Patents

Literature

43results about How to "Realize environmentally friendly emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

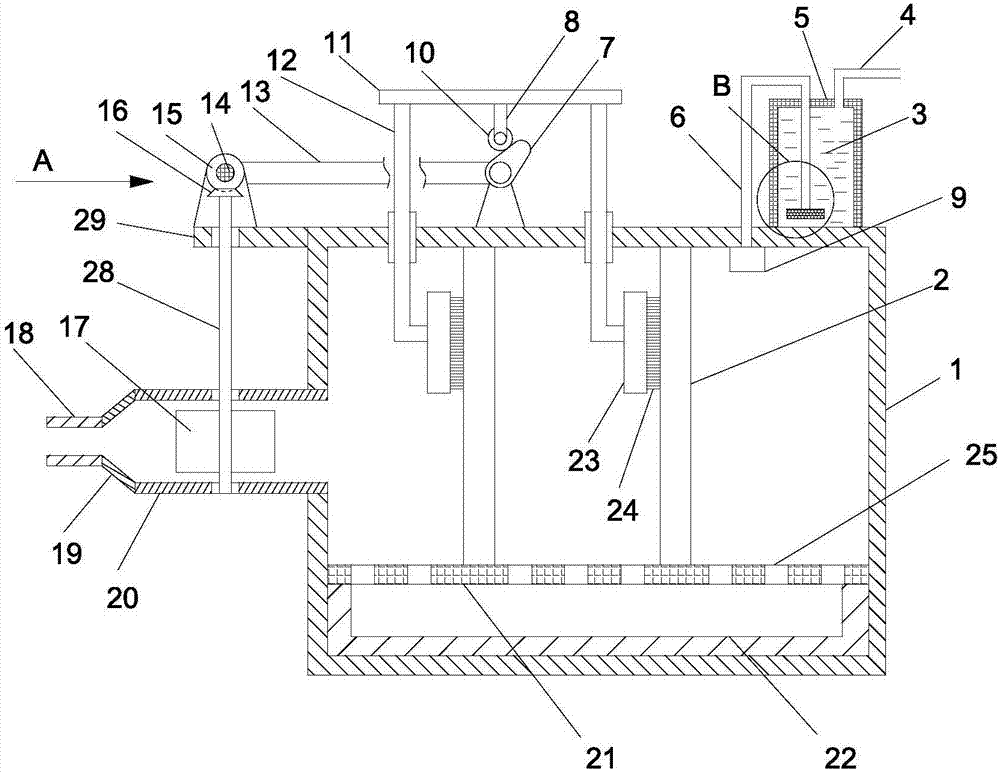

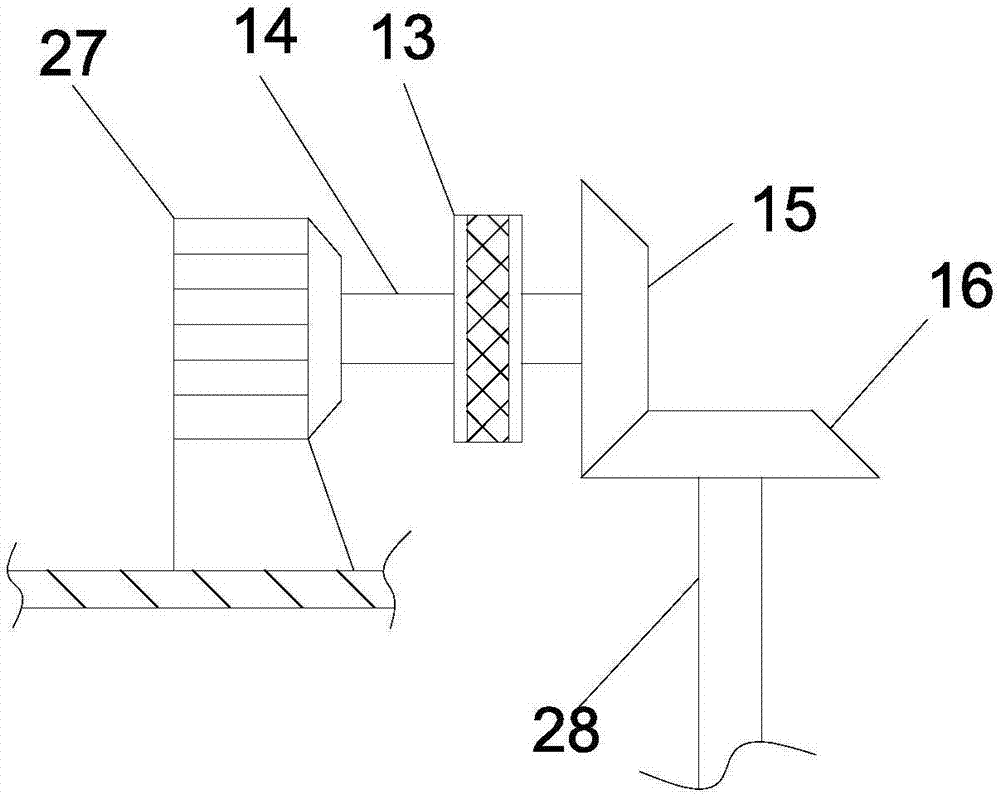

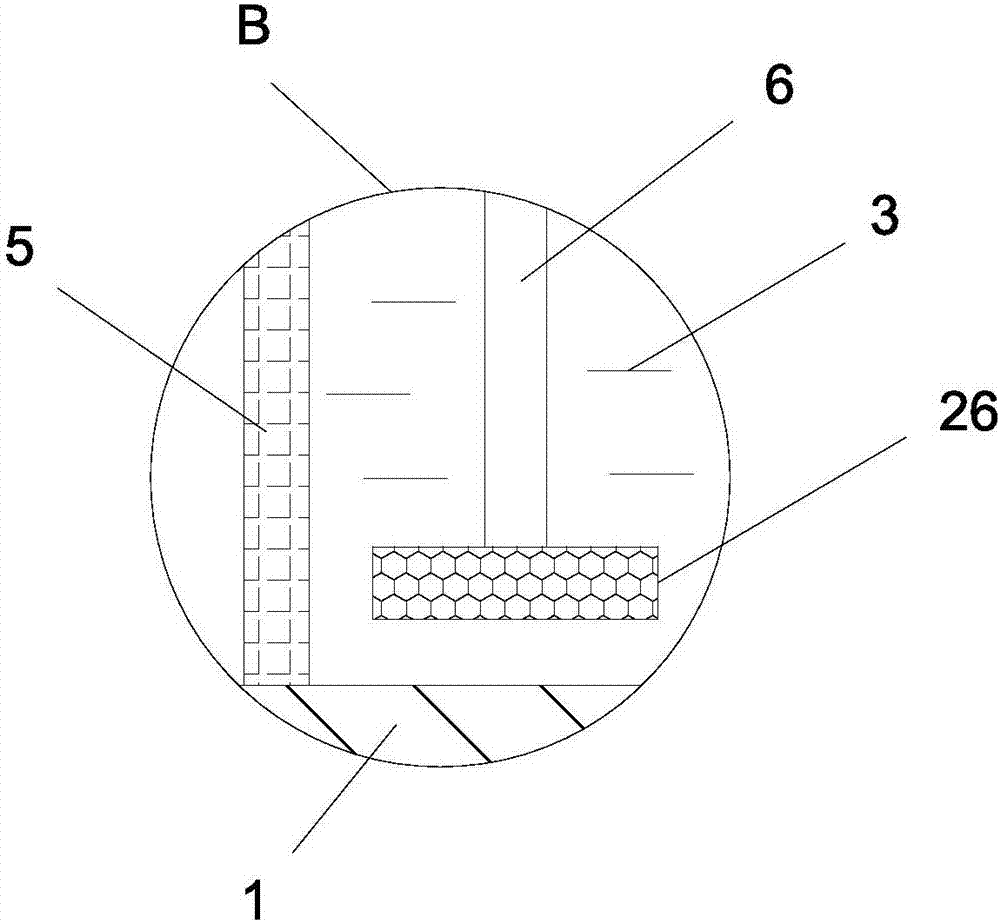

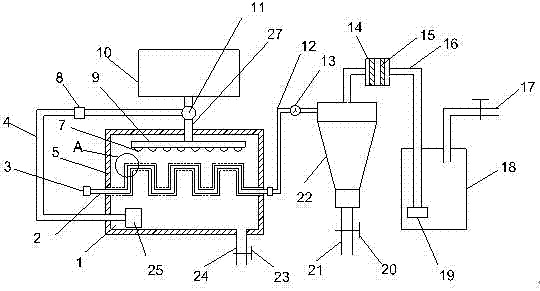

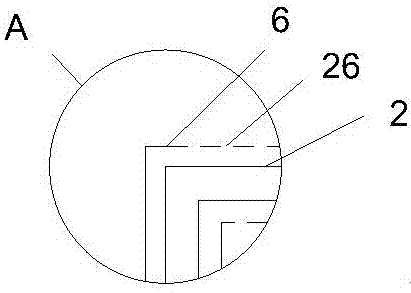

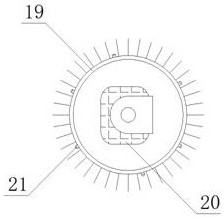

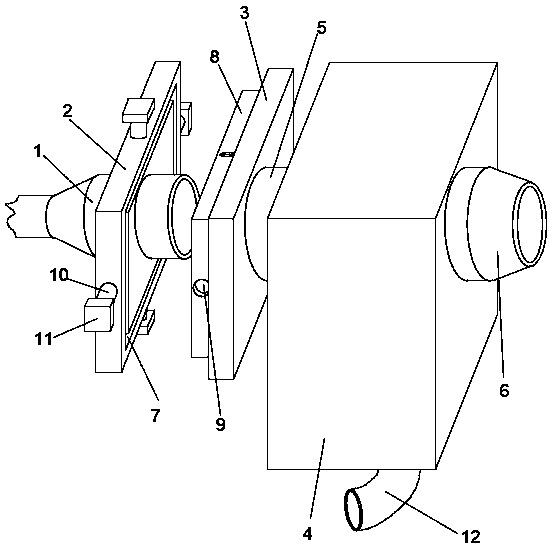

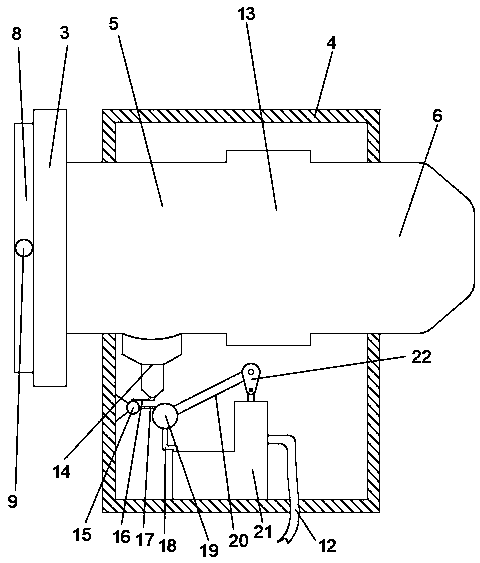

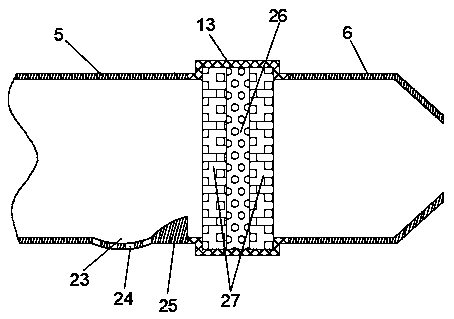

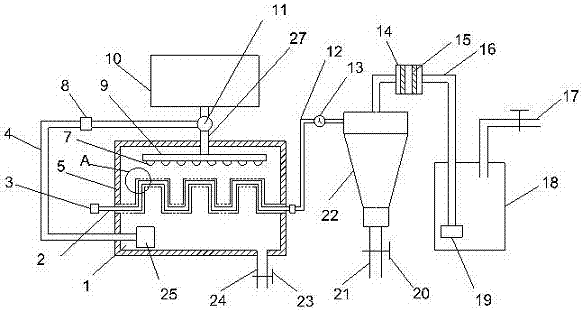

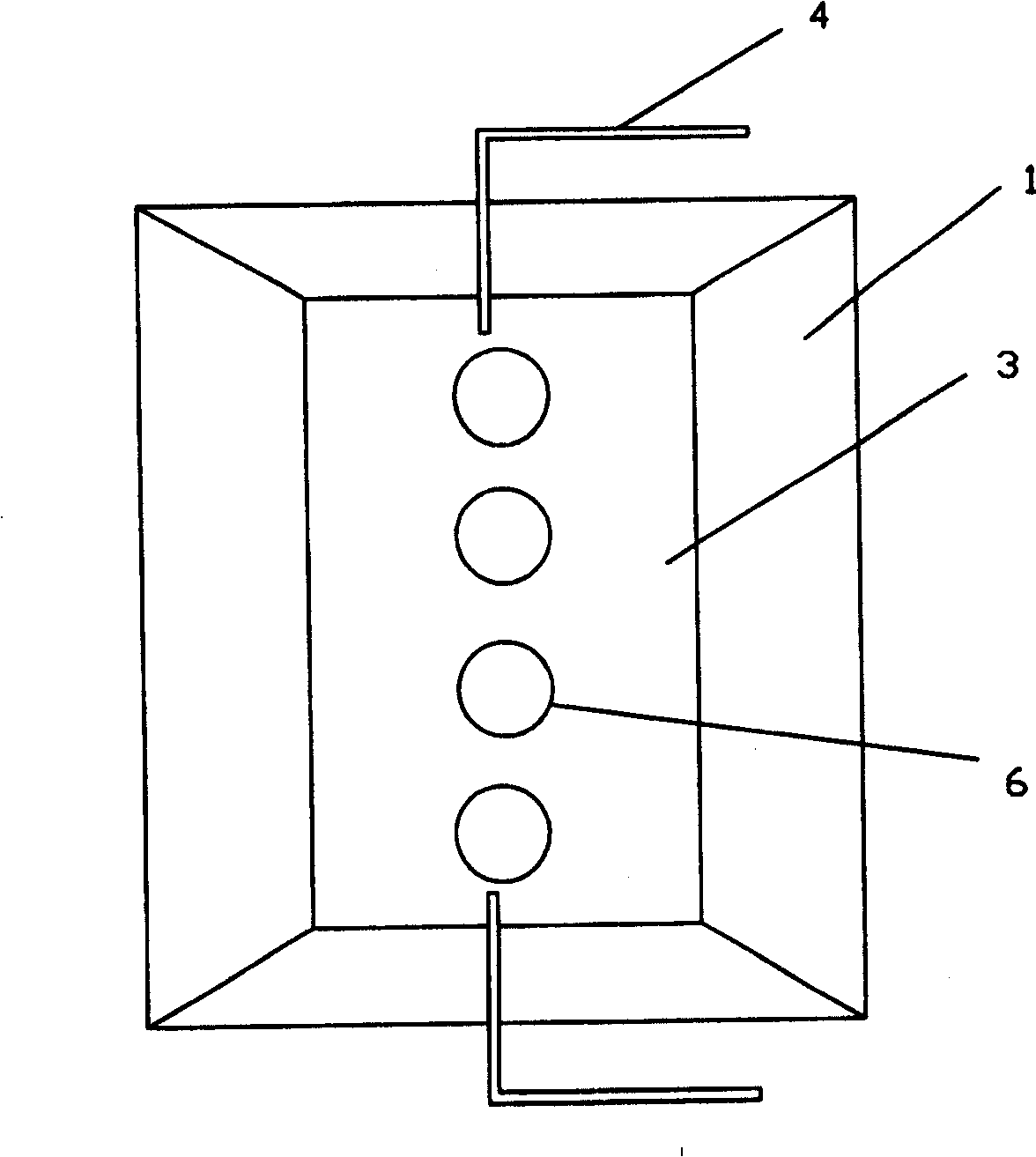

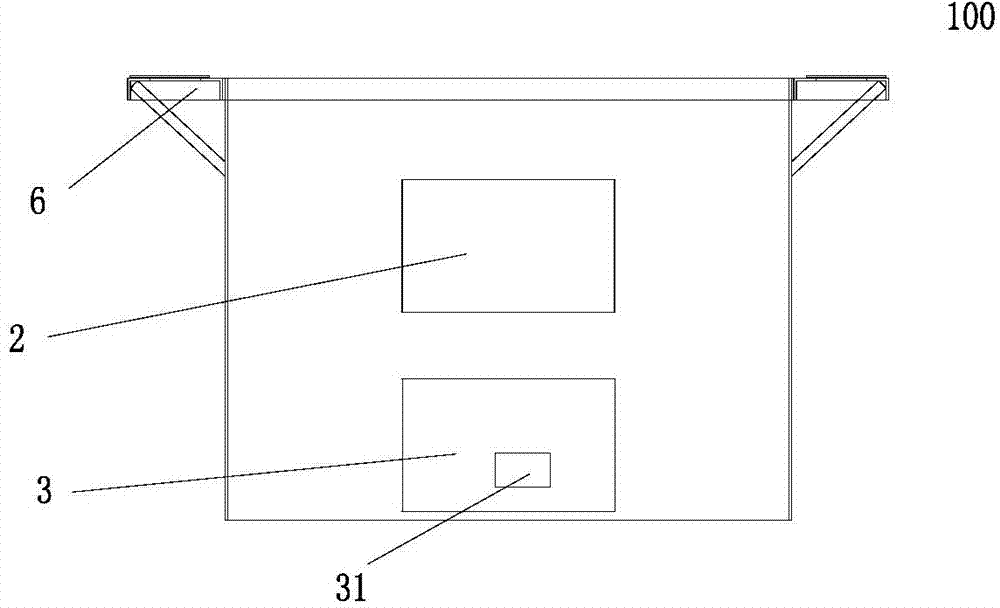

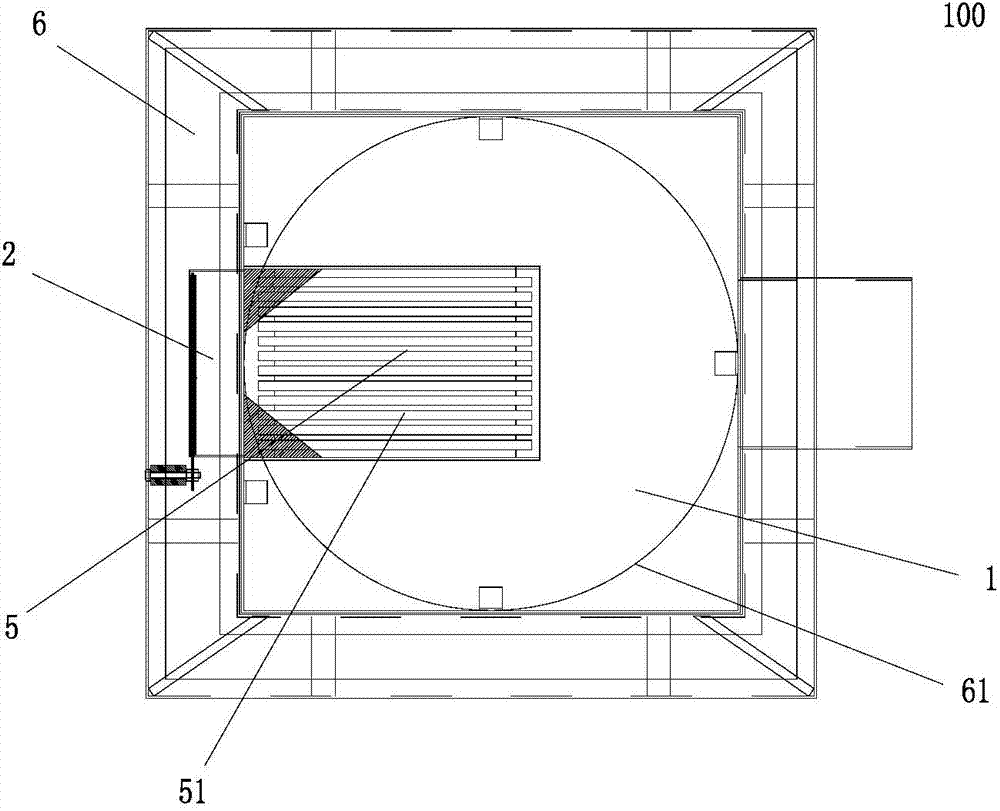

Boiler fuel gas dedusting purifying device

InactiveCN107096361AGood dust removal and filtration effectSpeed up the flowGas treatmentDispersed particle filtrationDrive shaftFlue gas

The invention discloses a boiler fuel gas dedusting purifying device. The boiler fuel gas dedusting purifying device comprises a dedusting chamber; the left side of the dedusting chamber is fixedly provided with an extension board; the extension board is fixedly provided with a driving motor; the driving motor is fixedly provided with a driving shaft; the right end of the driving shaft is fixedly provided with a driving bevel gear; the upper end of a driven shaft is fixedly provided with a driven bevel gear; the driven shaft is fixedly provided with a plurality of blades; the blades are uniformly fixedly arranged on the external surface of the driven shaft along the circumferential direction; two slide bars are arranged on the dedusting chamber; the upper side wall of the dedusting chamber is penetrated by the two slide bars; each of the slide bars is provided with a brushing board; the right side surface of each brushing board is fixedly provided with a hairbrush; the top of the dedusting chamber is provided with a desulphurization tank; one end of a conveyer pipe far from an air pump is provided with an aeration disc; the top of the desulphurization tank is provided with an exhaust pipe. The boiler fuel gas dedusting purifying device is excellent in dedusting filtering effect; flue gas is introduced into the aeration disc for aeration processing, so that sulfides in flue gas are absorbed by a desulfurizer completely, desulphurization effect is excellent; and environment protection emission is realized at last.

