Method for treating incineration tail gas of solid hazardous waste

A hazardous waste and treatment method technology, which is applied in the field of solid hazardous waste incineration tail gas treatment, can solve the problems of unresolved waste residue, large project investment, complex process, etc., and achieve low anti-corrosion requirements, simple process flow, and no equipment. Fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

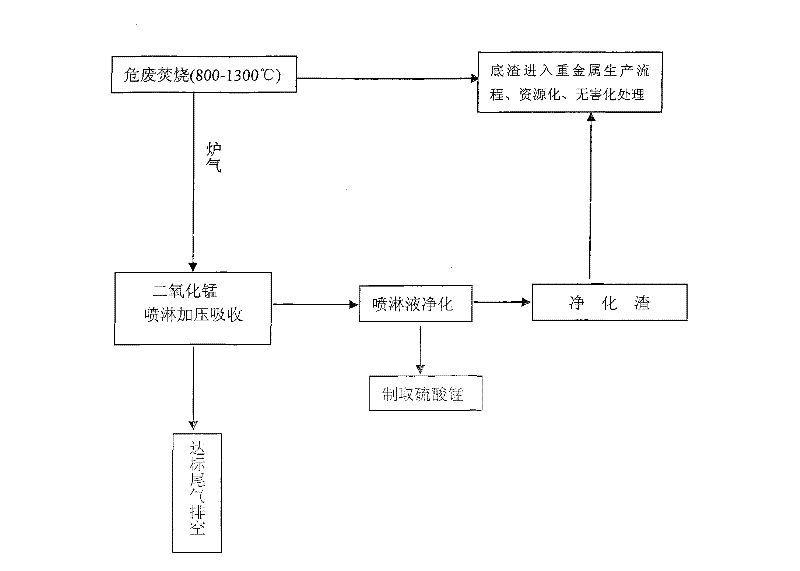

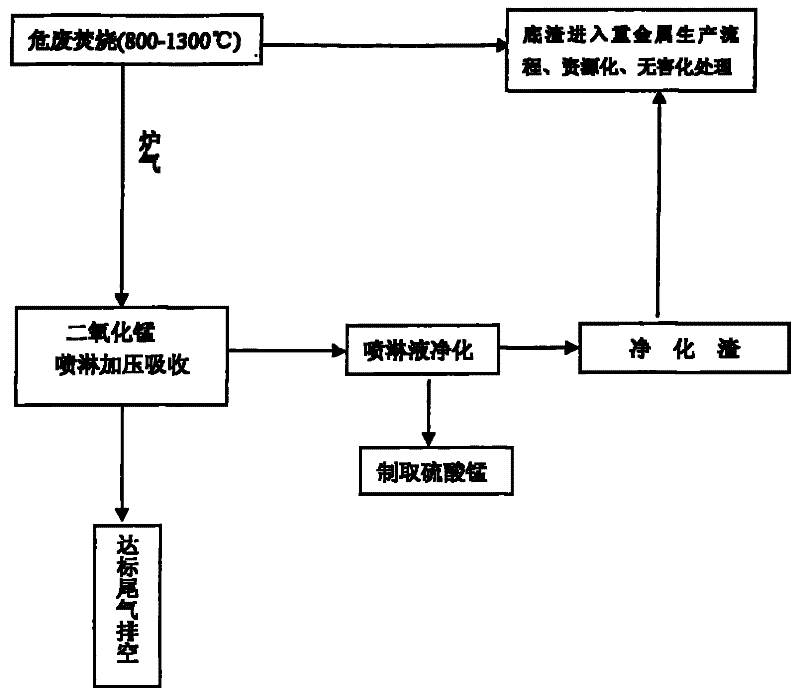

Method used

Image

Examples

Embodiment 1

[0030] Section 0031: The treatment flue gas is the incineration flue gas of heavy metal waste, and the slurry made by adding water to manganese dioxide ore powder at a weight ratio of 1:2 to 3 is preferably made of Fe content not less than 3%, CaCO 3 Manganese dioxide ore powder with a content of not less than 2%, the slurry is sent into the flue gas absorption tower, sprayed with fine mist, and the pressurized flue gas with a wind pressure of 1500-5000Pa is introduced into the bottom of the tower, preferably 1500-3000Pa, and the air inlet pipe It is a dispersion tube arranged under the liquid surface of the recovery liquid at the bottom of the tower, and the nozzle of the dispersion tube is arranged at 20-30 cm below the liquid level, and the temperature T range of the recovery liquid at the bottom of the tower is controlled to be 5≤T≤90°C, preferably 40≤T≤70℃, keep the pH value of the spray recovery liquid at the bottom of the tower ≥ 3.8, preferably PH value ≥ 4.2, the dust-...

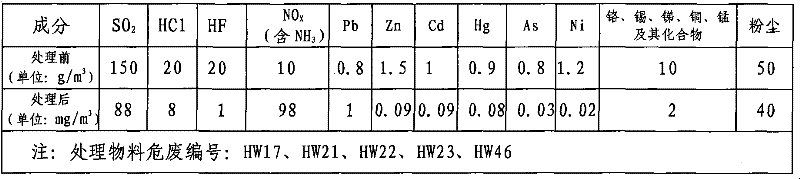

Embodiment 2

[0034] The treatment flue gas is the incineration flue gas of materials such as medical (medical) waste, discarded medicine and packing material, repeats embodiment 1 by the same step as described, SO 2 , HF, HCl and other acidic harmful gases, and NO X , NH 3 , As and other components are absorbed and oxidized by the slurry liquid, the dust is sprayed and washed into the bottom recovery liquid to be removed from the flue gas, the bottom recovery liquid is precipitated and separated, the solution part is used to produce manganese sulfate, and the bottom slag is used for heavy metal recovery , the treated tail gas meets the emission standards and can be discharged into the atmosphere. The detection status of harmful components before and after treatment is shown in the table below:

[0035] Table 2: Comparison table of harmful components before and after treatment of flue gas from incineration of pharmaceutical (medical) waste, waste drugs and packaging

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com