Method for removing mercury from flue gas

A technology for removing mercury and flue gas, applied in the field of mercury removal technology, can solve the problems of large area, large amount of catalyst, complicated process, etc., and achieve the effects of low manufacturing and installation cost, low investment and operation cost, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

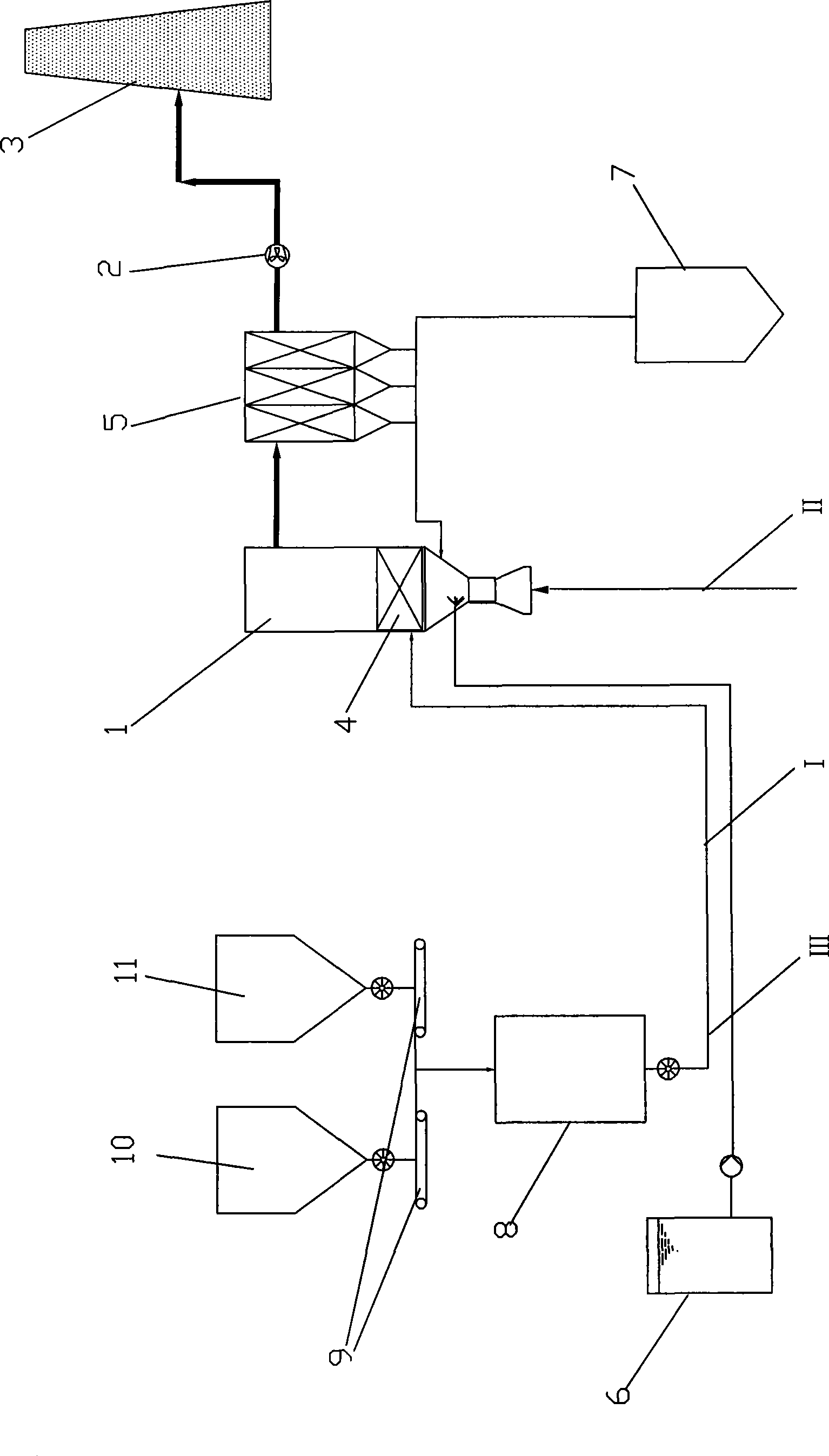

Image

Examples

Embodiment 2

[0042] The flue gas mercury removal method of the present embodiment comprises the following steps:

[0043] First carry out the preparation of modified activated carbon, including the following steps:

[0044] I. Activated carbon and elemental sulfur with a particle size of 20 to 40 mesh enter the heating furnace according to a certain ratio through a weighing feeder;

[0045] II. In the heating furnace, sulfur is loaded onto the activated carbon through thermal precipitation at a temperature of 500°C, and the modified activated carbon can be obtained by keeping the temperature for 90 minutes.

[0046] The modified activated carbon prepared by this method is suitable for a wide range of flue gas temperature, and can be arranged before and after flue gas denitrification or flue gas desulfurization, and the arrangement method is also relatively flexible;

[0047] The mercury removal process includes the following steps:

[0048] a. The mercury sorbent is loaded into the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com