Battery diaphragm and preparation method thereof, and lithium-sulfur battery

A technology of battery diaphragm and diaphragm, which is applied to battery components, circuits, electrical components, etc., and can solve problems such as polysulfide shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

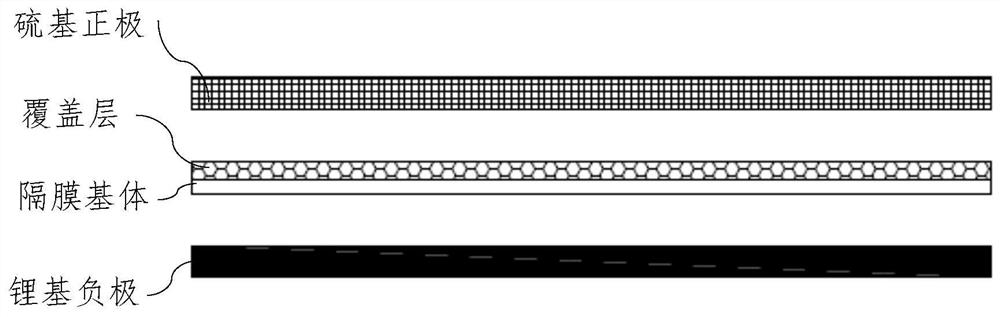

[0074] In another aspect, the present invention provides a method for preparing a battery separator as described above, comprising the following steps:

[0075] obtaining porous carbon materials;

[0076] Disperse the porous carbon material in a dispersing solvent, add a metal source and a sulfur source, perform a hydrothermal reaction, form a metal sulfide inside the pore body of the porous carbon material, filter, and dry to obtain a composite material;

[0077] The above composite material is covered on the surface of the separator matrix, and dried to form a battery separator.

[0078] In some embodiments, the method for obtaining the porous carbon material is:

[0079] Mix the large mesh resin with the metal ion salt solution, stir and then dry to obtain the resin that adsorbs metal ions;

[0080] Pulverizing the resin adsorbing metal ions, then adding a transitional cavity filler and mixing evenly;

[0081] Add the product obtained above into the pore-enlarging agent ...

Embodiment example 1

[0115] This implementation case is used to illustrate the battery separator, lithium-sulfur battery and its preparation method disclosed in the present invention, including the following steps:

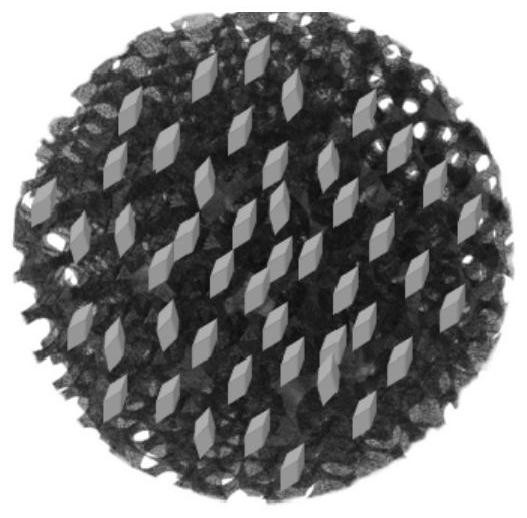

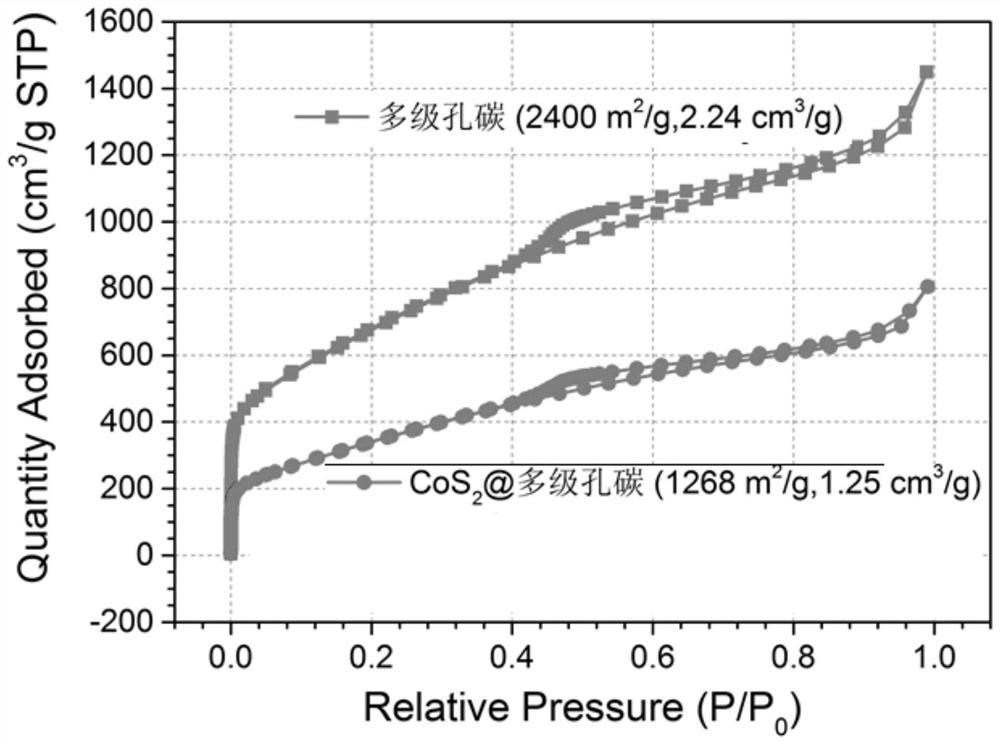

[0116] The porous carbon material prepared in the above example was ultrasonically dispersed in 2mol / L sodium hydroxide, then placed in a high-pressure hydrothermal kettle, and subjected to a hydrothermal reaction at 180 degrees Celsius for 2 hours, and then the obtained substance was suction-filtered with double-distilled water Wash until the pH is 7, and dry in an oven.

[0117] Take out 100 mg of functionalized porous carbon material, disperse it in ethylene glycol solution, ultrasonicate for half an hour, add cobalt acetate and thiourea in turn, conduct hydrothermal reaction at 120 degrees Celsius respectively, keep it warm for 10 hours, and heat it at 220 degrees Celsius for 10 hours. The obtained substance was washed four times with double distilled water and ethanol suction fil...

Embodiment example 2

[0124] This implementation case is used to illustrate the battery separator, lithium-sulfur battery and its preparation method disclosed in the present invention, including most of the operation steps in the implementation case 1, and the difference lies in:

[0125] The porous carbon material prepared in the above examples was ultrasonically dispersed in 2mol / L sulfuric acid, then placed in a high-pressure hydrothermal kettle, and subjected to a hydrothermal reaction at 180 degrees Celsius for 2 hours, and then the obtained substance was filtered and cleaned with double distilled water until PH is 7, put it in an oven for drying.

[0126] The obtained lithium-sulfur battery positive electrode has a specific capacity of 1000mAh / g and 900mAh / g for the first and second discharges at a current density of 0.1C, and the specific capacity is stable at 750mAh / g after 100 cycles. After 200 cycles, the specific capacity Stable at 600mAh / g.

[0127] The performance of the lithium-sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesoporous | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com