Patents

Literature

46results about How to "Realize secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tail gas treatment device and tail gas treatment method in process of recycling waste printed circuit boards

InactiveCN103537181ARealize environmentally friendly emissionsRealize secondary pollutionDispersed particle filtrationIncinerator apparatusCombustible gasProduct gas

The invention discloses a tail gas treatment device and a tail gas treatment method in a process of recycling waste printed circuit boards. The tail gas treatment method comprises the following steps: performing active carbon adsorption treatment on tail gas to be treated firstly, and filtering solid dust, heavy metal particles, part of inorganic nonmetal oxide and part of organic gas in the tail gas; then introducing the pretreated tail gas into a spray tower, fully contacting the pretreated tail gas with a purification solution in the spray tower, and removing most of inorganic nonmetal oxide and part of organic gas in the pretreated gas; finally, introducing the tail gas exhausted out of the top of the spray tower into a high-temperature combustion device so as to perform combustion, and discharging non-pollution tail gas through the combustion treatment device. Through the tail gas treatment device and the tail gas treatment method, the secondary pollution problem caused by the discharged tail gas in the process of recycling the waste printed circuit boards is effectively solved; meanwhile, part of combustible gas in the tail gas is used, so that a certain economic value is achieved.

Owner:HEFEI UNIV OF TECH

Medical waste recovery treatment device

ActiveCN108435755AAchieving processing powerAchieve partial recyclingSolid waste disposalMedical waste disposalMedical wasteClassification treatment

The invention relates to a medical waste recovery treatment device. The medical waste recovery treatment device comprises a rough crushing cavity, a fine crushing cavity, a grinding cavity, a sedimentchamber, a flotage treatment device, a liquid treatment device and a sediment treatment device. Crushing is optimized, crushed materials are directly divided into three kinds through comparison withthe water density, classification treatment is carried out on different kinds of waste, medical waste is treated more deeply, and the environment friendliness degree is high.

Owner:张言敏 +1

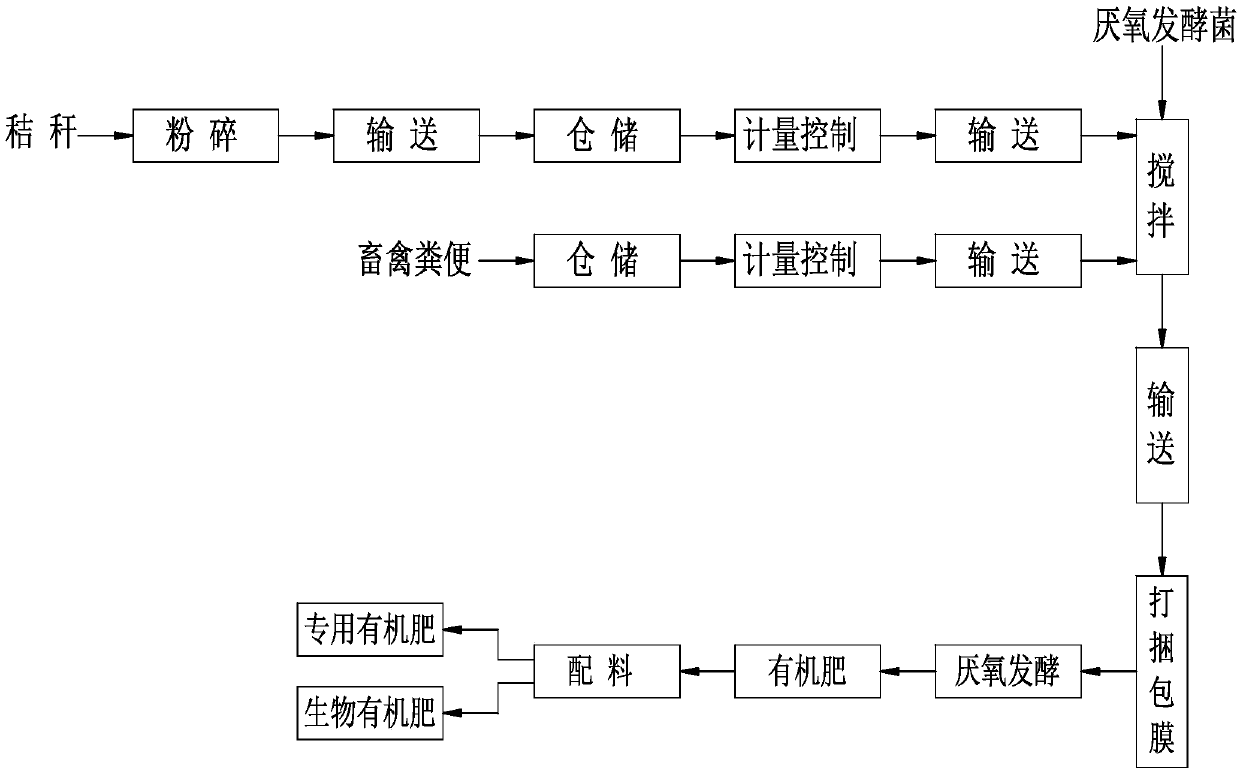

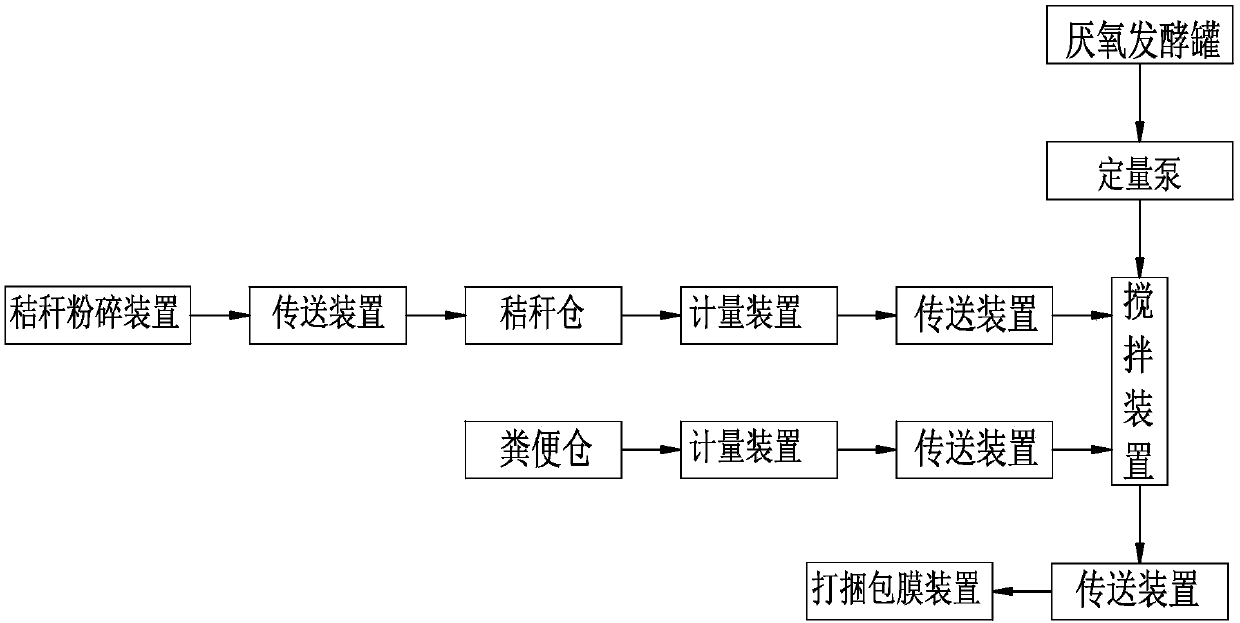

Process and system of producing organic fertilizer by anaerobically fermenting excrement of livestock and poultry

InactiveCN107827490AEasy to useReduce dosageBio-organic fraction processingExcrement fertilisersBiotechnologyAnimal feces

The invention discloses a process and a system of producing organic fertilizer by anaerobically fermenting excrement of livestock and poultry, wherein the process includes the following steps: 1) crushing crop straw into powder via a straw crusher, and feeding the straw powder into a straw bin; 2) collecting the excrement of livestock and poultry in an excrement bin; 3) outputting the straw powderand the excrement of livestock and poultry under metering control and delivering the materials into a stirring apparatus via a delivery device, and stirring the mixture, wherein anaerobic fermentation bacteria are added with uniform mixing; 4) conveying the stirred material into a bundling and coating device to bundle and coat the mixture, and storing the packed material in a natural environmentto perform anaerobic fermentation in a sealing status, so that the organic fertilizer is produced by completely fermenting and composting the excrement of livestock and poultry and straw. In the invention, the organic fertilizer is produced from the excrement of livestock and poultry and crop straw, so that problems of pollution due to livestock and poultry and incineration of straw are solved from the source, and pollution on water body, farmland and atmosphere and environment pollution due to incineration of straw are reduced. The system is reliable in operation and allows the bundling and film-coating operations to be carried out in one step, thus achieving automatic continuous operation. The method is effective for processing the excrement of livestock and poultry and the farmland waste straw.

Owner:WUZHENG +1

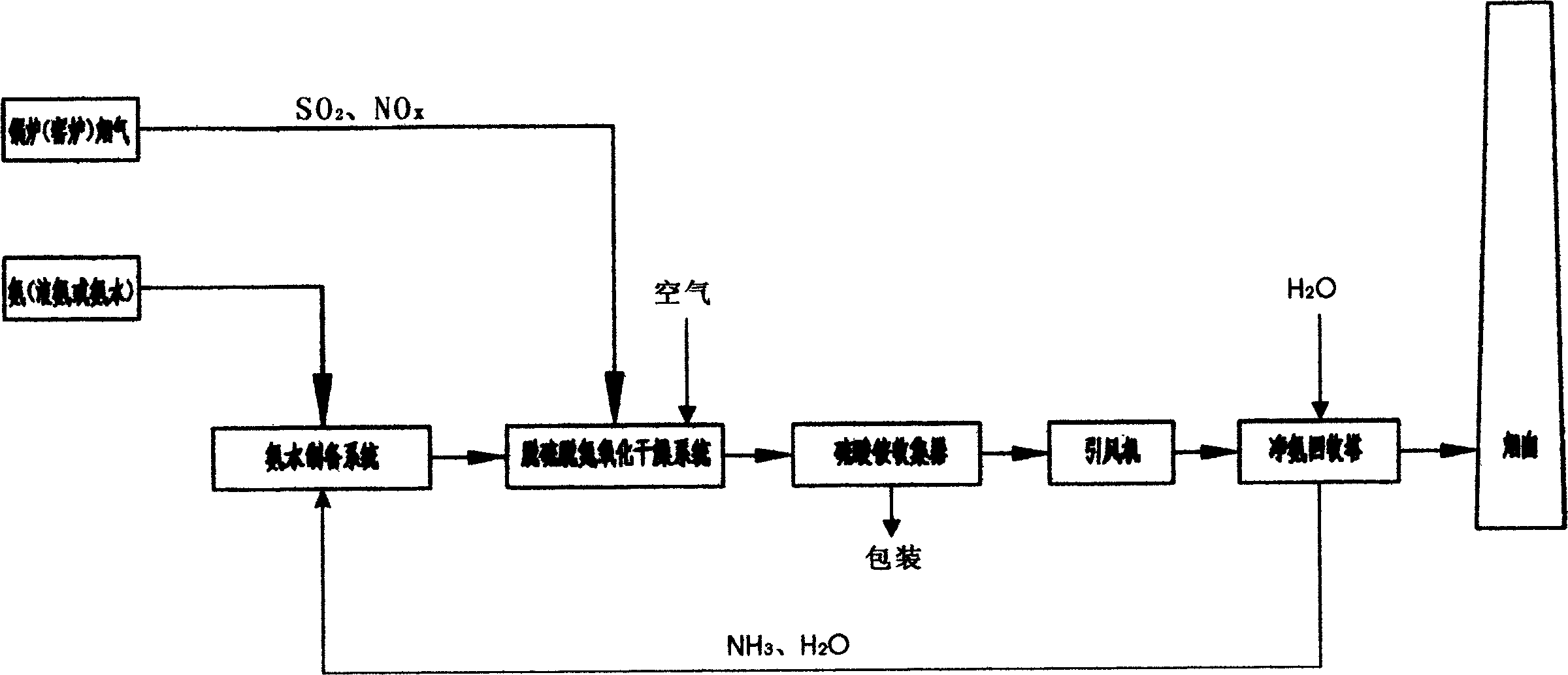

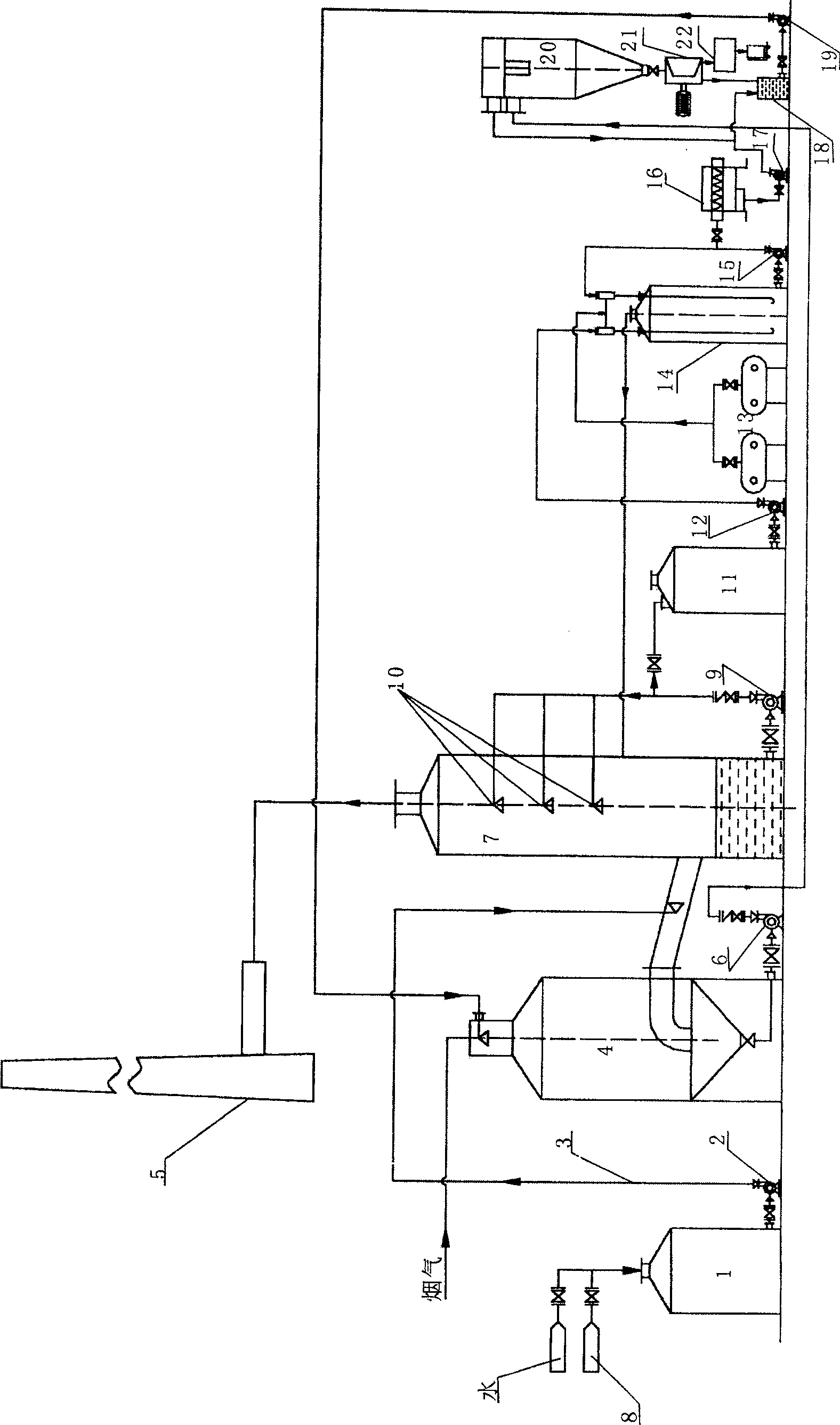

Ammonia-ammonia sulfate dry type flue gas desulfurizing denitrifying equipment and technique

InactiveCN1736559AGood economic valueRealize environmental protectionDispersed particle separationOxygenAmmonium nitrate

Discloses is an ammonia- ammonia sulfate dry-type device for desulfuration and denitrification from smoke gas and the technique method, which is characterized in that: ammonia solution of a concentration of among 1- 10% in storage pot is prepared with liquid ammonia or high- concentration ammonia solution; sulfur dioxide in smoke gas reacts with the ammonia solution to generate ammonium sulfite; oxygen reacts with the ammonium sulfite to generate ammonia sulfate solution; ammonia escaping from the storage pot is recovered and sent to the recovery pot; the 1- 10% ammonia solution prepared is pumped to a desulfuration and denitrification absorption tower by an ammonia feeding pump and a conduct pipe; smoke gas is sent to the desulfuration and denitrification absorption tower by a smoke gas tube; the generated solid mixture of ammonia sulfate with ammonium nitrate goes to ammonia sulfate collector with smoke gas by the power of draught fan, at last is packed, and the smoke gas enters the ammonia-purified recovery tower.

Owner:洛阳市天誉环保工程有限公司

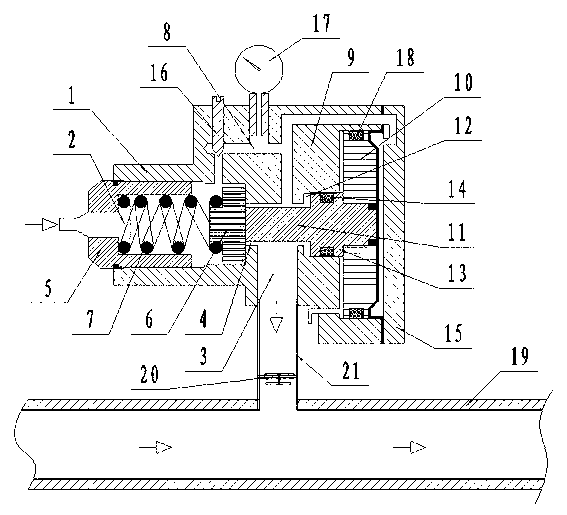

Air conveyor

InactiveCN103057964AReal-time monitoring of delivery conditionsRealize fully enclosed deliveryBulk conveyorsCylinder blockMechanical engineering

The invention discloses an air conveyor which comprises a body. The body internally comprises an air inlet chamber and an air outlet chamber which are communicated through an inner hole, a connecting pipe connected with the body is fixed at one inner end of the air inlet chamber, a valve plate is arranged at the position of the inner hole, a spring for compacting the valve plate is arranged between the valve plate and the connecting pipe, and a flowing hole communicated with the air outlet chamber is arranged on the side wall of the air inlet chamber. The body further comprises the air cylinder, the air cylinder comprises a cylinder block integrated with the body, a sealed end cover is matched at the other end of the cylinder block, a piston is slidably arranged in the cylinder block and is connected with the valve plate through a connecting rod, an air inlet end of the air cylinder is communicated with the flowing hole through a through hole, and the cross section of the valve plate is smaller than the area of the piston. The air conveyor has the advantages that the air conveyor is capable of monitoring pressure conditions in a conveying pipeline in real time and capable of supplementing air to increase inlet air when the pipeline is blocked, so that conveying capability is improved, and conveying cost is reduced. The air conveyor is capable of achieving totally-closed material conveyance, and secondary contamination to materials is avoided.

