Copper-containing solution impregnated modified biomass coke demercuration adsorbent and preparation method thereof

A technology of biomass coke and adsorbent, which is applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of low resistance to high temperature and low resistance to sulfur poisoning, and achieve improved affinity and applicable Small range, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

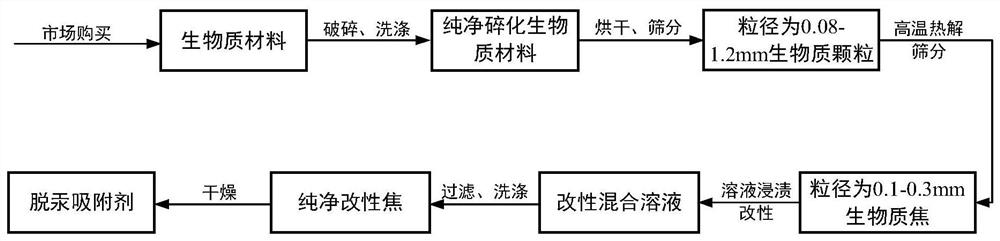

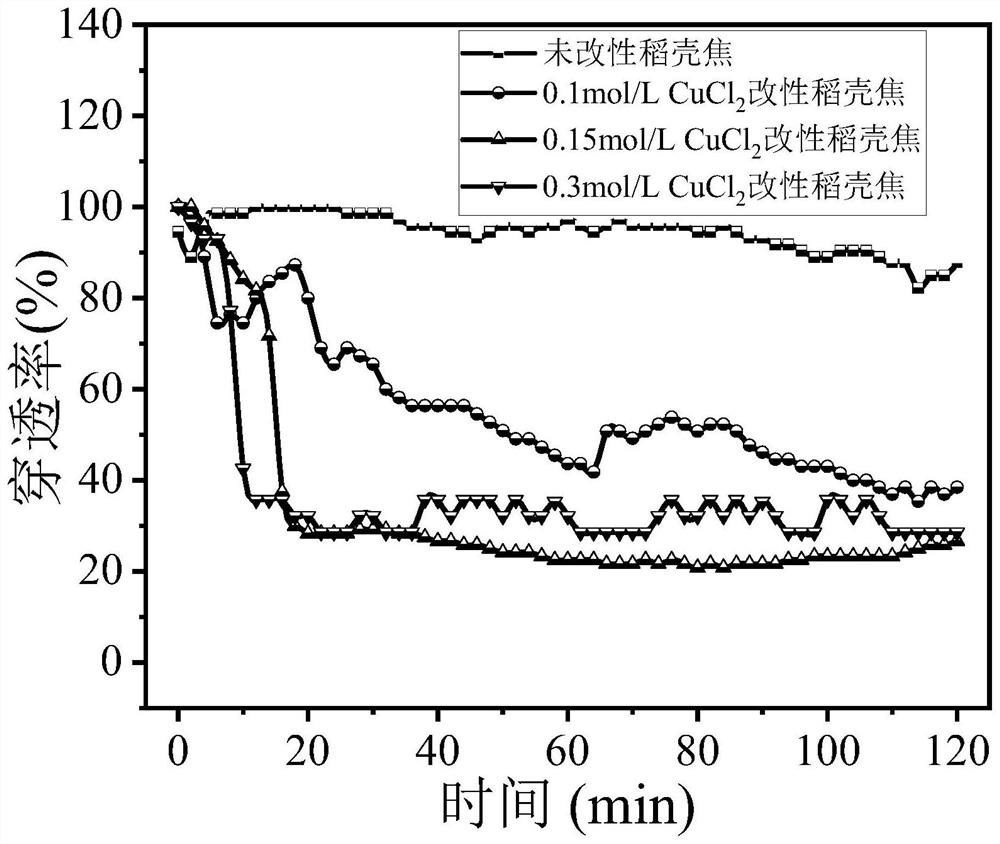

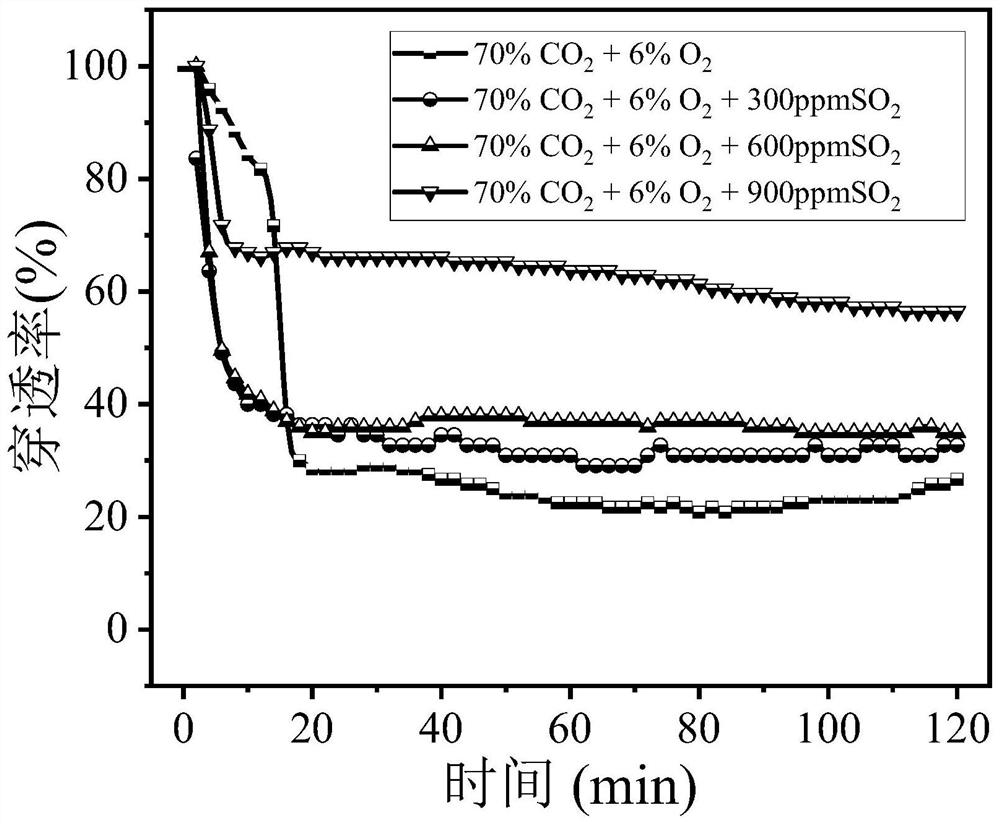

[0034] Select and purchase high-quality and cheap biomass materials from the market as raw materials, wash the purchased biomass materials, and then use a crusher to cut the biomass raw materials. After drying and sieving, the particle size is between 0.08-1.2mm. Biomass particles in between; put the sample into a crucible and place it in a muffle furnace, pyrolyze it for 10 minutes under the condition of anaerobic and high temperature of 500 ℃, and after natural cooling, grind and sieve to obtain 0.1-0.3mm biomass coke Particles; Weigh 5g of biomass char particles, pour into 250mL, 0.1mol / L CuCl 2 In the solution, use a magnetic stirrer to stir for 6 hours, and then let it stand for 12 hours; use a funnel to filter and separate the modified solution and the modified biomass coke, and use deionized water to wash the modified biomass coke until the water at the lower end of the funnel is colorless; The pure modified coke was placed in an oven and dried at 80°C for 6 hours to ob...

Embodiment 2

