Flue gas desulfurization technology with effect of ultra-clean emission

A desulfurization process and flue gas technology, applied in the direction of ammonium sulfate, combined devices, and dispersed particle separation, can solve the problems of large investment, high energy consumption, and ultra-low emissions of clean flue gas, and achieve low operating costs , the effect of high desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] This technology uses ammonia water as an absorbent to convert liquid ammonia into 8-20% ammonia water.

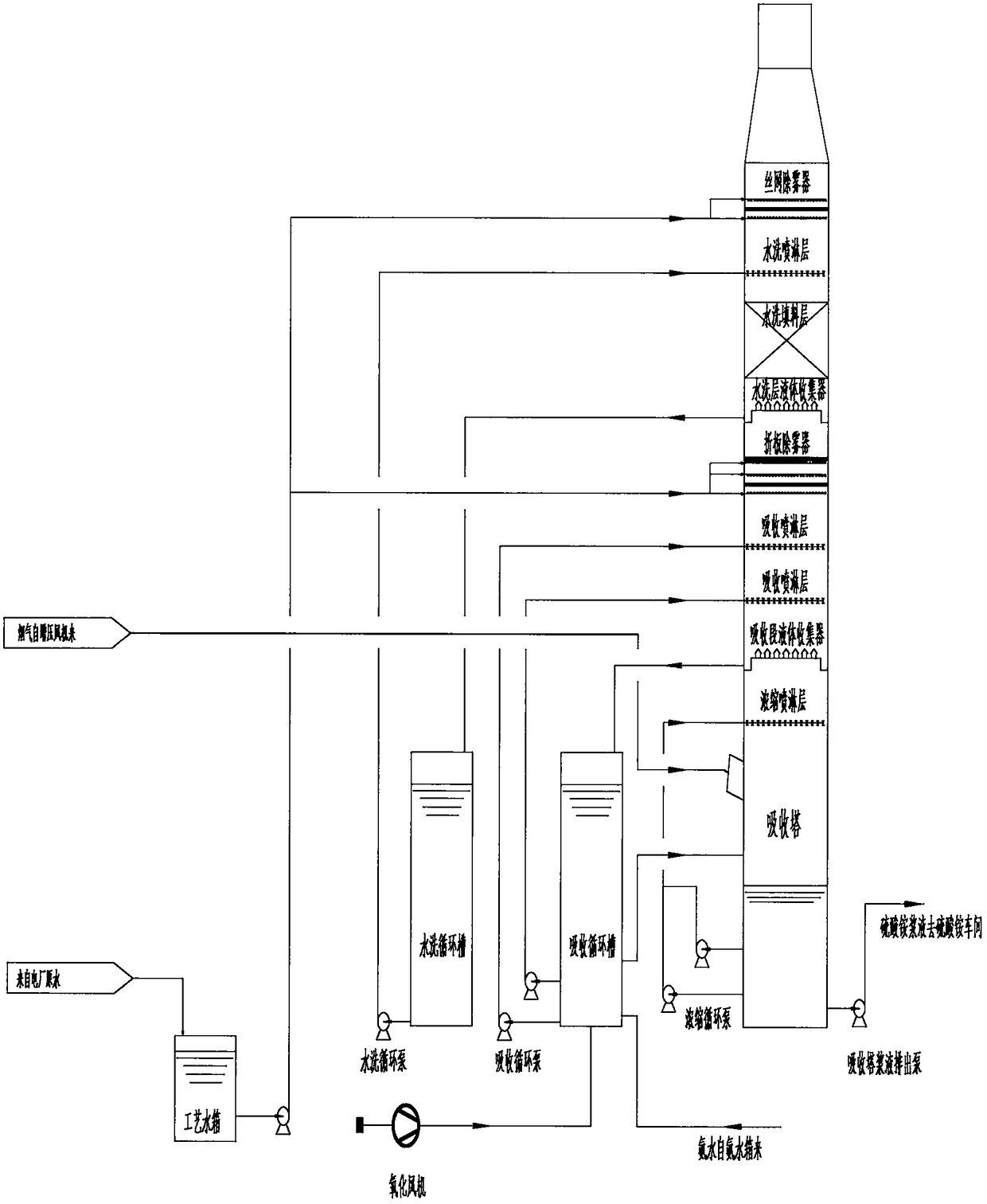

[0047] The absorption tower of this technology is divided into four parts: the concentration section, the absorption section, the demister, and the deep purification section of the flue gas after desulfurization.

[0048]The hot flue gas from the boiler enters the concentration section of the absorption tower after being dedusted by electricity or cloth bags. The ammonium sulfate slurry is pumped out from the concentration circulation tank at the bottom of the concentration section with a concentration circulation pump, and sprayed down from the upper part of the concentration section through the spray layer. The hot flue gas is contacted in countercurrent, and the flue gas is cooled to 50-70°C and then enters the absorption section of the absorption tower. After the water in the ammonium sulfate slurry is evaporated and concentrated to a saturated state by the high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com