Method for extracting dioscorea zingiberensis pigment by enzymatic method

A technology of enzymatic extraction and turmeric pigment, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problem of low extraction efficiency, and achieve the advantages of reducing environmental pollution, increasing extraction amount, and improving comprehensive utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

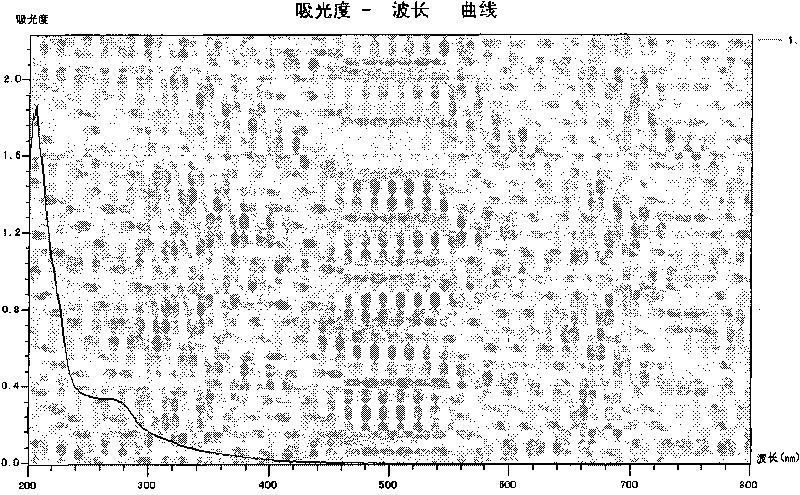

[0019] Embodiment 1: First, get fresh turmeric and dry it and pass it through a 60-mesh sieve after being crushed; secondly, get 60 mg of pectinase and dilute it to 10 mL with an acetic acid-sodium acetate buffer solution with a pH value of 3.6, and prepare 6 mg / mL of pectinase. Gelase enzyme solution: take 1.000g turmeric powder, add 1.5mL of the above pectinase enzyme solution, and make up to 8mL with acetic acid-sodium acetate buffer solution with a pH value of 3.6, react at 40°C for 5h, and then add 12mL of absolute ethanol , extracted in a constant temperature water bath at 65°C for 2.5h, wherein the ratio of solid to liquid was 1g: 20mL, repeated extraction 2 to 3 times, combined the filtrate, and then concentrated the filtrate to an ethanol concentration of less than 10% to obtain turmeric. figure 1 It is the obtained turmeric pigment of the present embodiment through dilution gained ultraviolet spectrum, and the absorption peak of pigment is at 275nm.

Embodiment 2

[0020] Embodiment 2: First, get fresh turmeric and dry it and pass it through a 60-mesh sieve after crushing; secondly, get 60 mg of pectinase and dilute it to 10 mL with an acetic acid-sodium acetate buffer solution with a pH value of 4.0, and prepare 6 mg / mL of pectinase. Gelase enzyme solution: take 1.000g turmeric powder, add 1.5mL of the above pectinase enzyme solution, and make up to 8mL with acetic acid-sodium acetate buffer solution with a pH value of 4.0, react at 45°C for 4h, then add 12mL of absolute ethanol , extracted in a constant temperature water bath at 68°C for 2.3h, wherein the ratio of solid to liquid was 1g: 20mL, repeated extraction 2 to 3 times, combined the filtrate, and then concentrated the filtrate to an ethanol concentration of less than 10% to obtain turmeric.

Embodiment 3

[0021] Embodiment 3: First, get fresh turmeric and dry it and pass it through a 60-mesh sieve after crushing; secondly, take 60 mg of pectinase and dilute it to 10 mL with an acetic acid-sodium acetate buffer solution with a pH value of 4.4, and prepare 6 mg / mL of pectinase. Glue enzyme enzyme solution: take 1.000g turmeric powder, add 1.5mL of the above pectinase enzyme solution, and make up to 8mL with acetic acid-sodium acetate buffer solution with a pH value of 4.4, react at 50°C for 3h, and then add 12mL of absolute ethanol , extracted in a constant temperature water bath at 70°C for 2 hours, wherein the ratio of solid to liquid was 1g: 20mL, repeated extraction 2 to 3 times, combined the filtrate, and concentrated the filtrate until the ethanol concentration was less than 10% to obtain turmeric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com