Owner:张炳强

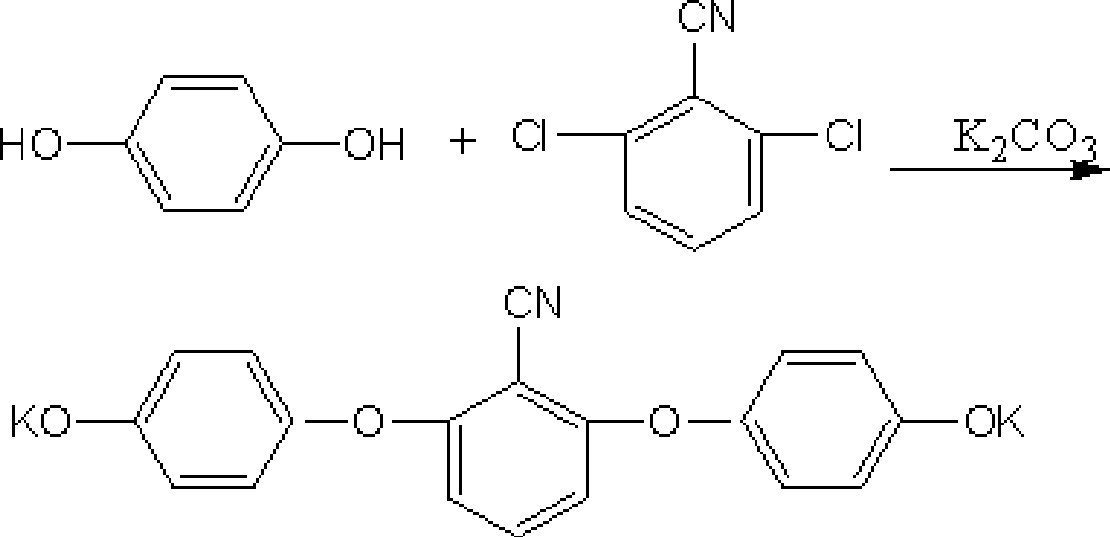

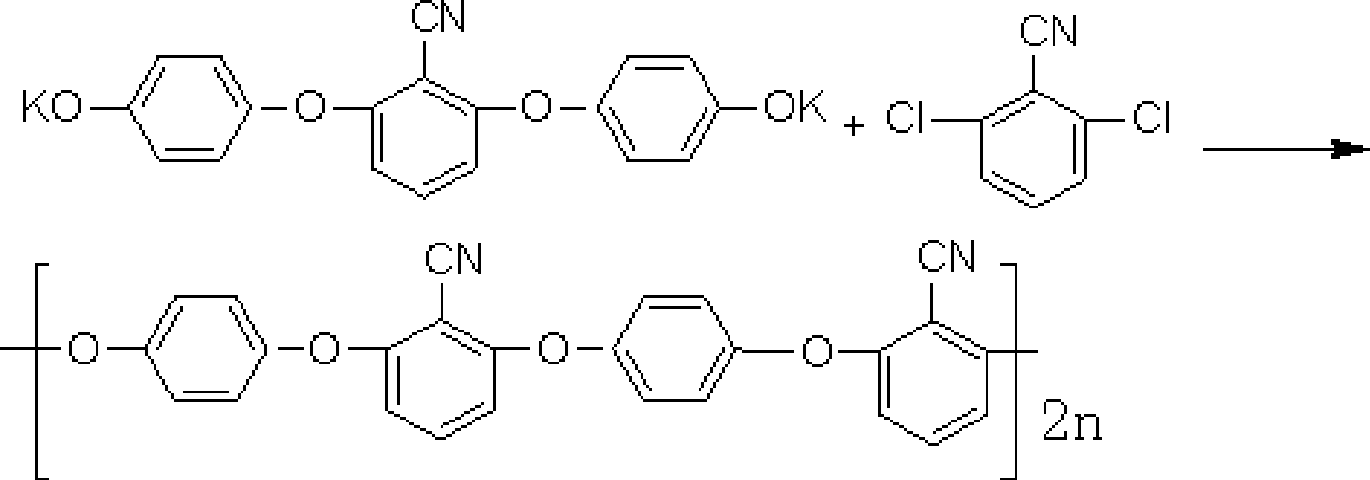

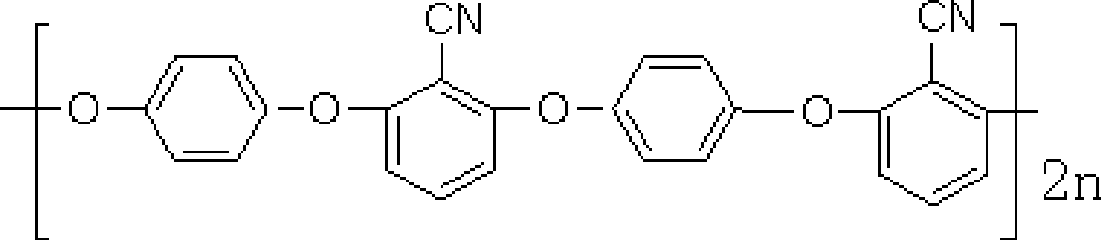

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and the catalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

Tail gas treatment device and tail gas treatment method in process of recycling waste printed circuit boards

InactiveCN103537181ARealize environmentally friendly emissionsRealize secondary pollutionDispersed particle filtrationIncinerator apparatusCombustible gasProduct gas

The invention discloses a tail gas treatment device and a tail gas treatment method in a process of recycling waste printed circuit boards. The tail gas treatment method comprises the following steps: performing active carbon adsorption treatment on tail gas to be treated firstly, and filtering solid dust, heavy metal particles, part of inorganic nonmetal oxide and part of organic gas in the tail gas; then introducing the pretreated tail gas into a spray tower, fully contacting the pretreated tail gas with a purification solution in the spray tower, and removing most of inorganic nonmetal oxide and part of organic gas in the pretreated gas; finally, introducing the tail gas exhausted out of the top of the spray tower into a high-temperature combustion device so as to perform combustion, and discharging non-pollution tail gas through the combustion treatment device. Through the tail gas treatment device and the tail gas treatment method, the secondary pollution problem caused by the discharged tail gas in the process of recycling the waste printed circuit boards is effectively solved; meanwhile, part of combustible gas in the tail gas is used, so that a certain economic value is achieved.

Owner:HEFEI UNIV OF TECH

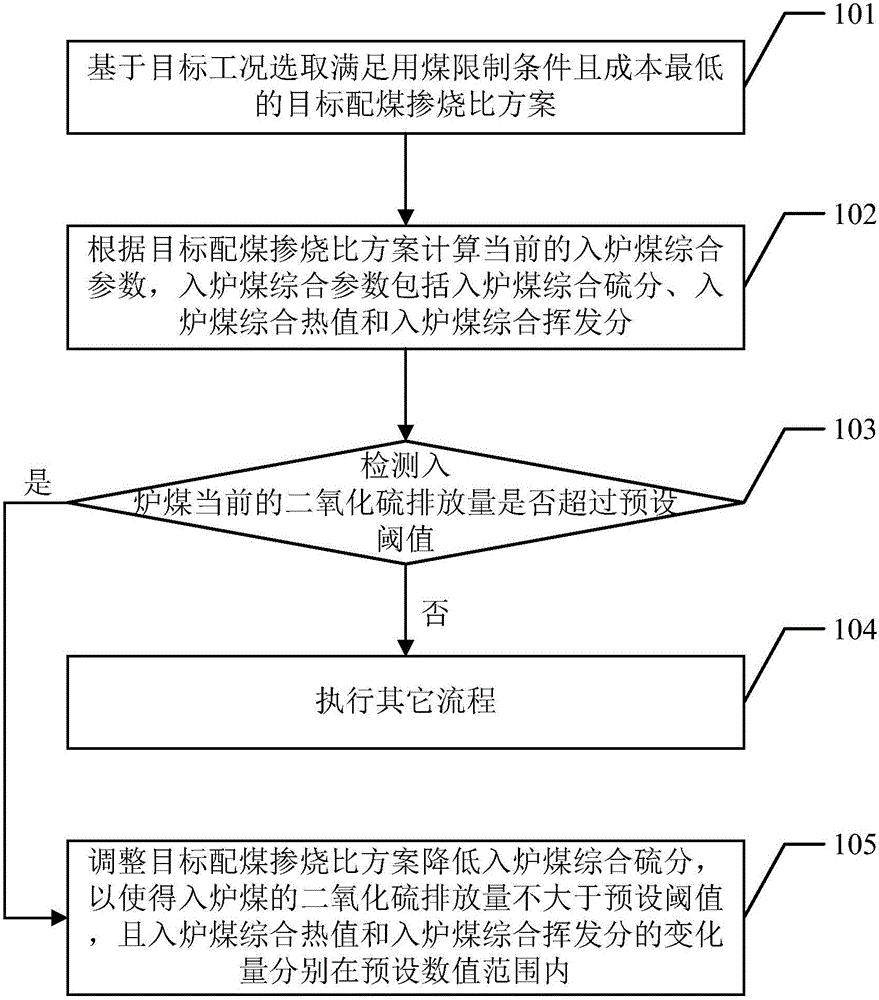

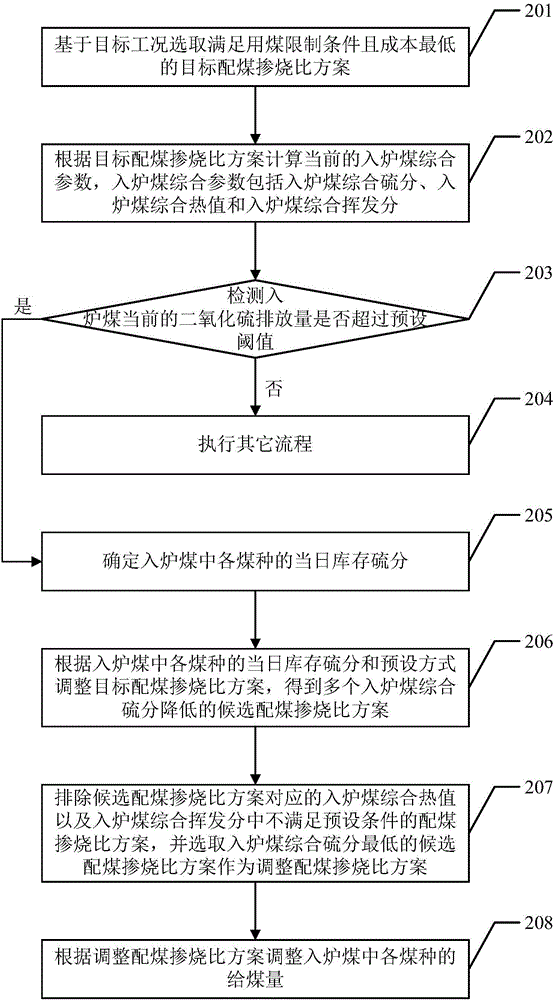

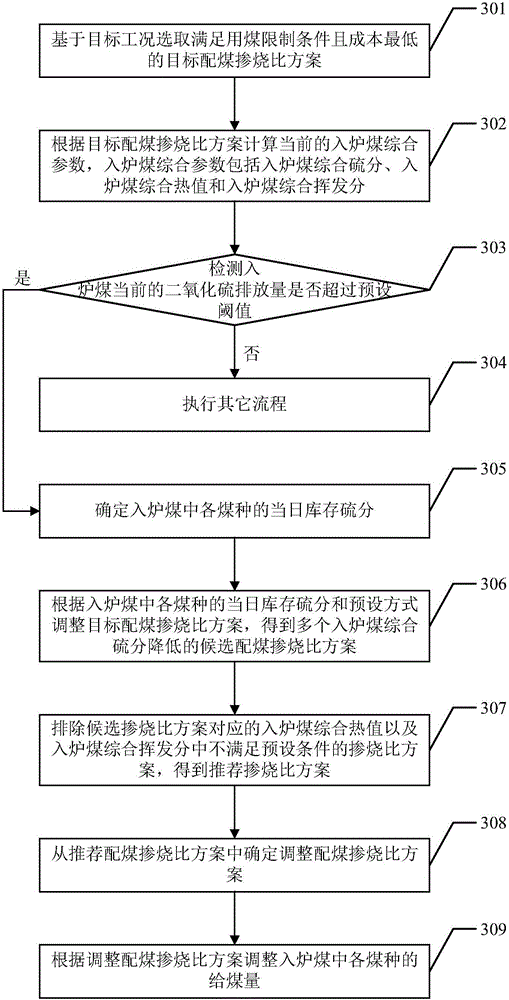

Environmental-protection coal blending method

InactiveCN106203801AMeet environmental protection operation requirementsReduce economic costsResourcesCombustionProcess engineering

The embodiment of the invention discloses an environmental-protection coal blending method, and the method achieves the environmental-protection blending combustion control of the sulfur content of fire coal, and achieves the safe and economical operation of a set. The method comprises the steps: selecting a target coal-blending combustion ratio scheme based on target work conditions, wherein the target coal-blending combustion ratio scheme meets a coal limit condition and is the lowest in cost; calculating the current fire coal comprehensive parameters according to the target coal-blending combustion ratio scheme, and detecting whether the current discharge value of sulfur dioxide of the fire coal exceeds a preset threshold value or not, wherein the fire coal comprehensive parameters comprise a fire coal comprehensive sulfur content, a fire coal comprehensive heat value and a fire coal comprehensive volatile component; adjusting the target coal-blending combustion ratio scheme to reduce the fire coal comprehensive sulfur content if the current discharge value of sulfur dioxide of the fire coal exceeds the preset threshold value, so as to enable the discharge value of sulfur dioxide of the fire coal not to be greater than the preset threshold value, and enable the variation of the fire coal comprehensive heat value and the variation of the fire coal comprehensive volatile component to be respectively within a preset range.

Owner:深圳市出新知识产权管理有限公司

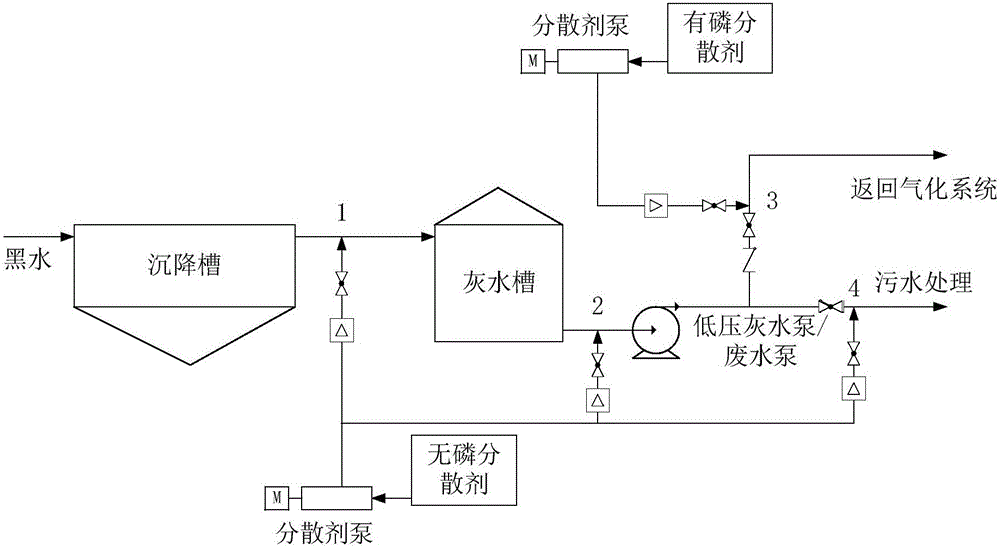

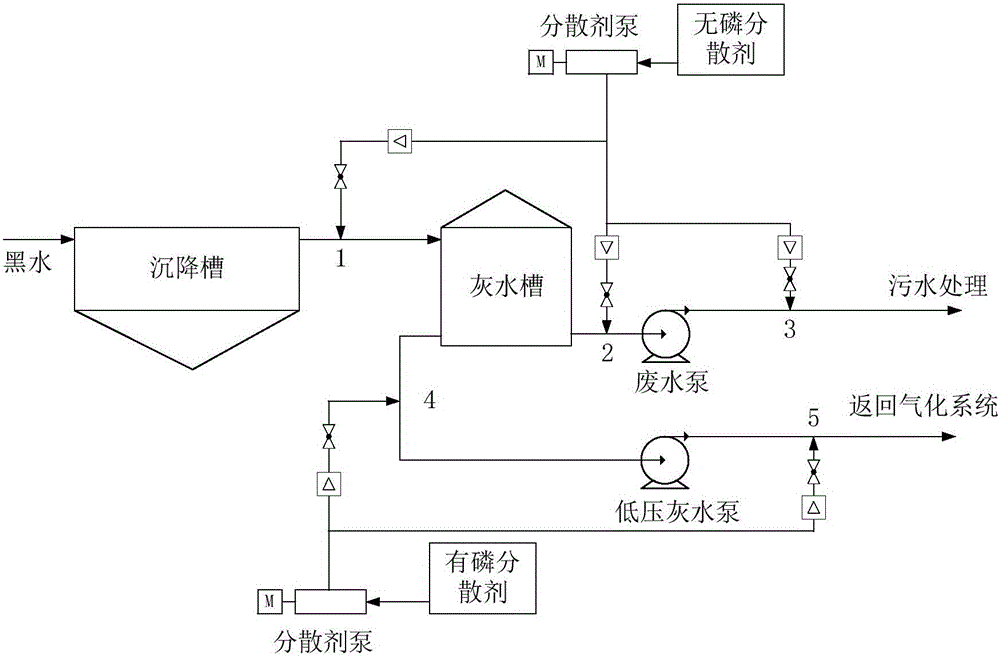

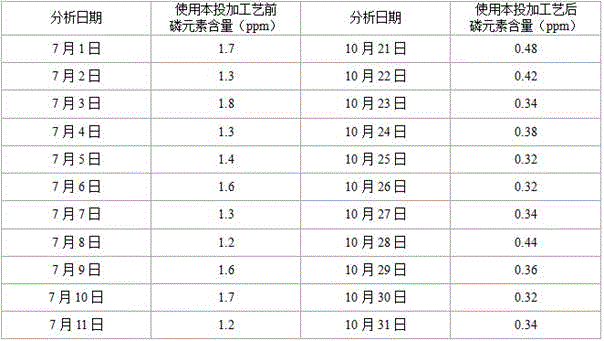

Addition technology of zero-phosphorus-low-phosphorus grey water scale inhibition and dispersion agent

ActiveCN105776591AReduce phosphorus contentGood anti-scaling and dispersing effectSpecific water treatment objectivesScale removal and water softeningPhosphorus lowWastewater

The invention discloses an addition technology of a zero-phosphorus-low-phosphorus grey water scale inhibition and dispersion agent, and belongs to the technical field of gasification water treatment. A formula and an addition technology of a scale inhibition and dispersion agent are improved, a low-phosphorus dispersion agent is added at a high-temperature part, a zero-phosphorus dispersion agent is added at a low-temperature part, and the low-phosphorus dispersion agent and the zero-phosphorus dispersion agent are combined and added at different sections, so that the content of phosphorus elements in externally discharged waste water of gasification enterprises is greatly reduced, the discharged waste water reaches the first-level industrial water discharge standard of China, environment-friendly discharge is realized, and besides, good grey waste scale inhibition and dispersion effects are achieved.