Owner:韩香莲

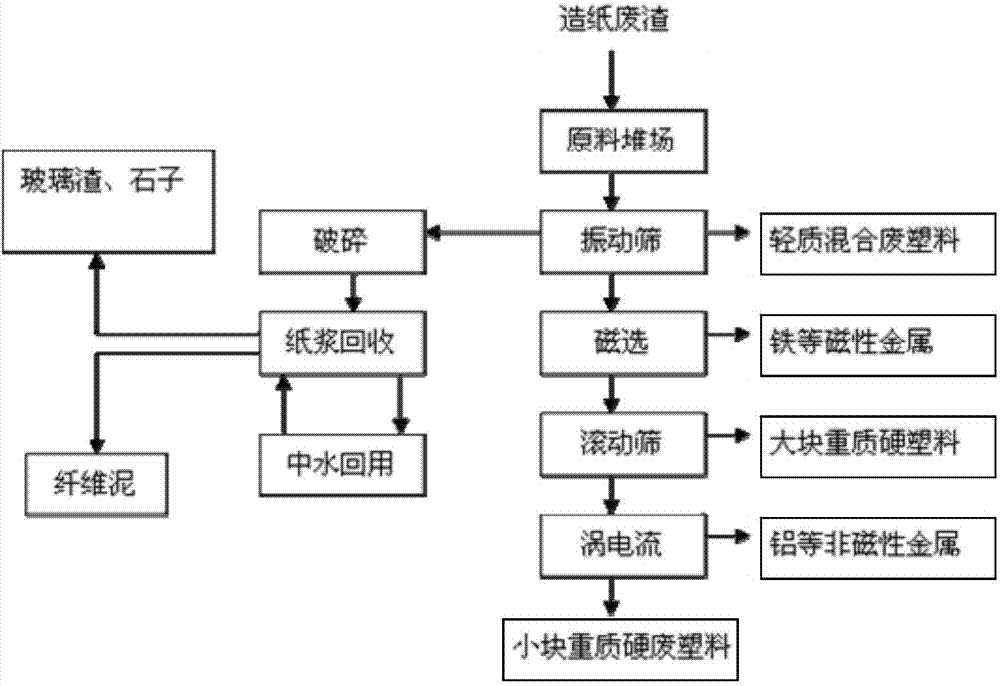

Method for harmless treatment of waste residue in paper making

InactiveCN103785670AAvoid secondary pollutionChange processing statusSolid waste disposalCelluloseSustainable development

The invention discloses a method for harmless treatment of waste residue in paper making. According to the method, light-weight plastic mixture, cellulose residue, magnetic and non-magnetic metals and small heavy hard plastics and the like are separated from waste residues in paper making through a pneumatic vibration screen, an incineration boiler, a magnetic separation device, a rolling screen and eddy current, namely, all the parts in the waste residue in paper making are continuously separated by machines so that all the waste sources are optimally disposed to achieve harmless treatment by changing waste residues of paper making into valuables, so that environmental pollution accidents are prevented. The method is necessary for economic sustainable development.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP +1

Catalyst for removing low-concentration formaldehyde in gases and application thereof

InactiveCN102000603AReduce energy consumptionIncrease storage capacityMolecular sieve catalystsDispersed particle separationMolecular sieveCarbon dioxide

The invention belongs to the technical field of gas purification treatment, relating to a catalyst for removing low-concentration formaldehyde in gases and the application thereof. The catalyst is characterized by using at least two of Ag, Co, Fe and Cu as main active components which are loaded on an HZSM-5 type molecular sieve carrier and are 1-20 percent by weight of the catalyst. The catalyst is filled in a reactor and applied to two alternately operating stages, i.e. a storage stage and a regeneration stage, wherein the reactor can be inflated with ozone, can be used for heating at a controlled temperature and can carry out DBD (Dielectric Barrier Discharges). At the storage stage, low-concentration formaldehyde in the gases is firstly stored on the catalyst; and at the regeneration stage, ozone or oxygen-contained gas is introduced for heating or carrying out the DBD so that the formaldehyde stored on the catalyst is fully oxidized into carbon dioxide and water, wherein the oxygen content in the introduced oxygen-contained gas at the regeneration stage is 20-100 percent, and air can be directly used as the oxygen-contained gas at the regeneration stage. In the invention, the provided catalyst with the function of selective storing and catalytic oxidation on the formaldehyde has the advantages of low energy consumption and no secondary pollution, is extremely suitable for removing low-concentration formaldehyde in gases and is particularly suitable for removing formaldehyde pollutants in indoor air.

Owner:DALIAN UNIV OF TECH

Vertical cyclic tape filter

InactiveCN105126419AEasy to useReasonable structureMoving filtering element filtersInlet channelDrive motor

The invention relates to a vertical cyclic tape filter. The vertical cyclic tape filter comprises a shell, a net chain, a paper pressing disk, a liquid inlet channel, a driving motor, a net chain driving unit, a net chain tensioning mechanism and a cyclic filter tape, wherein the net chain, the paper pressing disk, the liquid inlet channel, the driving motor, the net chain driving unit and the net chain tensioning mechanism are arranged in the shell; the cyclic filter tape is arranged on an outer ring of the net chain in a sleeving manner, is tensioned by a cyclic filter tape tensioning mechanism and is driven by the net chain to move cyclically; a clean liquid cavity is formed in the bottom of the shell and is positioned inside the net chain; the opening size of the clean liquid cavity is matched with the width of a circular arc formed by the net chain. The vertical cycle tape filter is simpler and more convenient to use, and more reasonable in structure; manpower and resources can be effectively saved, and cleaner and pollution-free filter liquid is obtained.

Owner:烟台开发区博森科技发展有限公司

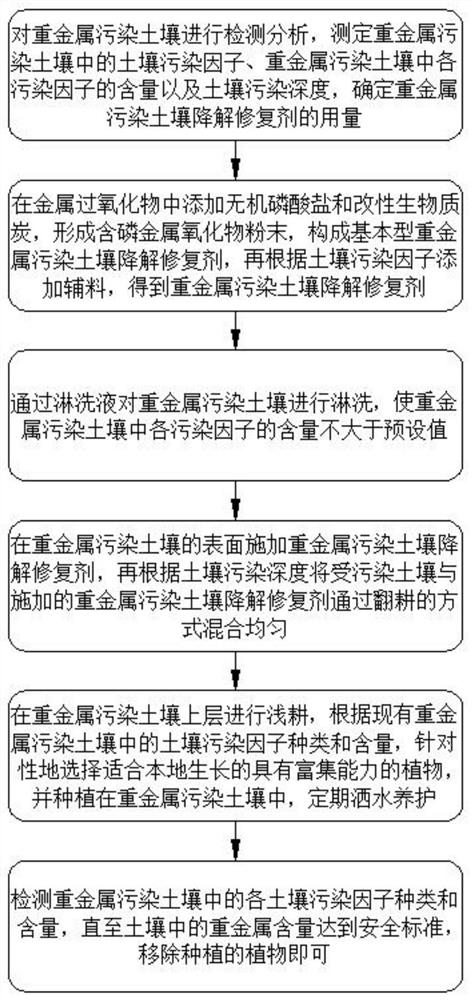

Heavy metal contaminated soil degradation harmless treatment method

InactiveCN113058985ANo secondary pollutionAvoid secondary pollutionContaminated soil reclamationSoil scienceEngineering

The invention discloses a heavy metal contaminated soil degradation harmless treatment method which comprises the following steps: S1, detecting and analyzing heavy metal contaminated soil, and determining the dosage of a heavy metal contaminated soil degradation repairing agent; S2, preparing the heavy metal contaminated soil degradation repairing agent; S3, leaching; S4, applying the heavy metal contaminated soil degradation repairing agent, and performing ploughing and mixing; S5, planting plants which are suitable for local growth and have enrichment capacity; and S6, detecting until the heavy metal content in the soil reaches the safety standard. Harmless treatment of the heavy metal contaminated soil is achieved, and the requirements of resource utilization, soil replacement and landfill are met; the technology application range is wide, and the method is suitable for remediation of various soils contaminated byheavy metals,including chromium, hexavalent chromium, lead, zinc, copper, chromium, nickel, mercury, arsenic and the like; the technical operation is simple and convenient, the repairing time is short, the capacity increase is less, secondary pollution is avoided, and the cost is lower; and the resource utilization of the polluted soil can be realized, and the repaired soil is suitable for various purposes.

