Dynamic adsorption-type toxic gas detection device

A toxic gas, dynamic adsorption technology, used in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of easy gas leakage, inaccurate data, complicated operation, etc., to avoid reading errors and detection. Accurate data and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

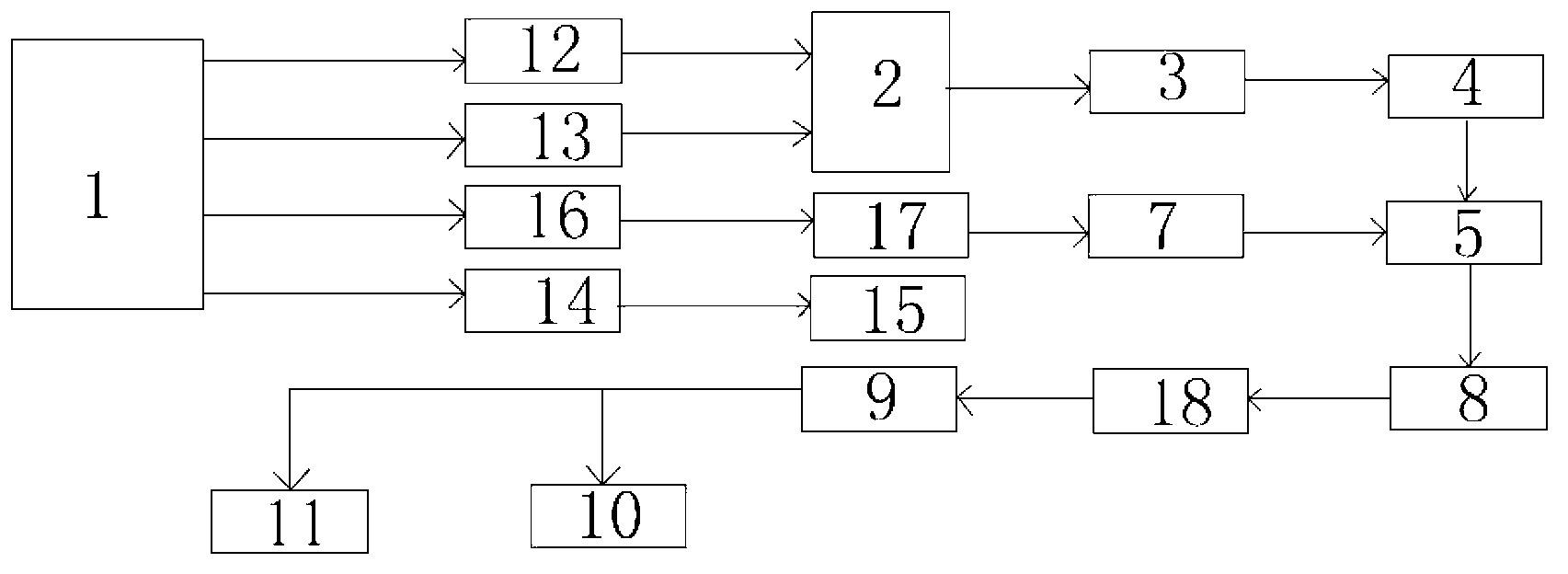

[0031] Such as figure 1 The shown dynamic adsorption toxic gas detection device includes a casing and a cover, and a hydraulic connector is provided at the connection between the casing and the cover, so that the connection between the casing and the cover is a hydraulic cylinder connection structure.

[0032] 1) An air purifier 1, a gas dry / humidity regulator 2, an electronic temperature / humidity meter 3, a gas flow meter 4, a gas mixer 5, a toxic gas concentration detector 8 and a timer are installed in the housing, and a Toxic gas source 7, toxic gas absorption filter 9 and penetration concentration detector 10;

[0033] 2) The air inlet of air purifier 1 is externally connected with compressed air, and the air outlet of air purifier 1 is connected to the air inlet of gas mixer 5 through gas dry / humidity regulator 2, electronic temperature / humidity meter 3 and gas flow meter 4 One; the gas outlet of the poisonous gas source 7 communicates with the gas inlet of the gas mixe...