Owner:TAIZHOU JIUYUN CHEM TECH CO LTD

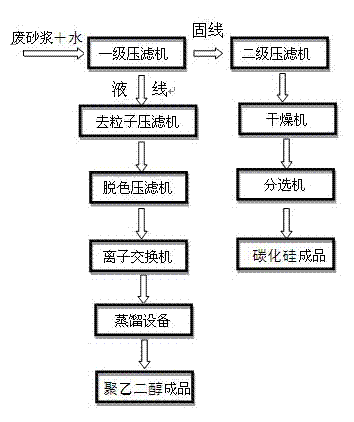

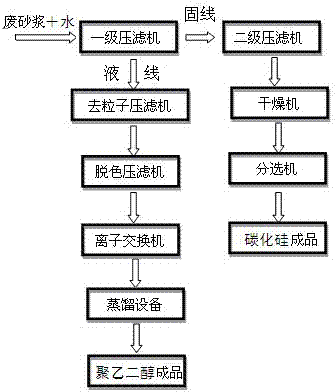

Silicon wafer-cutting waste slurry recovery method

ActiveCN102643710AProtect environmentReduce processing costsSilicon carbideLubricant compositionCarbide siliconSilicon chip

The invention discloses a silicon wafer-cutting waste slurry recovery method, which adopts a physical treatment process. The silicon wafer-cutting waste slurry recovery method includes the following steps of: (step 1) pretreatment: solid-liquid separation is carried out; (step 2) recovery of polyethylene glycol on a liquid line: the filtrate obtained by separation in the first step undergoes particle-removing pressing, decoloration, ion exchange, four-effect distillation and cooling, so that the finished polyethylene glycol product is obtained; and (step 3) recovery of silicon carbide on a solid line: the filter cake obtained in the first step undergoes primary filter pressing, secondary filter pressing, drying and impurity separation by a separator, so that the finished silicon carbide product is obtained. The silicon wafer-cutting waste slurry recovery method not only has the advantages of large separation capacity, high recovery rate and good quality of recovered polyethylene glycol and silicon carbide, but also realizes environment-friendliness and zero-pollution treatment, and also reduces the production cost.

Owner:泗阳瑞泰光伏材料有限公司

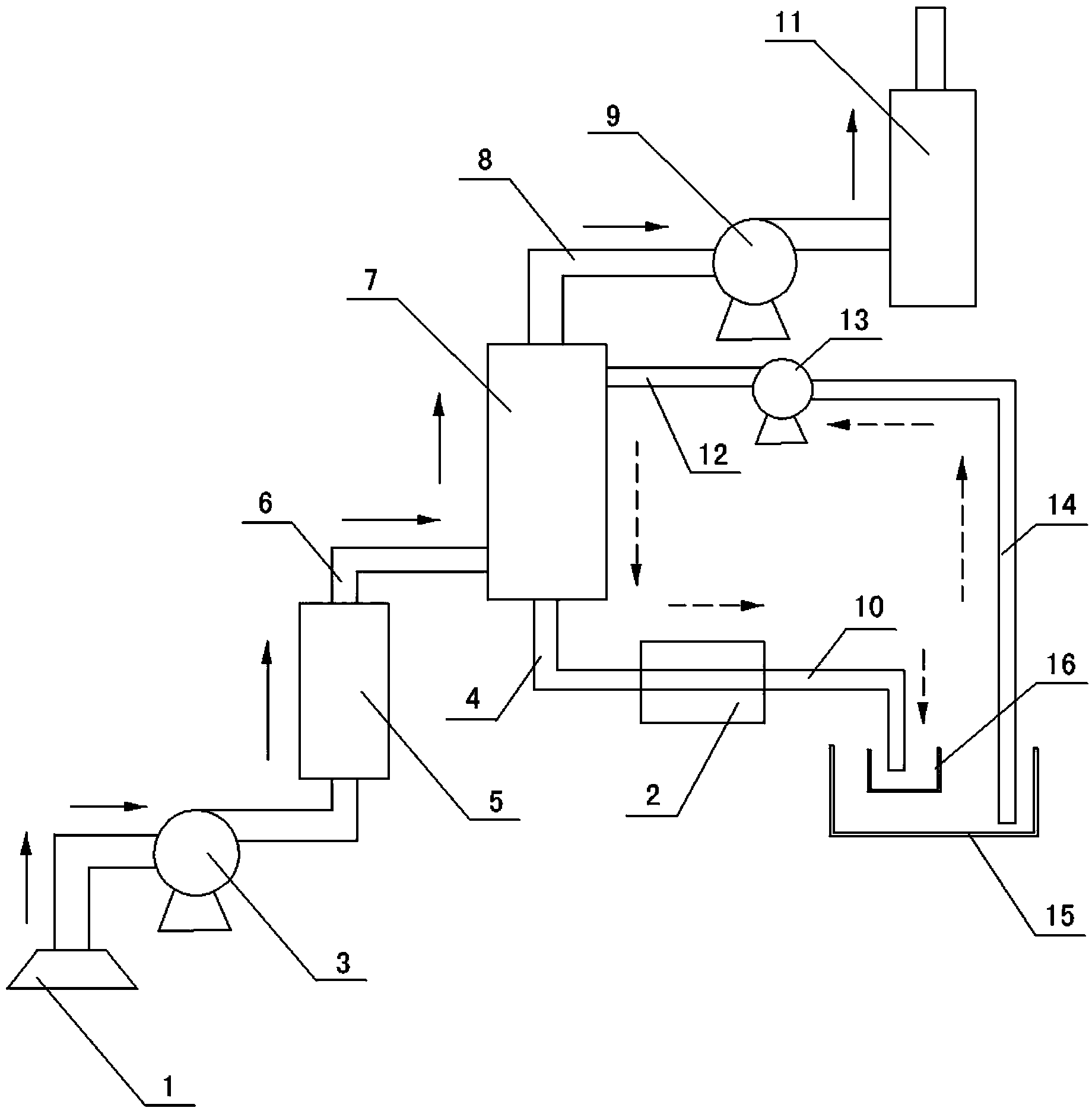

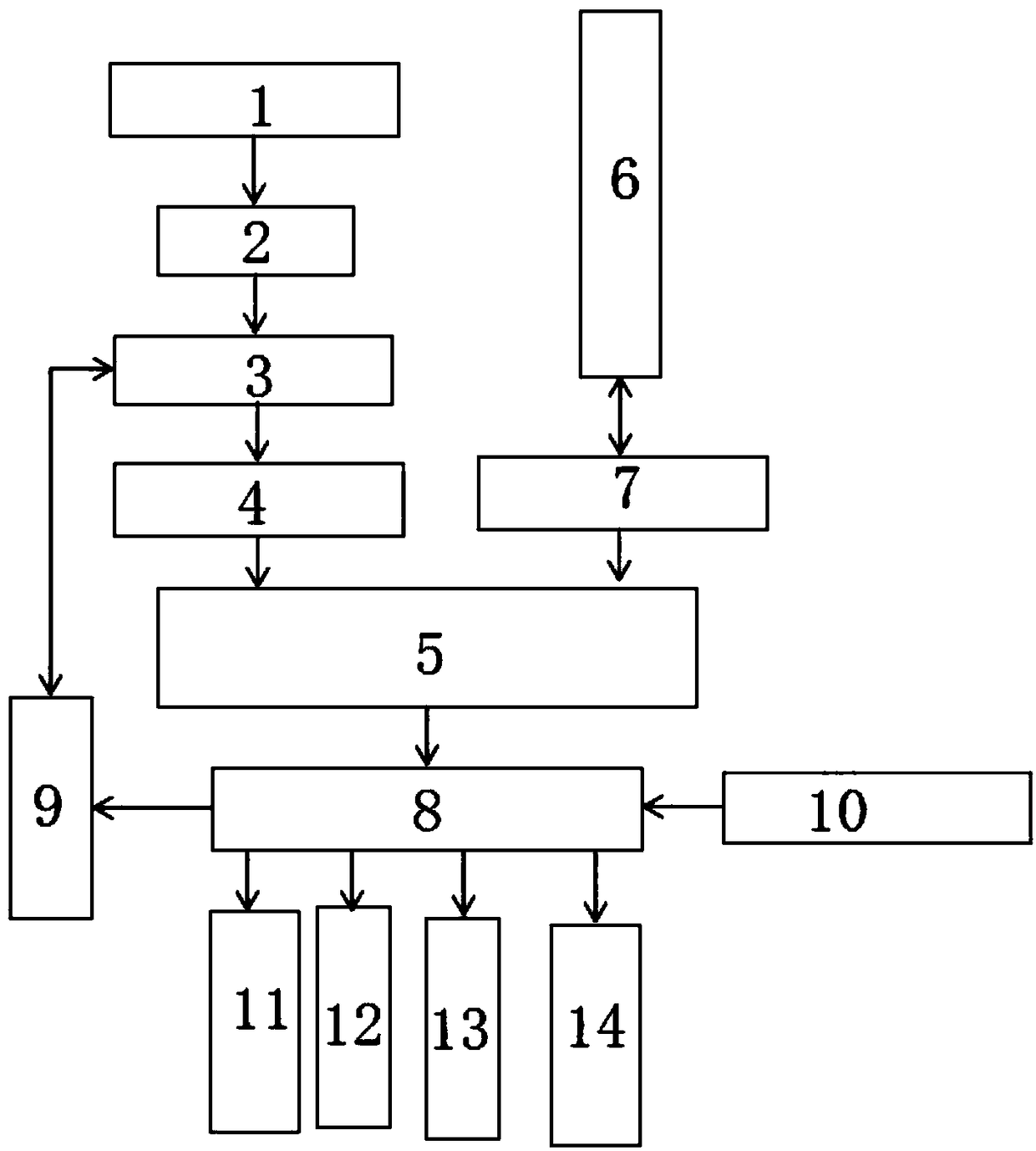

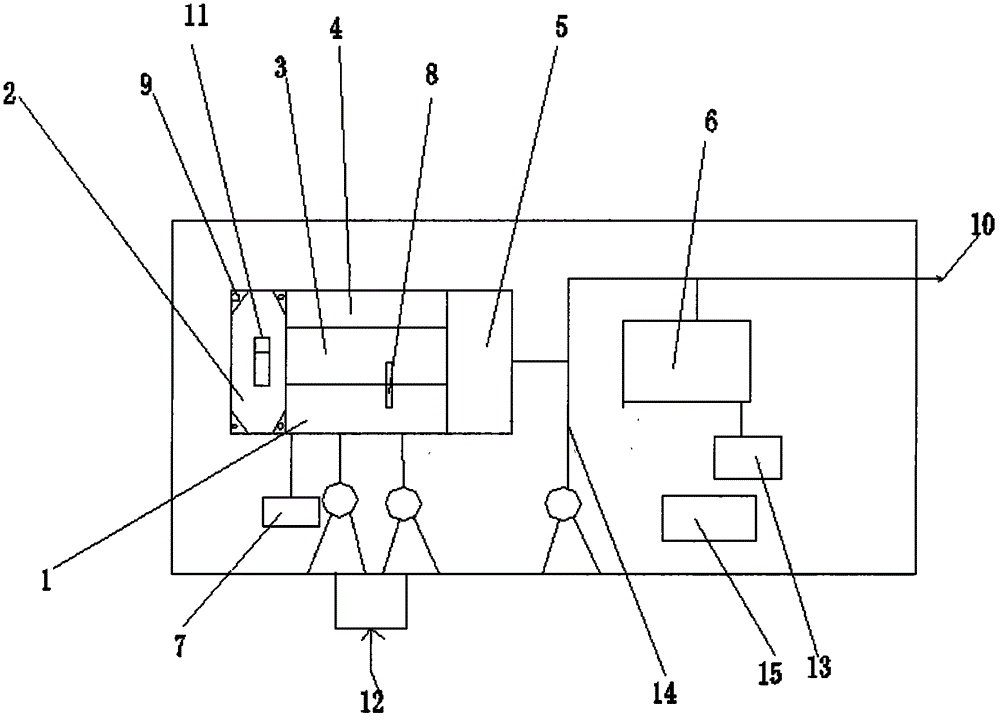

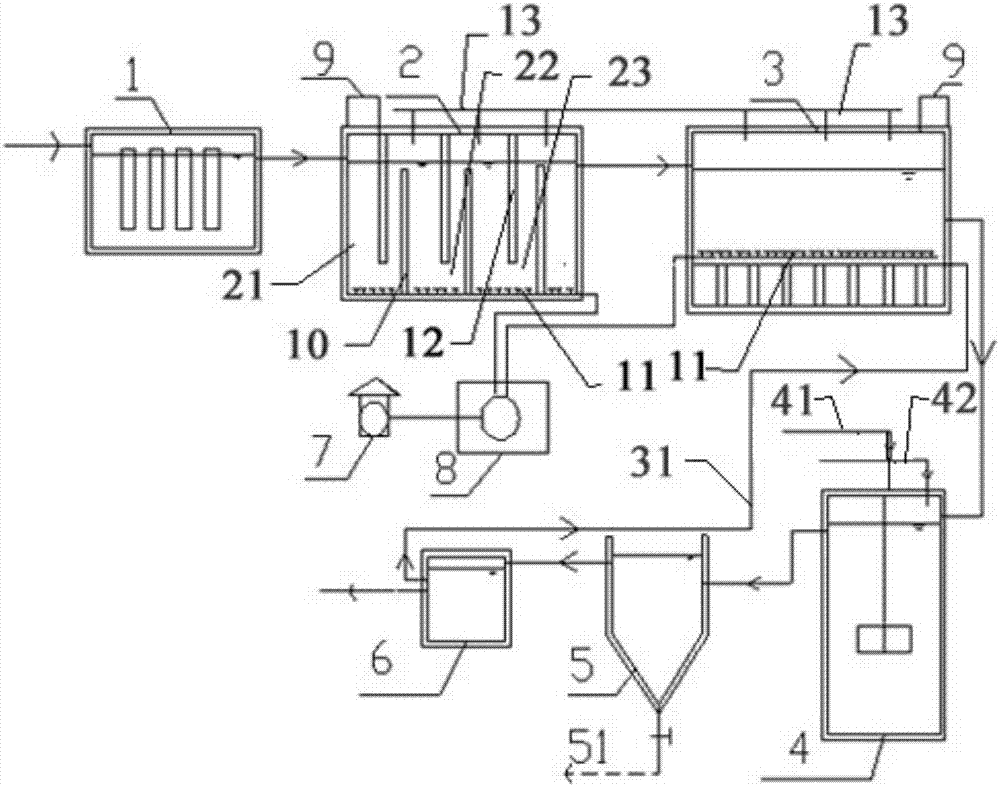

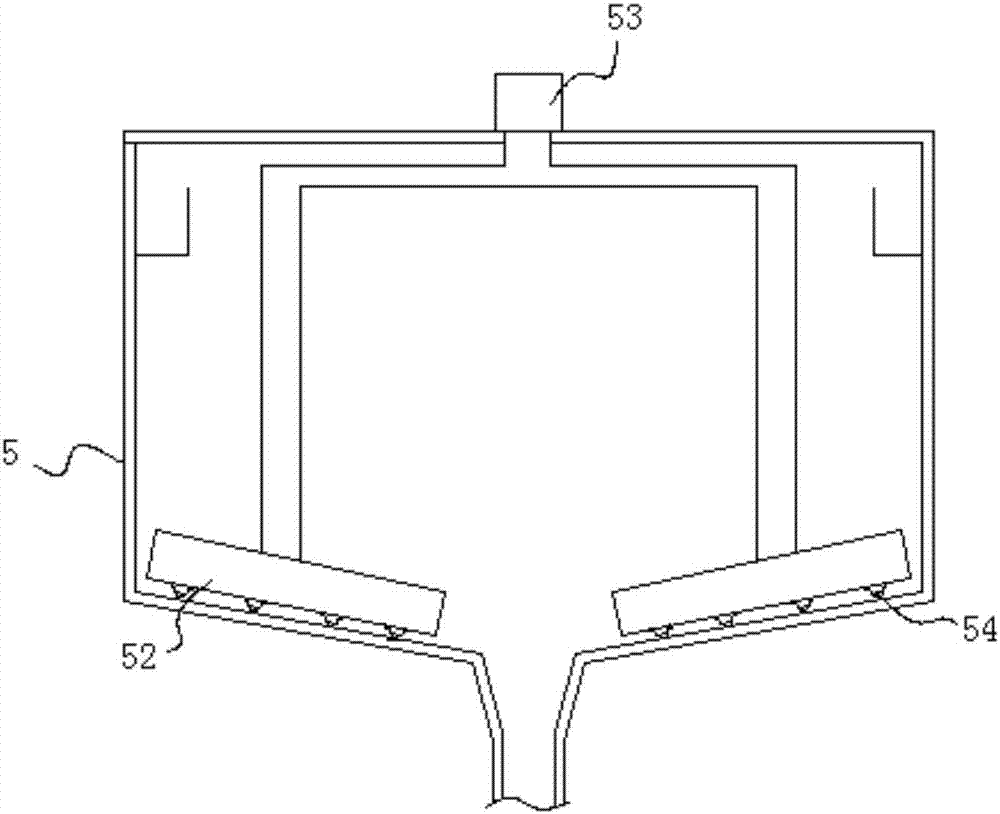

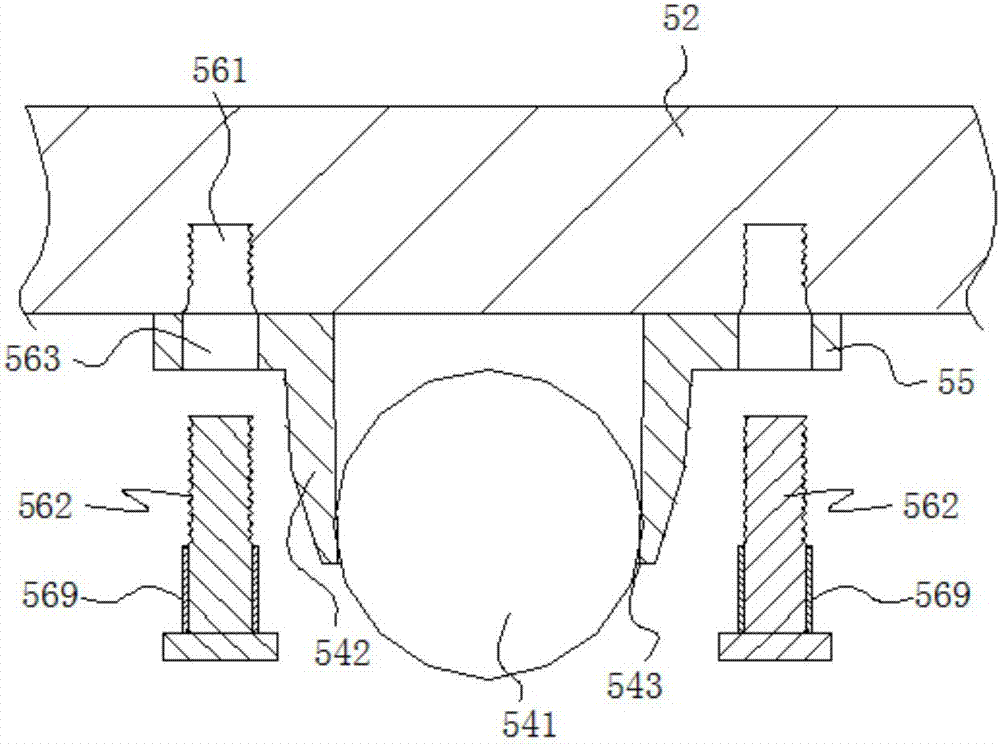

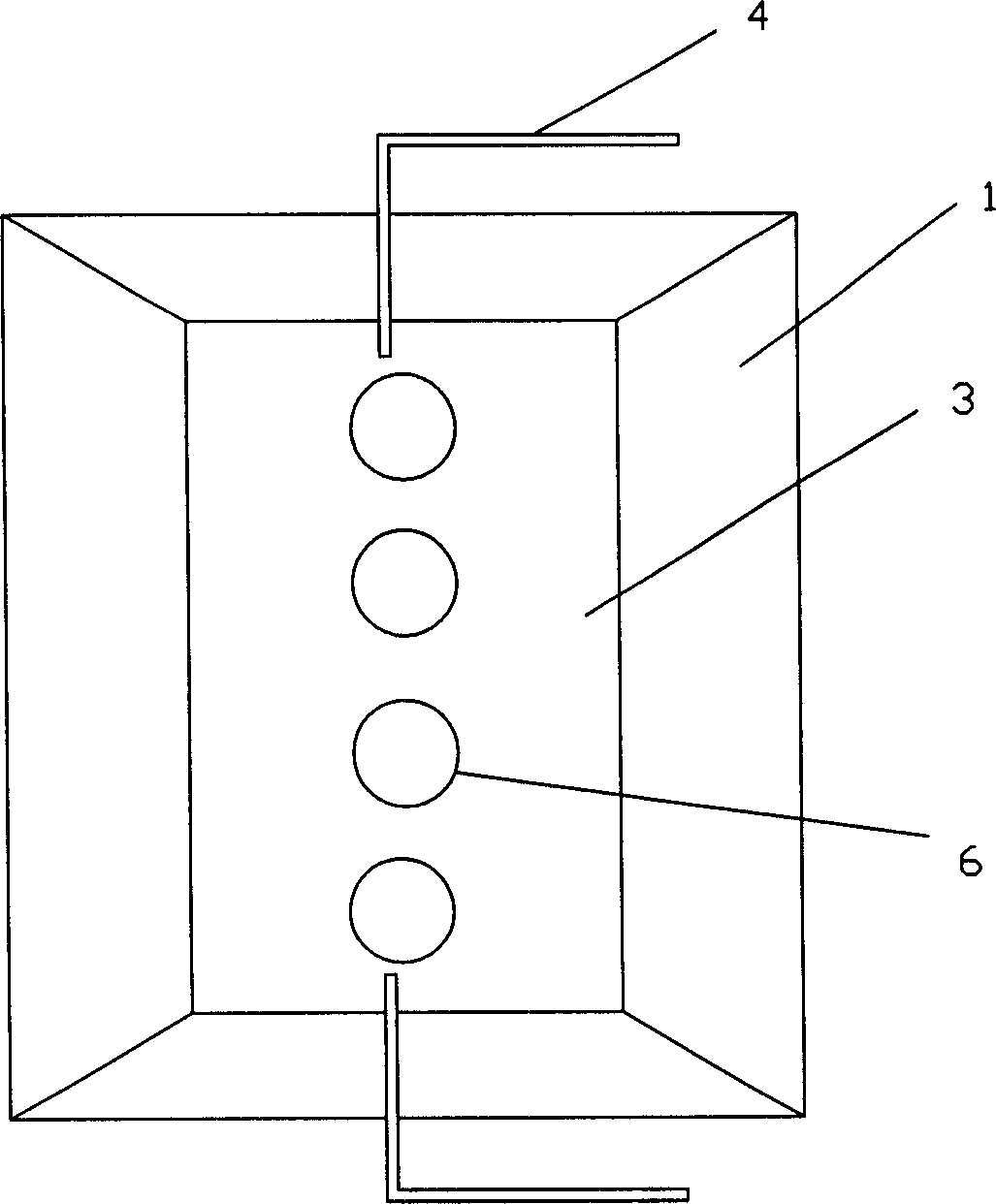

Self-adaptive sewage purifying apparatus system

InactiveCN108147581ARealize environmentally friendly emissionsReduce pollutionWater treatment parameter controlTreatment involving filtrationWater qualitySelf adaptive

The invention discloses a self-adaptive sewage purifying apparatus system, which relates to the technical field of sewage purification. The self-adaptive sewage purifying apparatus system comprises asewage discharging apparatus, a filtering apparatus, a water quality purifying apparatus, a first water quality detector, a comparison module, a qualified water discharging apparatus, a second water quality detector, a control module, a circulating apparatus, a state monitoring apparatus, a display apparatus, a discharging apparatus, an alarming apparatus and a storage apparatus; the sewage discharging apparatus is connected with a pipeline of the filtering apparatus, and the filtering apparatus is connected with a pipeline of the water quality purifying apparatus. According to the self-adaptive sewage purifying apparatus system, the water quality information in the qualified water discharging apparatus can be acquired in real time by virtue of a second water quality detector, and when a difference between the sewage water quality information and the qualified water quality information is within 10 percent, the sewage is discharged; and when the difference between the sewage water quality information and the qualified water quality information is greater than 10 percent, the sewage is circularly treated, so that the environment-friendly discharge of the sewage is realized, and thesewage pollution on the environment can be reduced.

