Deep desulfurization system for natural gas and desulphurization method

A technology for deep desulfurization and natural gas, applied in the field of desulfurization, to achieve the effect of low concentration, small reaction heat, and fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

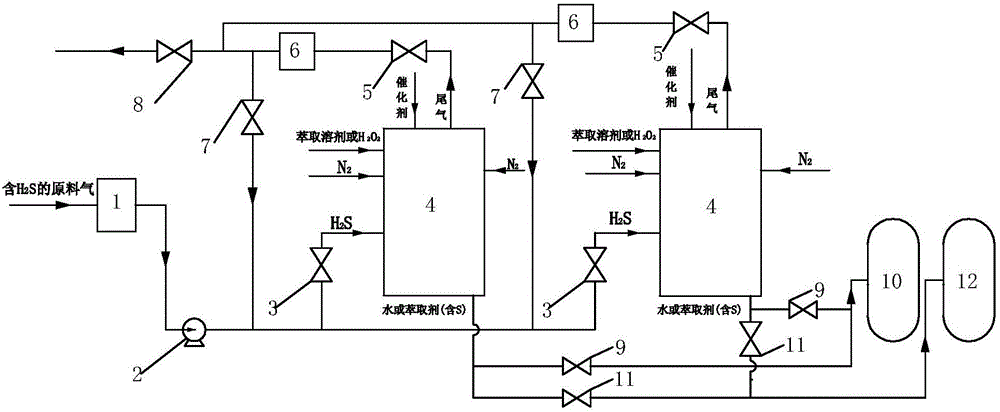

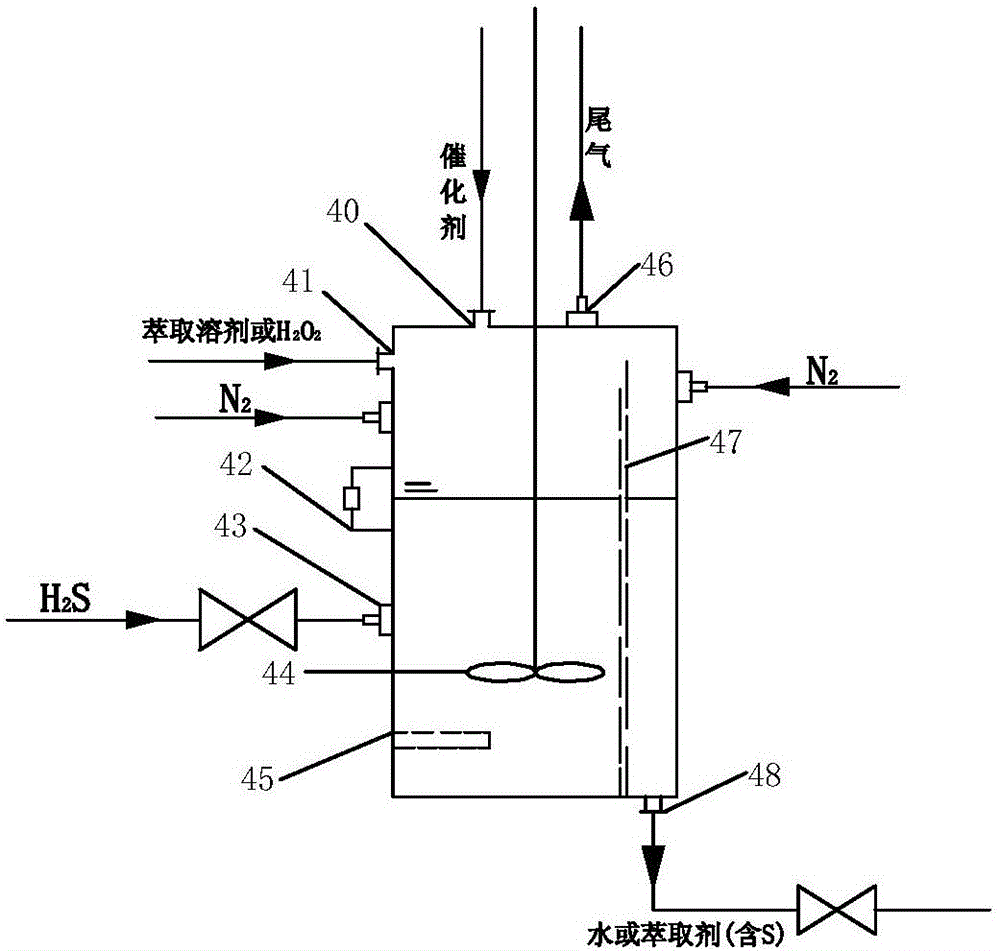

[0033] Such as figure 1 , 2 As shown, a natural gas deep desulfurization system includes two parallel desulfurization devices 4, containing H 2 Gas cabinet 1 for raw gas of S, tail gas device 6, induced draft fan 2, H 2 S intake control valve 3, water outlet control valve 9, water storage intermediate tank 10, extractant liquid outlet control valve 11 and sulfur-containing extractant intermediate tank 12, wherein the tail gas device 6 can detect H on-line 2 S and oxygen concentration, the structure of two desulfurization devices 4 is identical, and desulfurization device 4 comprises catalyst inlet 40, extraction agent or H 2 o 2 Feed port 41, H 2 S inlet 43, tail gas outlet 46, water or extractant outlet 48, liquid level controller 42, agitator 44, gas diffuser 45, nitrogen inlet and filter membrane 47, wherein H 2 The S air inlet 43 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com