Owner:益壤(厦门)环保科技有限公司

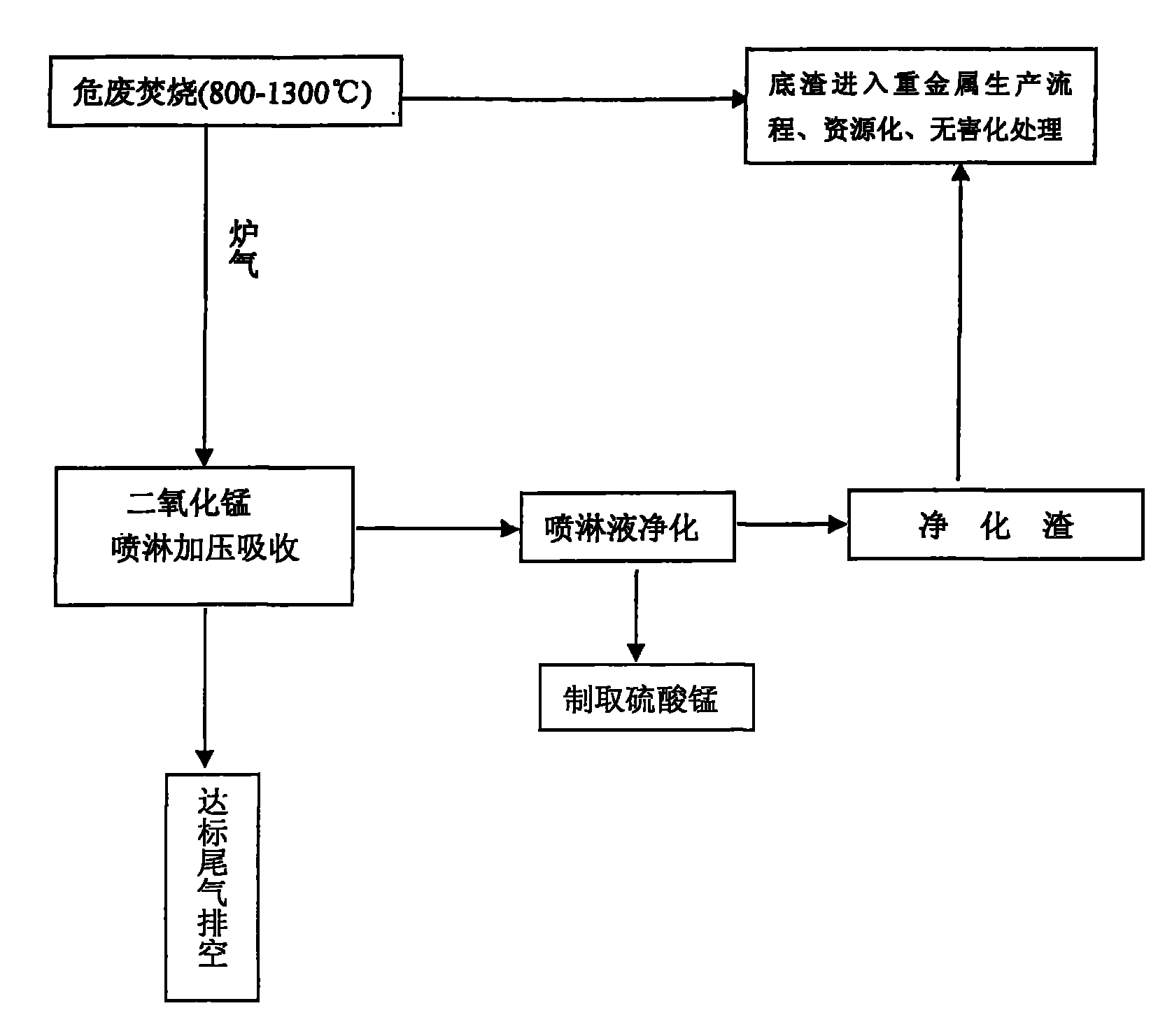

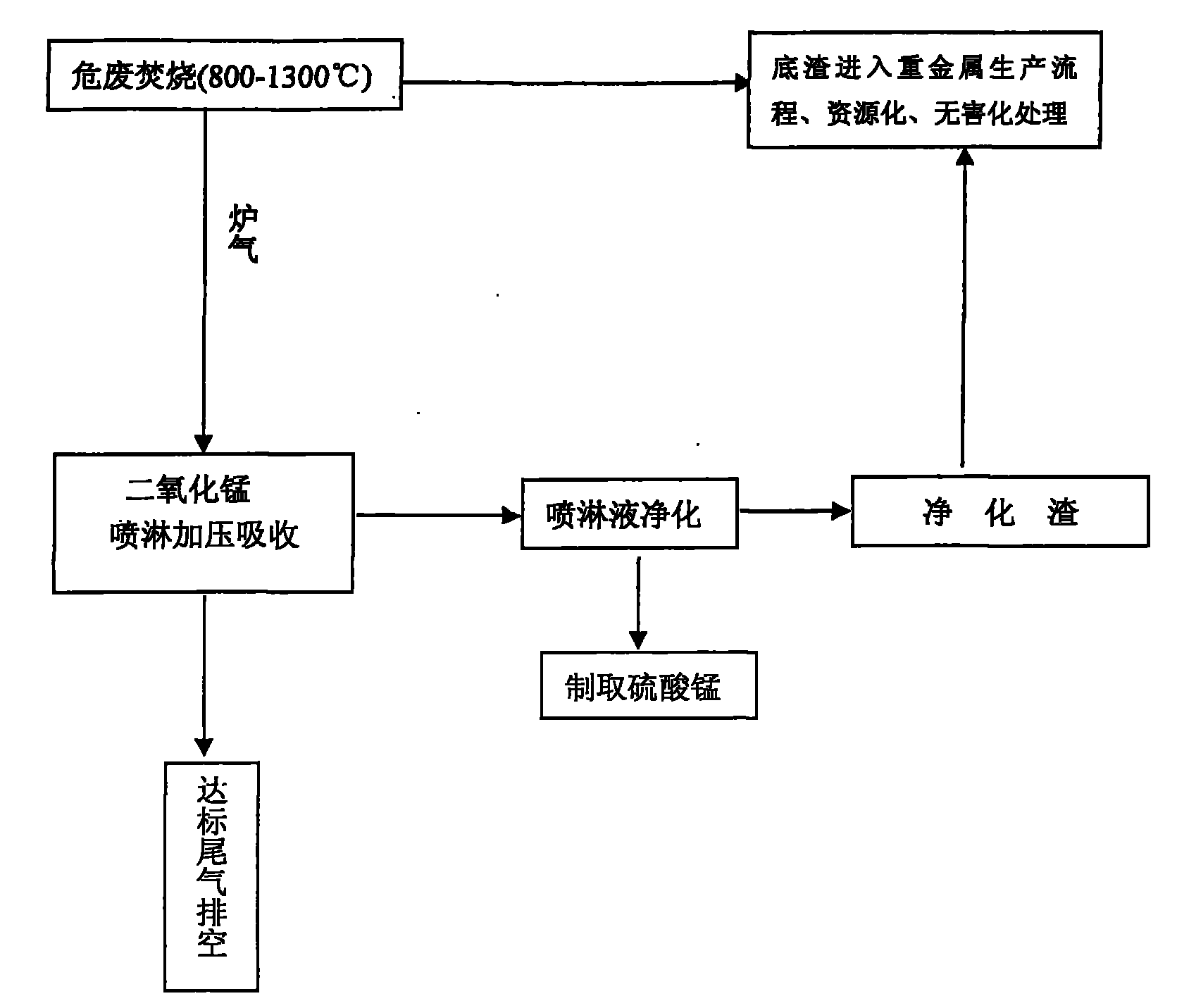

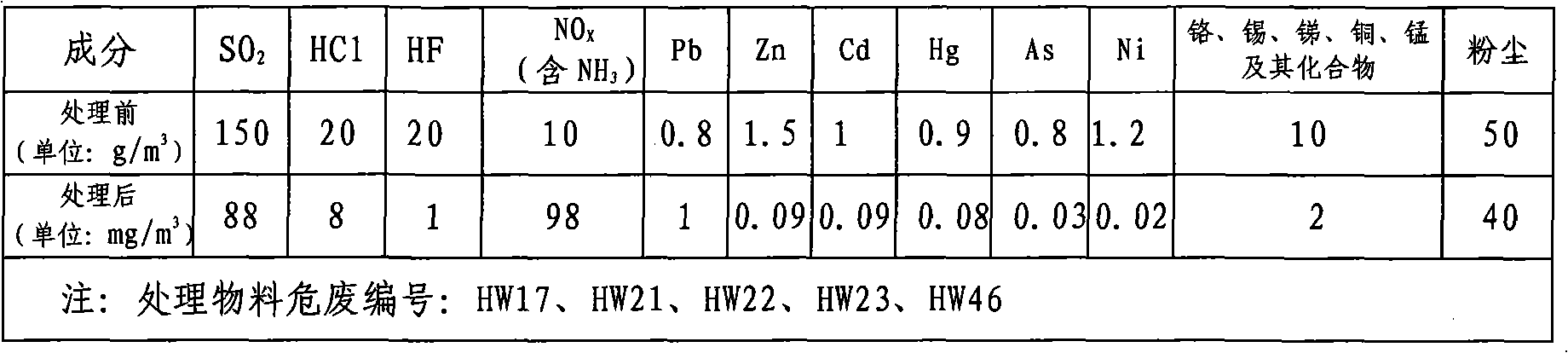

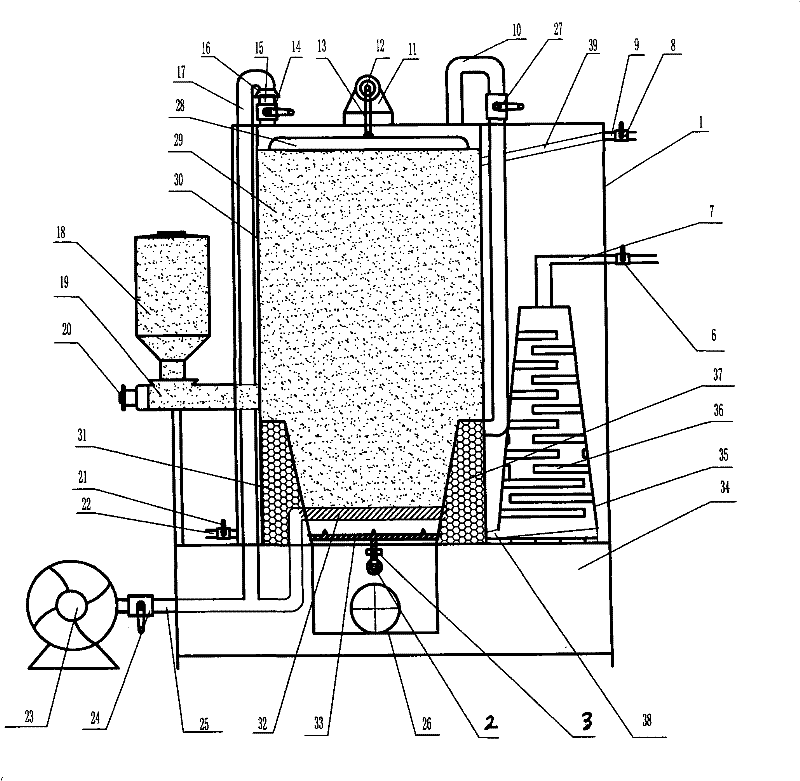

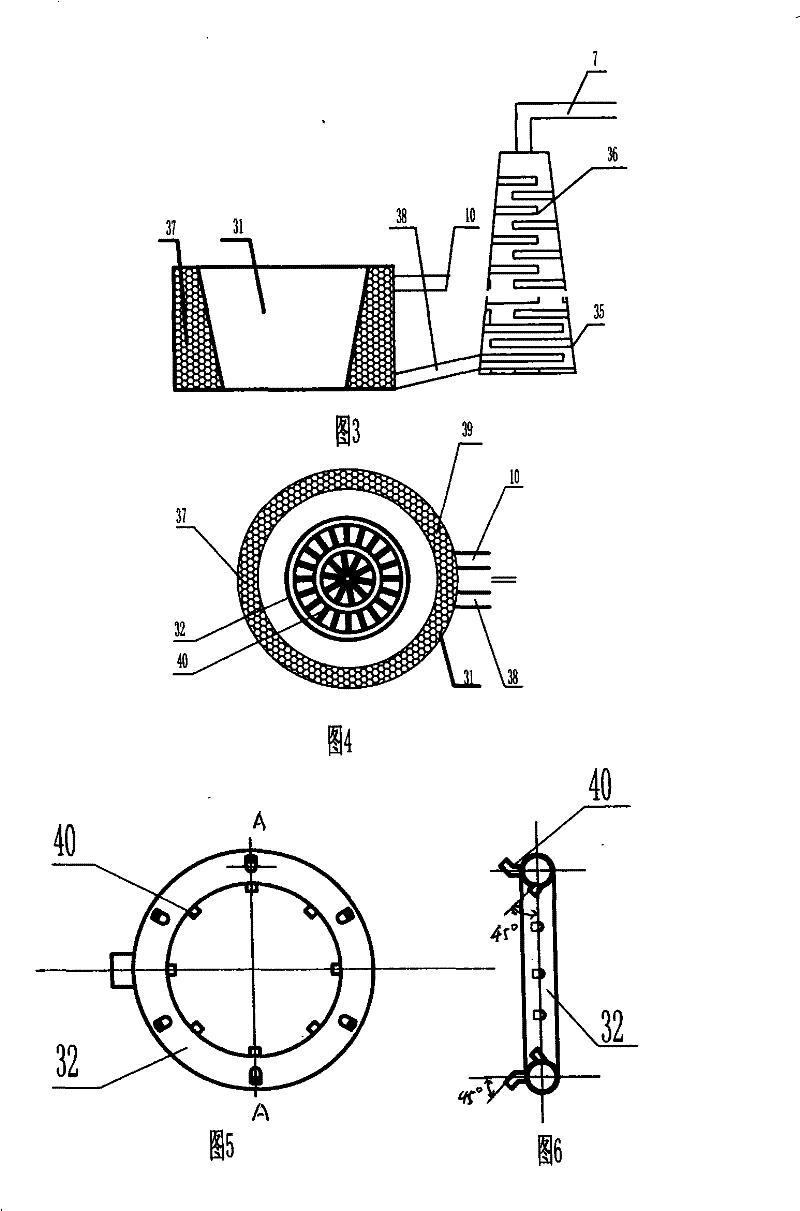

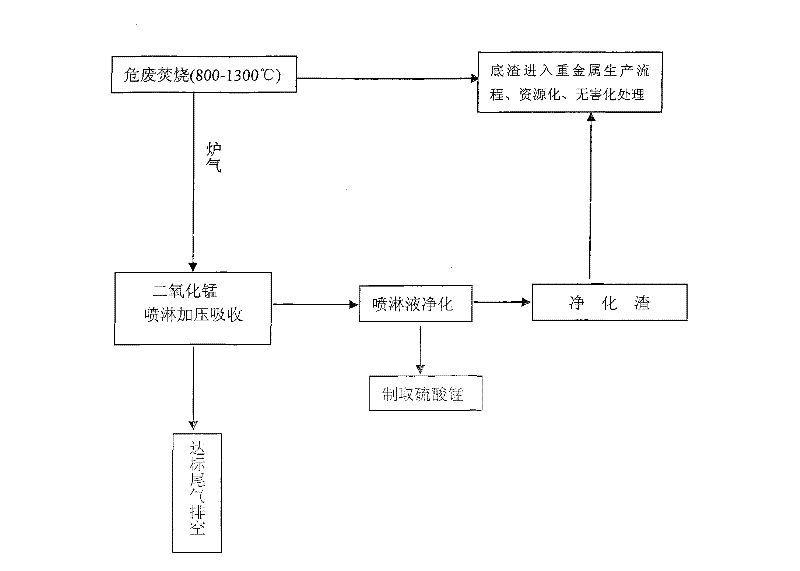

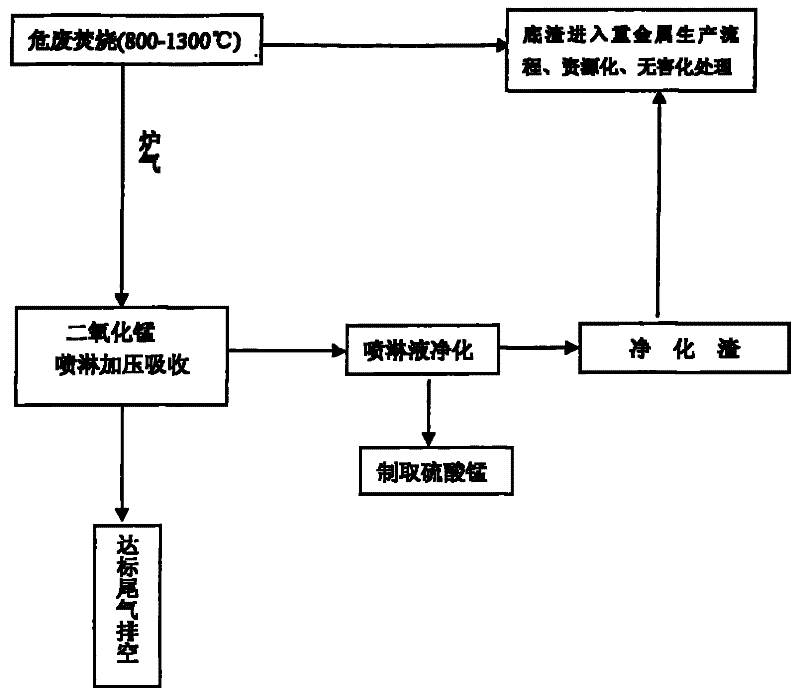

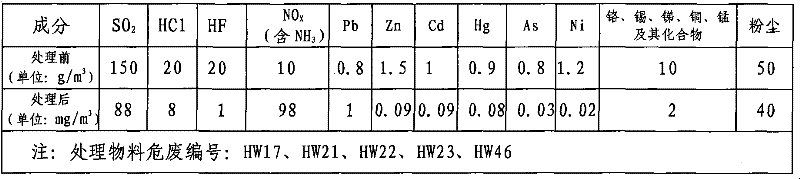

Method for treating incineration tail gas of solid hazardous waste

InactiveCN101785967AReduced corrosion protection requirementsAbsorb running cost reductionDispersed particle separationHazardous substanceEngineering

The invention discloses a method for treating incineration tail gas of solid hazardous waste, comprising the following steps of: (1) taking manganese dioxide as the oxidant, adding water to prepare a sizing agent; (2) delivering the size into the smoke absorption tower, spraying the sizing agent in mist, wherein the pressurized smoke with the wind pressure of 1500-5000Pa is introduced from the bottom of the tower, the gas inlet tubes are dispersed tubes under the liquid level of the sizing agent, wherein the temperature T of the tower bottom recovery liquid is controlled to be not below 5 DEG C and not above 90 DEG C, and the pH value is not less than 3.8; (3) separating the precipitation from the recovery liquid at the tower bottom, preparing manganese sulfate via the solution, and recovering the heavy metal from the bottom dross; (4) discharging the tail gas which is up to the standard. The method for treating incineration tail gas of solid hazardous waste has simple process flow, non-fouling equipment, smooth circulation, less equipment, and low operation cost; and the composite rate of removing the harmful substances reaches 98.5%. The heavy metals can be recovered from the bottom dross; the recycle and the harmlessness can be realized without secondary pollutant products.

Owner:重庆太锦环保科技有限公司

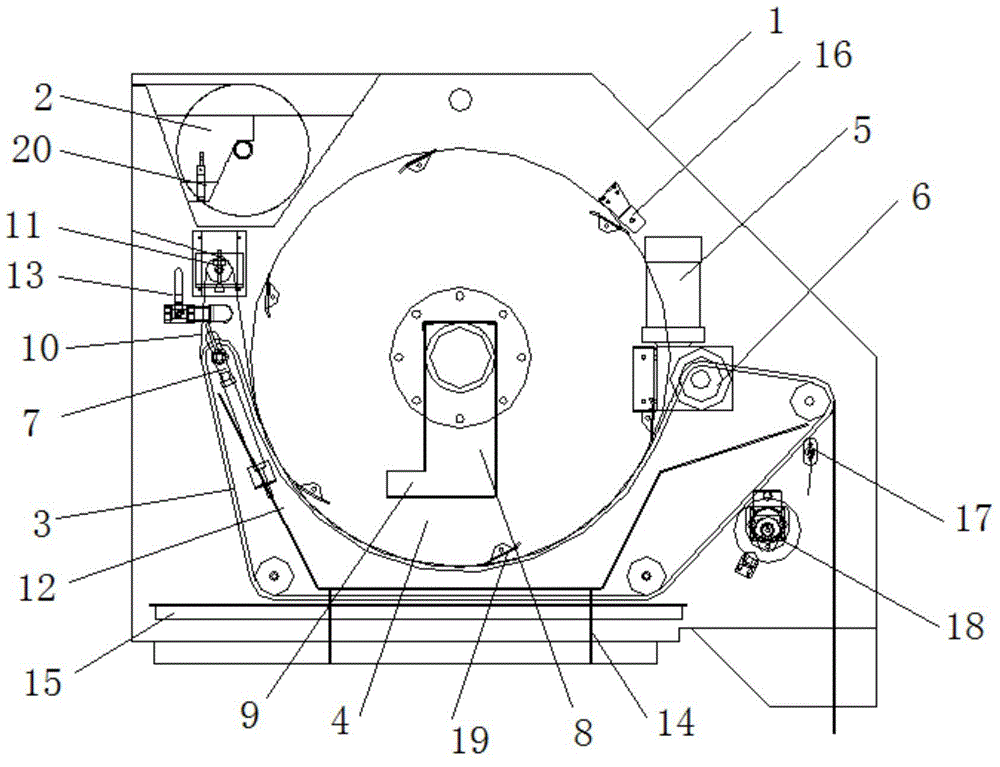

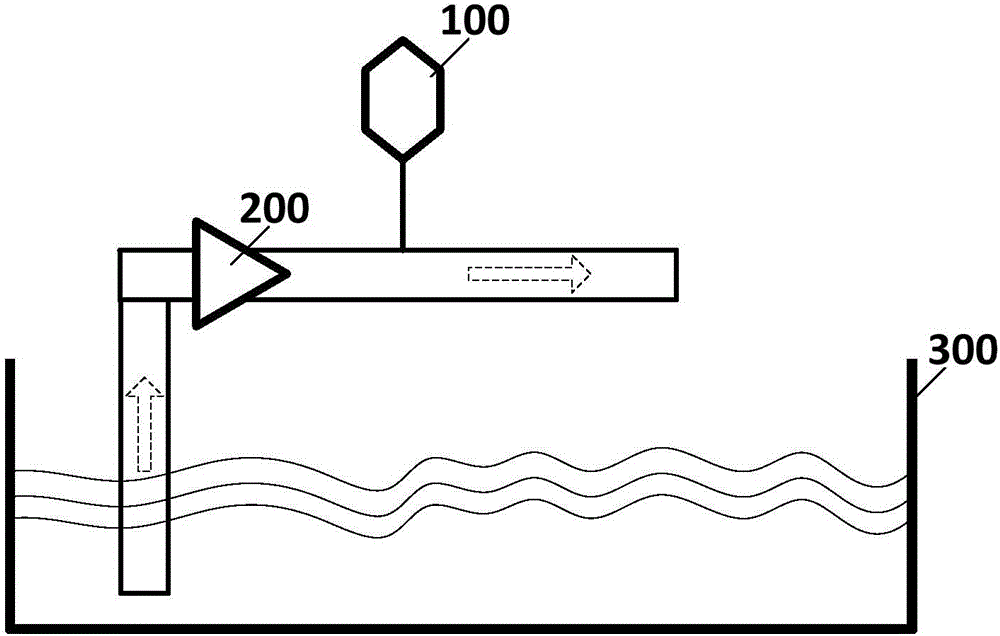

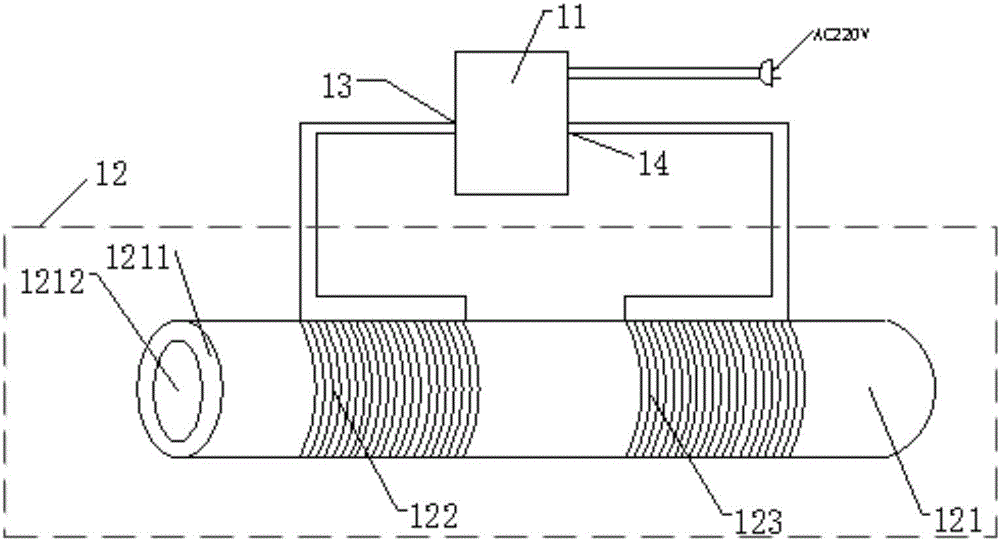

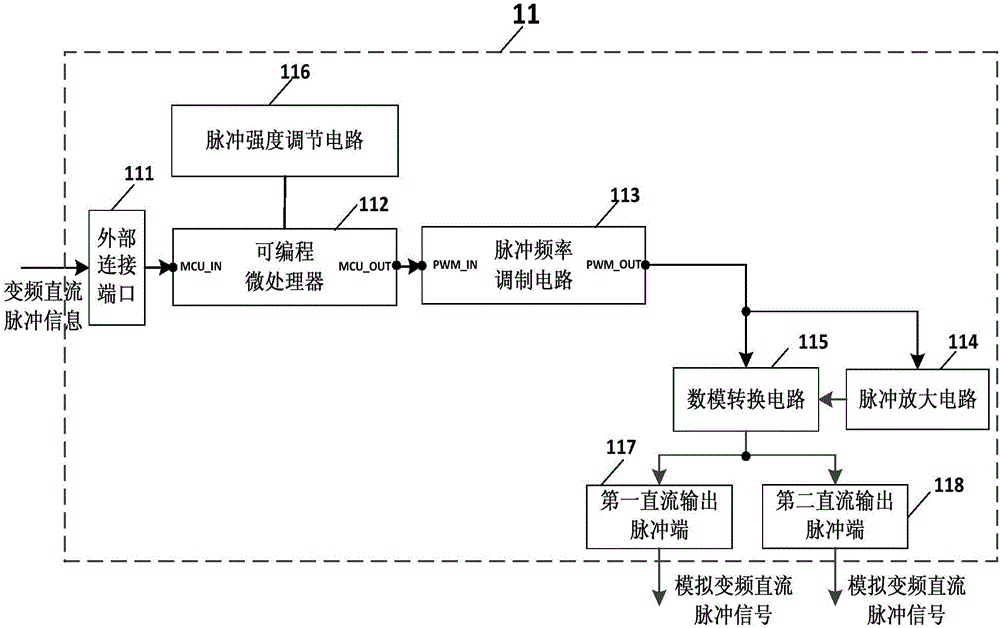

Water activation treatment apparatus, water activation treatment method and water activation treatment system for breeding

InactiveCN106167291AHigh activityImprove immunityWaste water treatment from animal husbandryWater/sewage treatment by magnetic/electric fieldsWater qualityElectromagnetic pulse

The invention discloses a water activation treatment apparatus for breeding. The water activation treatment apparatus comprises an electromagnetic pulse generator and an electromagnetic transducer, wherein the electromagnetic pulse generator is used for generating an analog frequency conversion direct current pulse signal and transmitting the analog frequency conversion direct current pulse signal to the electromagnetic transducer, and the electromagnetic transducer is used for generating a frequency conversion direct current pulse electromagnetic field according to the frequency change of the analog frequency conversion direct current pulse signal so as to carry out an activation treatment on the breeding water flowing through the electromagnetic transducer through the frequency conversion direct current pulse electromagnetic field. The invention further provides a water activation treatment method and a water activation treatment system for breeding. With the technical scheme of the present invention, the pollution-free activation treatment on the breeding water is achieved, the quality of the breeding water is improved, the soil odor inside the bred living organism is removed, and the biological benefits and the ecological benefits favorable to the aquiculture are produced.