Owner:合肥草木皆兵环境科技有限公司

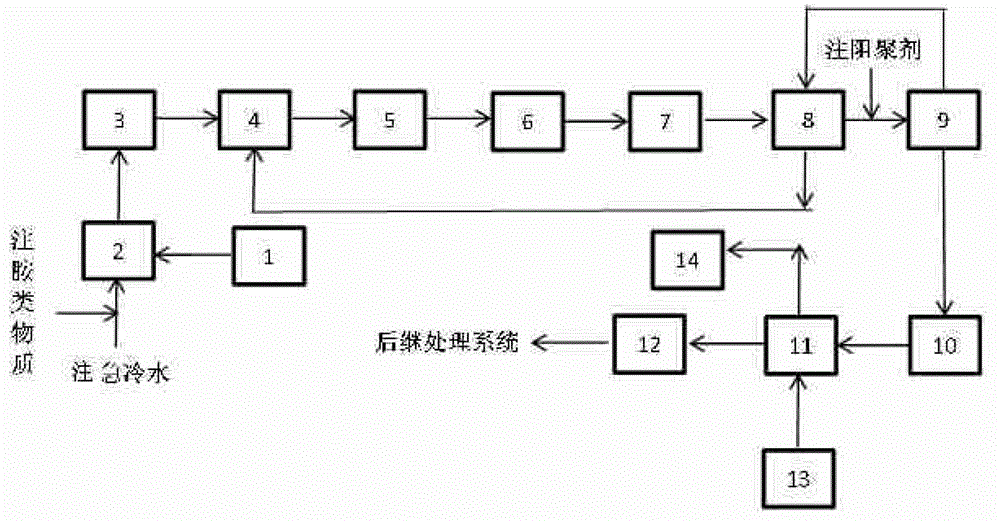

Method for purifying process condensate produced during application of catalytic dehydrogenation of ethyl benzene to produce styrene

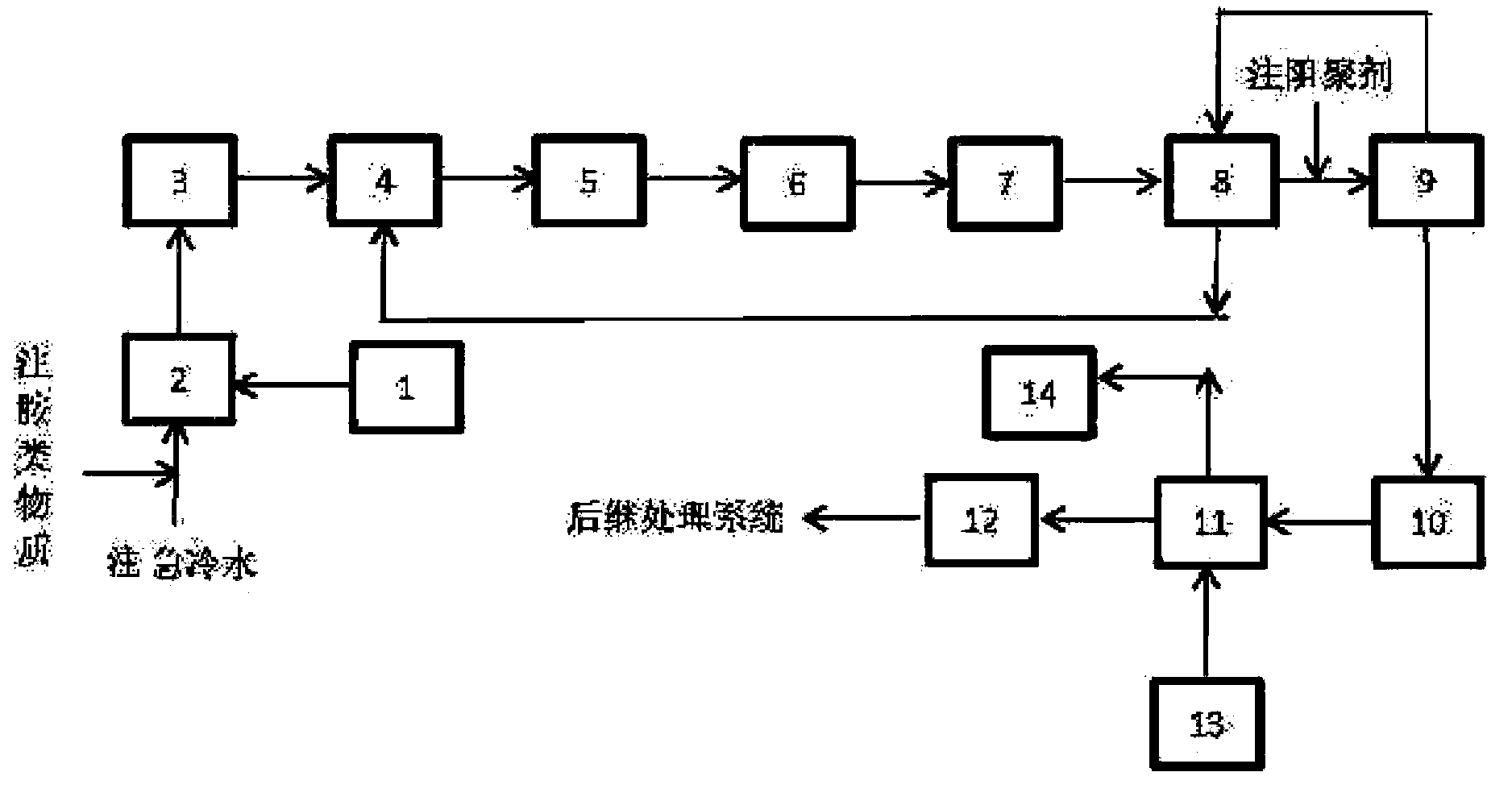

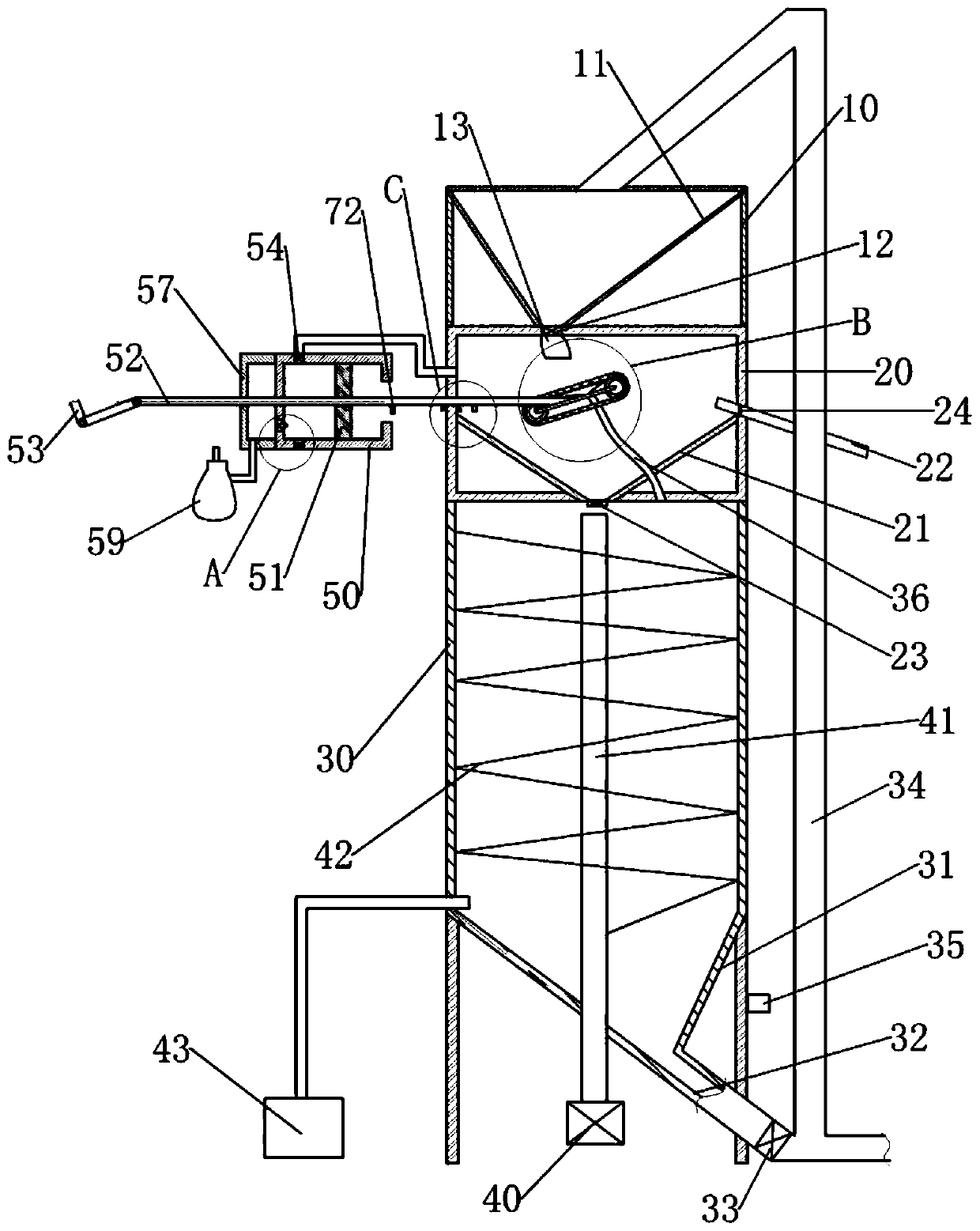

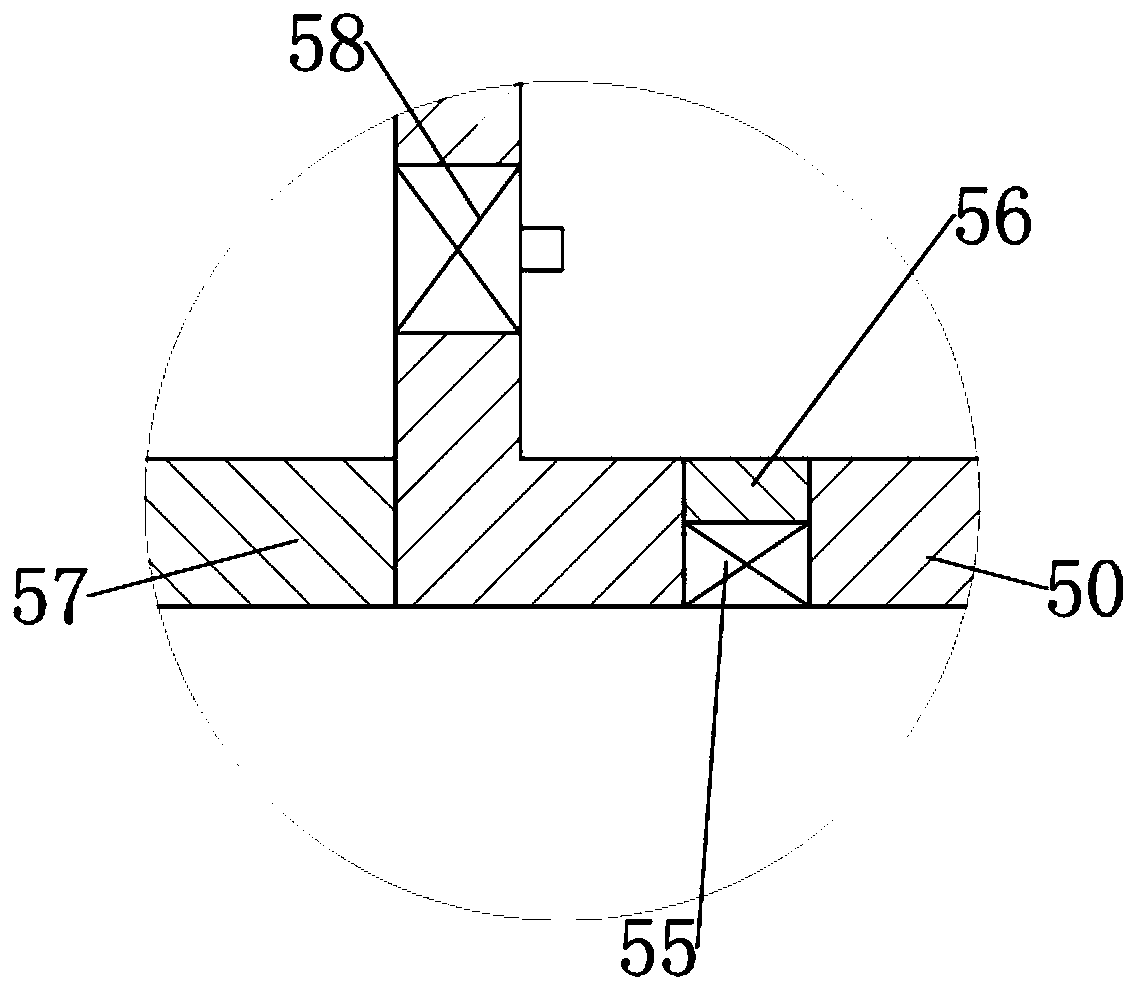

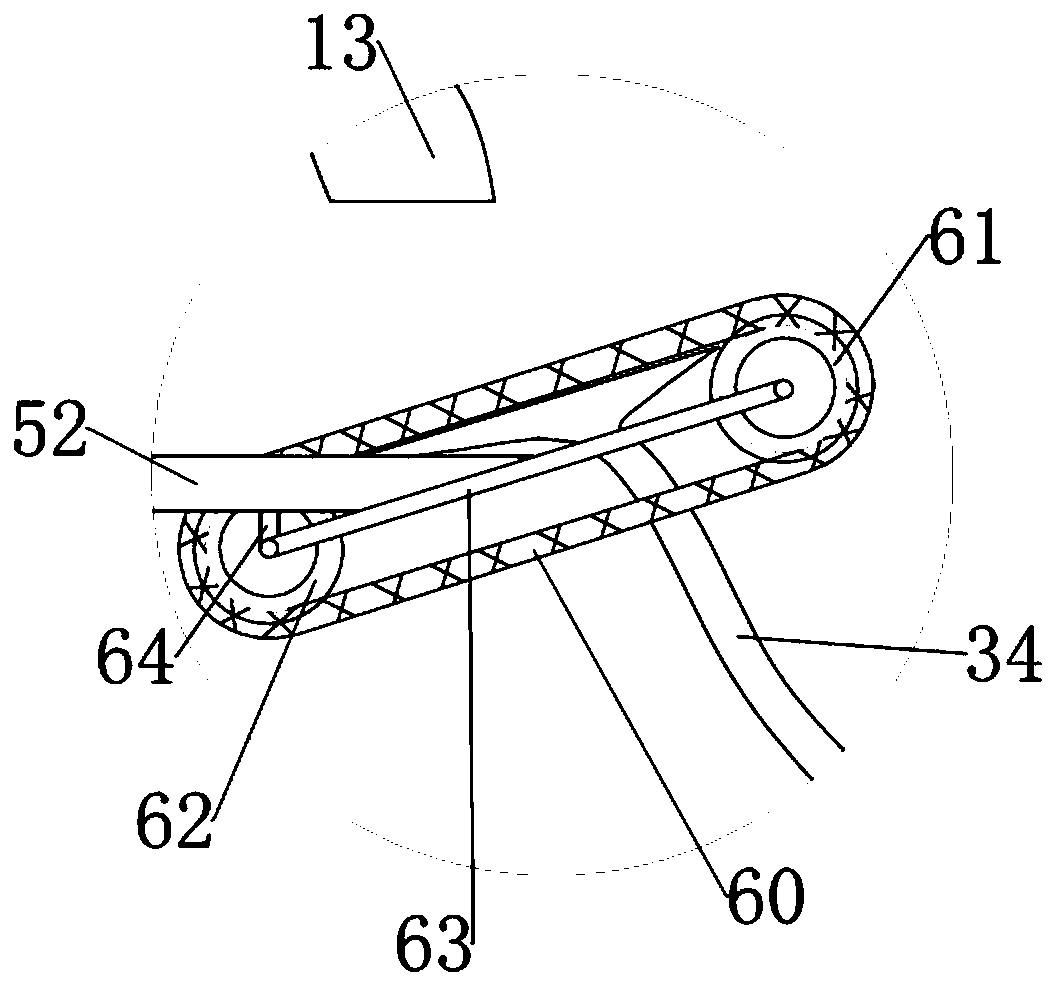

ActiveCN104341069AReduce generationEfficient Control of AggregationMultistage water/sewage treatmentWater/sewage treatment by neutralisationFiltrationPolystyrene

The present invention provides a method for purifying process condensate produced during application of catalytic dehydrogenation of ethyl benzene to produce styrene. The method is characterized in that an amine substance is added to an acidic dehydrogenation liquid to neutralize before the acidic dehydrogenation liquid enters an air cooler so as to prevent iron ion production caused by metal corrosion to the greatest extent; a polymerization inhibitor is added to the process condensate before entering a steam stripping tower, such that polymerization scaling of styrene and other components of the process condensate in the steam stripping tower is effectively controlled, and the steam stripping removing rate of hydrocarbons in the tower is increased; water from the bottom of the steam stripping tower is directly introduced into an air stripping tower without cooling so as to remove the hydrocarbons in the water and increase the stripping gas temperature, such that the thermal efficiency of the steam superheating furnace is improved; and the striped process condensate is fed into a sand filtration tower so as to remove the polystyrene formed by oxidation, colloidal hydrocarbons, metal oxides and the like.

