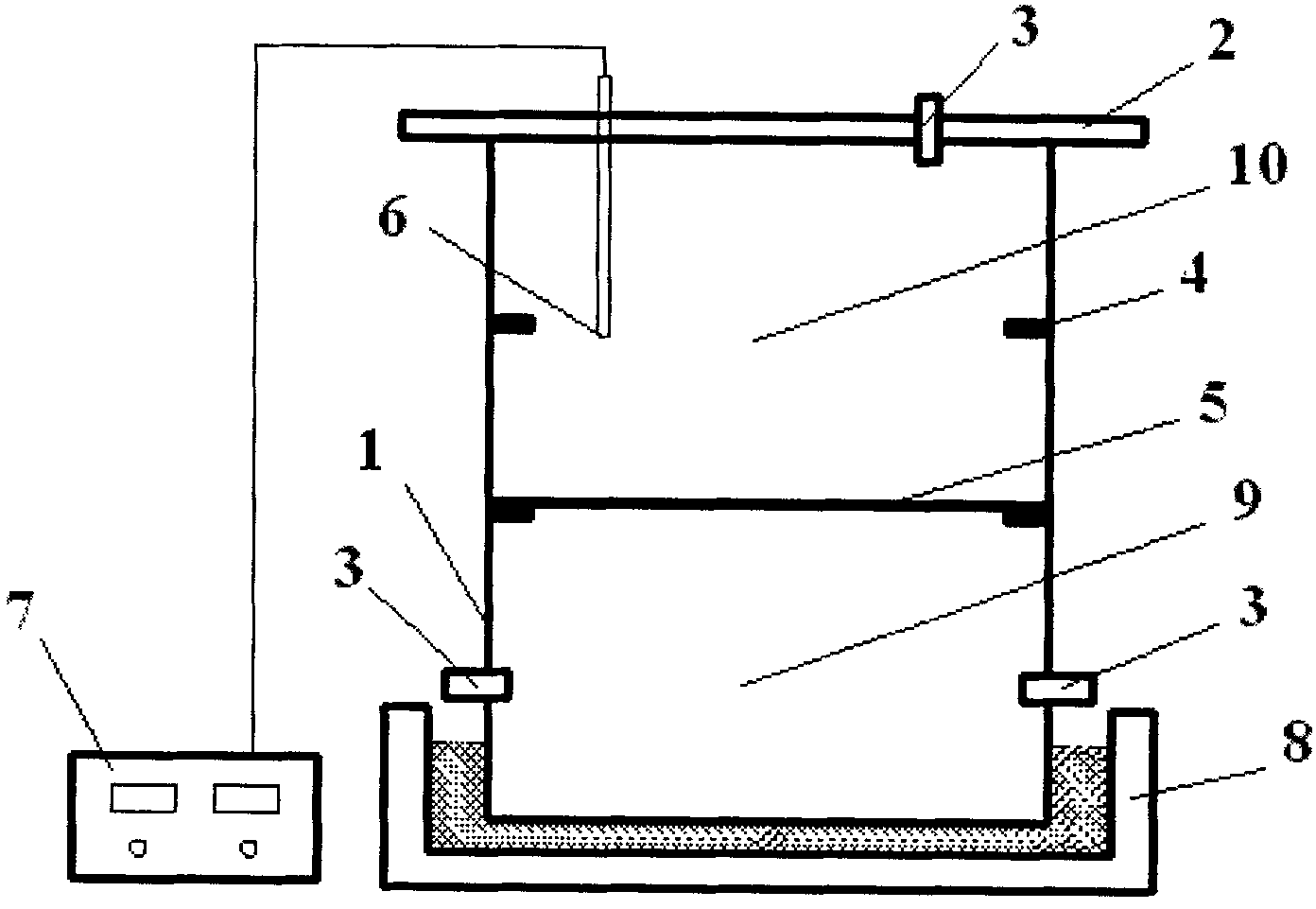

Accelerated testing apparatus for simulation of corrosion by industrially polluted atmosphere