Owner:谢崇泽

Gas disposal device and method for designing same

InactiveCN106268290AHighlight substantiveSignificant progressDispersed particle separationAir quality improvementChemical reactionAtmospheric air

The invention discloses a gas disposal device and a method for designing the same, and belongs to the technical field of air pollution control and environmental protection. The method for designing the gas disposal device includes that the gas disposal device is a gas input pipeline according to guidance which is a design idea that harmful gas CO2, SO2 and NO2 in gas is converted into organic matters by means of chemical reaction under the photosynthesis of cells of green leaves, and gas required to be disposed is inputted into an inner cavity of a gas disposal chamber; the inner cavity of the gas disposal chamber is provided with a disposal unit, the disposal unit comprises at least one vector barrier layer and a photosynthetic reaction chamber, the gas can be in contact with the cells of the green leaves in the vector barrier layers, and photosynthesis can be realized in the photosynthetic reaction chamber. Compared with the prior art, the gas disposal device and the method have the outstanding and substantial advantages that the gas disposal device and the method are novel and reliable and are free of secondary pollution, waste can be turned into wealthy, and the gas can be harmlessly treated and can be simultaneously recycled and disposed.

Owner:徐明好

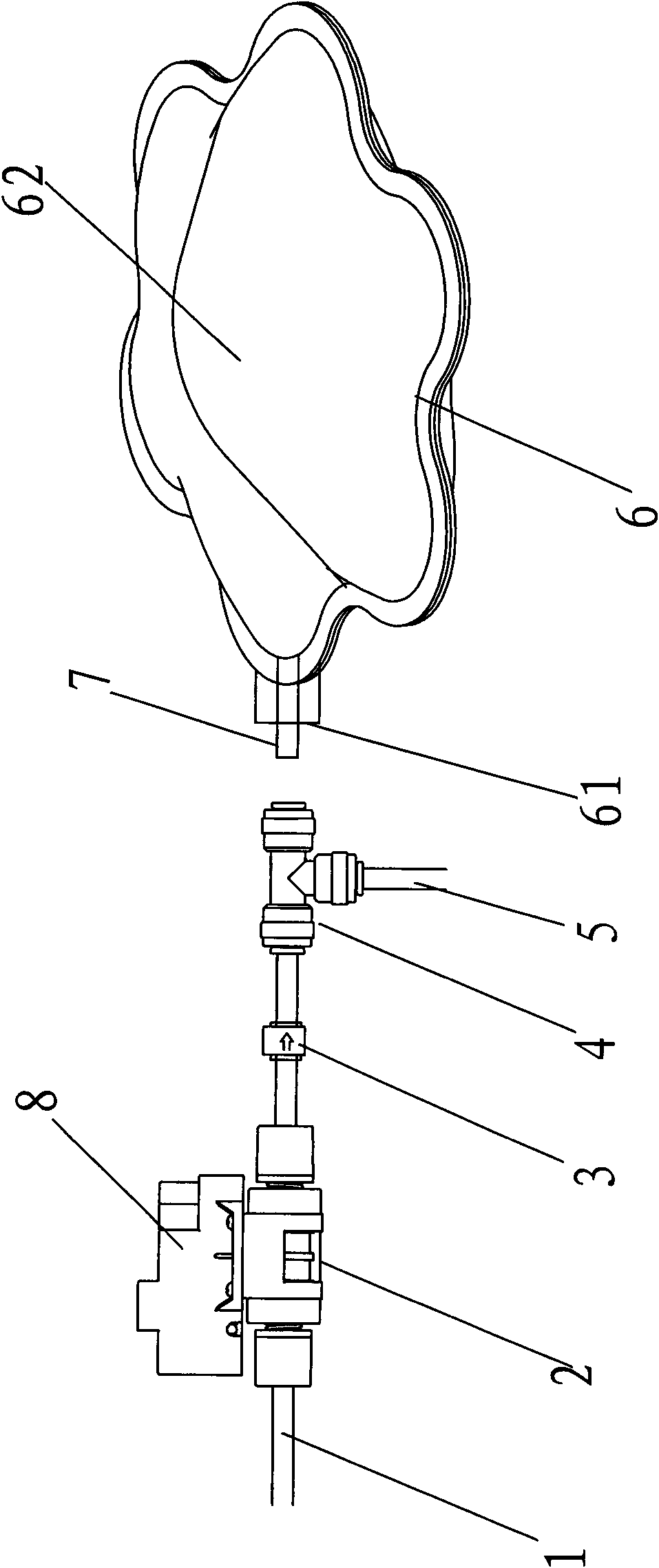

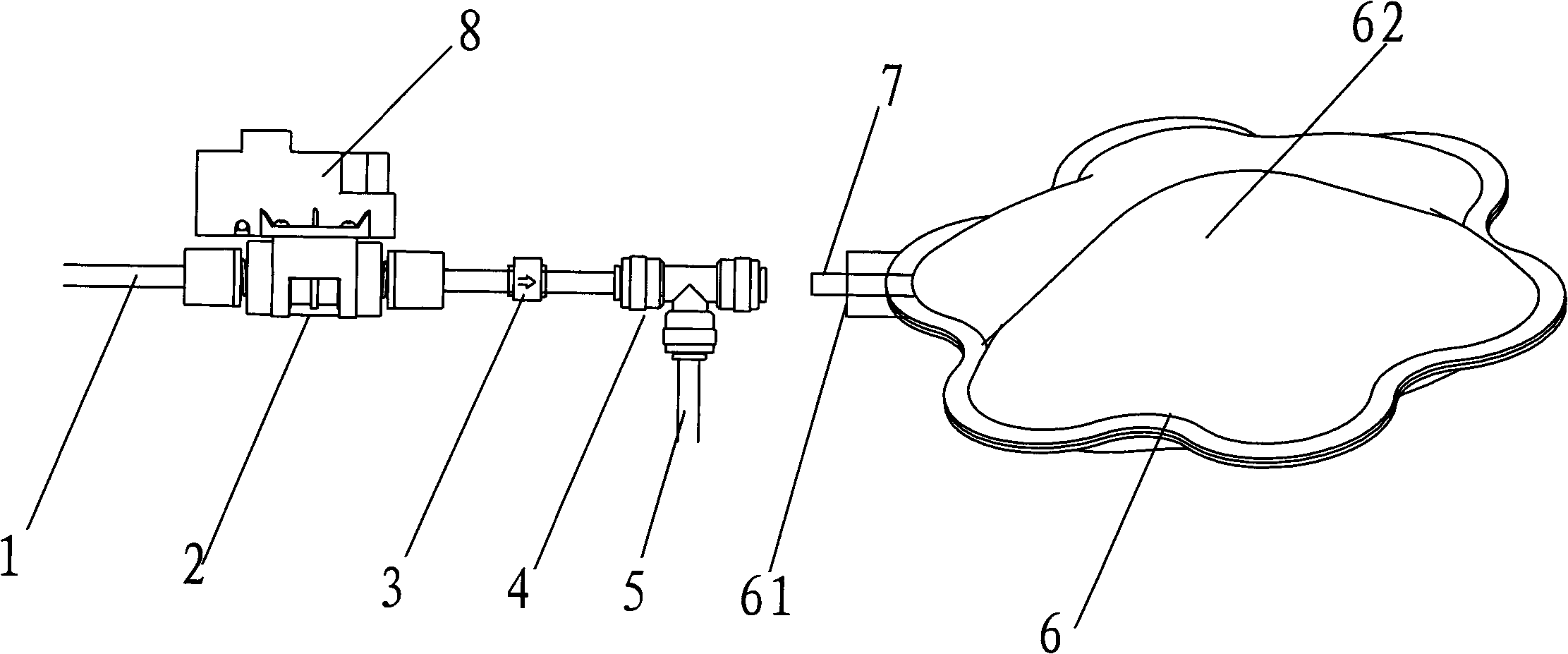

Special container device for antifouling energy-saving water machine

The invention discloses a special container device for an antifouling energy-saving water machine. The special container device comprises a purified water container for storing purified water, wherein the purified water container is provided with a water inlet which also serves as a water outlet; the water inlet of the purified water container is hermetically connected with water inlet and outletpipelines; the water inlet and outlet pipelines are communicated with a water inlet pipe and a water outlet pipe respectively; the water inlet pipe is provided with a pressure control switch, and thepressure control switch can detect the change of pressure in the purified water container and automatically open or close the water inlet pipe passage; and the volume and the capacity of the purifiedwater container can be expanded and shrunk together with the magnitude change of the stored water quantity in the purified water container. The traditional plastic barrel is replaced by adopting a special film bag and used as the purified water container; by automatic shrinkage and expansion of the purified water container, the possibility that the purified water in the container is directly contacted with the air is effectively avoided, so that secondary pollution is reduced and even eliminated; and the special container device has the advantages of simple structure, strong antifouling capacity, high automation degree and the like.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

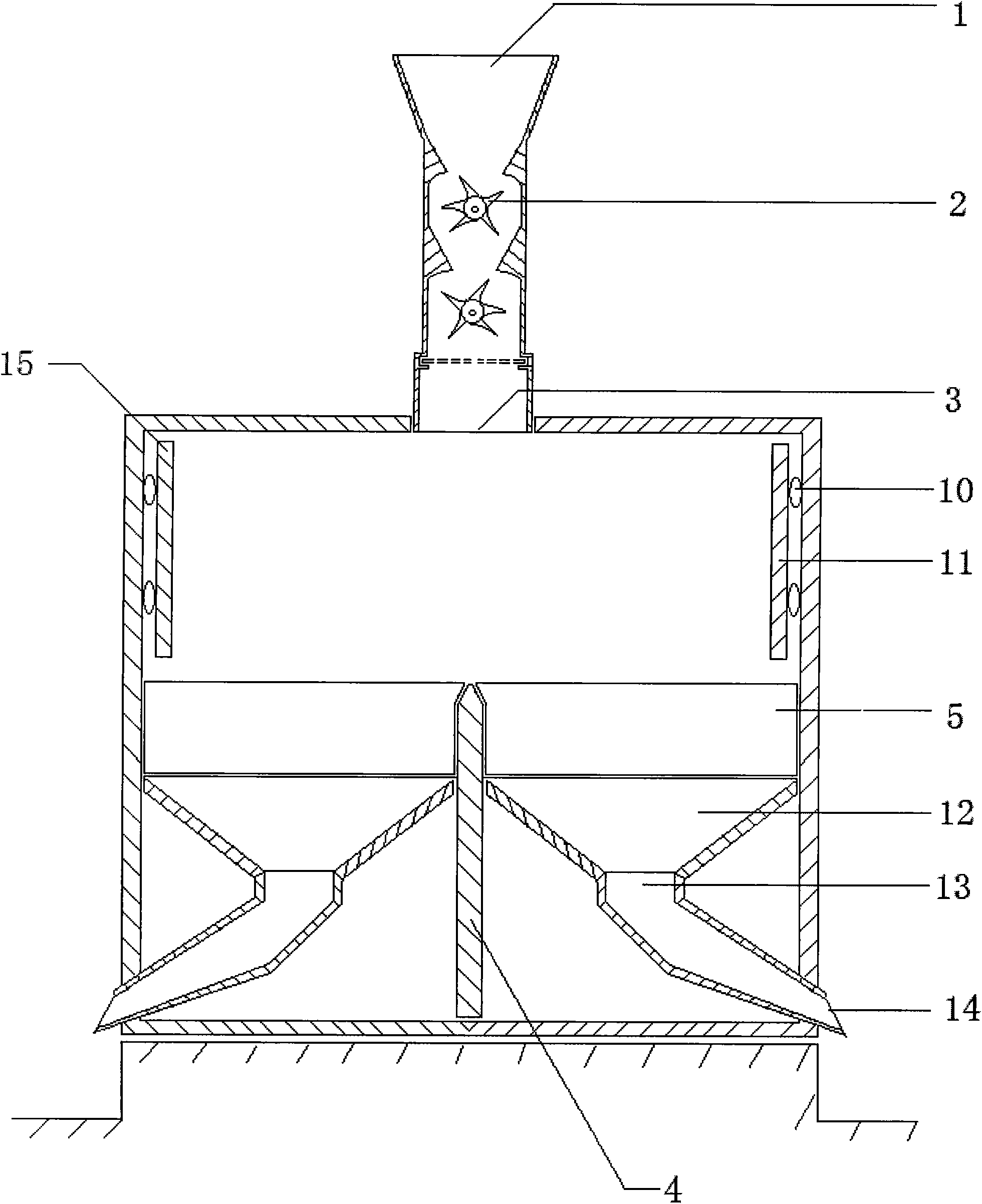

Crushing and sorting integrated automatic processor for waste plastics

InactiveCN101934563ARealize automatic sortingIncrease added valueGas current separationPlastic recyclingHelical lineVolumetric Mass Density

The invention relates to sorting machinery for waste plastics, in particular to a crushing and sorting integrated automatic processor for waste plastics, which comprises a tank body, a crushing device, a wind screening device, a cathode-anode electric field and a sorting bucket, wherein the crushing device is arranged on the central axis above the left side of the top of the tank body; the cathode-anode electric field mainly comprises an anode plate and a cathode plate; the cathode and the anode plates are arranged on the upper part at the inner side of the tank body; the wind screening device is arranged on the central axis on the left side of the tank body; and after the waste plastics crushed by the crushing device enter the tank body, the waste plastics fall down in a spiral line mode under the combined action of the wind blown by a branched passage of the wind screening device and the cathode-anode electric field and enter the sorting bucket arranged on the lower part in the tank body so as to realize the sorting of the waste plastics. The invention combines crushing, electrostatic sorting, wind power sorting and density sorting, saves a lot of labor force and simultaneously avoids the damage of germs in the sorting course of the waste plastics to human health so as to realize the automatic sorting of the waste plastics.