Owner:CHINA PETROLEUM & CHEM CORP

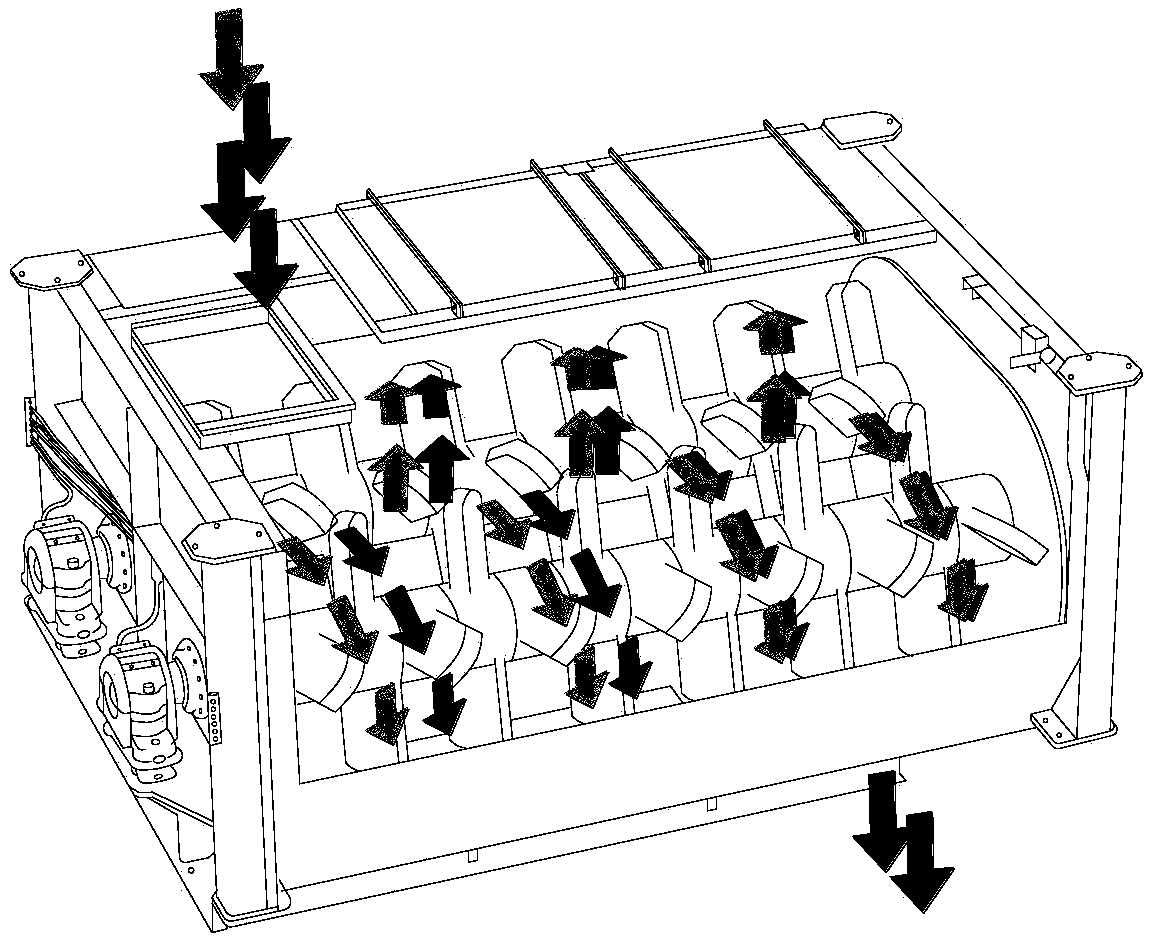

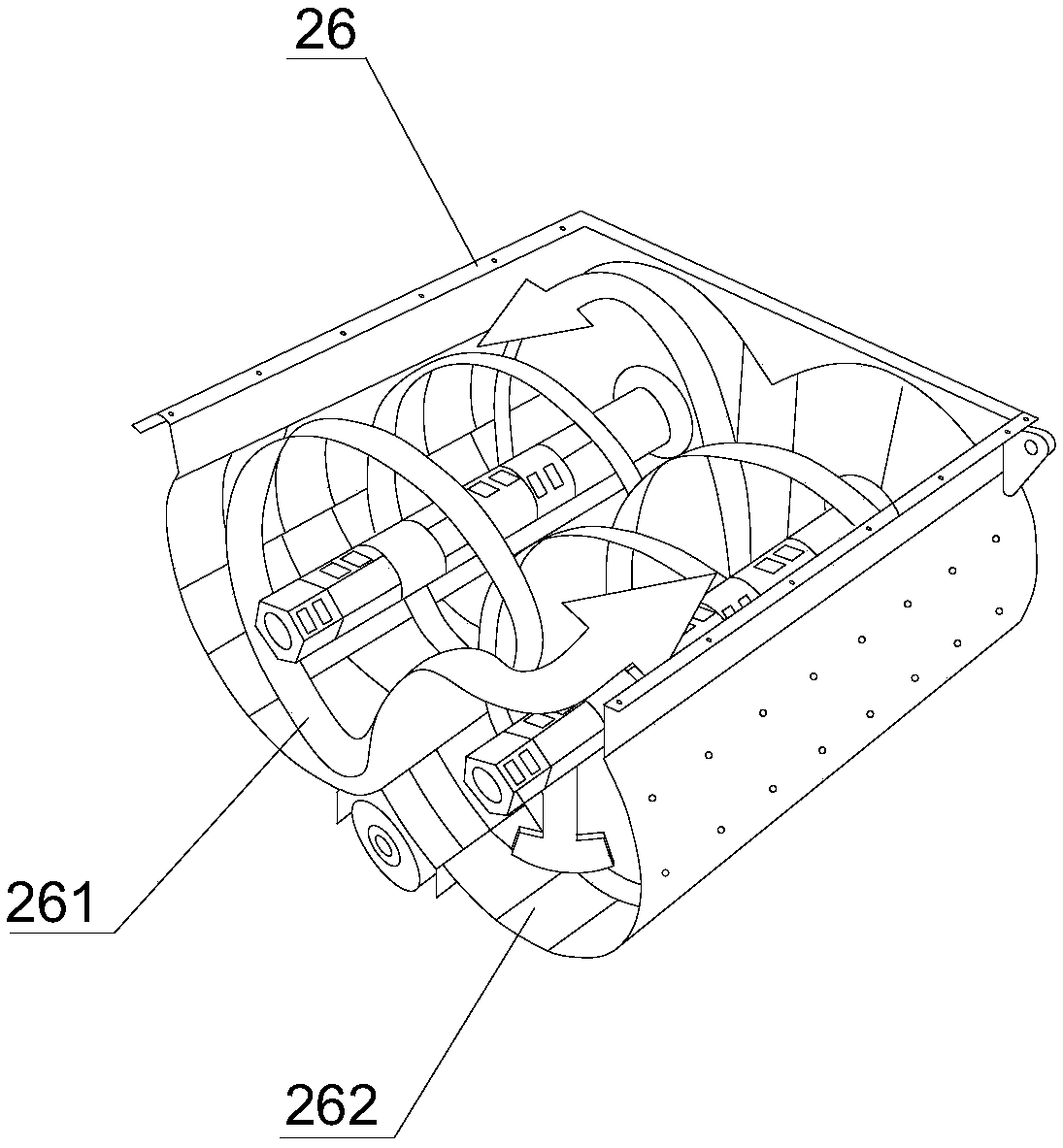

Environmentally-friendly cereal impurity removing and drying integrated machine

ActiveCN110064591AImprove drying rateRealize environmentally friendly emissionsGas current separationDispersed particle filtrationInlet valvePulp and paper industry

The invention relates to the technical field of drying equipment, and specifically discloses an environmentally-friendly cereal impurity removing and drying integrated machine. The machine comprises arack and a feeding box, wherein an impurity removing box is connected to the lower end of the feeding box; a drying box is connected to the lower end of the impurity removing box; a discharging pipeis connected to the lower end of the drying box; a first motor which is rotatably connected to a rotating rod is fixed into the drying box; and a spiral screening plate is fixed to the rotating rod. The machine further comprises a hot-blast stove; a cylinder body in which a piston is glidingly connected is fixed to the rack; a driving mechanism for driving the piston to slide in a reciprocating manner is arranged on the rack; an one-way air inlet valve and an one-way air outlet valve are arranged on the cylinder body; the one-way air inlet valve communicates with the inside of a dust removingchamber; and the drying box communicates with the dust removing box through an air pipe. The machine aims at solving the problems of simple function and lacking of impurity removing function of a drying device.

Owner:贵州汇创新能源科技有限公司

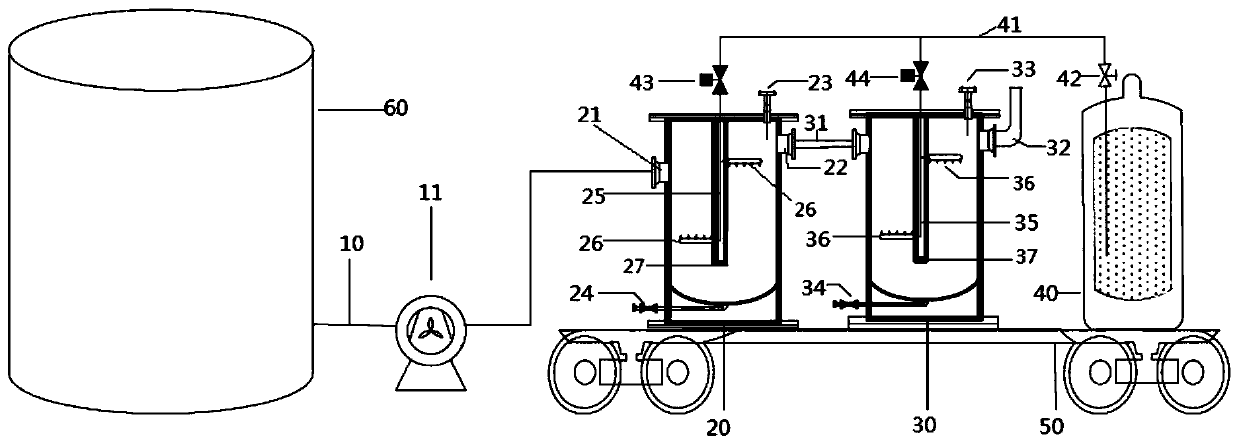

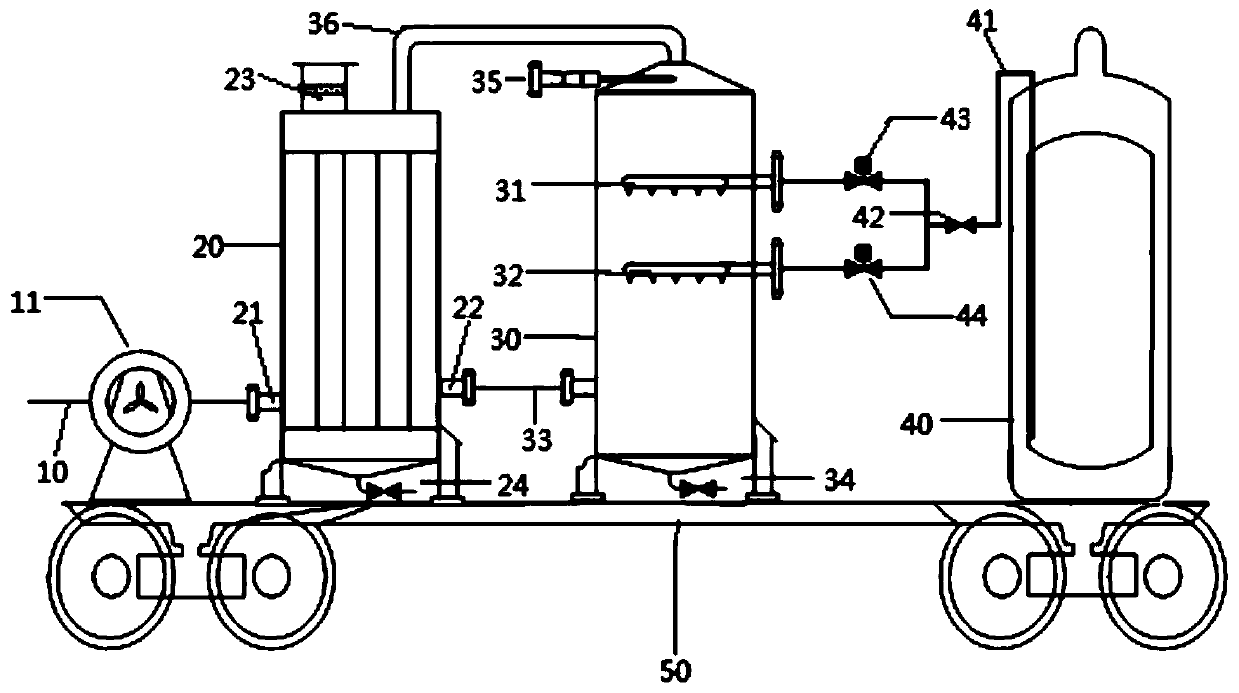

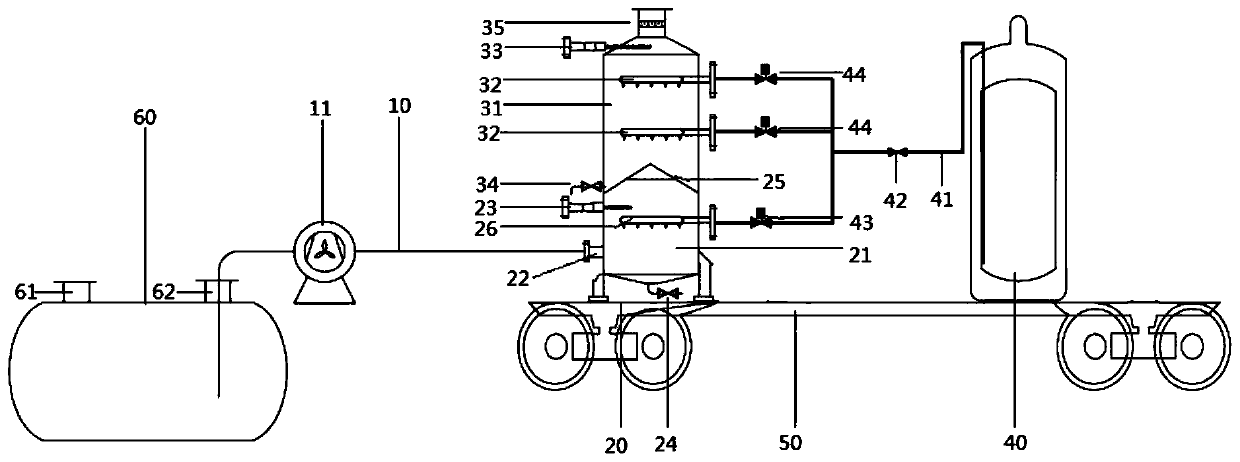

Storage tank oil gas treatment device based on liquid nitrogen condensation and oil gas treatment method

InactiveCN110871025ATreatment and purificationPrevent uncontrolled escapeGas treatmentDispersed particle separationSprayerExhaust pipe

The invention relates to the technical field of oil gas treatment, and discloses a storage tank oil gas treatment device based on liquid nitrogen condensation and an oil gas treatment method. The device includes: a first condensation tank (20), in which a condensation structure is arranged, and on which an oil gas inlet (21) and an oil gas outlet (22) are formed; a second condensation tank (30), in which a second sprayer (36) is formed, wherein a gas feeding pipe (31) and a gas discharge pipe (32) are connected to the second condensation tank (30), the gas feeding pipe being connected to the oil gas outlet; and a liquid nitrogen storage tank (40) connected to a liquid nitrogen pipeline (41), wherein the second sprayer is connected to the nitrogen pipeline through a second feeding pipe (35). In the device, oil is condensed by multiple times through the first and the second condensation tanks in the oil gas treatment device, thereby purifying the oil gas and preventing uncontrolled escape. The device not only prevents safety accidents but also achieves environment-friendly discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paint spraying wastewater treatment device

InactiveCN105884075AComply with Tier 3 emission standardsMeet people's needsWater/sewage treatment by irradiationMultistage water/sewage treatmentFlocculationAutomatic control

The invention discloses a paint spraying wastewater treatment device. The paint spraying wastewater treatment device includes an automatic control system, a water pump system, a dosing device, a pretreatment tank, an oxidation device, a reaction tank, a coagulation and flocculation tank, a sedimentation tank and a filter pressing device, wherein the pretreatment tank, the oxidation device, the reaction tank, the coagulation and flocculation tank, the sedimentation tank and the filter pressing device are sequentially connected, the pretreatment tank, the oxidation device, the reaction tank, the coagulation and flocculation tank, the sedimentation tank, the filter pressing device and the water pump system are electrically connected with the automatic control system, PH meters capable of detecting PH values are arranged in both the pretreatment tank and the reaction tank, an ultraviolet lamp and a stirring device capable of performing mechanical stirring are arranged in the oxidation device, the pretreatment tank, the oxidation device, the reaction tank and the coagulation and flocculation tank are connected with the dosing device capable of adding chemicals, and a mud pressing machine is arranged at the bottom of the filter pressing device. The paint spraying wastewater treatment device adopts the ultraviolet lamp and a Fenton oxidation technology combined treatment method and is matched with the corresponding oxidation device to conduct automatic oxygenolysis treatment on paint spraying wastewater, so that the removal rate of COD in the paint spraying wastewater can be 80% or above.

Owner:NINGBO QINGYUN ENVIRONMENTAL PROTECTION TECH CO LTD

A method for purifying process condensate produced in the process of catalytic dehydrogenation of ethylbenzene to produce styrene

ActiveCN104341069BReduce generationEfficient Control of AggregationMultistage water/sewage treatmentWater/sewage treatment by neutralisationFiltrationDehydrogenation

The present invention provides a method for purifying process condensate produced during application of catalytic dehydrogenation of ethyl benzene to produce styrene. The method is characterized in that an amine substance is added to an acidic dehydrogenation liquid to neutralize before the acidic dehydrogenation liquid enters an air cooler so as to prevent iron ion production caused by metal corrosion to the greatest extent; a polymerization inhibitor is added to the process condensate before entering a steam stripping tower, such that polymerization scaling of styrene and other components of the process condensate in the steam stripping tower is effectively controlled, and the steam stripping removing rate of hydrocarbons in the tower is increased; water from the bottom of the steam stripping tower is directly introduced into an air stripping tower without cooling so as to remove the hydrocarbons in the water and increase the stripping gas temperature, such that the thermal efficiency of the steam superheating furnace is improved; and the striped process condensate is fed into a sand filtration tower so as to remove the polystyrene formed by oxidation, colloidal hydrocarbons, metal oxides and the like.

Owner:CHINA PETROLEUM & CHEM CORP

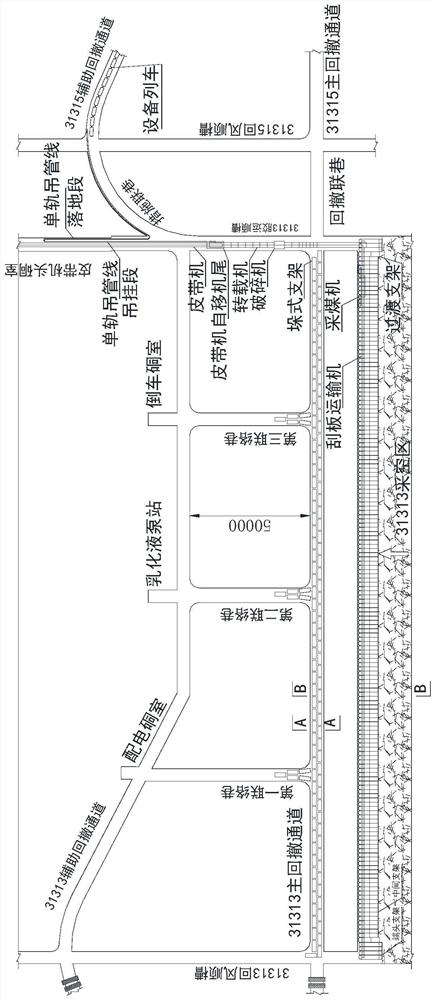

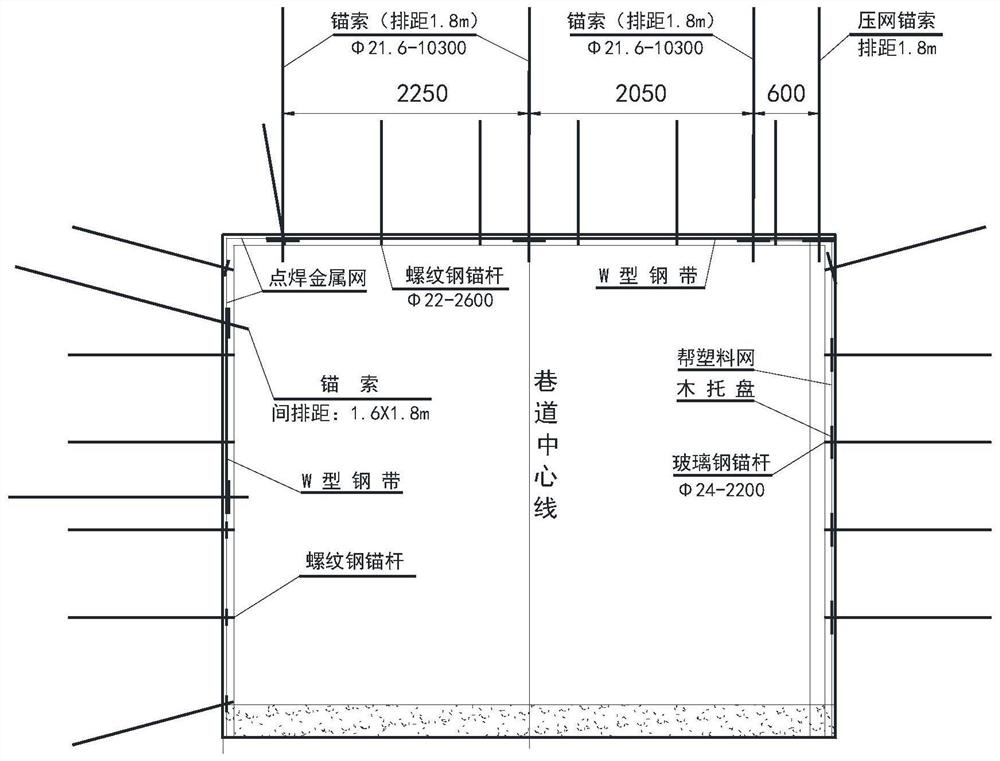

Underground coal mine fully mechanized mining face end mining and rapid withdrawing method

ActiveCN112196616AReduce exposure to fully mechanized face coal wallsShorten the timeMine roof supportsUnderground transportMining engineeringCoal

The invention discloses an underground coal mine fully mechanized mining face end mining and rapid withdrawing method. The method comprises the steps of S1, arrangement of a fully mechanized mining face; S2, end mining protection; and S3, quick withdrawing of the fully mechanized mining face. According to the method, protective measures and fully mechanized face withdrawing operation during roadway withdrawing and fully mechanized face end mining are optimally designed, the tunneling and supporting cost of an auxiliary withdrawing channel is reduced, the sinking speed of a top plate of the withdrawing channel is remarkably reduced, the floor heaving amount of the roadway is remarkably reduced, the labor intensity is reduced, the withdrawing time is shortened, the safety performance is improved, and the auxiliary withdrawing channel can be reused for the second time, so that the environment-friendly emission of solid waste is realized, and the emission cost of the solid waste is reduced.

