Processing method capable of reducing harmful microorganisms in feed

A processing method and feed processing technology, applied in the shaping or processing of animal feed, animal feed, application, etc., can solve problems such as endangering the safety of raised animals, products and consumers, contamination of harmful microorganisms, and reduction of feed quality. Effects of residual secondary pollution, rapid killing, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A processing method for reducing harmful microorganisms in feed. Before feed processing, feed raw materials are placed in a closed container and fumigated by ozone for 30 minutes. At the same time, before production, the conveying equipment and Clean the place where the mixer touches the material, and then use a sporicide to fully disinfect the mixer.

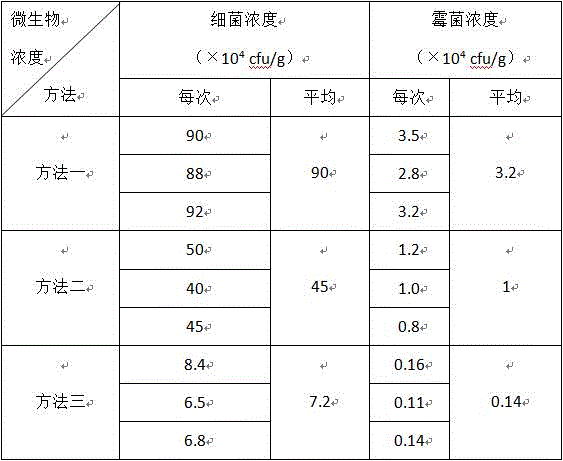

[0010] experimental research data

[0011] Experimental method: Purchasing a sufficient amount of raw materials of the same species, using three different processing methods to produce feed. In the first method, the raw materials are not subjected to ozone fumigation treatment, and the equipment is not sterilized by sporicide; in the second method, the raw material is treated with ozone fumigation, but the equipment is not sterilized by sporicide; the third method is to sterilize the raw material Ozone fumigation is performed while the equipment is also sterilized with a sporicide. The rest of the production process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com