Sulfur-containing and salt-containing organic waste liquid and waste gas pollution-free treatment device and method

A technology of organic waste liquid and treatment device, applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve problems such as the impact of production and operation on the lives of residents, lack of mature technology, and lack of localization, and achieve considerable economic value. , The comprehensive operation cost is low, and the effect of complete incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

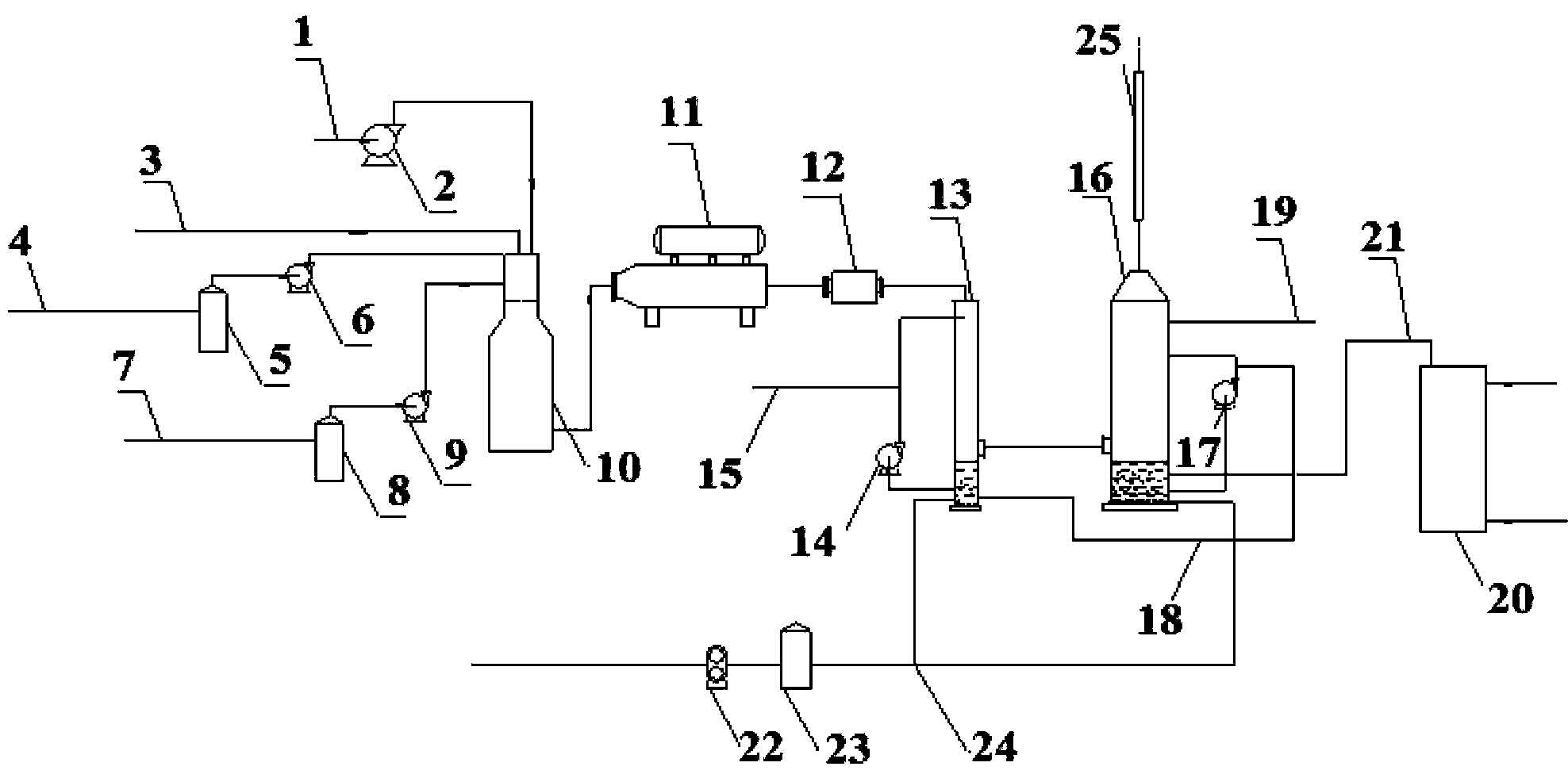

[0028] Such as figure 1 Shown is a pollution-free treatment device for treating organic waste liquid and waste gas containing sulfur and salt in the production process of methionine. The device includes an incinerator 10, a sulfur-containing organic waste gas supply system, a sulfur-containing and salt-containing organic waste liquid supply system, a fuel gas supply system and a combustion-supporting air supply system respectively connected to the inlet of the incinerator 10, and connected to the outlet of the incinerator 10 The waste heat recovery system, the desulfurization system connected with the waste heat recovery system.

[0029] The fuel gas supply system includes a fuel gas supply pipeline 3 under the condition of low calorific value waste gas and liquid. The fuel gas supply pipeline 3 is connected to the fuel gas inlet of the burner of the incinerator 10, that is, the fuel gas is directly sent into the incinerator for accompanying combustion, so as to provide fuel....

Embodiment 2

[0040] Such as figure 1 As shown, a pollution-free treatment method for treating sulfur-containing and salt-containing organic waste liquid and waste gas in the production process of methionine according to the present invention comprises the following steps:

[0041] (a) Transport the sulfur-containing organic waste gas to the combustion chamber of the incinerator 10 through the sulfur-containing organic waste gas supply system, and transport the sulfur-containing and salt-containing waste liquid to the combustion chamber of the incinerator 10 through the sulfur-containing and salt-containing organic waste liquid supply system; Natural gas enters the combustion chamber of the incinerator 10 through the fuel gas supply system; air is transported to the combustion chamber of the incinerator 10 through the combustion-supporting air supply system; °C or 1250 °C), the above-mentioned waste liquid and waste gas are pyrolyzed and oxidized in the incinerator 10 to produce 2 O.CO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com