Owner:国电建投内蒙古能源有限公司

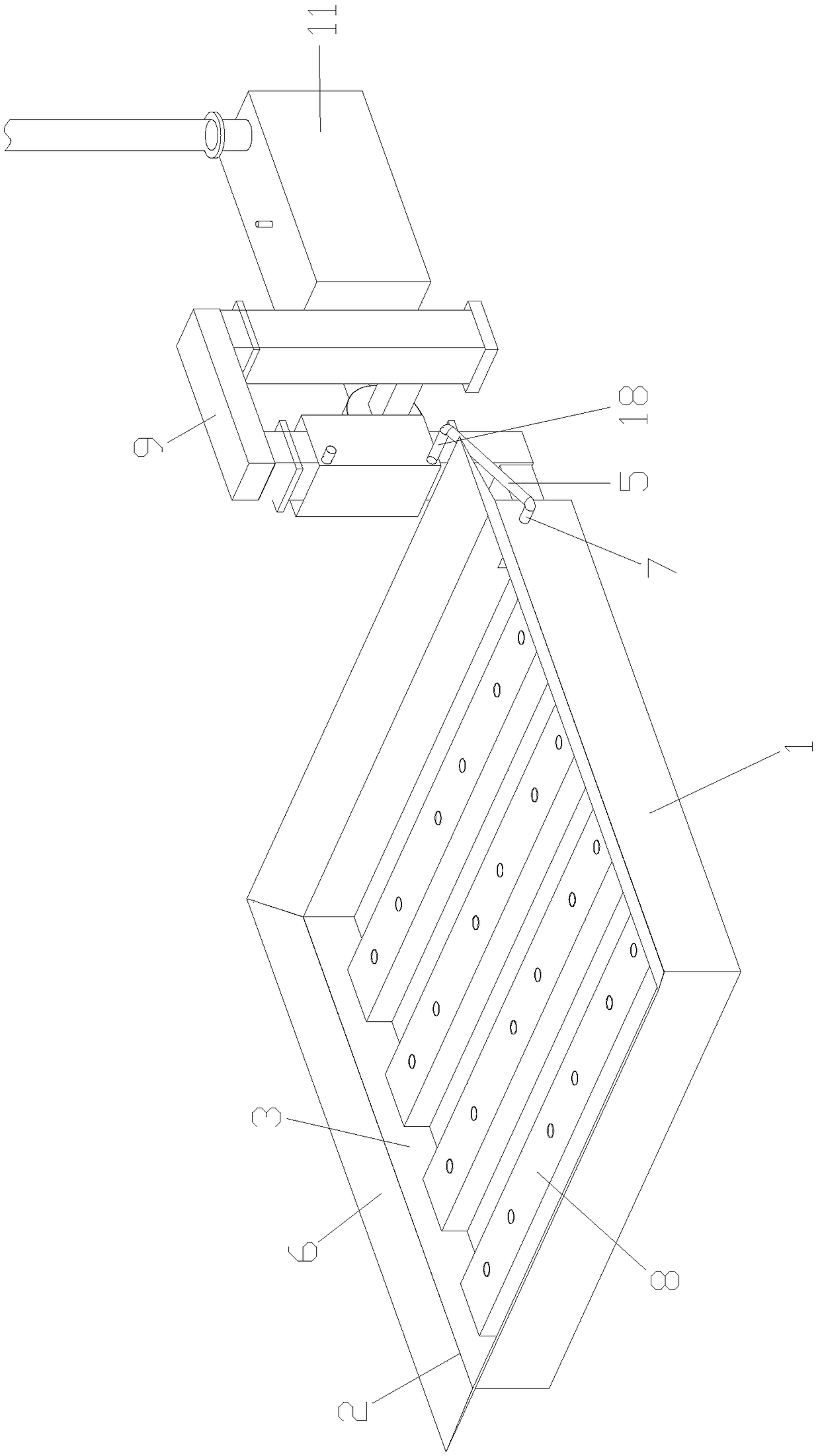

Device for purifying, treating and utilizing combustion furnace tail gas

InactiveCN107421356AFully heatedExtended stayCombination devicesRecuperative heat exchangersCombustionHeat transfer efficiency

The invention provides a device for purifying, treating and utilizing combustion furnace tail gas. The device comprises a heat exchange chamber and is characterized in that the outer surface of the heat exchange chamber is covered with heat preservation cotton; a bent coiled pipe is arranged in the heat exchange chamber; a gas inlet is formed in the left end of the coiled pipe; a casing pipe is sleeved outside the coiled pipe; a plurality of heat exchange leakage holes are uniformly formed in the surface of the casing pipe; a water distribution plate is arranged in the heat exchanger chamber; a plurality of nozzles are arranged at the bottom of the water distribution plate; the right end of the coiled pipe is communicated with a pressurizing pipe; a pressurizing fan is mounted on the pressurizing pipe; a cyclone separator is mounted at the right end of the pressurizing pipe; a conveying pipe is arranged at the top of the cyclone separator; a filtering box is mounted on the conveying pipe; a plurality of filtering screens are arranged in the filtering box. According to the device, the combustion furnace tail gas with characteristics of high temperature and high heat is capable of heating the casing pipe in the coiled pipe and exchanging heat with running water; the bent coiled pipe is capable of prolonging the staying time of the tail gas in the heat exchanger, so that the running water can be fully heated; higher heat transfer efficiency is achieved.

Owner:YANCHENG CIVIL MACHINERY CO LTD

Advanced treatment device for printing and dyeing wastewater

ActiveCN107140760AAvoid jammingEasy to replaceWater treatment compoundsWater contaminantsActivated carbonWater quality

The invention discloses an advanced treatment device for printing and dyeing wastewater. The advanced treatment device comprises a fiber turntable filter tank, an ozone contact tank, a filter tank, a reaction tank, a sedimentation tank and a waterstorage tank which are connected in sequence, wherein the ozone contact tank is connected with an ozone preparation device; the ozone preparation device is connected with an oxygen preparation device; tail gas breaking devices are arranged on both of the ozone contact tank and the filter tank; 3 extension boards are distributed at intervals in the ozone contact tank; the lower ends of the extension boards are fixedly connected with the lower wall of the ozone contact tank, so as to divide the ozone contact tank into a first tank body, a second tank body and a third tank body; an aeration device is arranged at the bottom of each of the first tank body, the second tank body and the third tank body; the aeration devices are connected with theozone preparation device. The advanced treatment device effectively improves the outlet water quality through the synergistic effect of powdered activated carbon and a flocculant, ensures that wastewater can meet the requirement of primary B drainage after being treated, andis good in water treatment effect, simple in technical operation and low in operation cost.

Owner:SHAOXING HEQIAO JIANGBIN WATER TREATMENT

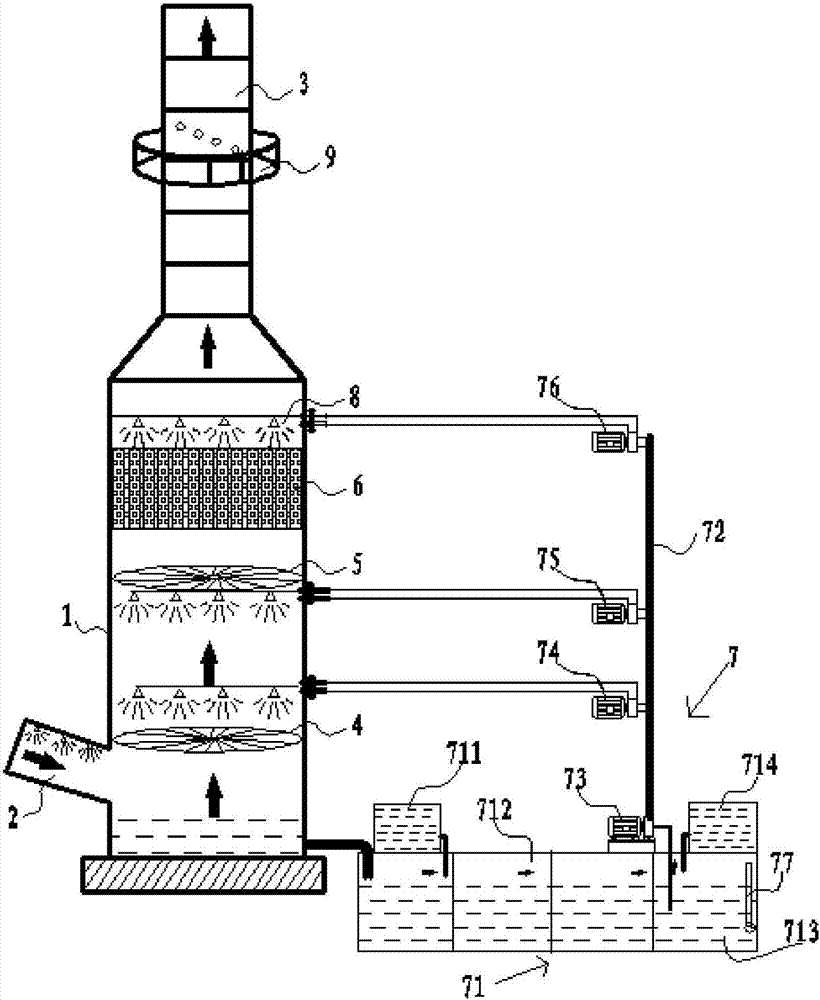

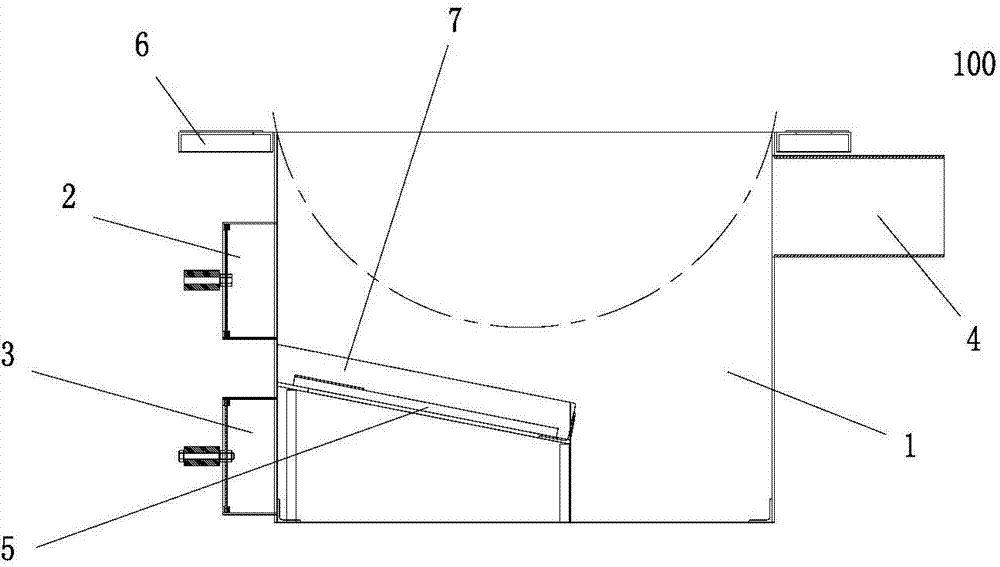

Desulfurizing and dedusting system

InactiveCN107213764ARealize environmentally friendly emissionsReduce sulfur dioxide contentGas treatmentUsing liquid separation agentSulfurBiochemical engineering

The invention discloses a desulfurizing and dedusting system. The desulfurizing and dedusting system comprises a tower body, a flue gas inlet, a discharging outlet, a first-stage desulfurizing layer, a second-stage desulfurizing layer, a third-stage desulfurizing layer and a circulating water system, wherein the flue gas inlet is formed in one side of the bottom part of the tower body; the first-stage desulfurizing layer, the second desulfurizing layer and the third-stage desulfurizing layer are arranged in the tower body from bottom to top; the circulating water system is respectively connected with the first-stage desulfurizing layer, the second desulfurizing layer and the third-stage desulfurizing layer; the third-stage desulfurizing layer is a biological membrane layer. The third-stage desulfurizing layer is filled with a biological membrane, and the biological membrane is small in gaps, so that flue gas is in full contact reaction with liquid medicine, dust is not easy to pass, and the liquid medicine attached to the biological membrane can drop down after being adhered to the dust; the biological membrane layer is 1 to 2 m in height, the adsorption effect is good, exhaust gas passing through the biological membrane is greatly purified, and national standard is met.

Owner:FOSHAN XINLICHENG MECHANICAL & ELECTRICAL EQUIP CO LTD

Waste gas treatment device and waste gas treatment device based on liquid nitrogen condensation

InactiveCN110871026AUncontrolled escapeAvoid safety accidentsGas treatmentDispersed particle separationSprayerExhaust fumes

The invention relates to technical field of waste gas treatment and discloses a waste gas treatment device and a waste gas treatment device based on liquid nitrogen condensation. The waste gas treatment device includes: a first condensation tank (20), in which a condensation structure is arranged, and on which an oil gas inlet (21) and an oil gas outlet (22) are formed; a second condensation tank(30), in which a sprayer is formed, wherein a gas feeding pipe (33) is connected to the side wall of the lower part and a gas discharge pipe (36) is connected to the top, the gas feeding pipe (33) being connected to the oil gas outlet (22); and a liquid nitrogen storage tank (40) connected to the sprayer via a liquid nitrogen pipeline (41). The waste gas treatment device allows two-stage condensation on waste gas, thereby purifying the discharged VOCs waste gas from a construction operation process of one-time pollution gas emission. The device can prevent uncontrolled escape of the pollutiongas, so that the device not only prevents safety accidents but also achieves environment-friendly discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

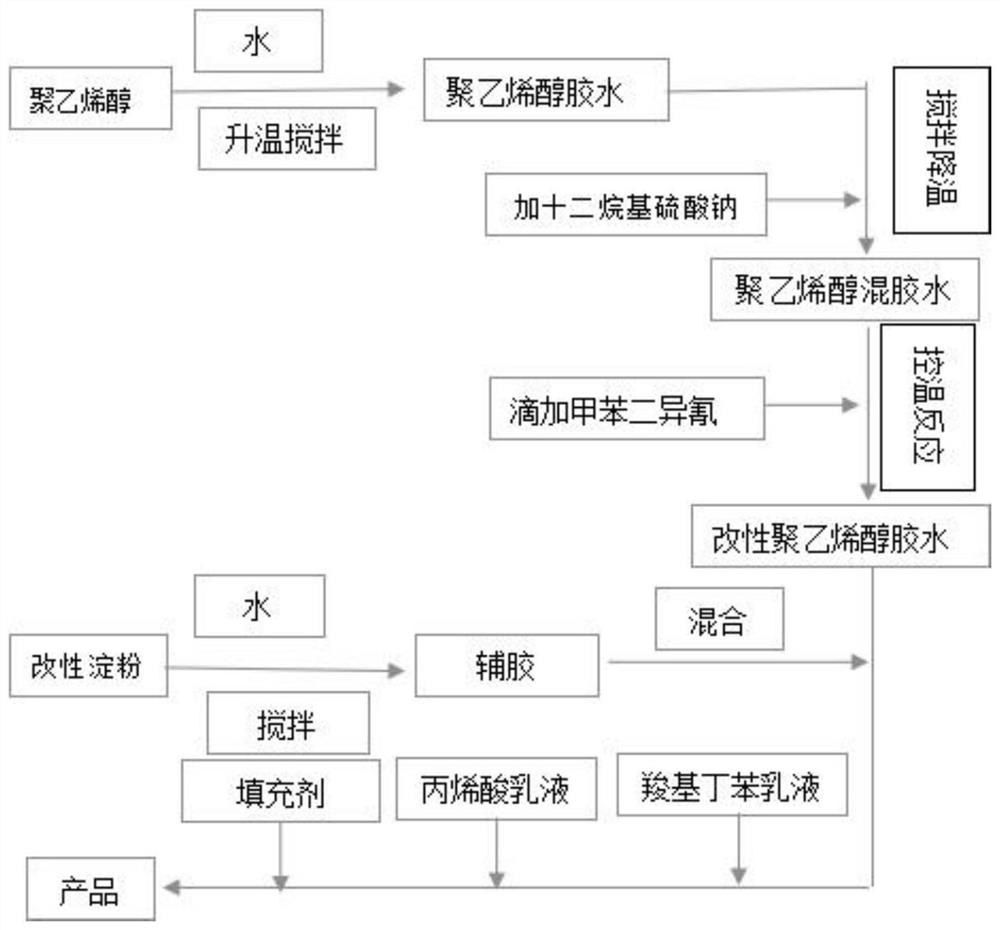

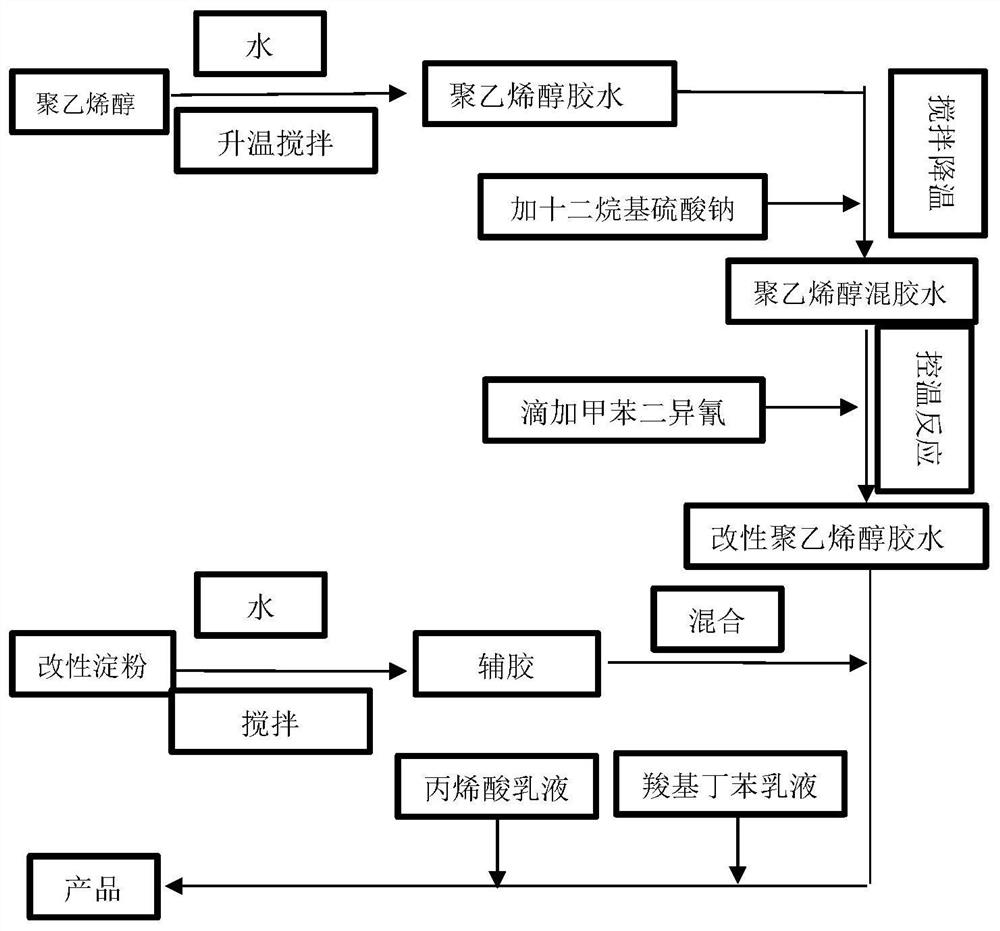

Water-based adhesive prepared by adding filler, and preparation method thereof

InactiveCN112111243AExtended opening hoursRealize environmentally friendly emissionsNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

The invention discloses a water-based adhesive added with a filler, and a preparation method of the water-based adhesive, and belongs to the technical field of fine polymer chemical engineering. According to the invention, the water-based adhesive is a water-based formaldehyde-free glue, and can achieve be formaldehyde-free, wherein only water vapor is released in the whole production and manufacturing process, so that the environment-friendly emission of a factory is realized; under the condition that raw materials of an existing adhesive are reduced, an auxiliary adhesive prepared from the water-based adhesive of the invention is used for preparing an adhesive with low cost, so that the material cost is reduced to about 2100 from original about 3200, and the bonding strength is not affected; by adding acrylic emulsion, the opening time of the adhesive is successfully increased from 20 minutes to 90 minutes, and the bonding strength is not changed after time delay; the use amount of flour is reduced, so that at least one million tons of flour can be saved for the country; and the filling agent mainly comprises mineral substances, the added filling agent can be used for uniformly coating the water-based glue on the plate, and the bonding strength is not changed.