[0036] Select and purchase high-quality and cheap biomass materials from the market as raw materials, wash the purchased biomass materials, and then use a crusher to cut the biomass raw materials. After drying and sieving, the particle size is between 0.08-1.2mm. Biomass particles in between; put the sample into a crucible and place it in a muffle furnace, and pyrolyze it for 10 minutes under the condition of anaerobic and high temperature of 600°C, and after natural cooling, grind and sieve to obtain 0.1-0.3mm biomass coke Particles; Weigh 5g of biomass char particles, pour into 250mL, 0.1mol / L CuCl 2 In the solution, use a magnetic stirrer to stir for 6 hours, and then let it stand for 12 hours; use a funnel to filter and separate the modified solution and the modified biomass coke, and use deionized water to wash the modified biomass coke until the water at the lower end of the funnel is colorless; The pure modified coke was placed in an oven and dried at 80°C for 6 hours t...

Embodiment 3

[0038] Select and purchase high-quality and cheap biomass materials from the market as raw materials, wash the purchased biomass materials, and then use a crusher to cut the biomass raw materials. After drying and sieving, the particle size is between 0.08-1.2mm. Biomass particles in between; put the sample into a crucible and place it in a muffle furnace, pyrolyze it for 10 minutes under the condition of anaerobic and high temperature of 500 ℃, and after natural cooling, grind and sieve to obtain 0.1-0.3mm biomass coke Particles; Weigh 5g of biomass char particles, pour into 250mL, 0.15mol / L CuCl 2In the solution, use a magnetic stirrer to stir for 6 hours, and then let it stand for 12 hours; use a funnel to filter and separate the modified solution and the modified biomass coke, and use deionized water to wash the modified biomass coke until the water at the lower end of the funnel is colorless; The pure modified coke was placed in an oven and dried at 80°C for 6 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com