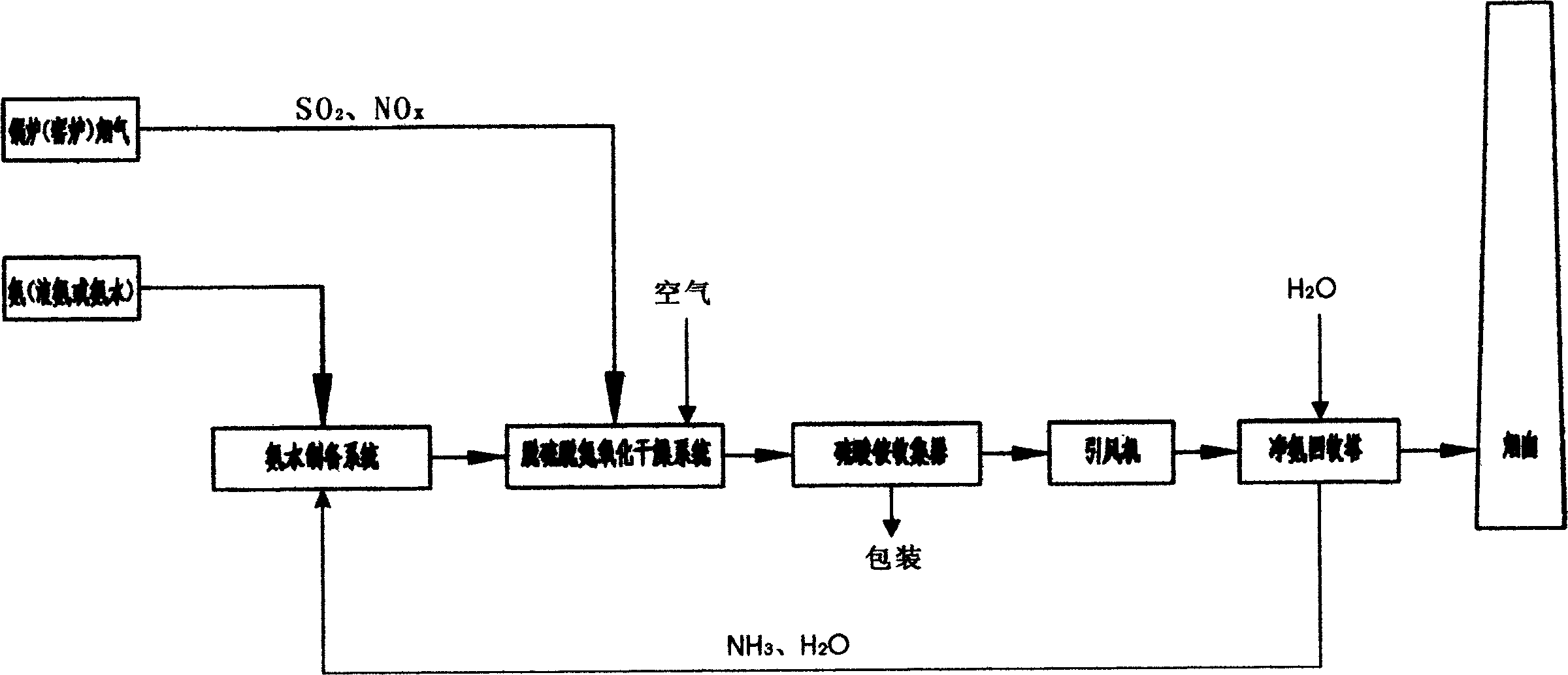

Ammonia-ammonia sulfate dry type flue gas desulfurizing denitrifying equipment and technique

A process method, ammonium sulfate technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of no recovery value of calcium sulfate and calcium sulfite, waste of waste water, low desulfurization efficiency, etc., and achieve considerable economic value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Ammonia supply system: mainly includes ammonia storage tanks, recovery tanks, ammonia supply pumps and pipeline systems.

[0025] The function of the storage tank is to configure liquid ammonia or high-concentration ammonia water into ammonia water with a concentration of 1-10% and store it for later use; the recovery tank is used to recover the ammonia gas that may escape during the configuration, storage and use of ammonia water; The ammonia pump and pipeline system are used to send the configured ammonia water to the desulfurization and denitrification absorption tower.

[0026] 2. Desulfurization and denitrification absorption tower

[0027] More than 90% of the sulfur dioxide in the flue gas reacts with ammonia water and is absorbed, and the by-product is ammonium sulfite. After some of them are dried at a temperature greater than 100°C in the flue gas, the solid ammonium sulfate enters the high-efficiency receiver along with the flue gas for collection.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com