Owner:杨益成

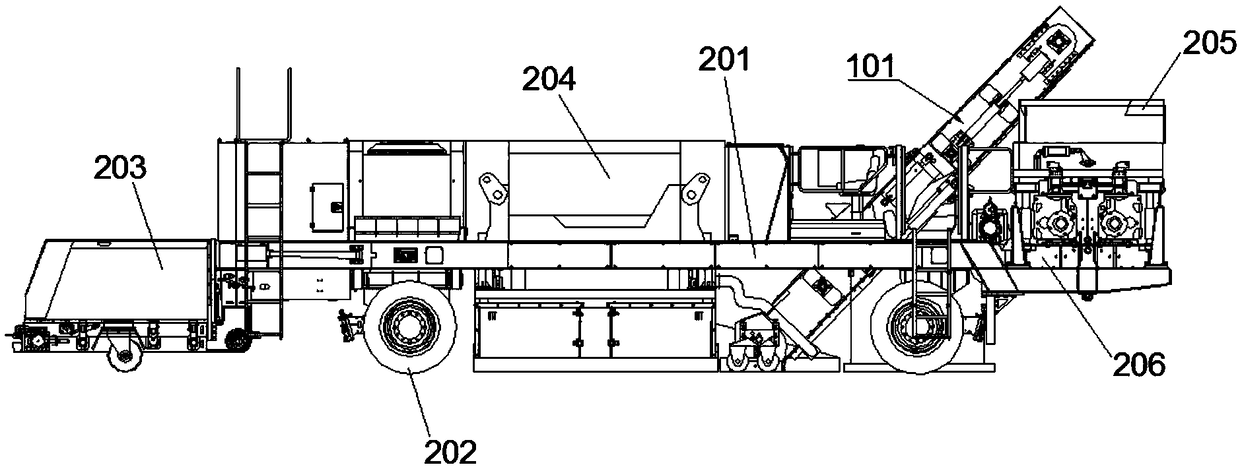

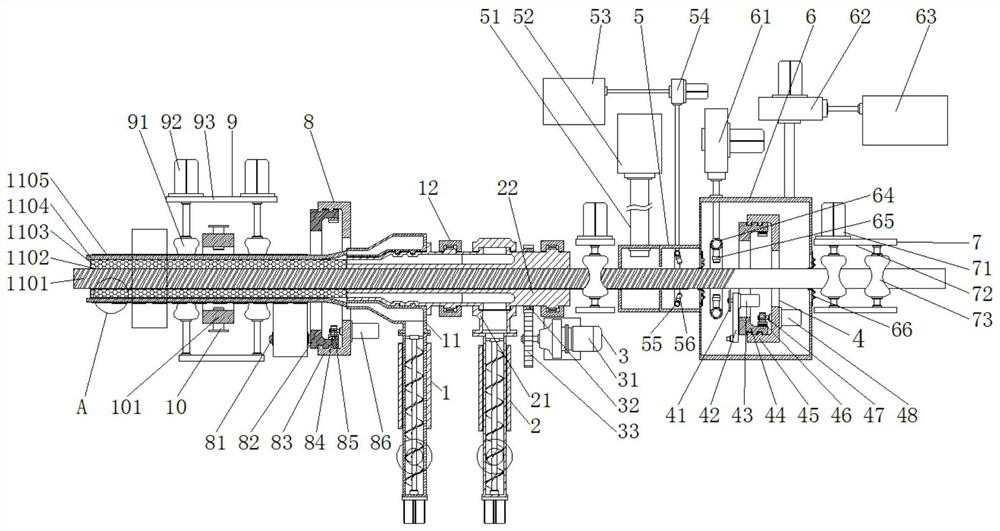

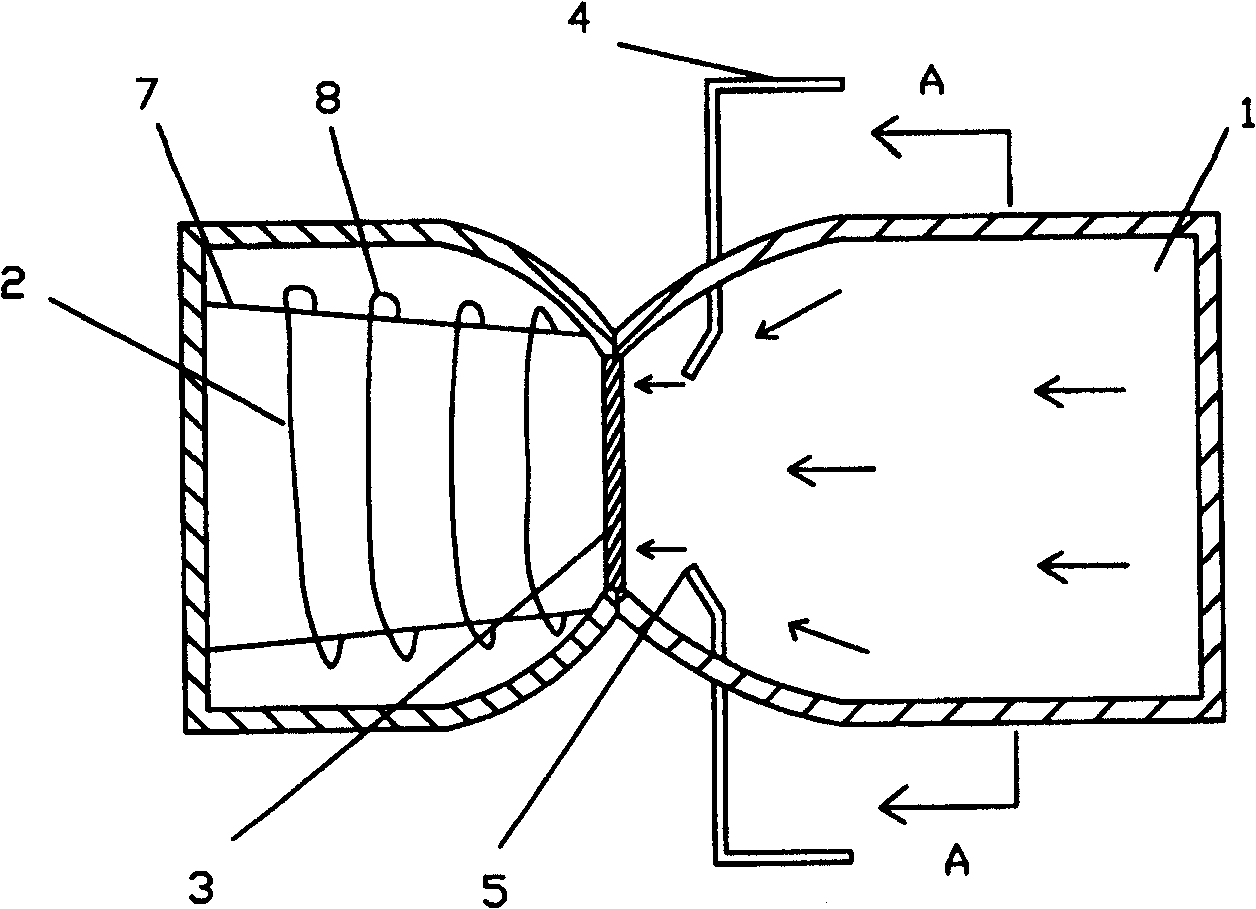

In-place hot recycling device for continuous mobile construction

The invention discloses an in-place hot recycling device for continuous mobile construction. The in-place hot recycling device comprises a flat vehicle body, wherein idler wheels are arranged on the bottom of the flat vehicle body; a hopper device is arranged on the front part of the flat vehicle body; a heating device is arranged on the flat vehicle body; a material carrying device is arranged onthe flat vehicle body and on the rear side of the heating device; a stock bin device is arranged on the rear side of the material carrying device and is located under the top of the material carryingdevice; a mixing vat device is arranged under the stock bin device. The invention firstly realizes mobile intermittent stirring at home and abroad; grading of asphalt concrete after heating and milling of pavement is realized; heat flow impact circular heating of exposed pavement after milling is realized; efficient circular treatment for visible pitch gas is realized; organized environment-friendly emission of circular flue gas is realized; high-efficient and energy-saving heating is realized; working heat preservation of working device is realized; starting preheating of working device is realized; promotion for milling asphalt concrete and grading asphalt concrete is realized.

Owner:嘉鹏再升科技(深圳)股份有限公司

Environment-friendly bolt-free adhesive with long opening time and preparation method thereof

ActiveCN112080226ARealize environmentally friendly emissionsExtended opening hoursNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive glueAdhesive cement

The invention discloses an environment-friendly bolt-free adhesive with long opening time and a preparation method thereof, which belong to the technical field of fine polymer chemical engineering. The adhesive disclosed by the invention is water-based formaldehyde-free glue, so that a product can be formaldehyde-free, only water vapor is released in the whole production and manufacturing process,and the environment-friendly emission of a factory is realized; under the condition that raw materials of an existing adhesive are reduced, the auxiliary adhesive prepared through the method is usedfor preparing the adhesive with low cost, the material cost is reduced to about 2100 from original about 3200, and the bonding strength is not affected; by adding an acrylic emulsion, the opening timeof the glue is successfully increased from 20 minutes to 90 minutes, and the bonding strength is not changed after time delay.

Owner:杨益成

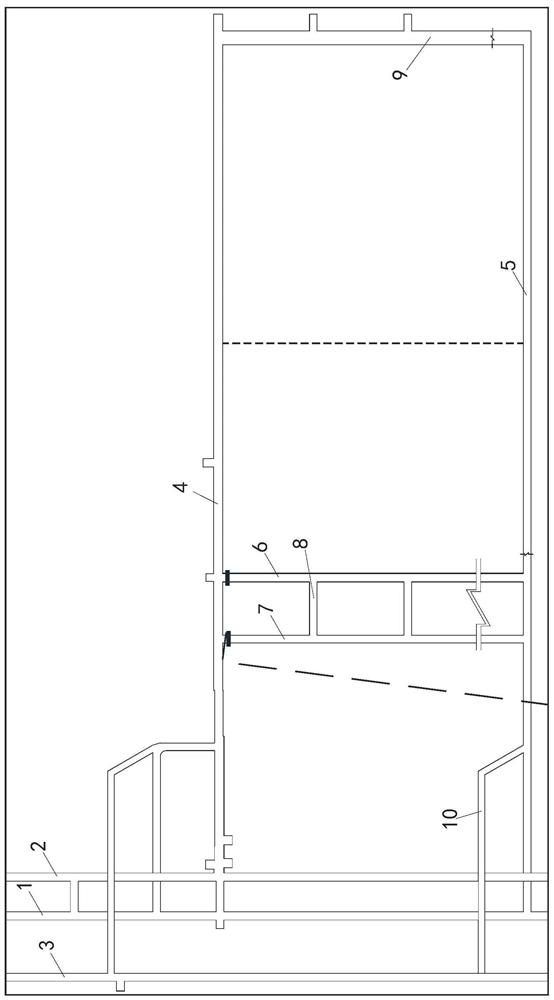

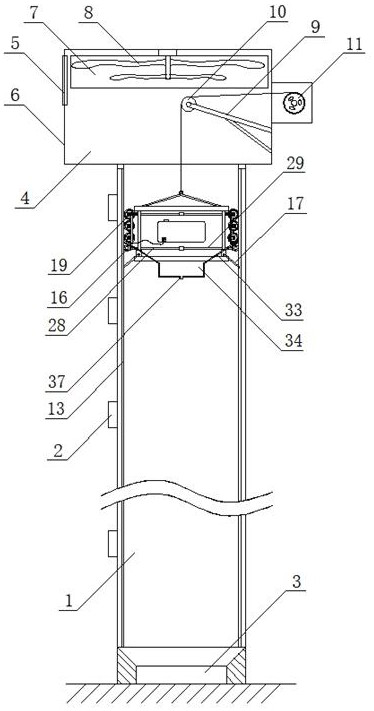

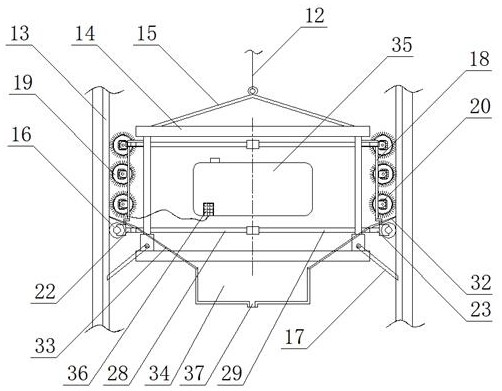

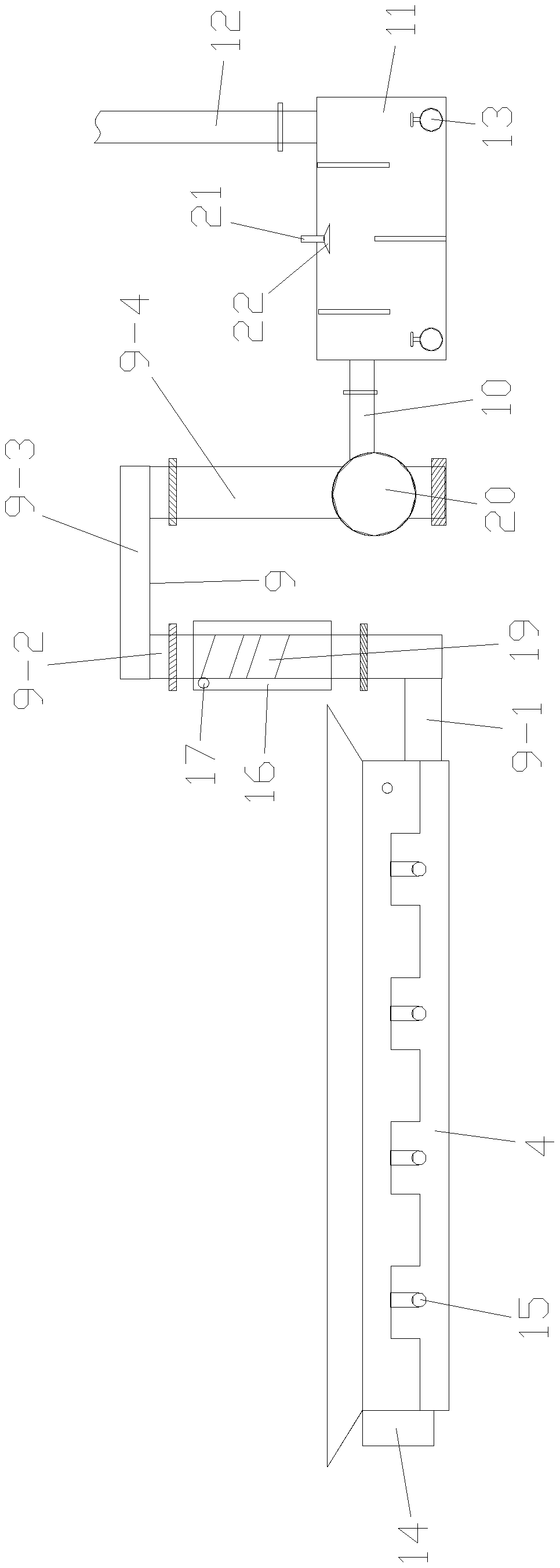

Environment-friendly high-rise building public flue structure and flue cleaning system

ActiveCN113531610ARealize environmentally friendly emissionsHigh efficiency filterabilityDomestic stoves or rangesLighting and heating apparatusSewageMechanical engineering

An environment-friendly high-rise building public flue structure and a flue cleaning system comprise a flue vertical shaft (1). The environment-friendly high-rise building public flue structure and a flue cleaning system are characterized in that vertical sliding rails (13) are fixedly arranged on the inner side wall of the flue vertical shaft (1), movable beams are installed on the outer sides of the four faces of the lower end of a machine frame (14) respectively, a telescopic adjusting mechanism is installed between every two opposite movable beams, one or more rotary cleaning cylinders (19) are horizontally arranged on a cleaning cylinder mounting seat (18), an elastic scraping plate (32) corresponding to the side wall of the flue vertical shaft (1) is arranged at the lower end of each movable beam, and a sewage collecting cover (33) with certain elasticity is arranged on the movable beams and the machine frame (14). The structure is reasonable, the structure and the system can enter a flue to perform automatic cleaning, cleaning sewage can be collected, a very good descaling and cleaning effect is achieved, lampblack and dirt are prevented from blocking a smoke exhaust channel, and meanwhile the fireproof safety performance is improved.

Owner:湖北全洲扬子江建设工程有限公司

Automobile exhaust gas treatment device

InactiveCN109611179ARealize secondary filter dischargeImprove protection efficiencyExhaust apparatusSilencing apparatusEngineeringRoad traffic

The invention discloses an automobile exhaust gas treatment device, and belongs to the field of automobile exhaust gas treatment. The automobile exhaust gas treatment device comprises an automobile exhaust gas pipe. The outer surface of the automobile exhaust gas pipe is fixedly connected with the middle part of a fixed clamping seat, threaded rods are connected to the periphery of the side edgesof the fixed clamping seat in a threaded mode, and an inserting slot is formed in the periphery of the inner side surfaces of the fixed clamping seat. The inserting slot is matched with an inserting plate, the inserting plate is fixedly connected with the inner side surface of a connecting clamping seat, penetrating holes are formed in the outer surfaces of the periphery of the inserting plate, and the penetrating holes are matched with the threaded rods. The middle part of the connecting clamping seat is fixedly connected with the outer surface of a gas inlet pipe, one end of the gas inlet pipe is matched with the automobile exhaust gas pipe, the other end of the gas inlet pipe is fixedly connected with one side of an exhaust gas treatment tank, the other side of the exhaust gas treatmenttank is fixedly connected with an exhaust pipe, and a water receiving tank pipe is fixedly connected to the bottom surface of the exhaust gas treatment tank. The automobile exhaust gas treatment device is convenient to install and disassemble, solves the problem that water discharged from the automobile exhaust gas is sprayed on the ground, the impact on the road traffic operation is reduced, andenvironmental protection discharge can be realized and the environment is protected.

Owner:LINYI UNIVERSITY

Combustion furnace tail gas purification treatment utilizing device

InactiveCN107421354AFully heatedExtended stayCombination devicesRecuperative heat exchangersCombustionEngineering

A combustion furnace tail gas purification treatment utilizing device comprises a heat exchanging chamber, and is characterized in that the outer surface of the heat exchanging chamber is covered with heat preserving cotton; a bent coiled pipe is arranged in the heat exchanging chamber; a gas inlet is formed in the left end of the coiled pipe; the exterior of the coiled pipe is sleeved with a sleeve; the surface of the sleeve is evenly provided with a plurality of heat exchanging leakage holes; a water distributing disk is arranged in the heat exchanging chamber; a plurality of spraying heads are arranged at the bottom of the water distributing disk; the right end of the coiled pipe is communicated with a pressure boosting pipe which is provided with a pressure boosting draught fan; a cyclone separator is installed at the right end of the pressure boosting pipe; a conveying pipe is arranged on the top of the cyclone separator, and is provided with a filtering box; and a plurality of filtering nets are arranged in the filtering box. Tail gas with a high temperature and high heat characteristic exists in the coiled pipe of the combustion furnace tail gas purification treatment utilizing device to heat the sleeve, and exchanges heat with tap water, the staying time of the tail gas in the heat exchanging chamber is prolonged by the bent coiled pipe, so that the tap water can be sufficiently heated, and the heat transfer efficiency is higher.

