Fume desulfurizing process with enhancement limestone method

A desulfurization process and limestone technology, applied in the field of flue gas desulfurization process and enhanced limestone flue gas desulfurization process, can solve the problems of high operating cost and large investment, and achieve the advantages of reducing desulfurization cost, improving desulfurization efficiency and improving utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

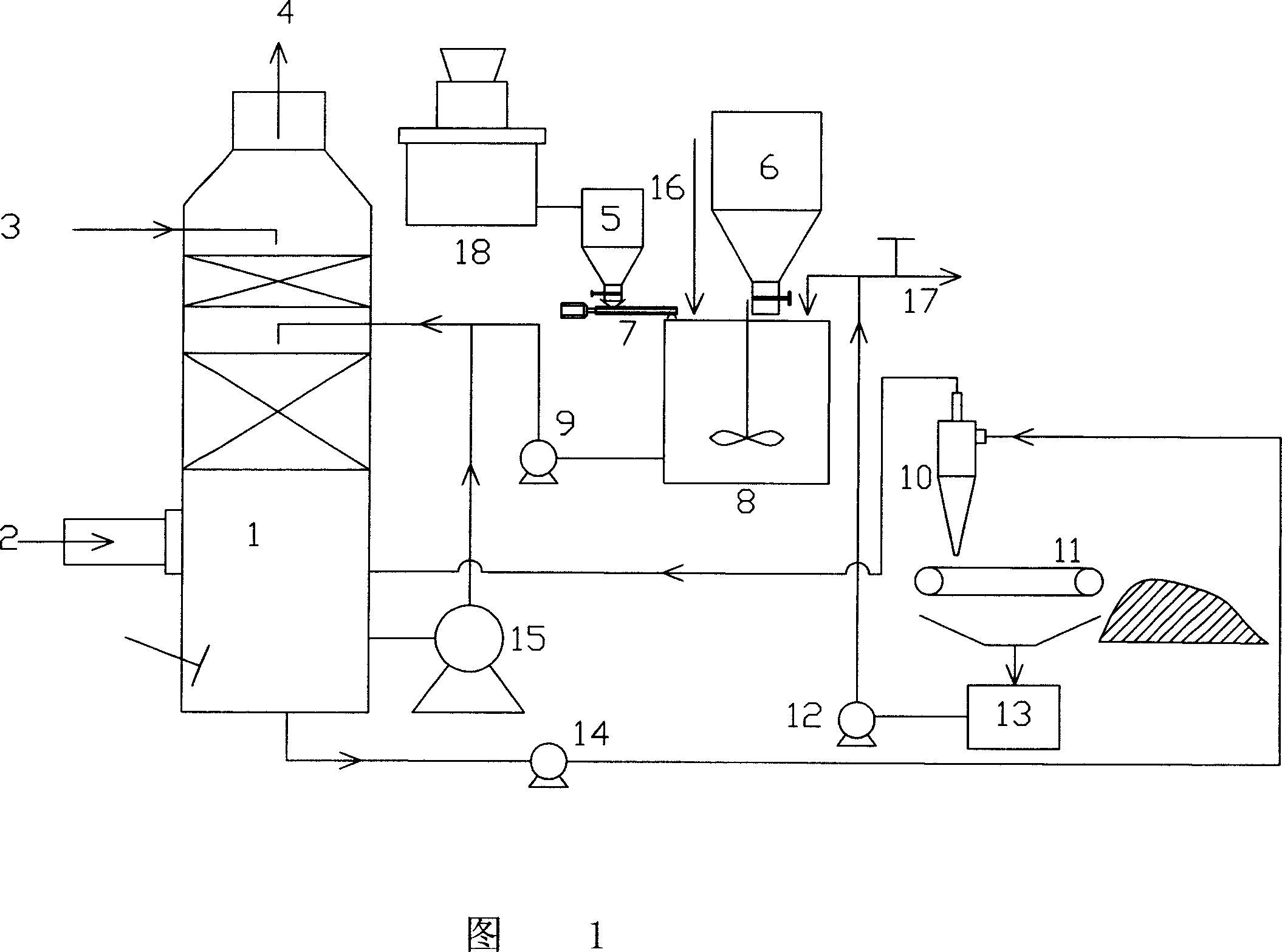

[0037] Referring to Fig. 1, absorbent limestone powder and additives are stored in limestone silo 5 and additive silo 6 respectively, and enter digestion reactor 8 through respective screw conveyors 7 and metering devices. If it is a limestone block, it will enter the limestone bin 5 after being ground into powder by the limestone grinder 18. If it is a liquid additive, the additive can be directly delivered to the digestion reactor 8 through the liquid delivery pipeline.

[0038] Limestone and additives are reacted with water (which may be process make-up water 16 or filtrate from filtrate tank 13 or overhead flow from cyclone 10) in digestion reactor 8 to form an absorption slurry.

[0039] The absorption slurry after the digestion reaction is delivered to the output pipeline of the main circulation pump 15 through the absorption slurry delivery pump 9 , or directly enters the absorption tower 1 .

[0040] The sulfur-containing flue gas 2 enters the absorption tower 1 and r...

Embodiment 2

[0045] According to the process described in Example 1, the 220t / h boiler supporting flue gas desulfurization is carried out. Boiler flue gas inlet SO 2 The concentration is 9690mg / m 3 , the temperature is 160°C, the inlet pH is 5.0, and the liquid-gas ratio is 20.0L / m 3 , the sodium sulfate ion concentration is 2852mg / L, the calcium ion concentration is 620mg / L, the absorption slurry concentration mass ratio is 11.7%, and the desulfurization efficiency reaches 97.0%.

Embodiment 3

[0047] Carry out 130t / h boiler matching flue gas desulfurization process according to the technological process described in embodiment 1, boiler flue gas imports SO 2 The concentration is 2050mg / m 3, the temperature is 155°C, the inlet pH is 6.5, and the liquid-gas ratio is 5.0L / m 3 , the concentration of sodium nitrate is 5096mg / L, the concentration of calcium ion is 600mg / L, the concentration-mass ratio of the absorption slurry is 13.0%, and the desulfurization efficiency is 96.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com