Owner:FUJIAN NORMAL UNIV

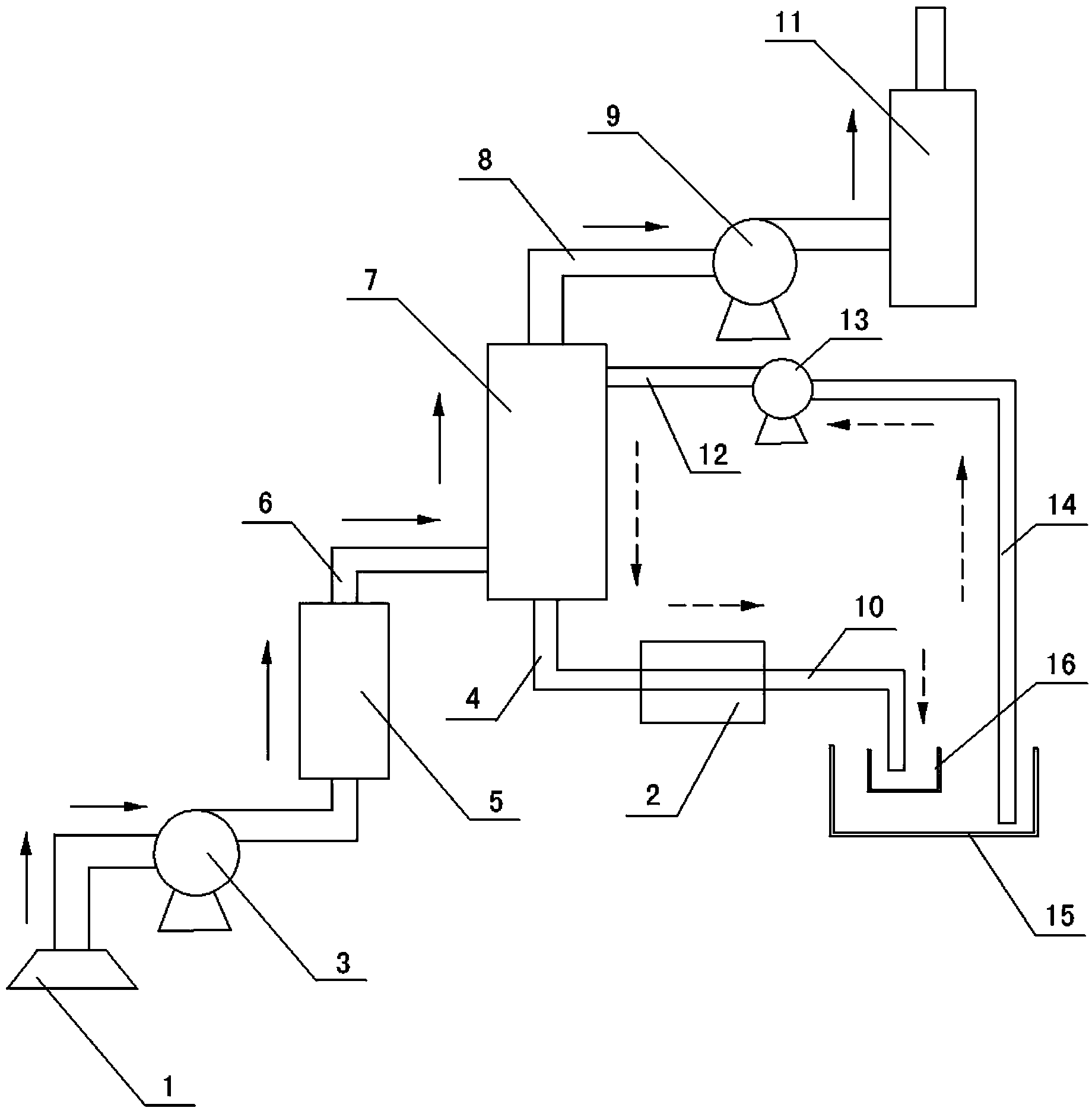

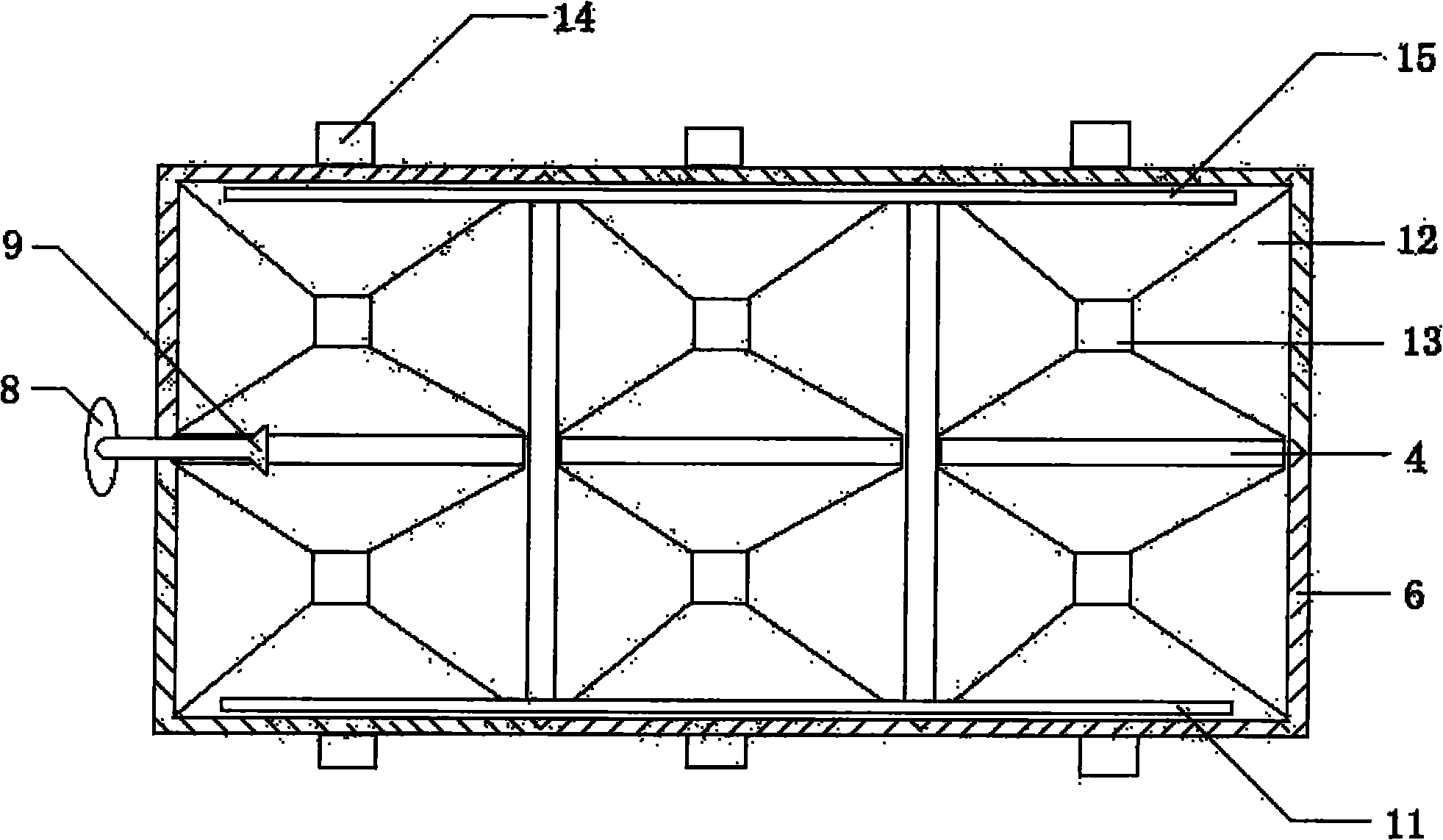

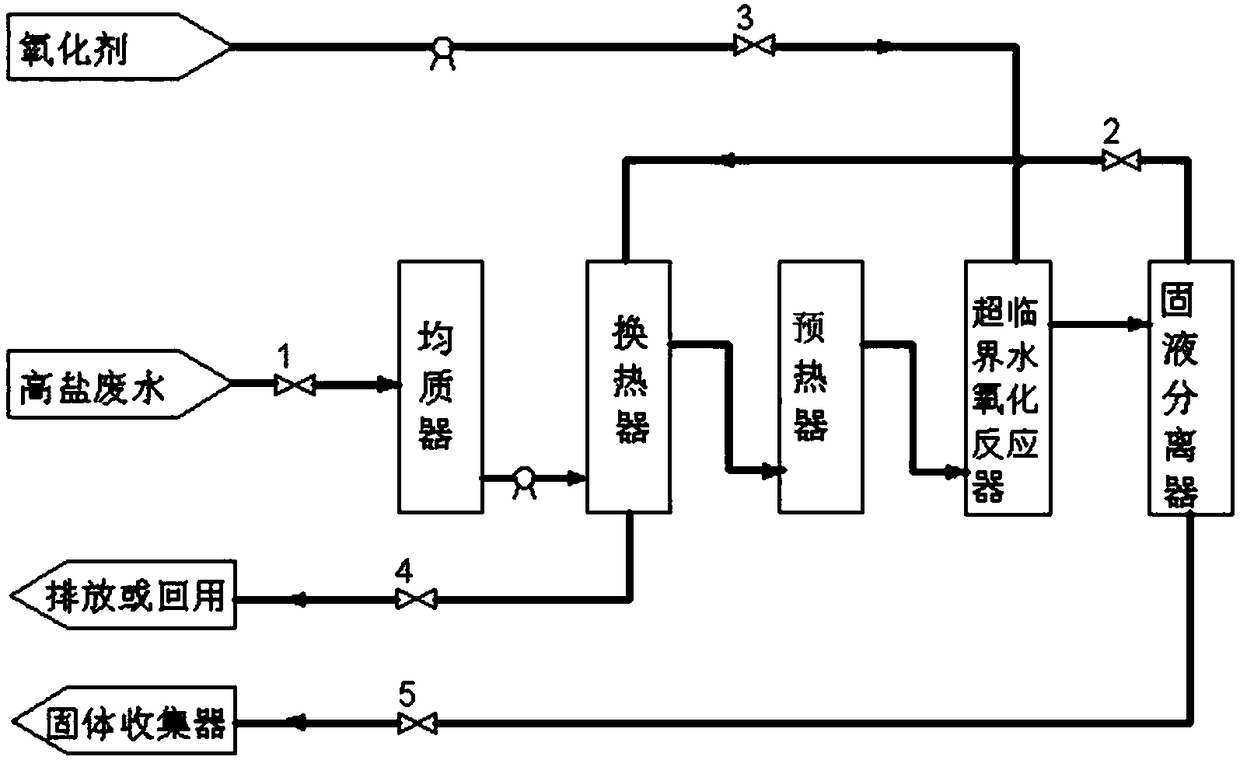

System and method for treating high-salt wastewater by utilizing supercritical water oxidation method

InactiveCN108217906ARapid responseReactor is smallSpecific water treatment objectivesWater contaminantsPlunger pumpProcess engineering

The invention relates to a system and method for treating high-salt wastewater by utilizing a supercritical water oxidation method. The system comprises a water pump, a homogenizing device, a high-pressure plunger pump, an oxidant pressurizing device, a heat exchanger, a pre-heater, a supercritical water oxidation reactor and a solid-liquid separator, wherein the water pump, the homogenizing device, the high-pressure plunger pump, the heat exchanger, the pre-heater, the supercritical water oxidation reactor and the solid-liquid separator are connected in sequence through a conveying pipeline;a supercritical fluid outlet of the solid-liquid separator is connected with a supercritical water fluid inlet of the heat exchanger, and residual heat recycling is carried out on cold fluid enteringthe heat exchanger; the oxidant pressurizing device is connected with the supercritical water oxidation reactor through a pipeline; a heat medium outlet of the heat exchanger is connected with decompression equipment, and fluid is decompressed and then is discharged or recycled. The system provided by the invention has the advantages of rapid reaction, small reaction device, small occupied area, no secondary pollution and the like; if the content of organic matters in the wastewater reaches certain concentration, self-heating operation can be realized in a reaction process.

