Low-consumption high-quality ammonium sulfate fertilizer recovery wet ammonia process desulfurizing technology

A technology of ammonia desulfurization and ammonium sulfate, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of secondary pollution, high production cost of ammonium sulfate, and low quality of ammonium sulfate products, and achieve desulfurization efficiency The effect of high and comprehensive operation cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

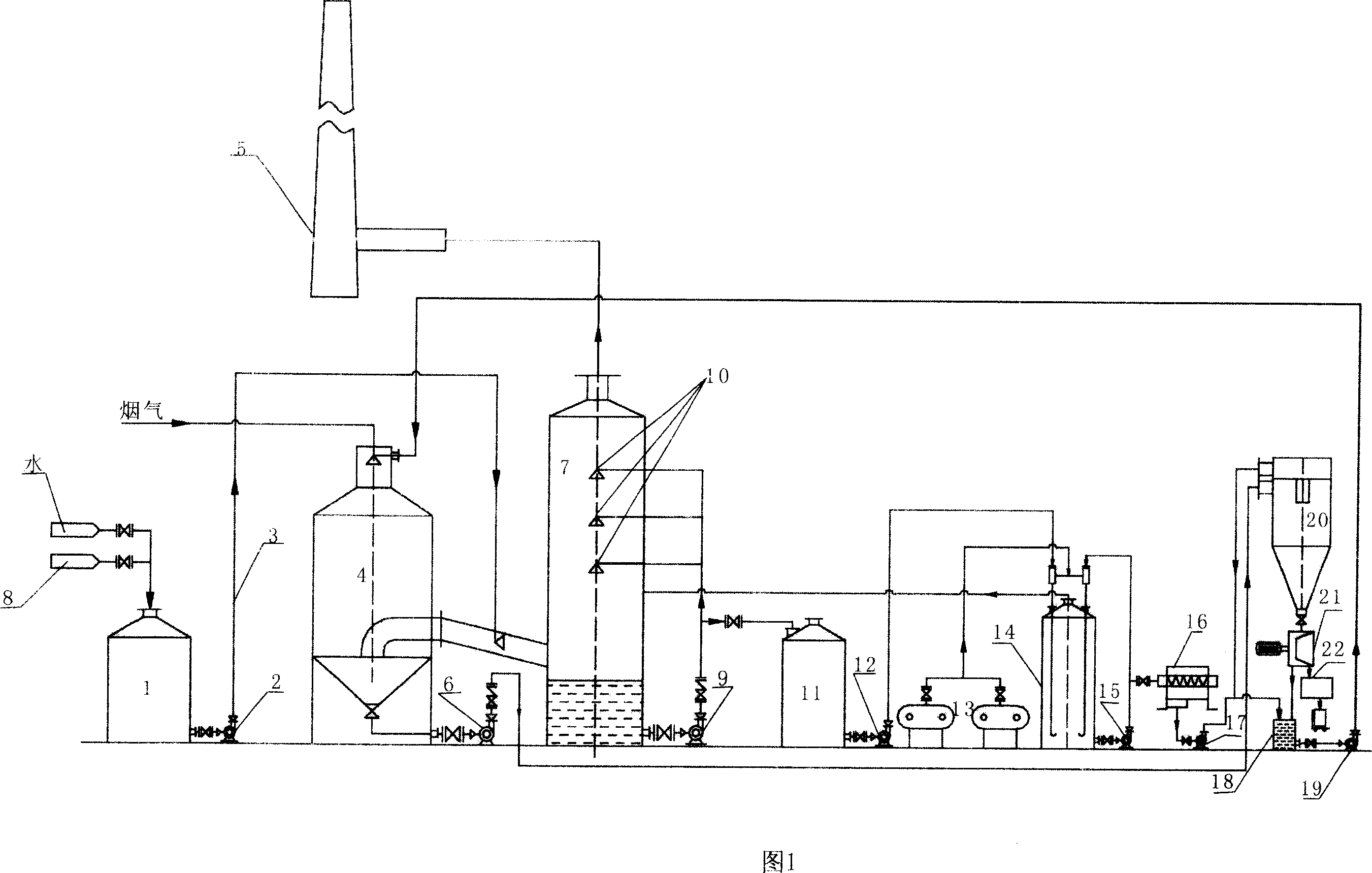

[0039] In view of the disadvantages that the desulfurization technology in the prior art is easy to cause secondary pollution to the environment, or the cost of recycling ammonium sulfate fertilizer is too high and the quality is not high, the present invention proposes a wet ammonia desulfurization method for recycling high-quality ammonium sulfate fertilizer with low energy consumption Technology, this technical scheme uses ammonia as the desulfurization and denitrification absorbent, the system and flow diagram of the wet ammonia desulfurization process technology of the present invention provided below with reference to Fig. 1, the technological process of the present invention comprises the following steps:

[0040] a), configure ammonia water in the ammonia water configuration storage tank (1), and send the prepared ammonia water into the desulfurization tower (7) through the ammonia supply pump (2) and the pipeline system (3);

[0041] b) After the high-temperature flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com