Technology of sintering chromium residue detoxified in vertical kiln at high temperature for ironmaking

A technology of chromium slag and high temperature, which is applied in the field of chromium slag treatment and comprehensive utilization, can solve the problems of increasing chromium slag hexavalent chromium ironmaking plant surrounding environmental pollution possibility and risk, and achieves obvious environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

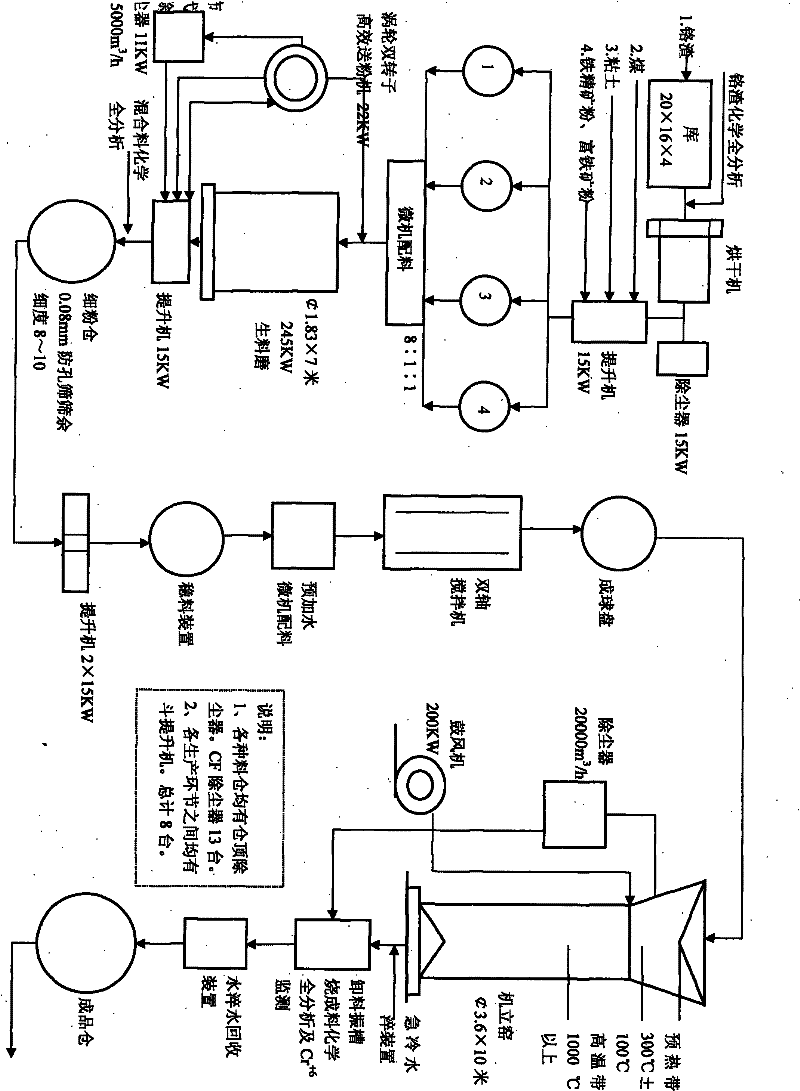

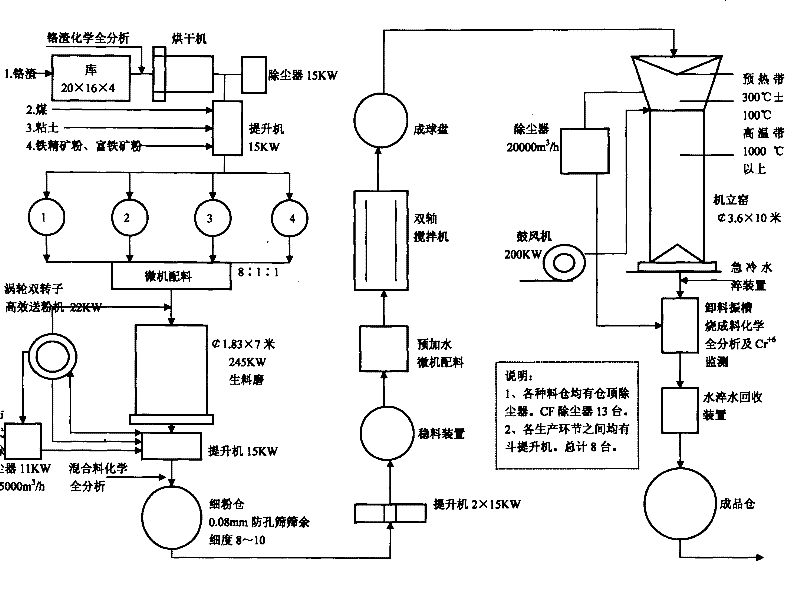

[0007] According to the schematic diagram of the project in Figure 1, put the chromium slag in the dryer to dry, and then enter it separately with coal and clay through the batching scale. Then enter the raw material powder and grind it into raw material powder, then go through the elevator, pre-add water, form a ball, and then enter the shaft kiln for firing. ℃ above 2, the sintered material for ironmaking is fired in the carbon monoxide atmosphere, and the sintered material discharged from the shaft kiln is rapidly cooled with water to meet the regulations on hexavalent chromium in GB5085.3-1996 "National Hazardous Waste Identification Standards" Index ≤ 1.5mg / L becomes sintering material for ironmaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com