Owner:NANJING UNIV OF TECH +1

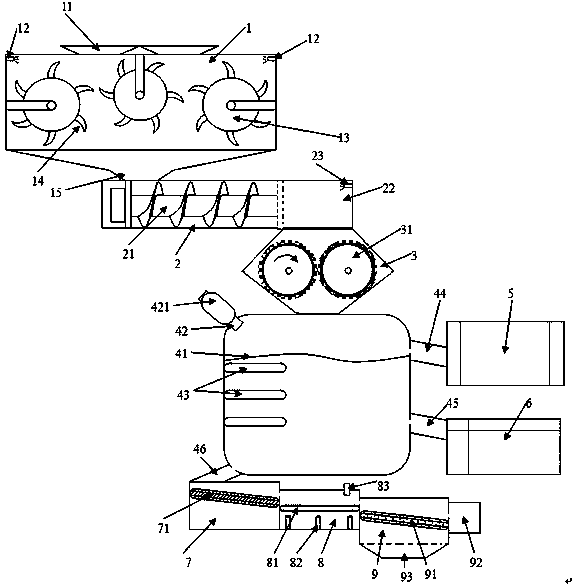

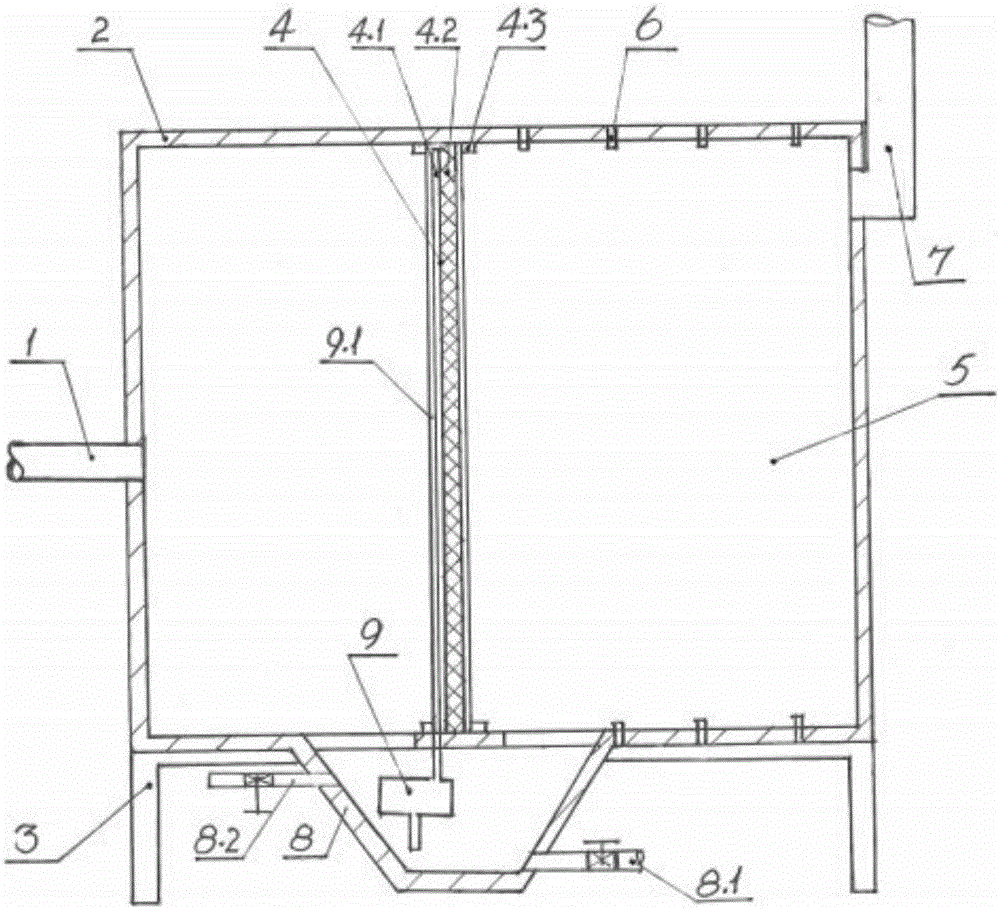

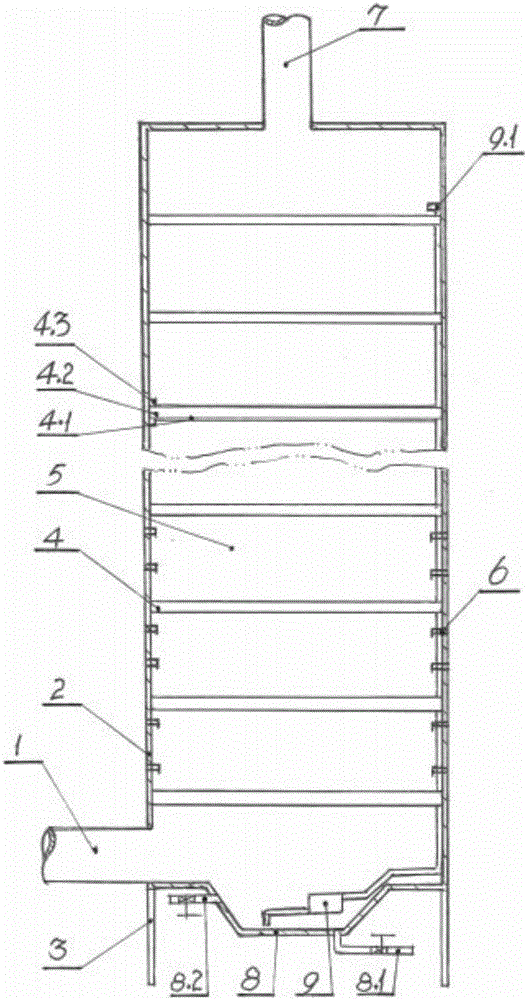

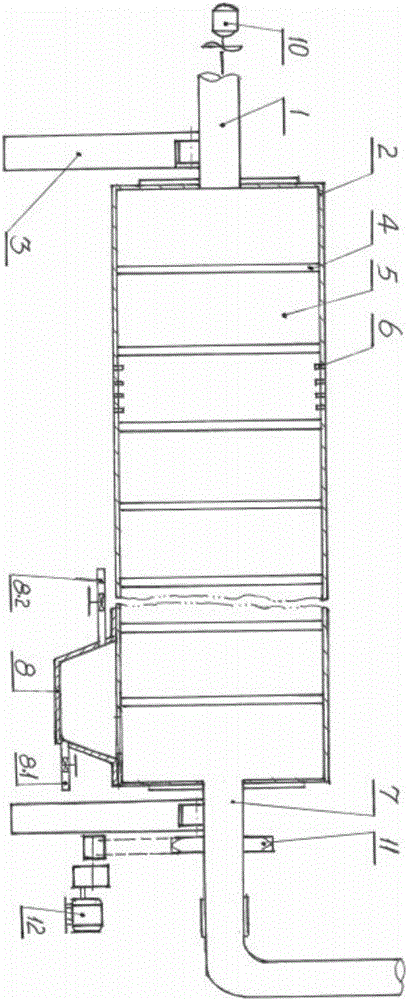

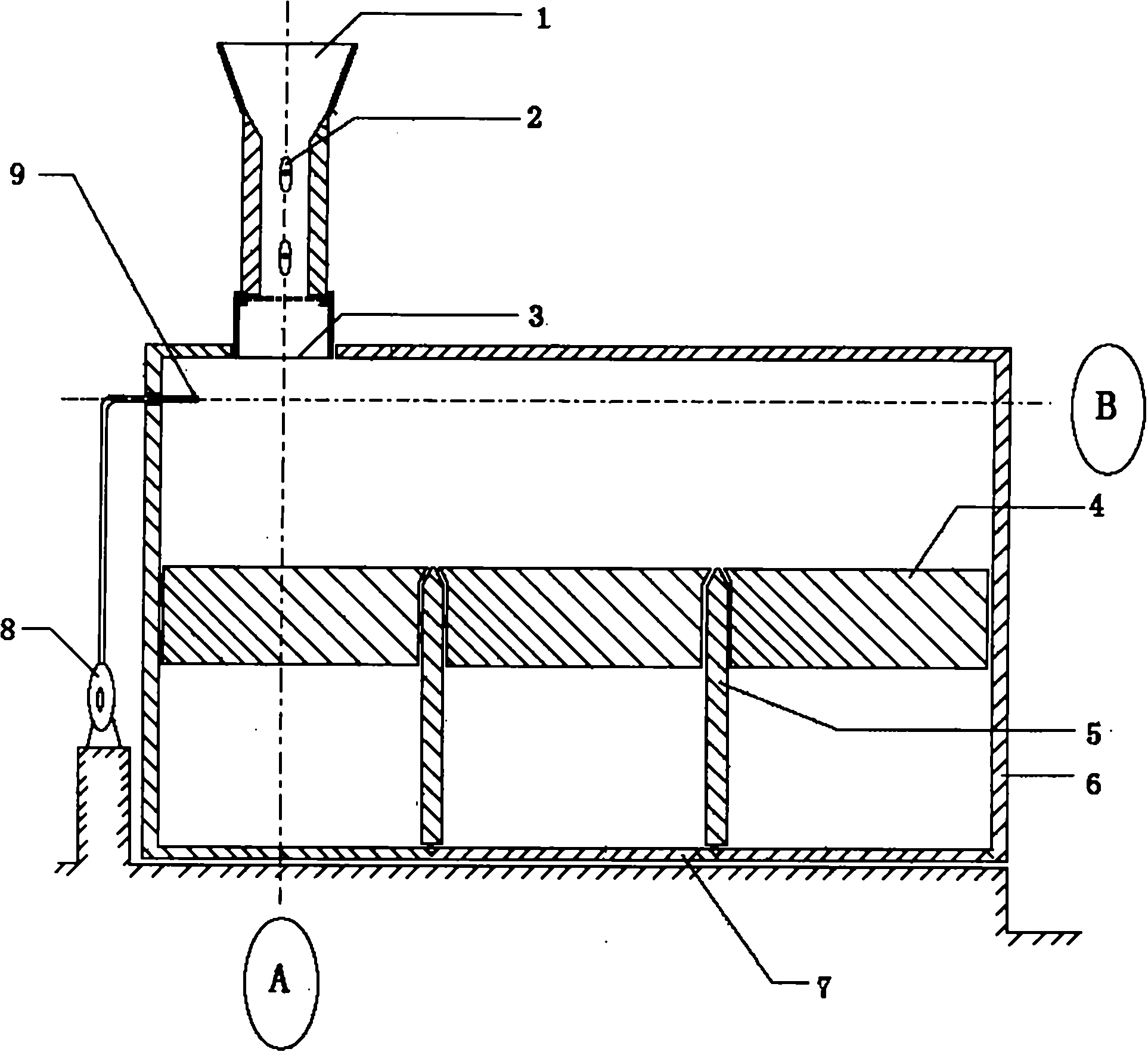

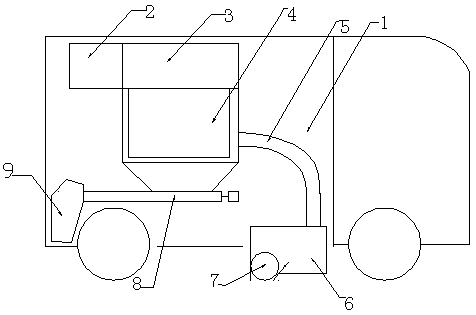

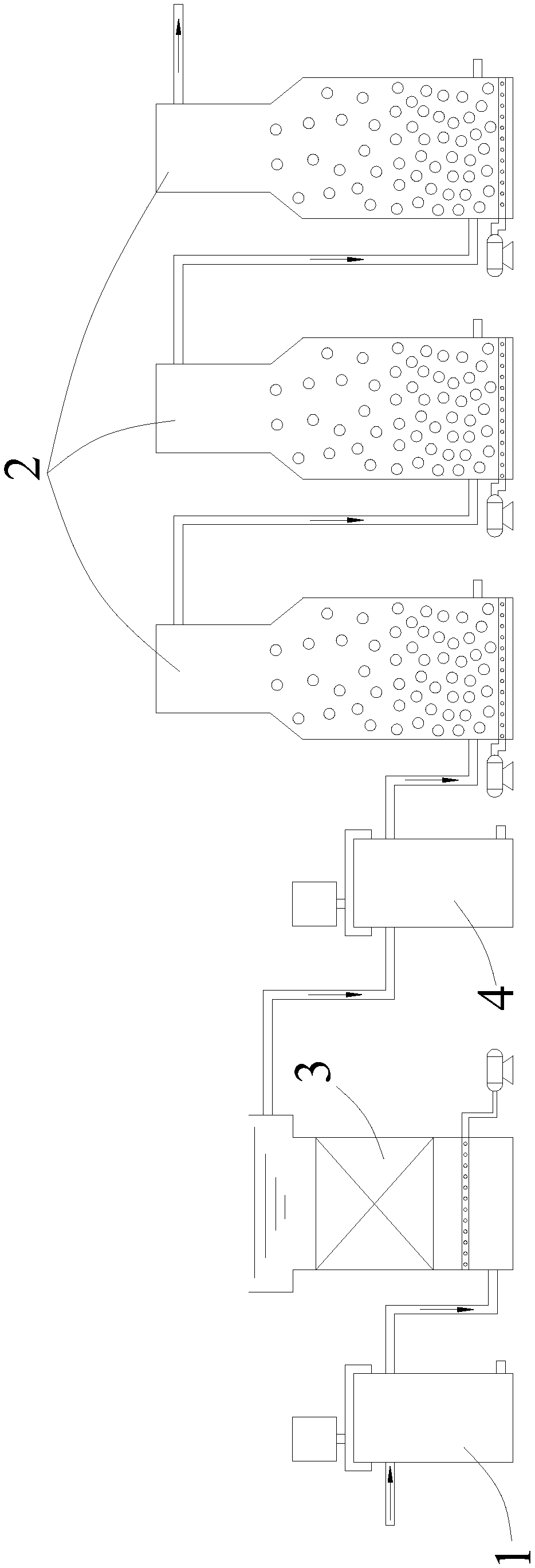

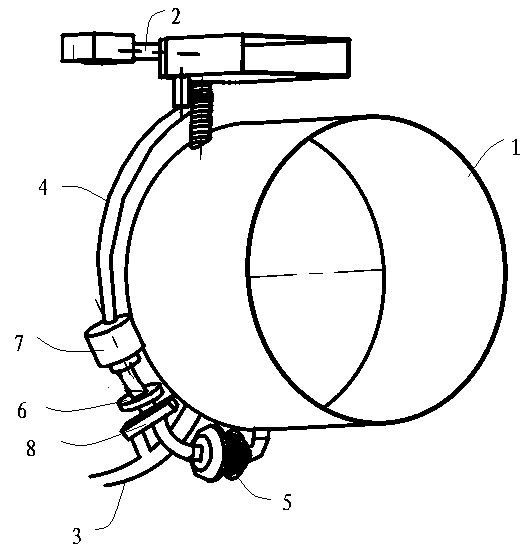

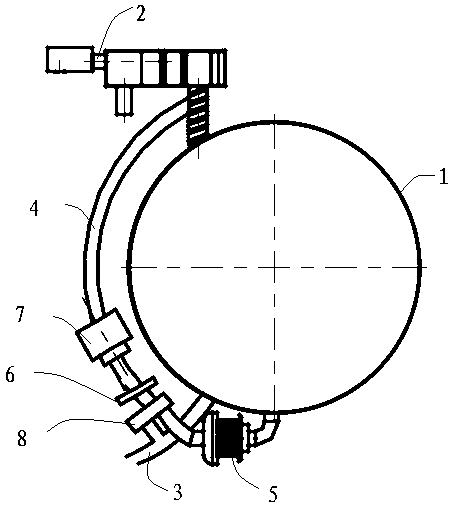

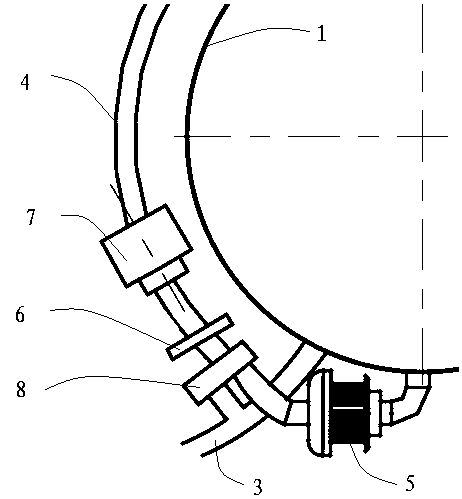

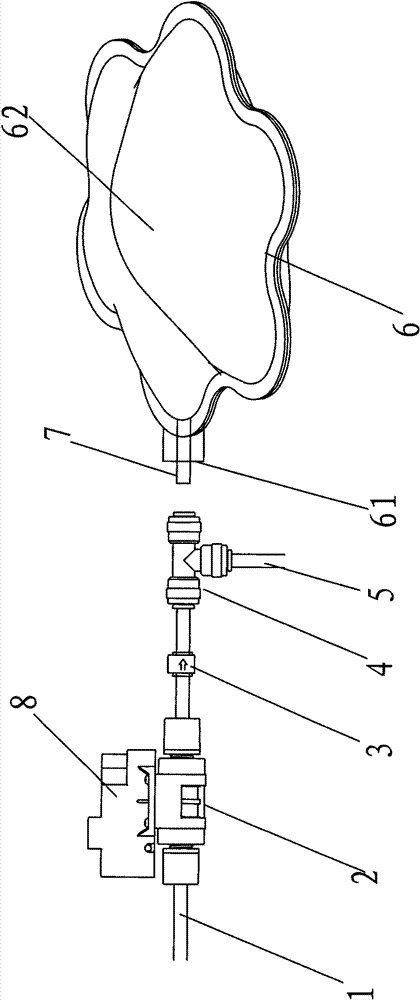

Garbage packaging device for solar sweeper

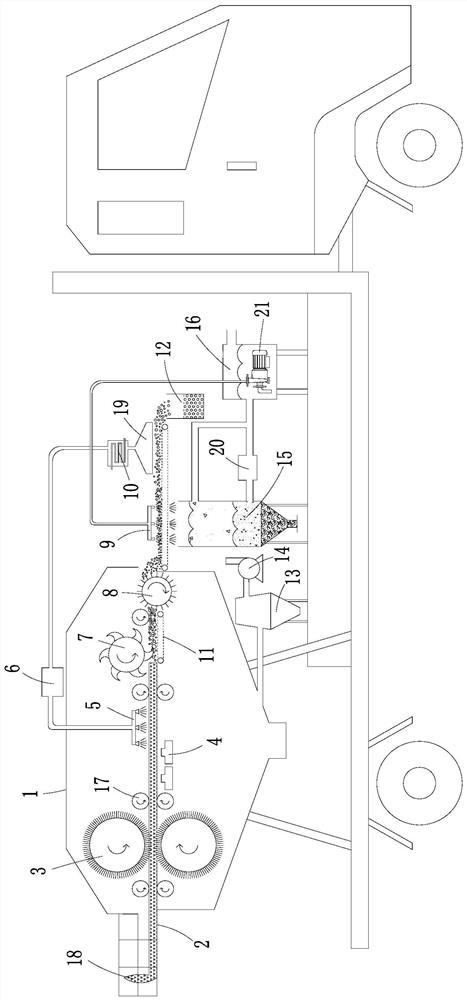

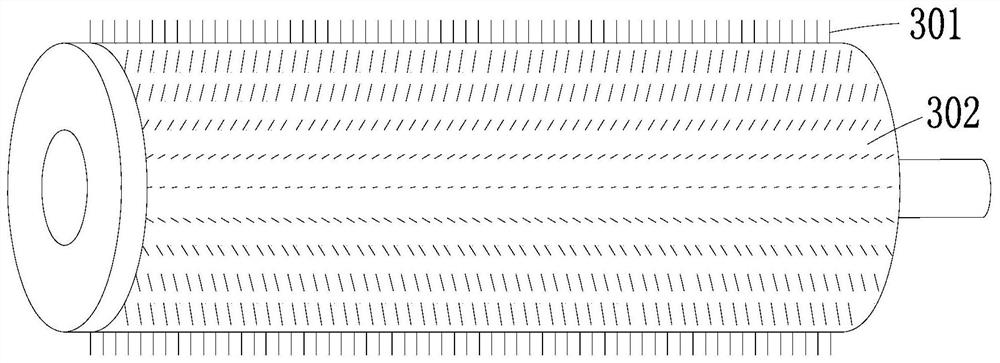

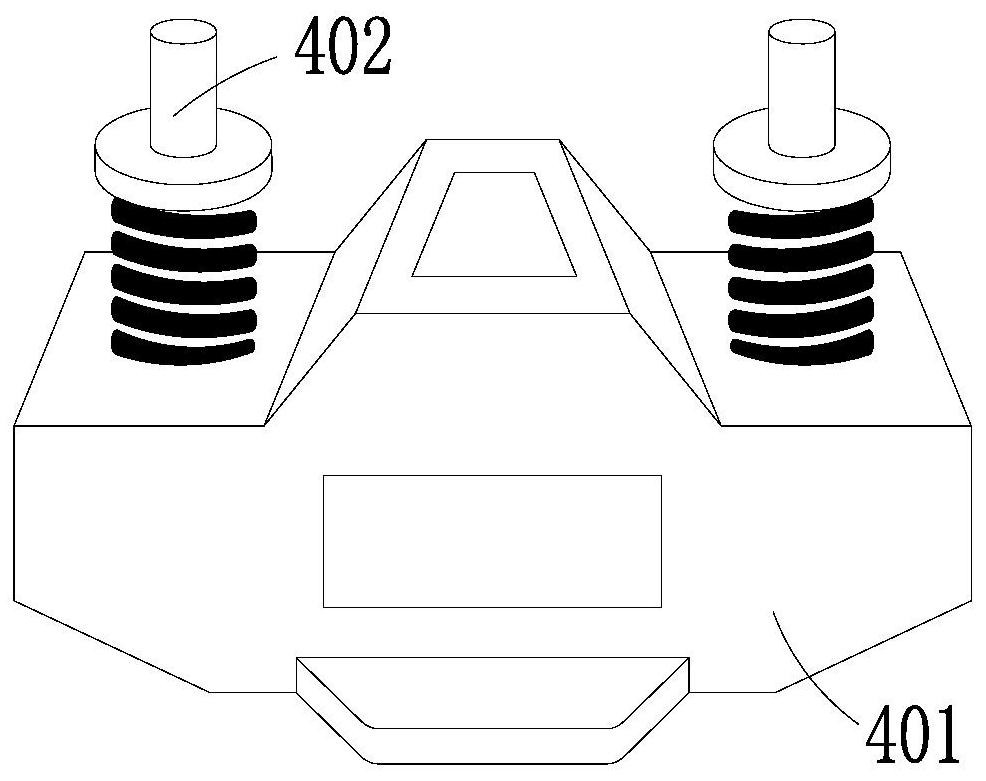

InactiveCN108505476AImprove work performanceImproved work performanceRoad cleaningEngineeringScrew conveyor

The invention provides a garbage packaging device for a solar sweeper. The garbage packaging device for the solar sweeper aims at realizing garbage packaging treatment by using a negative pressure suction principle to suck garbage to the bottom of a negative pressure box via a suction nozzle and using a screw conveyor to convey the garbage into a garbage bag to be packaged and treated, wherein garbage exposure and secondary pollution are avoided in the whole process. The core part of the garbage packaging device for the solar sweeper is that the solar sweeper moves forwards, a fan provides a negative pressure to a negative pressure box, the negative pressure box is connected with the suction nozzle through a suction hose, and a rolling brush in the suction nozzle rotates at a high speed ina direction reverse to the rotation direction of a wheel to raise garbage on the ground; under an effect of the negative pressure, the garbage enters the bottom of the negative pressure box along thesuction hose, and the screw conveyor at the bottom of the negative pressure box conveys the garbage into the garbage bag to be packaged and treated so as to realize a function of packaging and treating the garbage. The attached map is the working principle diagram of the invention; in the attached map, No. 1 is the solar sweeper, No. 2 is the fan, No. 3 is the negative pressure box, No. 4 is a dust collection cloth bag, No. 5 is the suction hose, No. 6 is the suction nozzle, No. 7 is the rolling brush, No. 8 is the spiral conveyor, and No. 9 is the garbage bag.

Owner:王晓东 +2

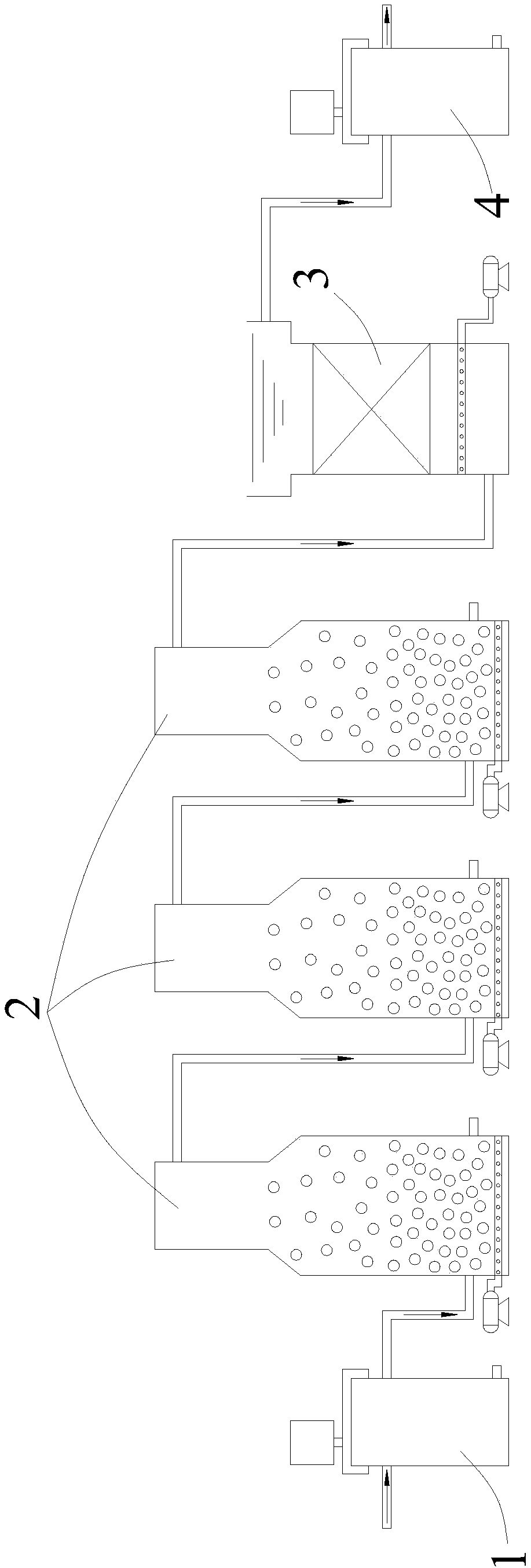

Coal chemical wastewater pretreatment method and pretreatment system

PendingCN108383299AReduce pollutionImprove flocculation and sedimentation abilityMultistage water/sewage treatmentNature of treatment waterChemistryCoal chemical industry

The invention discloses a coal chemical wastewater pretreatment method. The method includes flocculent settling treatment, hydrogen peroxide catalytic oxidation treatment and internal electrolysis treatment, and effluent quality reaches that COD is smaller than or equal to 500mg / L, ammonia nitrogen content is smaller than or equal to 200mg / L, and suspended matter content is smaller than or equal to 70mg / L after treatment. After treatment according to the pretreatment method, wastewater available for biochemical treatment is obtained and can be directly discharged or recycled after biochemicaltreatment. A treatment system is stable in operation, and biochemical degradability of coal chemical wastewater is effectively achieved. The coal chemical wastewater pretreatment method and the pretreatment system have positive popularization significance and remarkable application value.