specific Embodiment 2

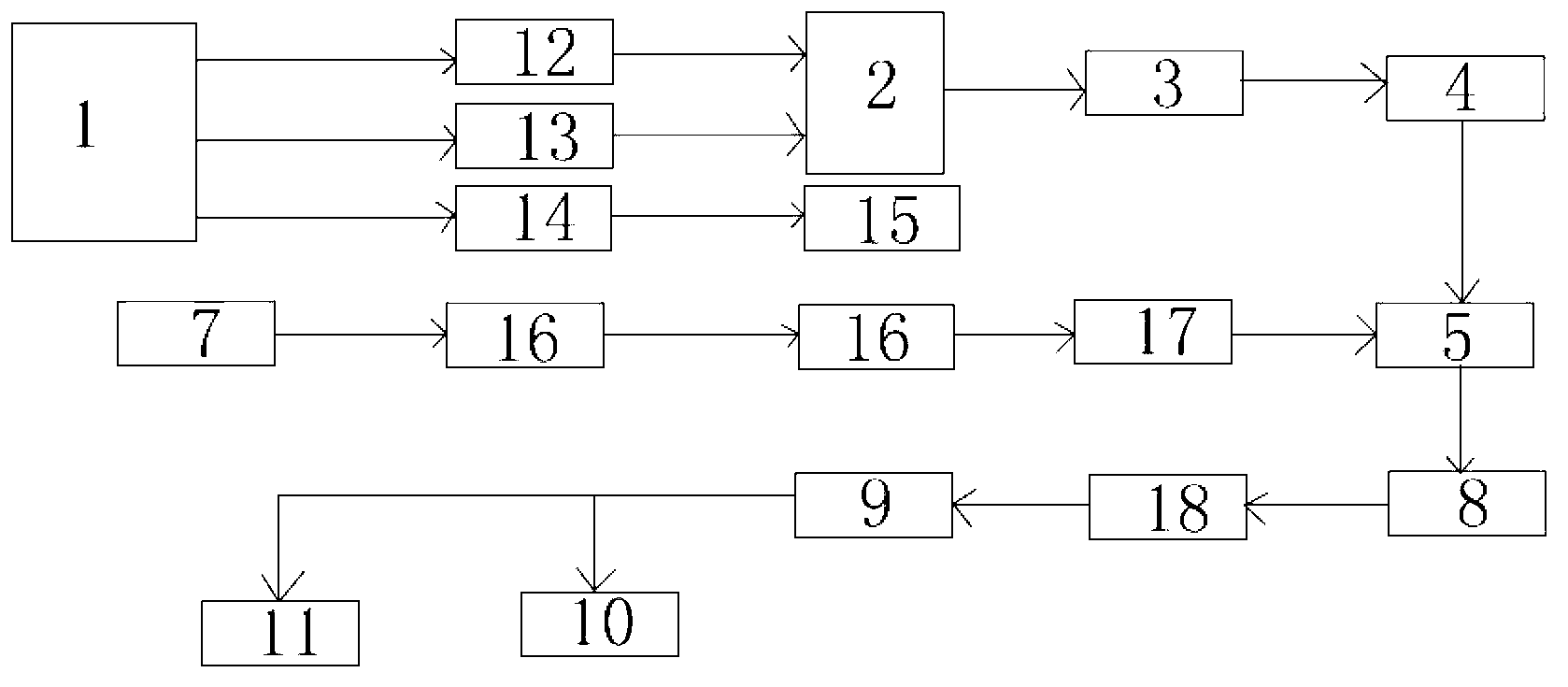

[0047] Such as figure 2 As shown, the characteristics of this embodiment are: the poisonous gas source 7 adopts ammonia or sulfur dioxide, the ammonia is provided by the ammonia device, the sulfur dioxide is provided by the sulfur dioxide device, the inlet end of the air cleaner 1 is connected to the compressed air, and the air The gas outlet of the purifier 1 is connected to three pipelines, of which the two pipelines are connected to the gas dry / humidity regulator 2 through the gas humidity control valve 12 and the gas dryness control valve 13, and the gas outlet of the gas dry / humidity regulator 2 passes through The electronic temperature / humidity meter 3 and the gas flow meter 4 are connected to one of the air inlets of the gas mixer 5, and a balance valve 14 is installed on the third pipeline, and the gas outlet of the balance valve 14 is provided with a muffler 15, an ammonia device Or the gas outlet of sulfur dioxide device links to each other with two of the inlet por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com