Method for harmless treatment of waste residue in paper making

A technology of harmless treatment and papermaking waste residue, applied in the direction of solid waste removal, etc., can solve problems such as waste gas pollution, and achieve the effects of avoiding secondary pollution, preventing vicious environmental pollution accidents, preventing illegal transshipment and illegal disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

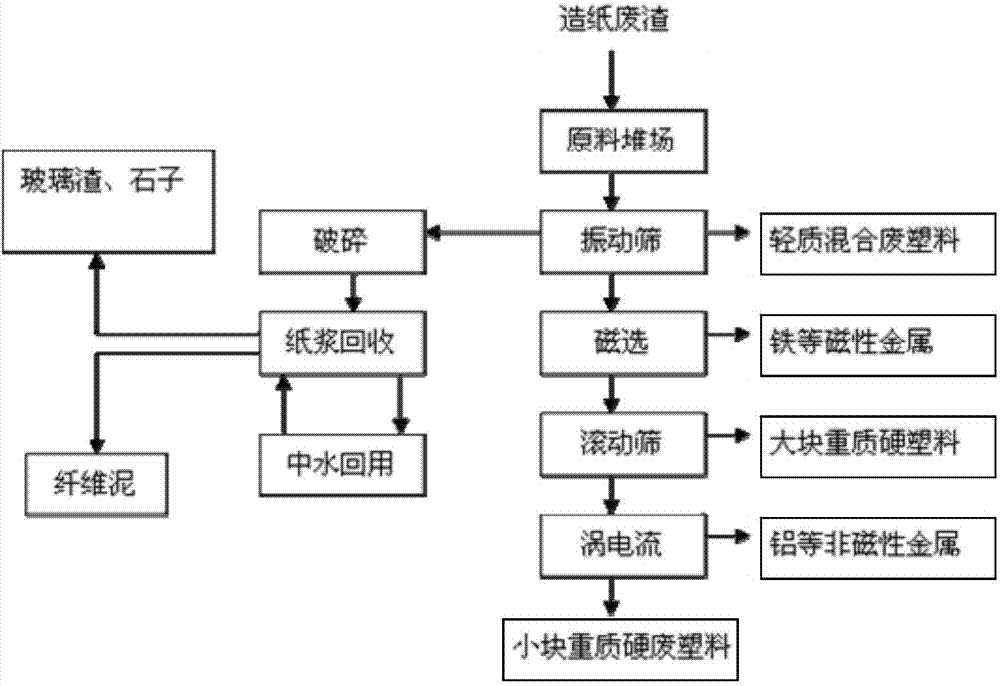

[0019] Such as figure 1 As shown, the harmless treatment method of papermaking waste slag of the present invention comprises the following steps:

[0020] 1) Firstly, the papermaking waste in the papermaking waste yard is separated from the light mixed waste plastics and pulp fiber slag through the wind vibrating screen. Waste plastics and pulp fiber slag are separated from different outlets. After the pulp fiber slag is broken, it is sent to the pulping section for fiber recovery, and the fine fiber sludge that is finally eliminated is dried and sent to the incineration boiler; the glass and stones screened out from the pulping raw materials are sent to road landfills or sent to cement plants, etc.; light mixed waste Plastics are sent to chemical factories as raw materials, such as oil refining, building exterior wall decoration panels, and so on.

[0021] 2) Magnetically select magnetic metal materials, such as iron blocks and iron wires, from the waste left over from step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com