InactiveCN102169083ASolve the problem of single dependence on external air sourceImprove good performanceWeather/light/corrosion resistanceAtmospheric airEngineering

The invention relates to a simulation technology of atmosphere corrosion on material and anticorrosion paint, and especially provides an accelerated testing apparatus for the simulation of the corrosion by industrially polluted atmosphere. The apparatus is provided with a reaction box, a box cover, an air inlet and outlet pipe, and a humiture monitoring probe. Besides, an inner chamber of the reaction box is divided into an upper layer chamber and a lower layer chamber, and the upper layer chamber is a corroding chamber and the lower layer chamber is an atmosphere generating chamber; the box cover is movably arranged on the top of the reaction box, and the air inlet and outlet pipe and the humiture monitoring probe are inserted into the box cover; and the air inlet and outlet pipe is inserted into the sidewall of the reaction box which has the atmosphere generating chamber. The apparatus has two methods of generating corrosive atmosphere: the chemical method and the external connection of gas source method, and a problem of relying on the single external connection of gas source to generate the corrosive atmosphere is solved. Simulation of the corrosion by polluted atmosphere especially by heavy-industry polluted atmosphere with the invention could be used for researching and evaluating the corrosion action of metal material and the anticorrosion paint in the heavy-industry polluted atmosphere, so as to provide evidence for reasonably choosing the material and choosing the appropriate protection method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Oxygen helmet

InactiveUS20100300435A1High catalytic efficiencyProlong lifeCombination devicesGas treatmentAtmospheric layerOxygen

A motorcycle helmet having an oxygen conversion unit, which converts polluted air to breathable oxygen and other harmless compounds, while riding through the polluted atmosphere.