Owner:HEBEI CHAOLYU ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

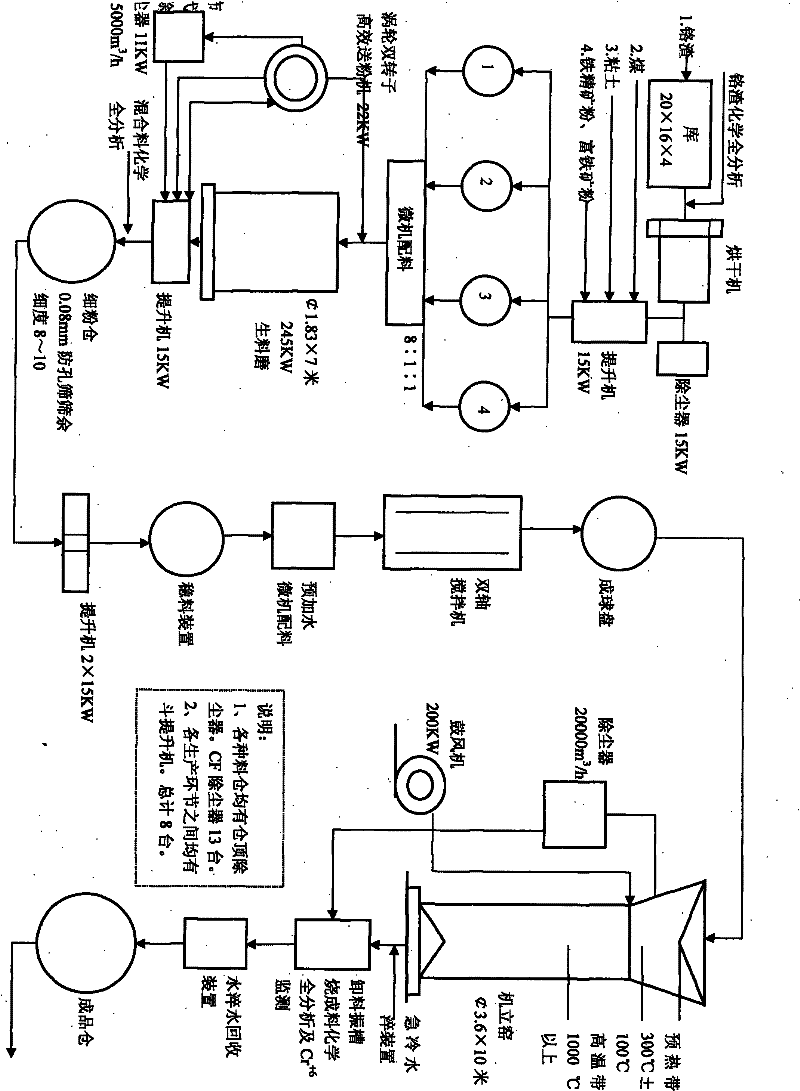

Technology of sintering chromium residue detoxified in vertical kiln at high temperature for ironmaking

InactiveCN102206746ARealize secondary pollutionGood environmental benefitsShaft furnaceChromium oxides/hydratesSocial benefitsEconomic benefits

The invention belongs to the technology of treatment and comprehensive utilization of chromium residues. Since the content of CaO and MgO in chromium residues is the same as that in dolomite, sintered chromium residues can be used to fully or partially substitute dolomite as the sintering material for ironmaking. According to the invention, when the reducing atmosphere generated by sintering the chromium residues with deep and hidden fire in the vertical kiln at a temperature of 900 DEG C passes through a preheating zone with a temperature of more than 900 DEG C, hexavalent chromium in the chromium residues is reduced to trivalent chromium which is melted in a molten mass; the trivalent chromium in the sintered chromium residues is oxidized by quenching with water in a cooling zone at a temperature of between 750 and 850 DEG C; therefore, the chromium residues are detoxified and are prepared into a sintering material used in ironmaking enterprises. The invention is a comprehensive utilization technology for chromium residues, which is safe, produces no secondary pollution, and has significant economic benefits, social benefits and environmental benefits.

Owner:TIANJIN ORIENT ENVIRONMENTAL PROTECTION ENERGY SAVING ENG TECH

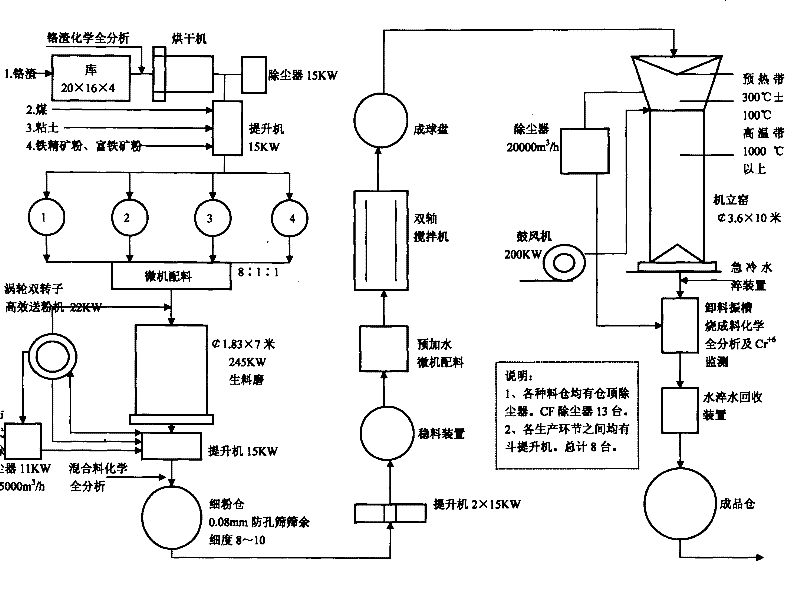

Recycling method for waste CO sulfur-tolerant shift catalysts

ActiveCN104353471AImprove sulfur resistanceNo secondary pollutionHydrogenPhysical/chemical process catalystsChemical industryResource utilization

The invention relates to a recycling method for waste CO sulfur-tolerant shift catalysts. The recycling method comprises the following steps: crushing the waste CO sulfur-tolerant shift catalysts, milling the crushed waste CO sulfur-tolerant shift catalysts, Fe(OH)3 and Cr(OH)3 together for 1-2 hours to be made into particles through a 8-mesh screen cloth, roasting the particles for 6-8 hours at the low temperature of 250-300 DEG C, cooling the roasted particles, and then tabletting and shaping the cooled particles to obtain CO high-temperature shift catalysts. Through detection according to the national chemical industry standard HG / T 3546-2011, all the performance indexes are much higher than quality technology requirements of B116 type CO high-temperature shift catalysts which are sold in the market. Through the adoption of the recycling method, the resource utilization rate of the waste CO sulfur-tolerant shift catalysts reaches 100%, sulfur in waste catalysts does not need to be removed, SO2 waste gas, NO waste gas and NO2 waste gas are not generated in the whole recovery process, and waste liquid and waste residues are not generated, so that the purposes of zero secondary pollution and zero new 'three wastes' are really realized, and not only are molybdenum sources saved, but also the recycling method is environmental-friendly.

Owner:湖北双雄催化剂有限公司

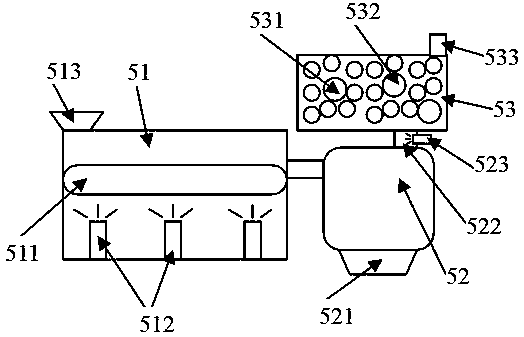

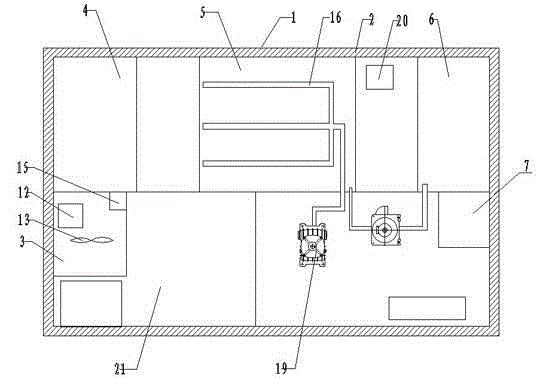

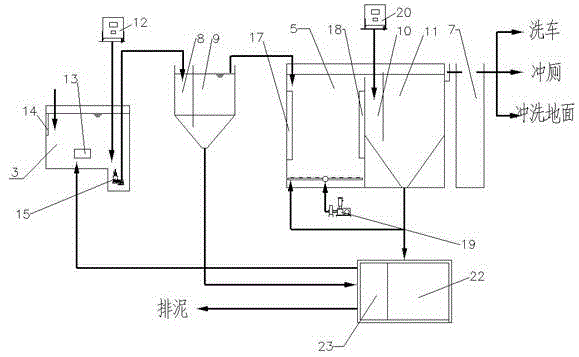

Device and treatment method for treating and recycling car washing wastewater by using diatomite

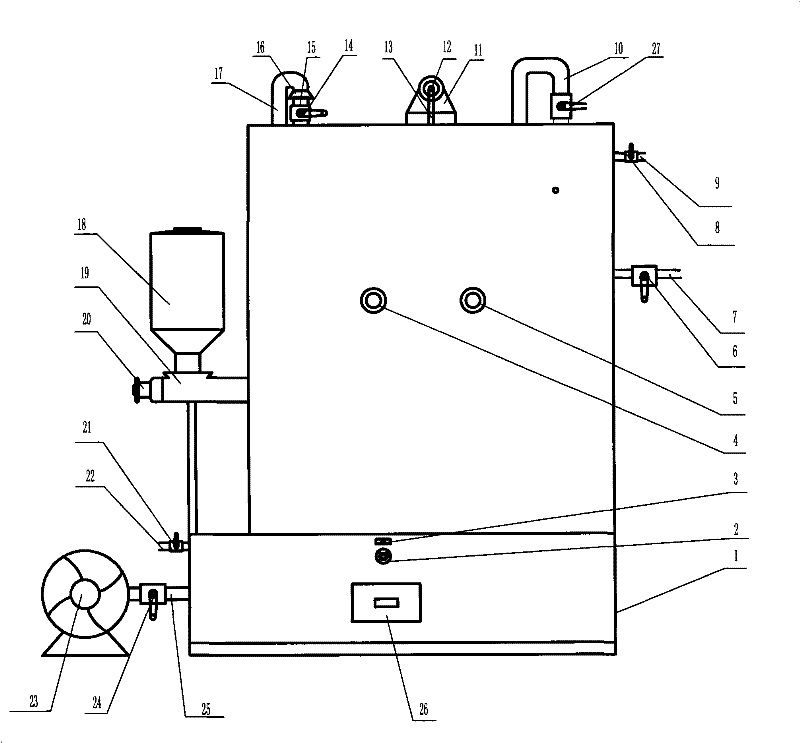

ActiveCN104909518AEffective interceptionEasy to separateMultistage water/sewage treatmentWaste water treatment from vehicle washingRefluxWastewater

The invention relates to a device for treating and recycling car washing wastewater by using diatomite. A wastewater regulating tank, a first reactor, an aerobic chamber, a second reactor and a disinfection chamber are arranged in the van body; the first reactor is composed of a first reaction chamber and a first clarifying chamber; the second reactor is composed of a second reaction chamber and a second clarifying chamber; a first feeder is arranged above the wastewater regulating tank; the wastewater regulating tank is communicated with the first reaction chamber through a submersible sewage pump on the bottom; the first clarifying chamber is communicated with the aerobic chamber through the top; the aerobic chamber is communicated with the second reaction chamber through the top; the second clarifying chamber is communicated with the disinfection chamber through the top; the aerobic chamber is communicated with the bottom of the second reactor through a reflux pump; a second feeder is arranged above the second reaction chamber; and a sludge dewatering device is communicated with the first reactor and second reactor and also communicated with the wastewater regulating tank. The device can effectively intercept sludge, microbes and heavy metals, and has the advantages of favorable flocculating settling effect, thorough sludge-water separation and high effluent water quality.

Owner:SHANXI KEYUAN SHENGDI TECH

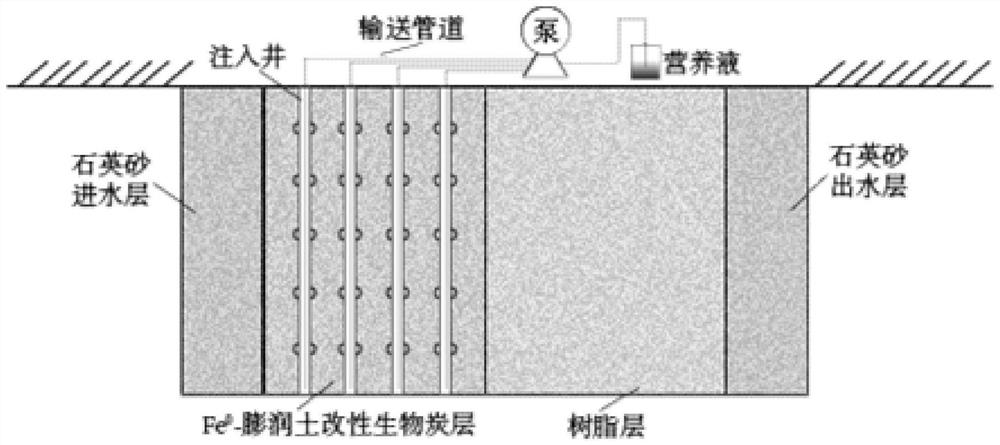

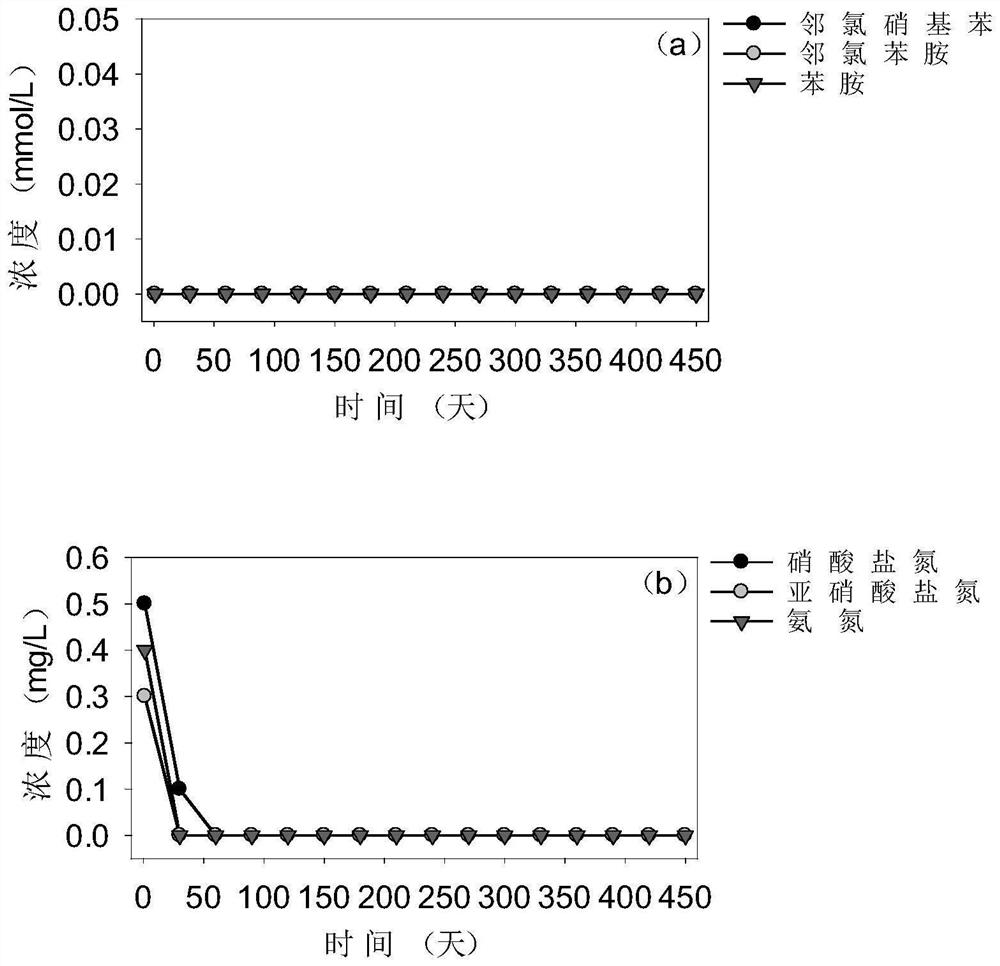

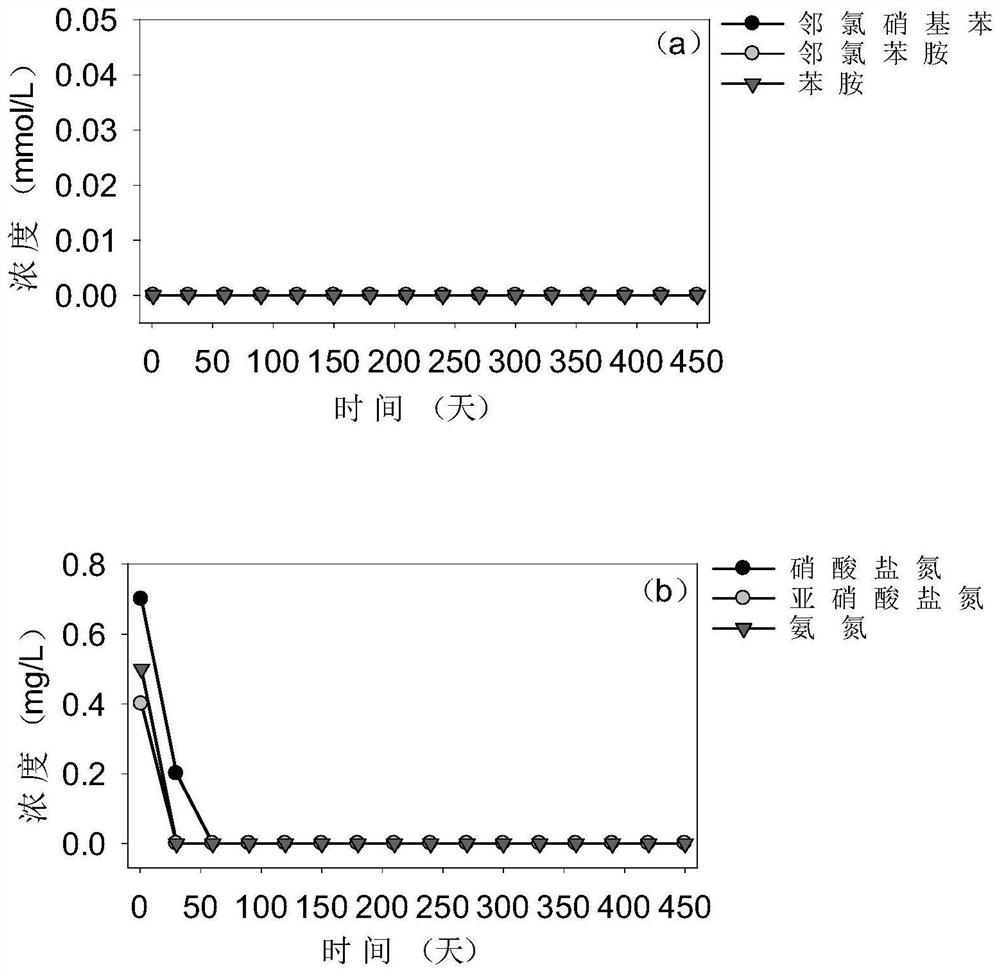

Composite permeable reactive barrier system based on Fe < 0 >-bentonite modified biochar filler and application of composite permeable reactive barrier system