Owner:盐城海之诺机械有限公司

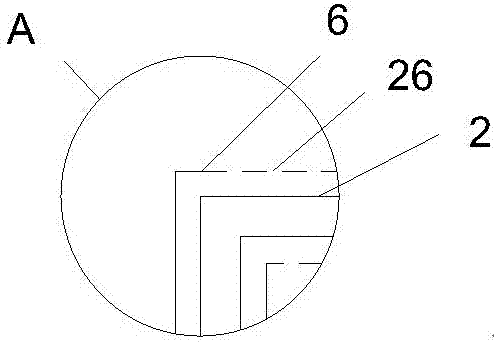

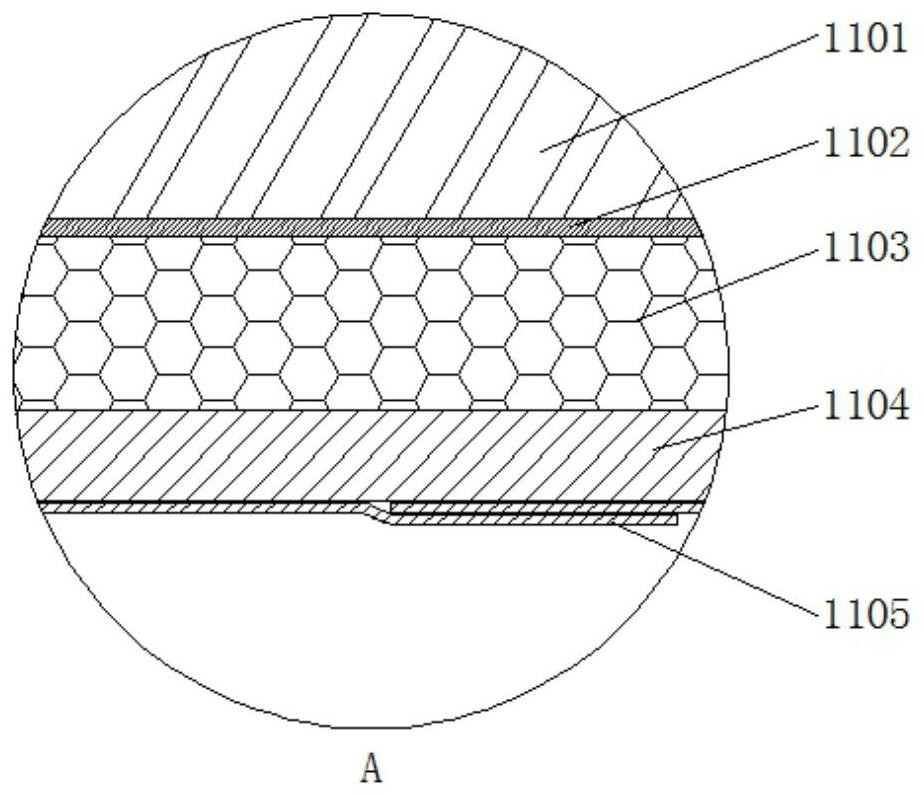

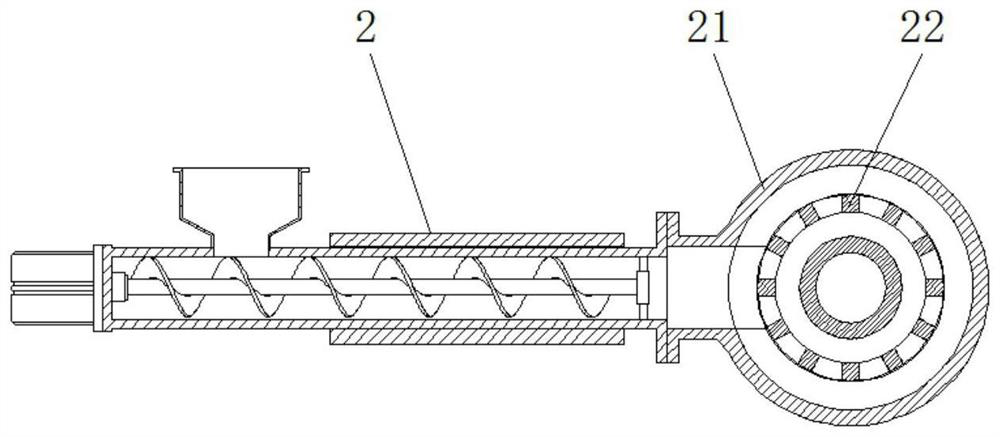

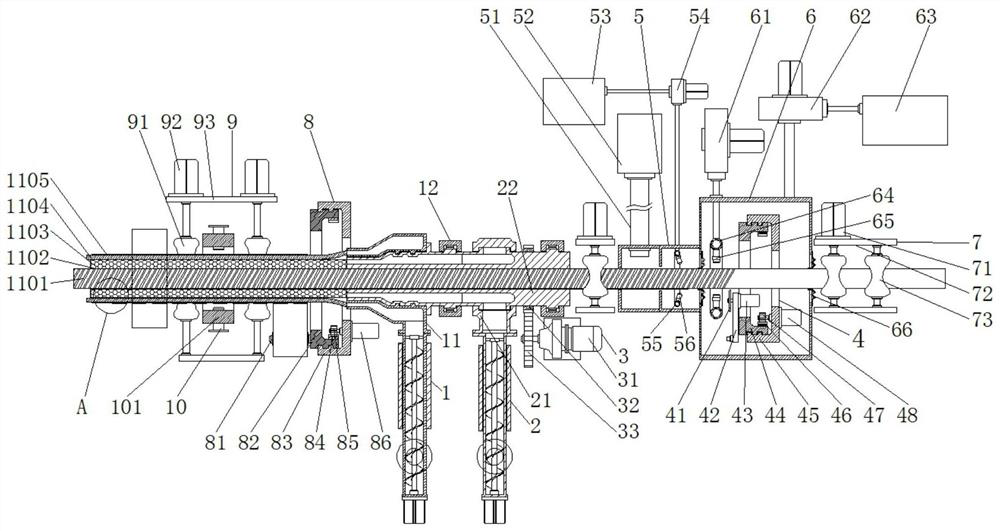

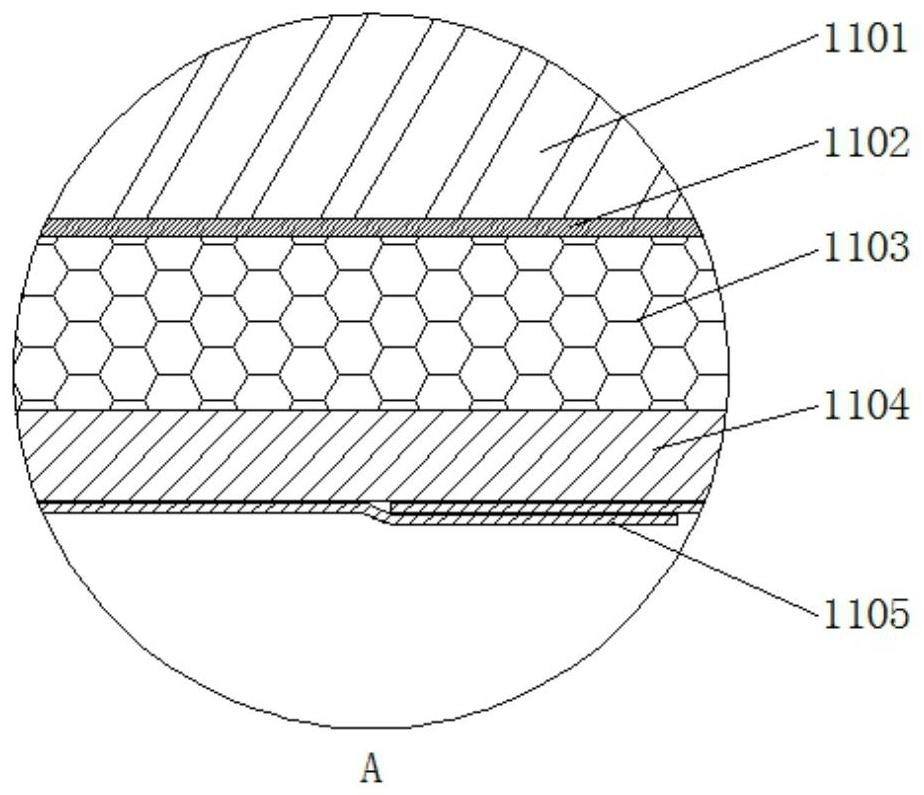

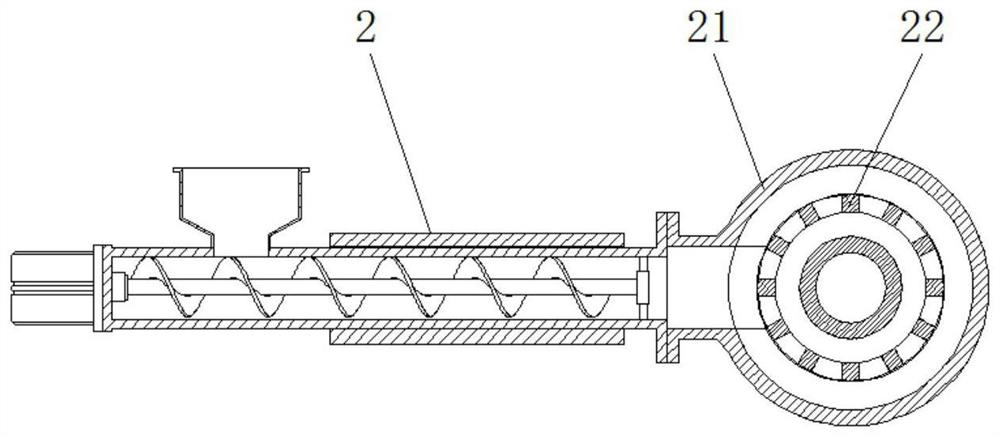

Polyurethane thermal insulation composite tube and forming device thereof

ActiveCN113513638AImprove integrityBond evenly and firmlyThermal insulationPipe protection by thermal insulationPolymer scienceInsulation layer

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to a polyurethane thermal insulation composite tube. The polyurethane thermal insulation composite tube comprises an inner tube, wherein the outer wall of the inner tube is evenly covered with an anti-corrosion layer; the inner tube is sleeved with an outer tube; a polyurethane insulation coating is filled between the anti-corrosion layer on the outer tube and the anti-corrosion layer on the inner tube; the outer tube is wrapped with a thermal insulation layer. A forming device of the polyurethane thermal insulation composite tube comprises a foaming extrusion machine head, wherein a round hole matched with the diameter of an inner tube is formed in the middle of the foaming extrusion machine head, the foaming extrusion machine head is rotationally sleeved with an outer tube extrusion machine head, and a spraying box is arranged at one side of the tail end of the foaming extrusion machine head. By means of the matching structure of the foaming extrusion machine head and the outer tube extrusion machine head, the inner tube can penetrate through, meanwhile, wrapping and covering of the outer tube and filling of the polyurethane insulation coating are conducted, the inner tube, the polyurethane insulation coating and the outer tube are synchronously formed in a section of area, higher efficiency is achieved, and the integrity of the tube is higher after the tube is formed.

Owner:浙江天诚绝热科技股份有限公司

Energy-saving method for denitrogenation of horizontal chained coal fired boiler

InactiveCN1843573ALower oxygen levelsReduce contentDispersed particle separationNon-combustible gases/liquids supplyFresh airNitrogen

The invention discloses a denitrogenation energy-saving method of horizontal chain coal-fired boiler, which comprises: (1) feeding the smoke discharged from the smoke channel of boiler into the fan of boiler, and via adjusting the rate between the smoke and the fresh air to control the oxygen content and control the burning speed of coal, therefore, it can realize the control on the temperature of furnace; (2) guiding fresh air into the interface between the main furnace and the heat exchanging chamber, or the part of smoke channel whose temperature is not less than 700Deg. C, to mix the fresh air and the boiler gas discharged from the main furnace, and using the oxygen of fresh air to fully burn the fuel gas of boiler gas. The inventive method can effectively reduce the discharged gas amount of smoke and the NOx content of smoke, to realize the utilization on the left heat of part smoke, and the environment-friendly discharge of industrial boiler.

Owner:北京布鲁斯盖环保科技发展有限公司

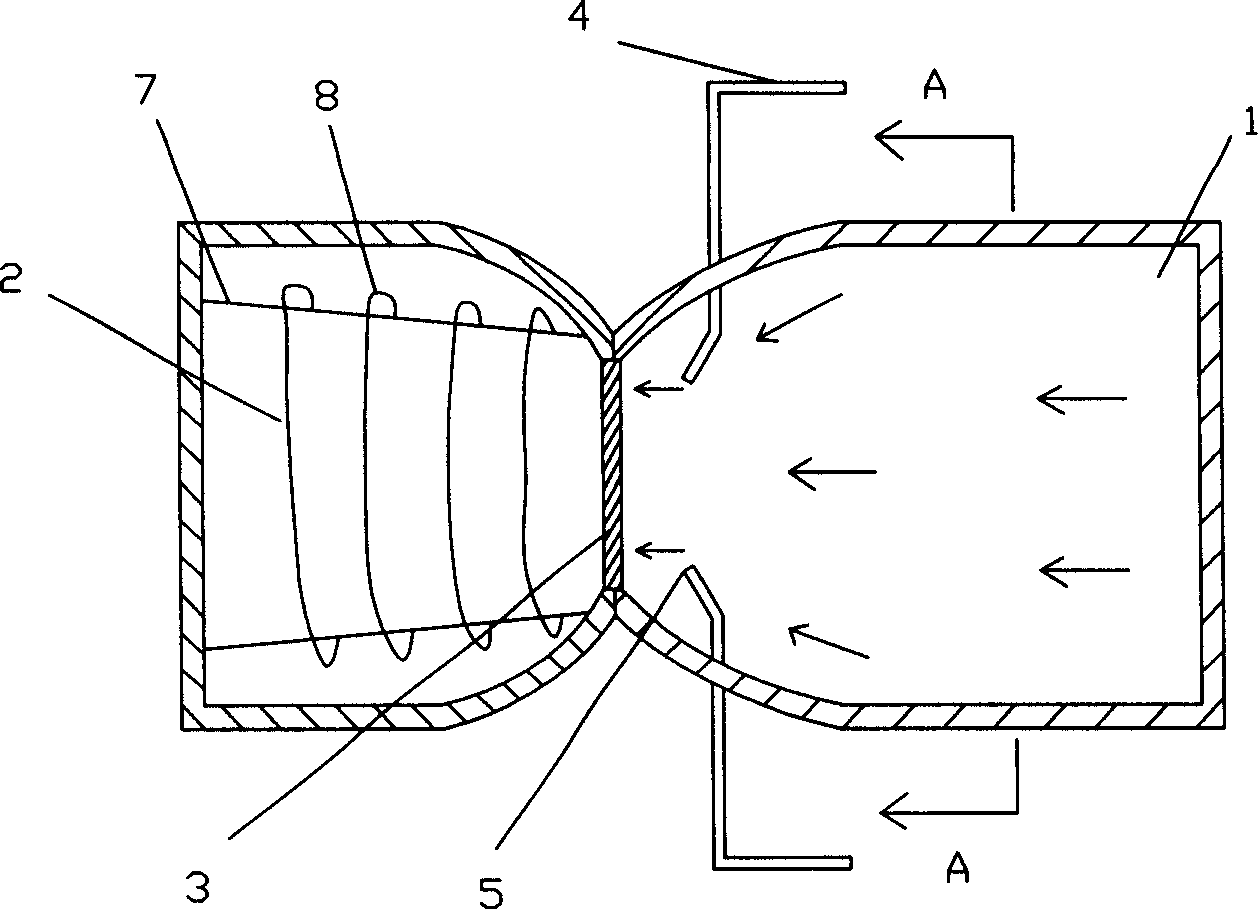

Oil gas treatment device and oil gas treatment method for oil gas tank based on liquid nitrogen condensation

InactiveCN110871024ATreatment and purificationAvoid safety accidentsGas treatmentDispersed particle separationTemperature controlSprayer

The invention relates to the technical field of oil gas treatment and discloses an oil gas treatment device and an oil gas treatment method for an oil gas tank based on liquid nitrogen condensation. The oil gas treatment device includes: a condensation tank (20) which includes an oil gas inlet (22), a gas discharge pipe (35) and a grating plate (25) that is disposed therebetween in height direction to separate the interior of the condensation tank (20) into a first condensation chamber (21) and a second condensation chamber (31), wherein a condensation structure is arranged inside the first condensation chamber and a second sprayer (32) is arranged in the second condensation chamber; and a liquid nitrogen storage tank (40) connected to a second feeding pipe via a liquid nitrogen pipeline (41). The oil gas successively passes through the first condensation chamber and the second condensation chamber, of which the temperatures are controlled to be different, so that the oil gas can be purified, thereby preventing uncontrolled escape and achieving environment-friendly emission.

Owner:CHINA PETROLEUM & CHEM CORP +1

Forming device for polyurethane thermal insulation composite pipe

ActiveCN113513638BImprove integrityBond evenly and firmlyThermal insulationPipe protection by thermal insulationPolymer scienceInsulation layer

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to polyurethane thermal insulation composite pipes, including an inner pipe, the outer wall of the inner pipe is evenly covered with an anti-corrosion layer, and an outer pipe is provided on the outer wall of the inner pipe, and the anti-corrosion layer on the outer pipe and the inner pipe The polyurethane insulation layer is filled in between, and the outer pipe is covered with a heat insulation layer. The molding device of the polyurethane insulation composite pipe includes a foaming extrusion head, and the middle of the foaming extrusion head is provided with an inner pipe. Round holes with matching diameters, and an outer tube extruder head is set on the outer rotating sleeve of the foam extruder head, and a spray box is arranged on the tail end side of the foam extruder head. The present invention can realize the wrapping and covering of the outer pipe and the filling of the polyurethane insulation layer while the inner pipe passes through the matching structure of the foam extrusion head and the outer pipe extrusion head, so that the inner pipe, the polyurethane insulation layer and the The outer tube is formed synchronously in a certain area, which is more efficient and makes the integrity of the tube higher after forming.

Owner:浙江天诚绝热科技股份有限公司

Energy-saving method for denitrogenation of horizontal chained coal fired boiler

InactiveCN100431670CLower oxygen levelsReduce the temperatureDispersed particle separationNon-combustible gases/liquids supplyFresh airCombustible gas

The invention discloses a denitrogenation energy-saving method of horizontal chain coal-fired boiler, which comprises: (1) feeding the smoke discharged from the smoke channel of boiler into the fan of boiler, and via adjusting the rate between the smoke and the fresh air to control the oxygen content and control the burning speed of coal, therefore, it can realize the control on the temperature of furnace; (2) guiding fresh air into the interface between the main furnace and the heat exchanging chamber, or the part of smoke channel whose temperature is not less than 700Deg. C, to mix the fresh air and the boiler gas discharged from the main furnace, and using the oxygen of fresh air to fully burn the fuel gas of boiler gas. The inventive method can effectively reduce the discharged gas amount of smoke and the NOx content of smoke, to realize the utilization on the left heat of part smoke, and the environment-friendly discharge of industrial boiler.

Owner:北京布鲁斯盖环保科技发展有限公司

Automatic efficient energy-saving sterilization machine special for shiitake mushroom sticks

PendingCN109429908ACompact designIncrease the heating areaCultivating equipmentsMushroom cultivationFlue gasEngineering

The invention relates to an automatic efficient energy-saving sterilization machine special for shiitake mushroom sticks. The sterilization machine comprises an outer furnace body and an inner hearthmounted in the outer furnace body, the inner hearth is provided with a liquid inner hearth body and a heating inner hearth body mounted in the liquid inner hearth body, a first water inlet pipe communicated with the interior of the liquid inner hearth body is mounted on the outer peripheral surface of the lower end of the outer furnace body, and a circle of edge covers are mounted at the upper endof the outer furnace body; the liquid inner hearth body is separated from the heating inner hearth body through partition plates, the heating inner hearth body is connected to a flue gas output pipe,the lower end of the flue gas output pipe is connected to a dust guiding pipe, the right tail end of the dust guiding pipe is connected to a dust removing pool, a smoke discharge pipe is mounted at the upper end of the dust removing pool, and a pair of sewage discharge ports are formed in the lower end of the dust removing pool; a control cabinet is mounted on the outer peripheral surface of theouter furnace body. The automatic efficient energy-saving sterilization machine special for the shiitake mushroom sticks is compact in structural design, large in heating area, long in flue gas flow,good in heat transfer effect, low in smoke discharge temperature and running cost, capable of ensuring the purity of flue gas and realizing environment-friendly emission and worthy of popularization.

Owner:庆元县菇星节能机械有限公司

Large stove and application method thereof

InactiveCN104713135ABig hearthEasy to cookDomestic stoves or rangesLighting and heating apparatusFlueExhaust gas

The invention discloses a large stove and an application method thereof. The large stove comprises a hearth encircled by the side wall of a stove body and used for combusting fuels, wherein a fire hole capable of being positioned at the bottom of a pot is arranged above the hearth; a flue outlet for leading out combustion tail gas is formed in the side wall of the stove body; a feed port and an ash cleaning port leading to the insideof the hearth are formed in the side wall of the furnace body; the feed port is higher than the ash cleaning port; a grate is arranged in the hearth corresponding to the feed port, and is provided with a stacking area for concentrating particle-shaped biomass fuels; the area of the stacking area is smaller than the area of the fire hole; and an air supply grille is formed below the grate. The large stove and the application method thereof are suitable for concentrated combustion of the particular-shaped biomass fuels, prevent the atmospheric pollution, and improve the combustion efficiency.

Owner:车战斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com