Device and process for recycling organic gas through low-pressure dry-type indirect heating desorption

An organic gas and desorption technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., to achieve the effects of easy condensation recovery, avoiding explosion hazards, and good solvent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

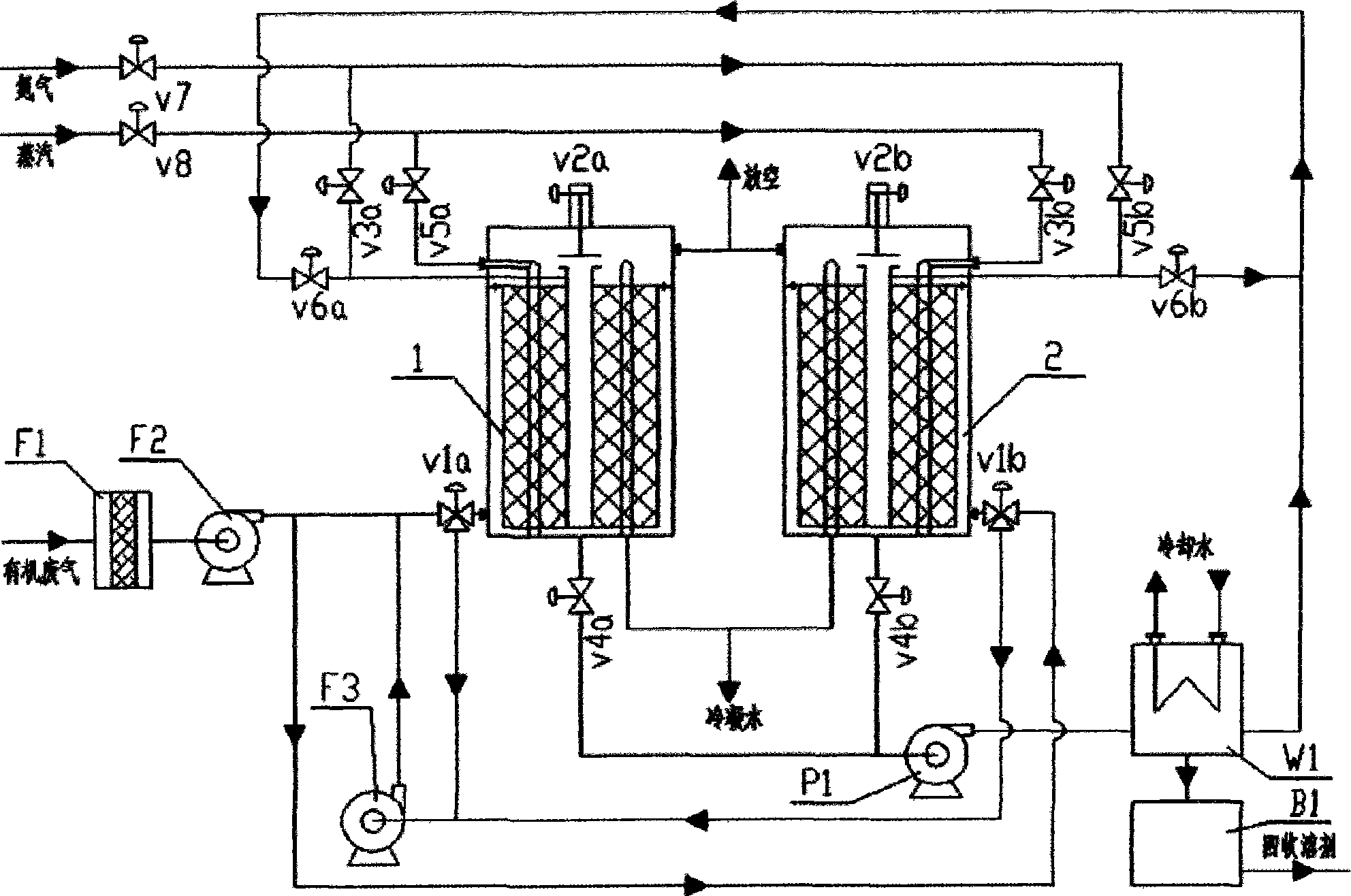

[0027] In Fig. 1, 1 and 2 are adsorbers, there are at least two adsorbers, and the two adsorbers form a circulation system. Adsorbers can also be 3, 4, 5...etc., used in parallel. Multiple series can be used as a group. In this way, the application range of the device of the present invention is wider and more flexible. The whole process can be controlled by PLC program, switch automatically, and alternately carry out the operation of adsorption and desorption (desorption) process.

[0028] Adsorption process:

[0029] Volatile organic gases come from the gas collection system of the production workshop and enter the pre-treatment system (F1) (the gas processed by the system is volatile organic waste gas. The previous treatment equipment is more guaranteed for the safety of the system. At the same time, impurities in the waste gas must be removed to play a role Protect the adsorption material, extend the life of the adsorption material, and ensure that the adsorption materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com