Preparation method of visible light photoactivated octahedrite type titanium oxide colloidal sols

An anatase-type, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of obvious target biological resistance, harsh preparation conditions, and aggravated agricultural environmental pollution, so as to improve the utilization rate of visible light, Inexpensive, avoid hard agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Example 1. Taking titanium tetrachloride as a precursor to prepare high-purity titanium dioxide sol

[0040]Measure 50ml of titanium tetrachloride in a separatory funnel, dropwise add dropwise to 200ml of water in an ice-water bath, after the dropwise addition, stir for one hour, then add dropwise the ammonia water whose initial concentration is 4M and control its addition speed, and During the process of hydrolysis and precipitation, the concentration of ammonia water was continuously reduced to a minimum of 0.05M. After the precipitation is fully hydrolyzed, use ammonia water with a concentration of 1M to adjust the pH to above 9, stir for 3 hours, filter and wash until no chloride ions are detected (tested by adding 1.0M silver nitrate solution dropwise), and then Mix the filter cake with water to prepare the concentration, add a certain amount of 10% nitric acid, adjust the pH to 1.0, stir at room temperature for 4 hours, and then heat and stir in a 65-degree water ...

example 2

[0041] Example 2. Change pH and temperature to prepare sol

[0042] Follow the steps of Example 1 to hydrolyze the precipitate, filter and wash, then mix the filter cake with water according to the required preparation concentration, add a certain amount of 8% nitric acid, adjust the pH to 1.5, stir at room temperature for 6 hours, and then heat in a 90-degree water bath After stirring for more than 3 hours, a stable sol was obtained, but it was cloudier than the sol obtained in Example 1.

[0043] Still follow the steps of Example 1 to hydrolyze the precipitate, filter and wash, then mix the filter cake with water according to the required preparation concentration, add a certain amount of 15% nitric acid, adjust the pH to 0.3, stir at room temperature for 3 hours, and then place it in a 40-degree water bath After heating and stirring for more than 10 hours, a stable sol was obtained, but it was cloudier than the sol obtained in Example 1.