Owner:THIRUPPATHI DEVARAJ

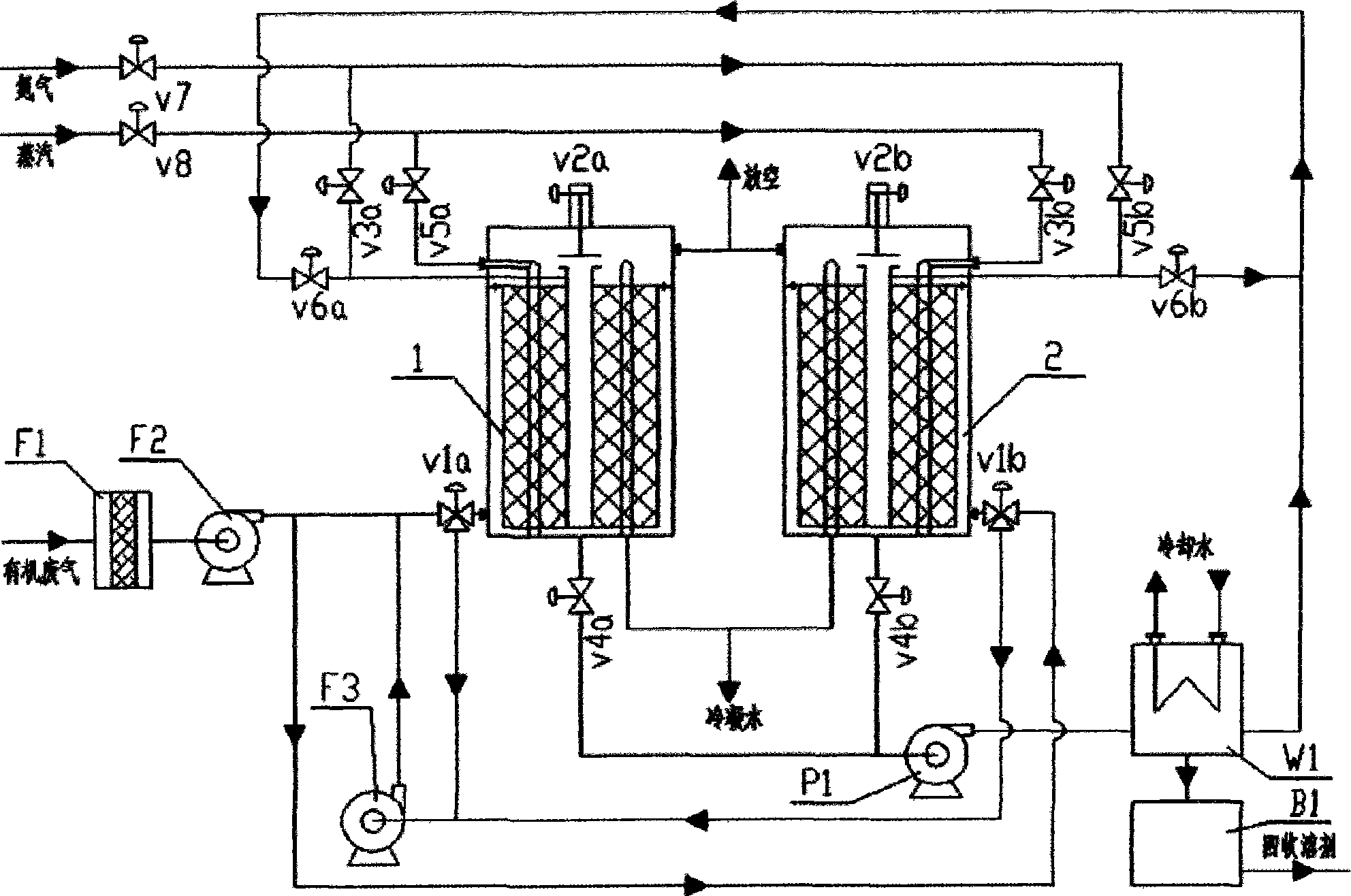

Device and process for recycling organic gas through low-pressure dry-type indirect heating desorption

InactiveCN104028075AQuality improvementReduce separation drainageDispersed particle separationDesorptionWater soluble

The invention relates to a device and a process for recycling organic gas through low-pressure dry-type indirect heating desorption. Particularly, volatile organic waste gas is adsorbed and purified in an absorber, in the desorption period, the absorber is depressurized, an adsorption material is indirectly heated, and organic matters in the organic gas discharged from industrial production are recycled in a low-pressure dry-type indirect heating desorption mode. The problem that a great deal of separated discharged water is generated in an occasion that recycled and treated discharge water is mingled with a water-soluble solvent is solved, the secondary pollution is prevented, the later water treatment stress is alleviated, the device investment and the operation cost for the waste gas treatment are lowered, and the quality of the recycled solvent is improved. The device and the process belong to the technical field of atmospheric pollution treatment in the sanitary production and energy-saving and environmental-friendly industry.