PendingCN114249507ANo secondary pollutionEfficient and long-lasting removalWater contaminantsTreatment involving filtrationMicroorganismInjection well

The invention discloses a composite permeable reactive barrier system based on Fe < 0 >-bentonite modified biochar filler and application of the composite permeable reactive barrier system. The composite permeable reactive barrier system is sequentially provided with a quartz sand water inlet layer, a Fe < 0 >-bentonite modified biochar layer, a resin layer and a quartz sand water outlet layer. Wherein an injection well is arranged in the Fe < 0 >-bentonite modified charcoal layer, and the rest part of the Fe < 0 >-bentonite modified charcoal layer is filled with Fe < 0 >-bentonite modified charcoal loaded with microorganisms and quartz sand. The composite permeable reactive barrier disclosed by the invention can realize efficient and lasting removal of chlorinated organics and nitrates in underground water, does not generate secondary pollution caused by degradation by-products, is long in service life, and has a wide application prospect in the field of underground water pollution remediation.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

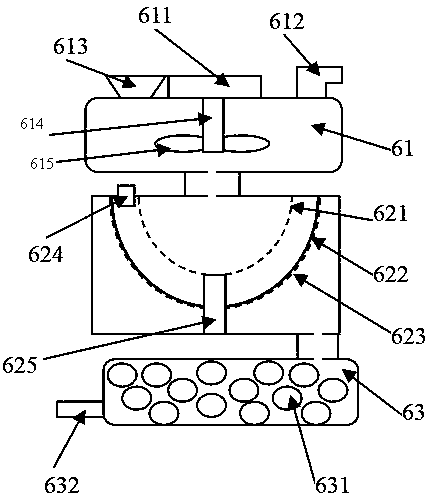

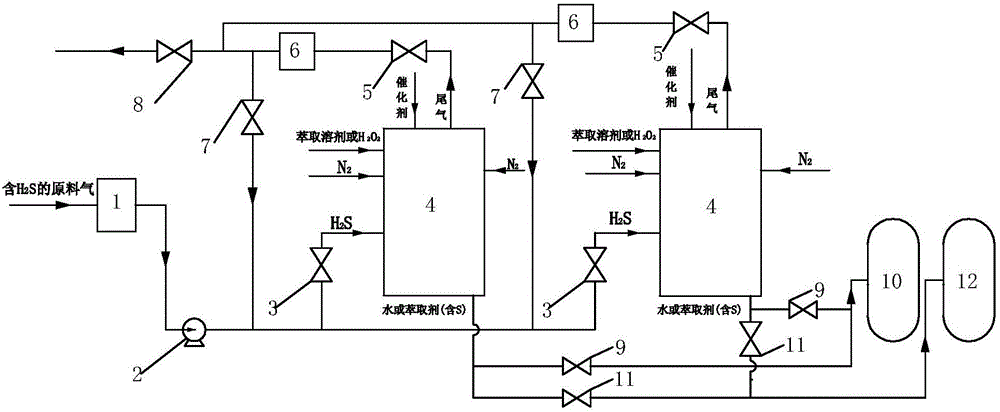

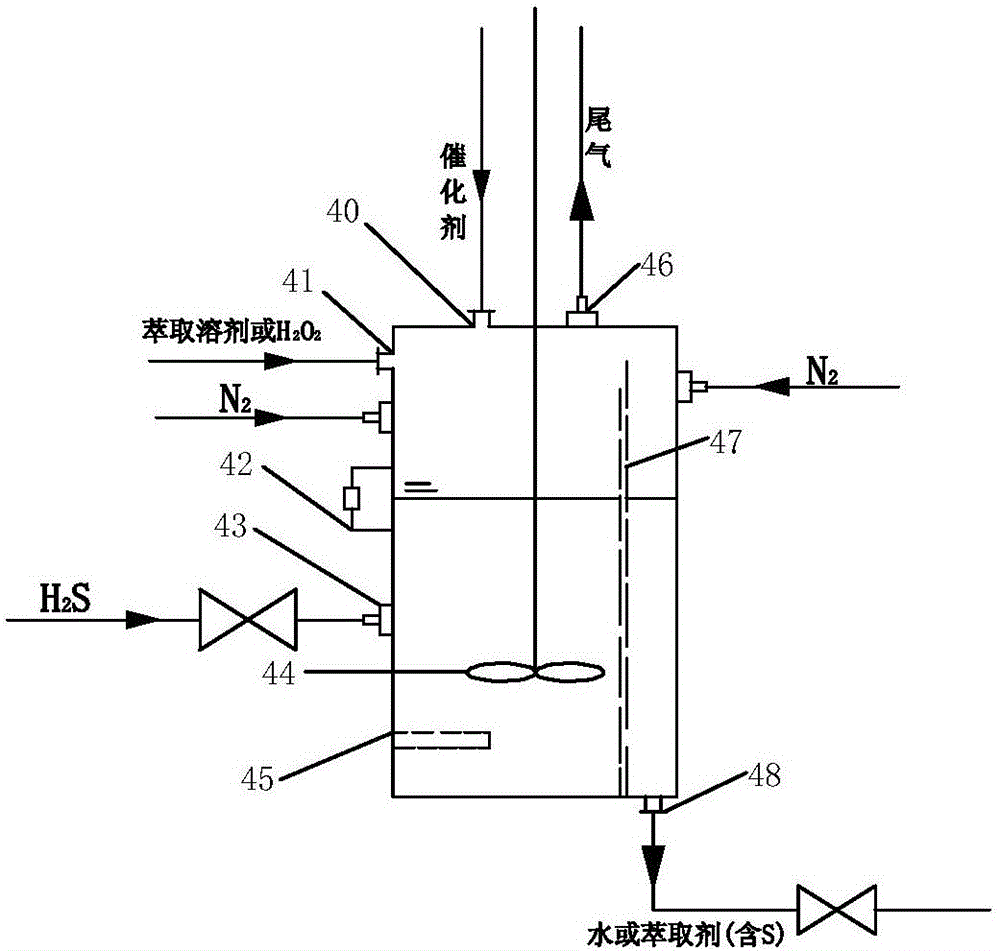

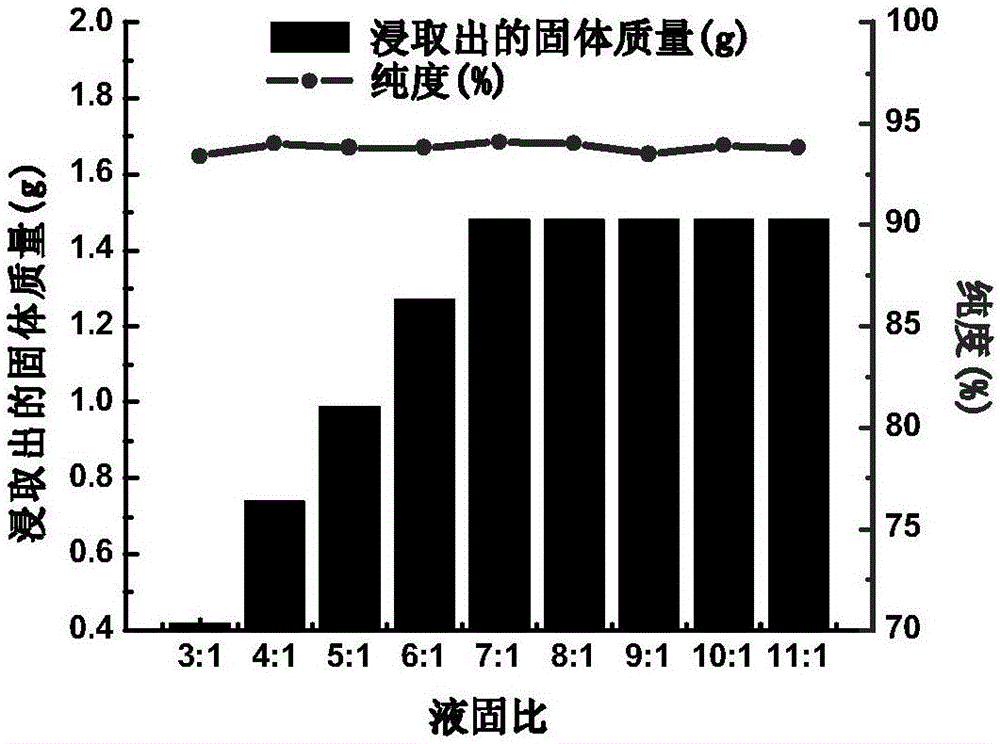

Deep desulfurization system for natural gas and desulphurization method

ActiveCN106833783AReduce concentrationAchieve recyclingDispersed particle separationGaseous fuelsProcess engineeringWater circulation

The invention discloses a deep desulfurization system for a natural gas and a desulphurization method. The deep desulfurization system comprises two desulfurization devices which are connected in parallel, a gas tank and a tail gas device, wherein a catalyst feeding hole, an extractant or H2O2 feeding hole, an H2S gas inlet, a tail gas outlet and a water or extractant liquid outlet are arranged in each desulfurization device; each H2S gas inlet is connected with the gas tank and each tail gas outlet is connected with the tail gas device; and a stirrer, a filter membrane and a gas diffuser are arranged in each desulfurization device. The desulphurization method comprises the steps of firstly adding a catalyst and H2O2 to one desulfurization device for reactive desulfurization, discharging a tail gas; after the catalyst is deactivated or the H2S removal rate is reduced, shutting down the desulfurization device and starting the other desulfurization device for desulfurization; and separating and purifying elemental sulfur by employing an extractant as a leaching agent. The deep desulfurization system integrates multiple processes of oxidative absorption, catalyst regeneration, extractant circulation, water circulation and elemental sulfur recycling; simultaneous implementation of deep desulfurization of the natural gas and elemental sulfur recovery is achieved; the content of a hydrogen sulfide tail gas is lower than an emission limit value; the conversion rate reaches 95-99%; and the deep desulfurization system has the characteristics of being safe, efficient and free of a secondary pollutant.

Owner:ZHEJIANG OCEAN UNIV

Washing machine and control method thereof

PendingCN110952265AExtended service lifeImprove dissolution efficiencyOther washing machinesControl devices for washing apparatusWater savingLaundry washing machine

The invention discloses a washing machine and a control method thereof. A water pump, a filtering device and a bubble generating device are arranged on a circulating pipeline, communicating with an outer barrel, of the washing machine, wherein the filtering device and the bubble generating device are sequentially arranged in the water flow direction of the circulating pipeline. The bubble generating device can improve the dissolving efficiency of a detergent and reduce the use of the detergent, can achieve the effects of sterilization, environmental protection and water saving, and has the cleaning effect on an inner barrel and the outer barrel, thereby reducing secondary pollution. When the water pump works, washing water in the washing machine firstly passes through the filtering deviceto filter out impurities and dirt and then passes through the bubble generating device to generate bubbles, and the filtering device can generate the protective effect on the bubble generating device,so that the service life of the bubble generating device is prolonged and the secondary pollution caused by the fact that the impurities and the dirt enter the washing barrel is prevented. Accordingto the washing machine, the effects of filtering the impurities and the dirt and generating the bubbles can be synchronously realized in the same circulating pipeline, the structure is simplified, thewashing efficiency and the rinsing efficiency are greatly improved, and water resources are saved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

Special container device for antifouling energy-saving water machine

ActiveCN102151083BReduce oxidationAvoid contactBeverage vesselsPressure controlled ventilationPollution

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

Cleaning device and method for resource recycling of waste filter bag

The invention discloses a cleaning device and method for resource recycling of a waste filter bag. The device comprises a negative-pressure ash chamber, a feeding platform, a double-roller brush, electromagnetic vibrators, compressed air blowing pipes, an air compressor, a cutting and tearing machine, an opener, high-pressure water pipes, an electric heating coil, a net curtain, a fiber collectinghopper, a dust remover, an exhaust fan, a sewage tank and a purified water tank. The method comprises the following steps of: carrying and transferring the waste filter bag through the feeding platform and the net curtain, removing loose and hardened dust on the surface of the filter bag through the powerful brush, removing the dust clamped in a filter material layer in an electromagnetic vibration mode, and blowing off the residual dust on the surface of the filter bag through compressed air; carrying out fragmentation treatment on the whole filter bag through the cutting and tearing machineand the opener, and flushing loose fragment fibers with high-pressure water to effectively remove remaining dust; and finally, heating the compressed air through the electric heating coil, carrying out drying treatment on the fragment fibers through hot air, and obtaining a clean raw material product capable of being recycled as a resource.

Owner:NORTHEASTERN UNIV

Method for preparing autoclaved aerated concrete block by taking blast furnace slag-gold tailings as raw materials

The invention relates to the technical field of autoclaved aerated concrete building blocks, in particular to a method for preparing autoclaved aerated concrete building blocks by taking blast furnace slag-gold tailings as raw materials, which comprises the following steps: aging, crushing, mixing, precuring and cutting, and carrying out aerated autoclaving on the raw materials to obtain concrete building blocks with high strength, no mold collapse, good heat insulation effect and few surface cracks. Compared with the prior art, the method has the advantages that the blast furnace slag and the gold tailings are used as main raw materials, harmless, reduction and resourceful treatment of the blast furnace slag and the gold tailings is realized, zero emission, total recovery and no secondary pollution in the whole process can be realized, and the method has better economic benefits and environmental benefits.

Owner:徐州市正峰锌业有限公司 +2

Biomass non-pressure gas making machine

InactiveCN101486929BImprove gasification efficiencyRealization of secondary crackingCatalytic crackingGas purification by catalytic conversionChemical reactionDecomposition

Owner:熊天东

Method for treating incineration tail gas of solid hazardous waste

InactiveCN101785967BReduced corrosion protection requirementsAbsorb running cost reductionDispersed particle separationHazardous substanceSulfate

The invention discloses a method for treating incineration tail gas of solid hazardous waste, comprising the following steps of: (1) taking manganese dioxide as the oxidant, adding water to prepare a sizing agent; (2) delivering the size into the smoke absorption tower, spraying the sizing agent in mist, wherein the pressurized smoke with the wind pressure of 1500-5000pa is introduced from the bottom of the tower, the gas inlet tubes are dispersed tubes under the liquid level of the recovery liquid at the tower bottom, wherein the temperature T of the tower bottom recovery liquid is controlled to be not below 5 DEGC and not above 90 DEG C, and the pH value is not less than 3.8; (3) separating the precipitation from the recovery liquid at the tower bottom, preparing manganese sulfate via the solution, and recovering the heavy metal from the bottom dross; (4) discharging the tail gas which is up to the standard. The method for treating incineration tail gas of solid hazardous waste has simple process flow, non-fouling equipment, smooth circulation, less equipment, and low operation cost; and the composite rate of removing the harmful substances reaches 98.5%. The heavy metals can be recovered from the bottom dross; the recycle and the harmlessness can be realized without secondary pollutant products.

Owner:重庆太锦环保科技有限公司

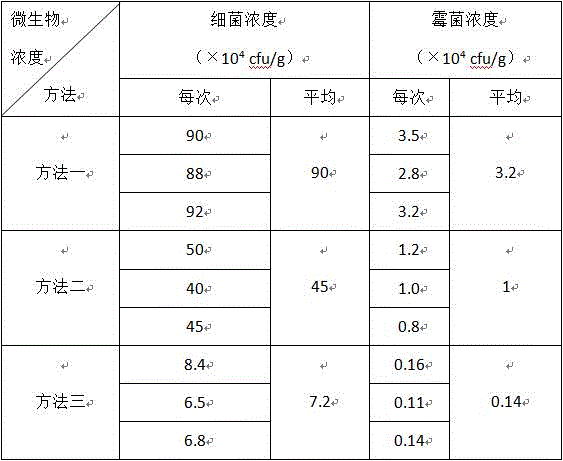

Processing method capable of reducing harmful microorganisms in feed

InactiveCN106387366AChange permeabilityAchieve residue-freeWorking-up animal fodderMicroorganismTorch

The invention relates to a processing method capable of reducing harmful microorganisms in a feed. The processing method comprises the following steps of before the feed is processed, firstly placing raw materials of the feed in a sealed container, enabling the sealed container to be filled with ozone for smoking for 30 minutes; and besides, before production, firstly cleaning places where conveying equipment and a mixing machine are in contact with materials with a high-pressure water torch, and then performing comprehensive sterilizing treatment on the mixing machine with a sporicide. According to the processing method capable of reducing harmful microorganisms in the feed, provided by the invention, the total bacterial count in the feed can be reduced by 90%, the total mould amount can be reduced by 95%, the quantity of the harmful microorganisms in the feed is greatly reduced, and the quality of the feed is improved.

Owner:胡云龙

Low-consumption high-quality ammonium sulfate fertilizer recovery wet ammonia process desulfurizing technology

InactiveCN100518889CLow recycling comprehensive operating costConsiderable "positive benefit"Dispersed particle separationPollutionDenitrification

The invention relates to the desulfurization and denitrification process technology for air pollution control in the field of environmental protection, aiming at the problem that the existing ammonium-fertilizer method desulfurization technology recycles ammonium sulfate fertilizer with high production cost and the quality of the recovered ammonium sulfate product is low and the semi-dry ammonia method Desulfurization technology causes secondary pollution to the environment. The present invention proposes a wet ammonia desulfurization process for recycling high-quality ammonium sulfate fertilizers with low energy consumption. It uses ammonia water as a desulfurizer and generates flue gas after two-stage full desulfurization. Ammonium sulfite is subjected to two-stage oxidation outside the tower, so that ammonium sulfite can fully react to generate ammonium sulfate, and the generated ammonium sulfate solution is contacted with high-temperature flue gas to exchange heat, so as to cool down the flue gas while concentrating the ammonium sulfate solution. Thereby greatly saving the cost of making ammonium sulfate fertilizer products by evaporation and drying. Therefore, the technical solution of the present invention not only recycles fertilizer ammonium sulfate products with high quality, but also has low recycling cost. secondary pollution.

Owner:史选增

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com