Flue gas desulfurization process suitable for sintering machine of steel mill

A technology of sintering flue gas and sintering machine, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc. It can solve the problems of large amount of sintering flue gas, fluctuating flue gas temperature, and high moisture content, and achieve low operating costs , no three wastes discharge, high desulfurization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

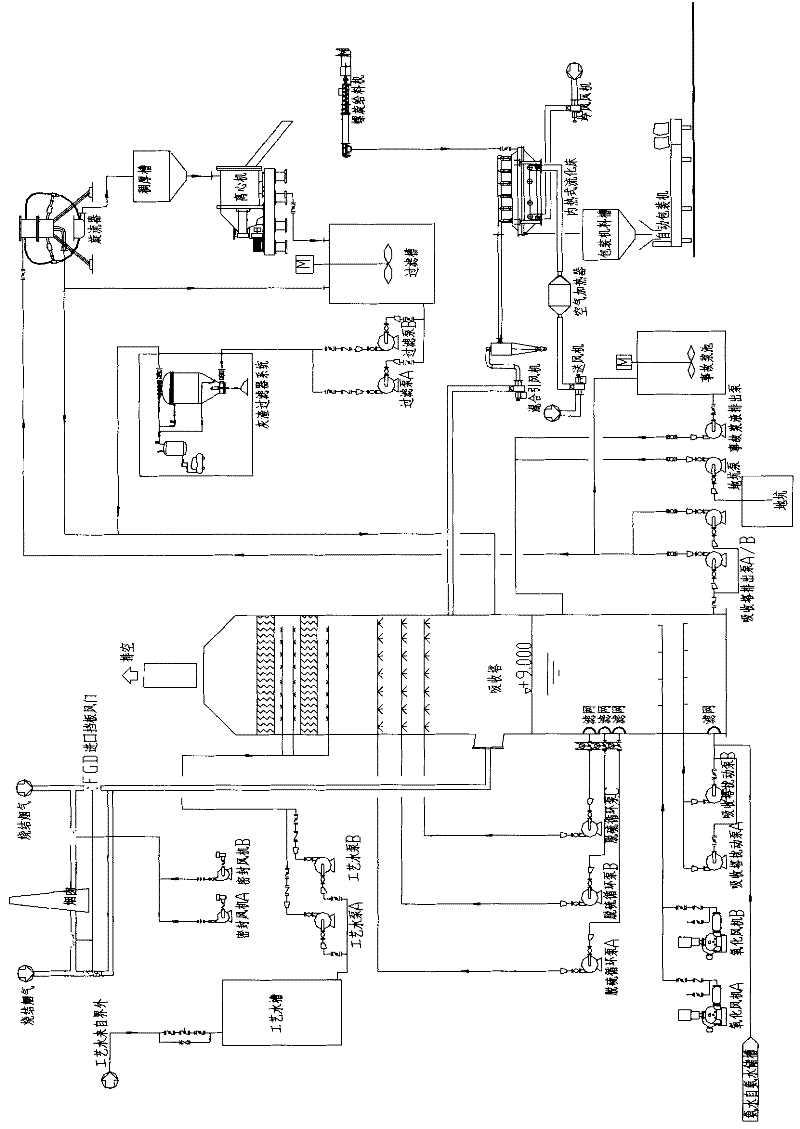

Image

Examples

Embodiment Construction

[0049] This technology uses ammonia water as an absorbent to convert liquid ammonia into 8-20% ammonia water.

[0050] The hot flue gas from the sintering machine enters the absorption tower after being dedusted by electricity or cloth bags. A double baffle isolation door is installed at the entrance of the desulfurization device, and an adjustable bypass baffle door is installed on the bypass flue, which is used for accidents or accidents. Used during maintenance. The hot flue gas enters the absorption tower, contacts with the hot flue gas countercurrently, the flue gas is cooled to 50~70°C, and at the same time completes absorption, oxidation, concentration and then evacuates. When the slurry has a solid content of 5%, the ammonium sulfate slurry is discharged by the pump and sent to the cyclone for solid-liquid separation.

[0051] Start the desulfurization circulation pump to spray the mixed liquid at the bottom of the tower through the spray layer, and contact with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com