Owner:蔡博

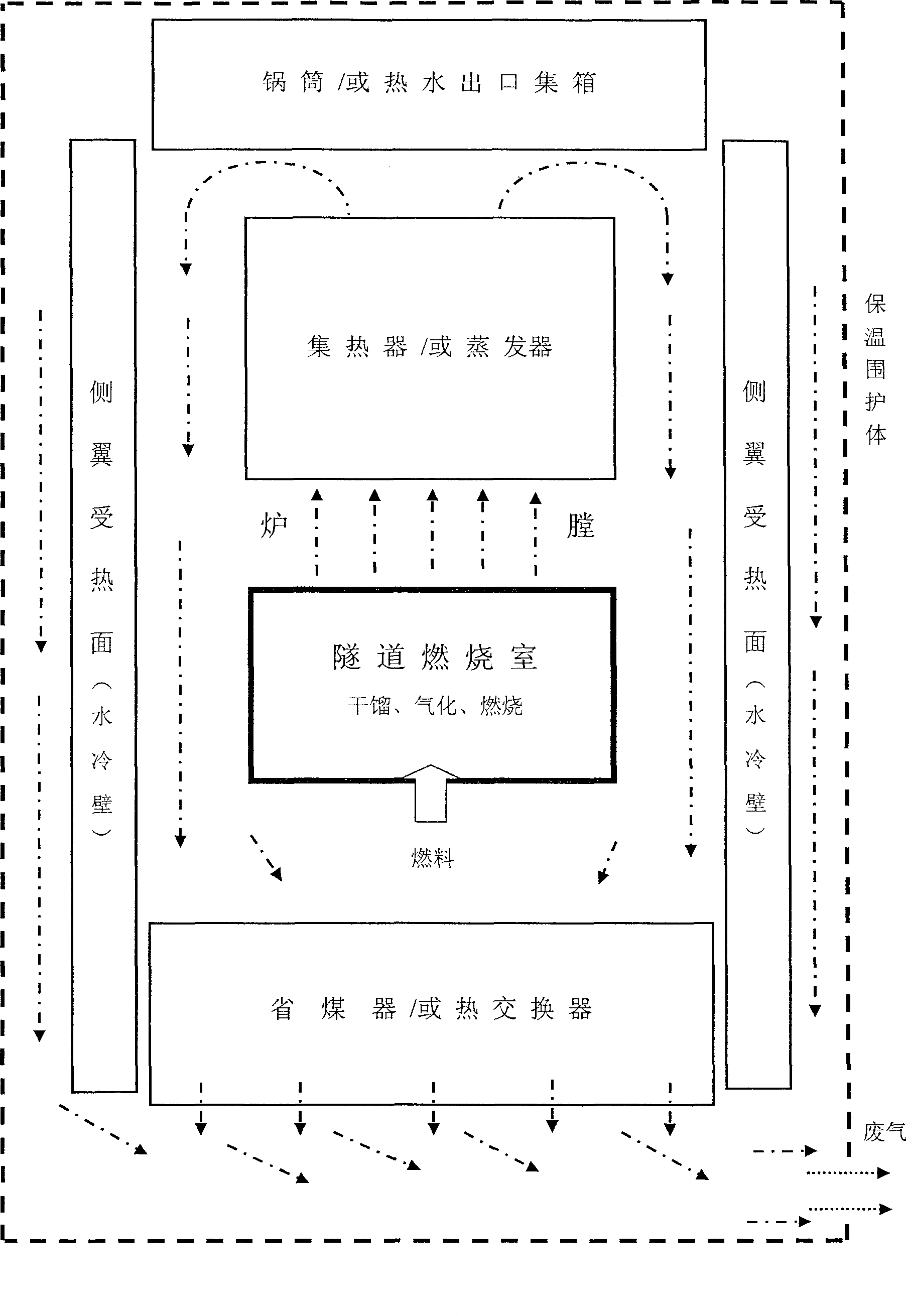

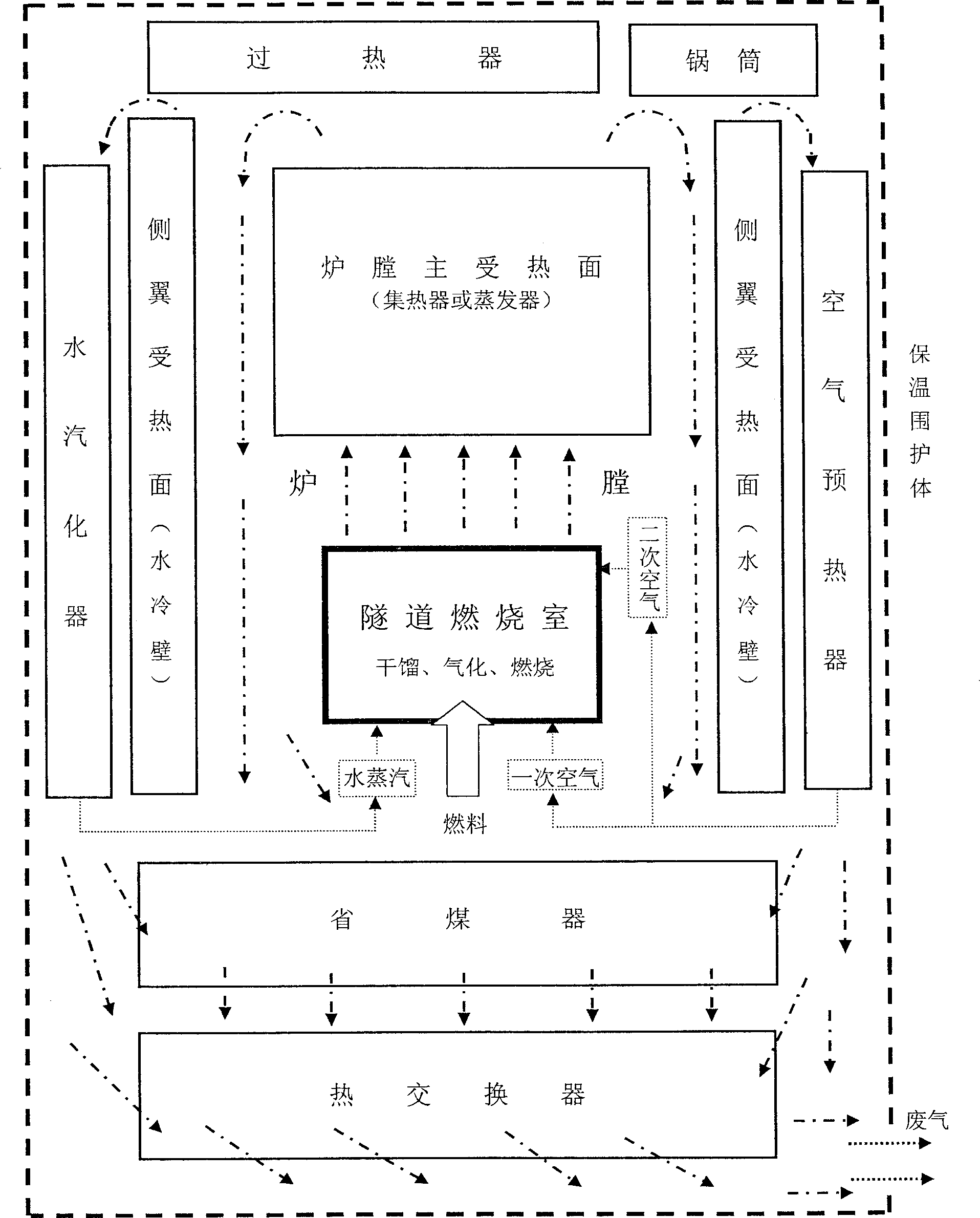

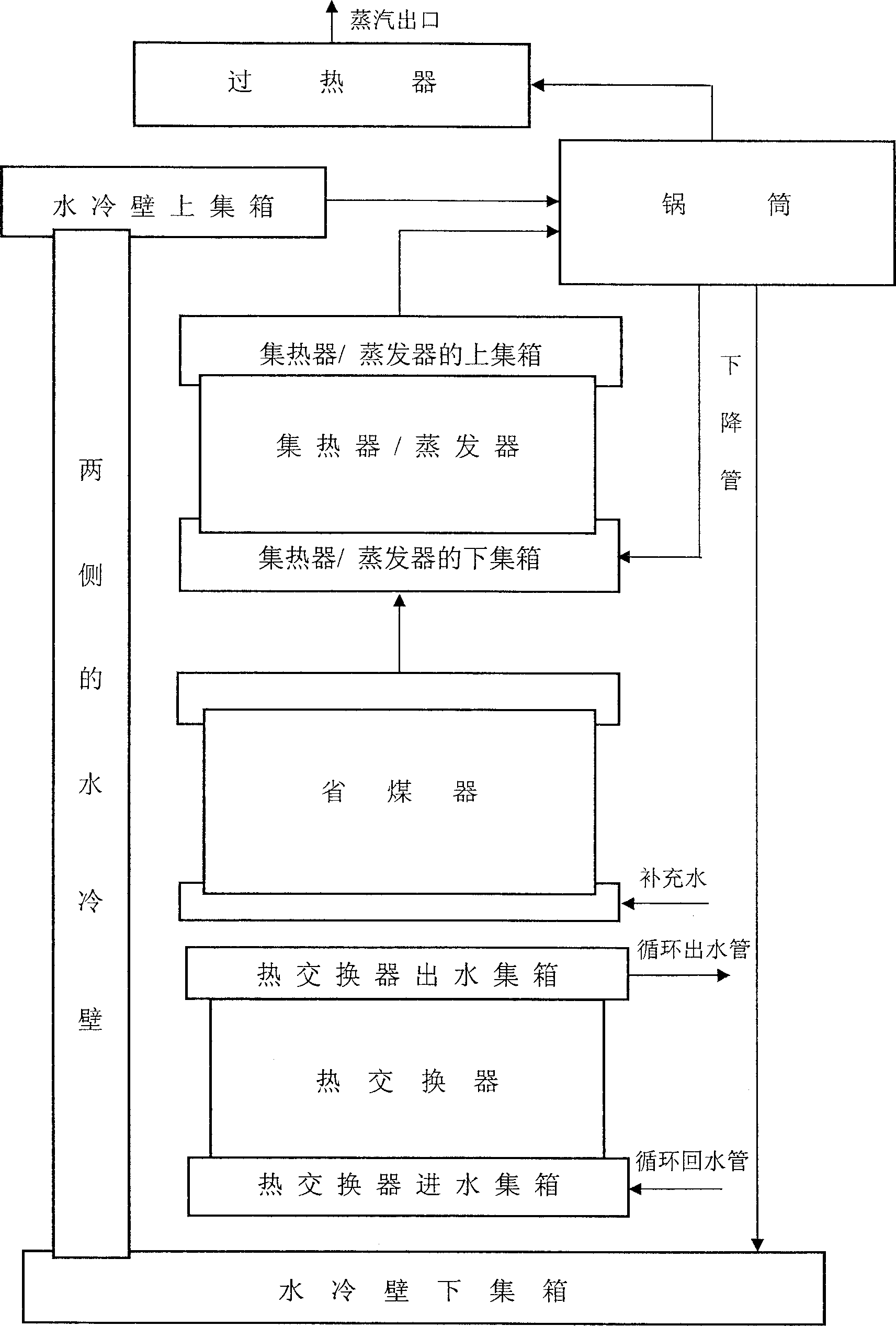

Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

InactiveCN1904479ARaise the gradePrevent escapeCasings/liningsNon-combustible gases/liquids supplyResource depletionCombustion chamber

The tunnel combustion chamber and its constitute of burning coal and organism without smoke and dust relate to boiler, furnace and aerify equipment whose fuel is coal and organism. The tunnel combustion chamber has wide fuel scope. It can carry out the cleanness combustion of the smoke raw coal, the spread coal, the organism, the type coal and the biologic coal. It applies the biologic fuels reasonably and has high thermal efficiency. It realizes the large-scale and mechanical burning. The invention resolves the problem of pollution atmosphere environment by coal burning device. It makes the equipments the cleanness combustion when burning the coals. The small equipment doesn't need air blast and induced air and it can burn. And it doesn't need the ash handling equipment to protect the environment. The invention sends the vapour to the tunnel combustion chamber. It is used to restrain the smoke and translate to the gas fuel. It carries out cleanness combustion when realizes the increase the combustion value of the fuels. It lowers the resources depletion and relief the energy strain. It creates a condition for pushing economy social overall coordination sustained developing.

Owner:周开根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com