example 3

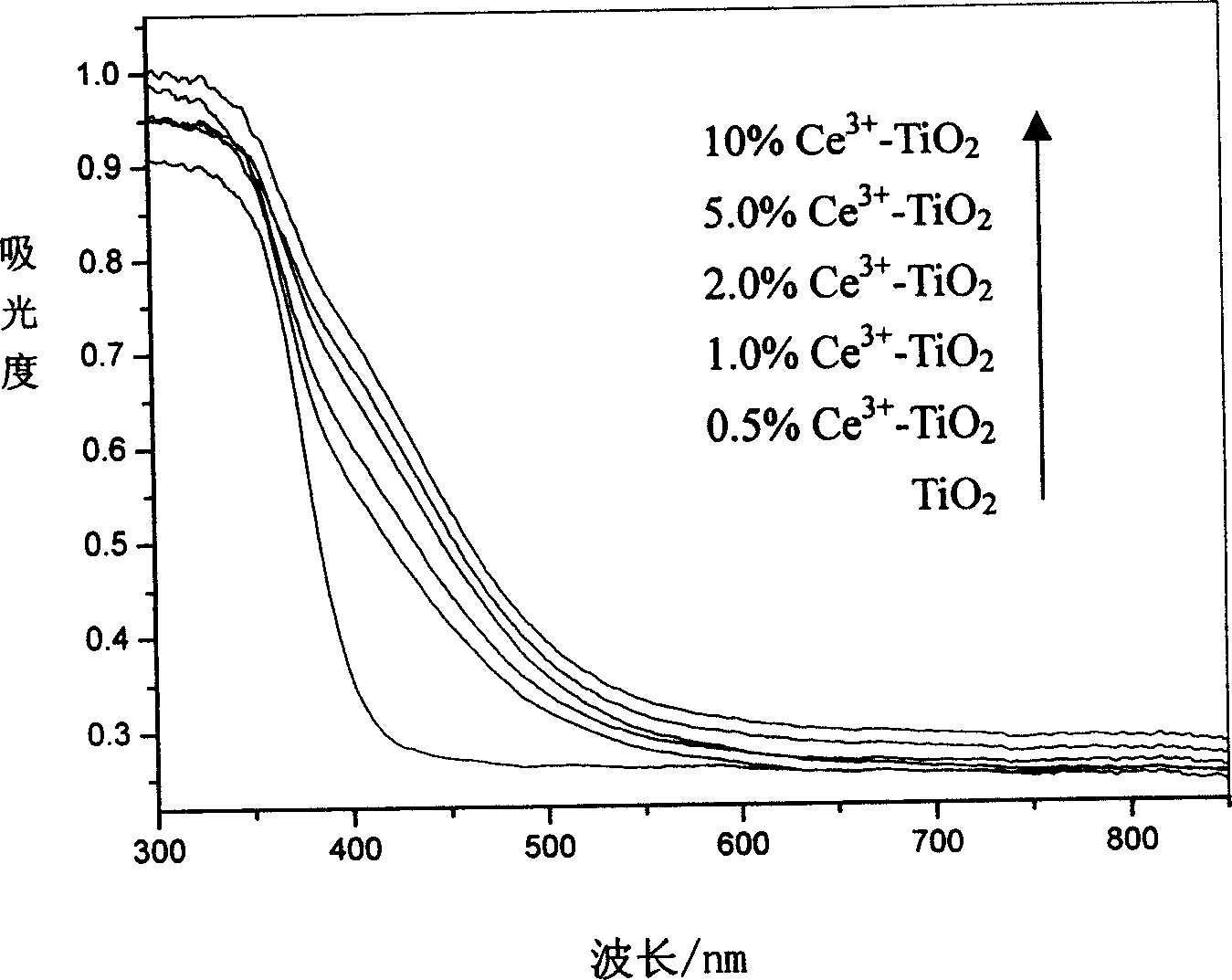

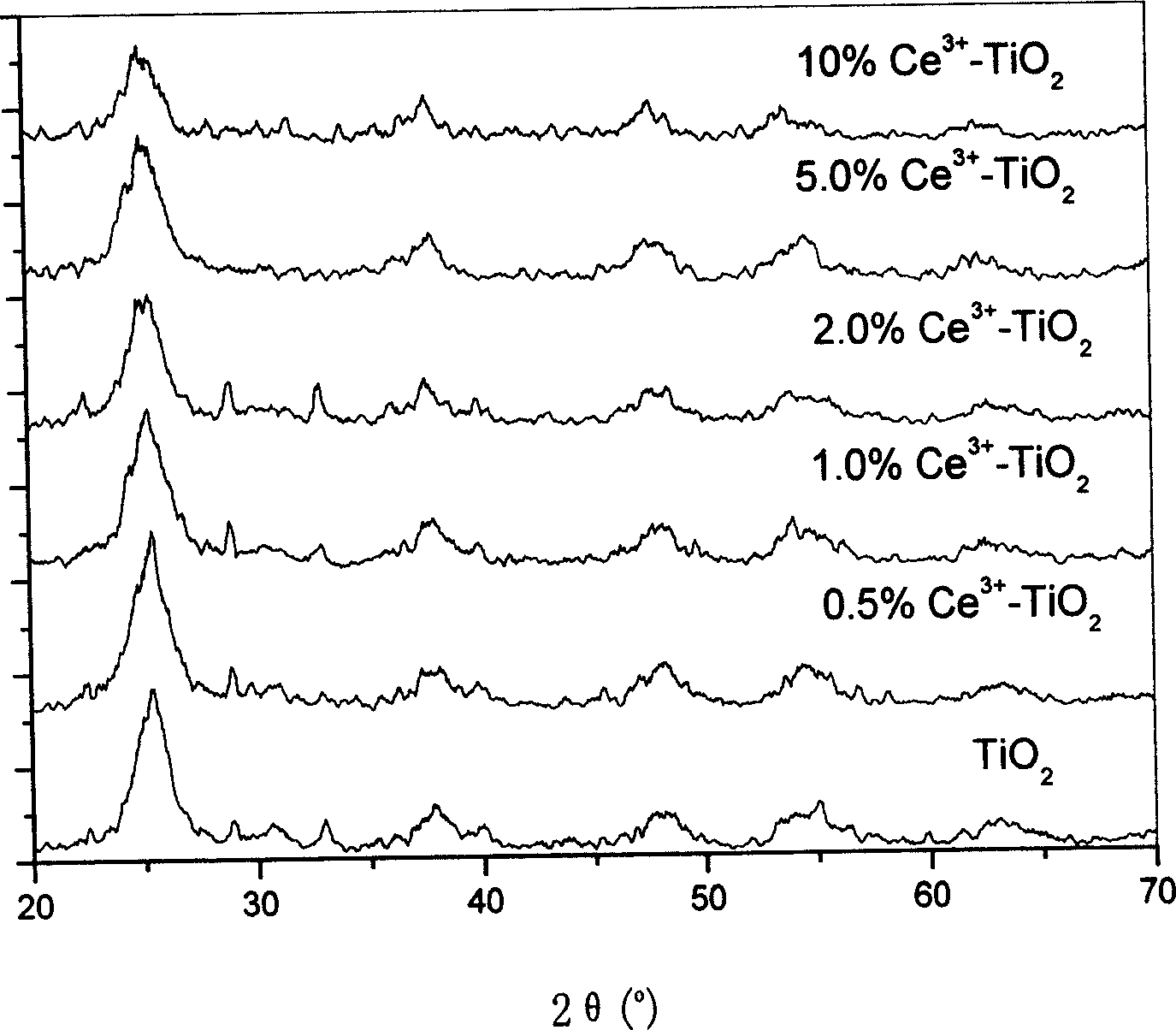

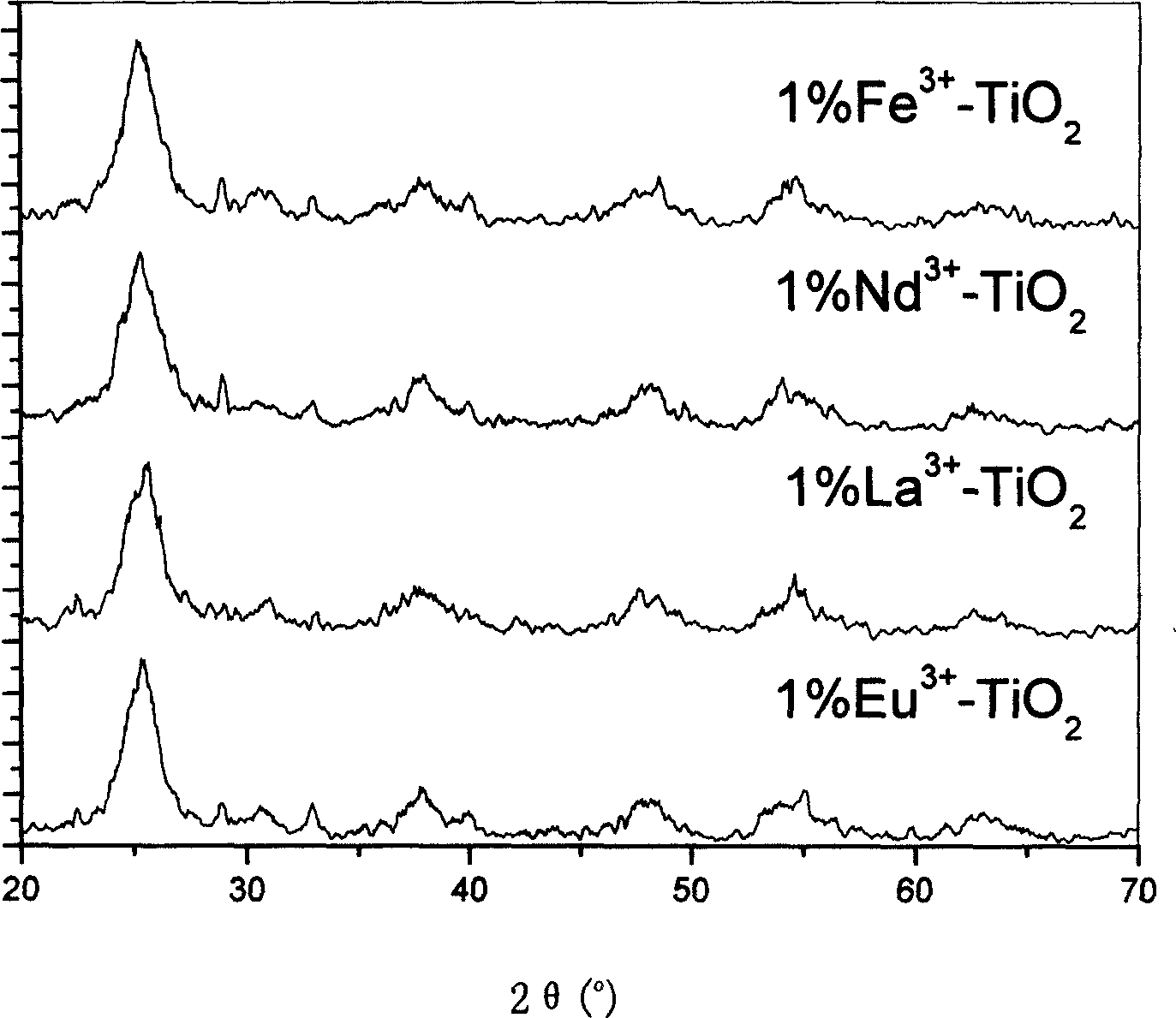

[0044] Example 3. Preparation and characterization of cerium-doped titania sol

[0045] Accurately weigh a certain amount of cerium nitrate, dissolve it in 250ml of water, and freeze it below 4 degrees, measure 50ml of titanium tetrachloride and put it in a separatory funnel, add dropwise to 250ml of cerium nitrate solution in an ice-water bath, add dropwise After completion, stir for 1 hour, then add dropwise ammonia water with an initial concentration of 3.5M and control its addition rate, and continuously reduce the ammonia water concentration during the hydrolysis and precipitation process to a minimum of 0.025M. After fully hydrolyzing the precipitate, use 1.5M ammonia water to adjust the pH to above 9, stir for 4 hours, filter and wash until no chlorine ions are detected, then mix the filter cake with water according to the required preparation concentration, and add a certain amount 10% nitric acid, adjust the pH to 0.9, stir at room temperature for 4 hours, and then he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com