Waste gas treatment device and waste gas treatment device based on liquid nitrogen condensation

A waste gas treatment device and waste gas technology, which are applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of no process and scheme, fire explosion, polluting gas discharge, etc., to prevent uncontrolled escape and prevent safety Accidents, the effect of achieving environmentally friendly emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

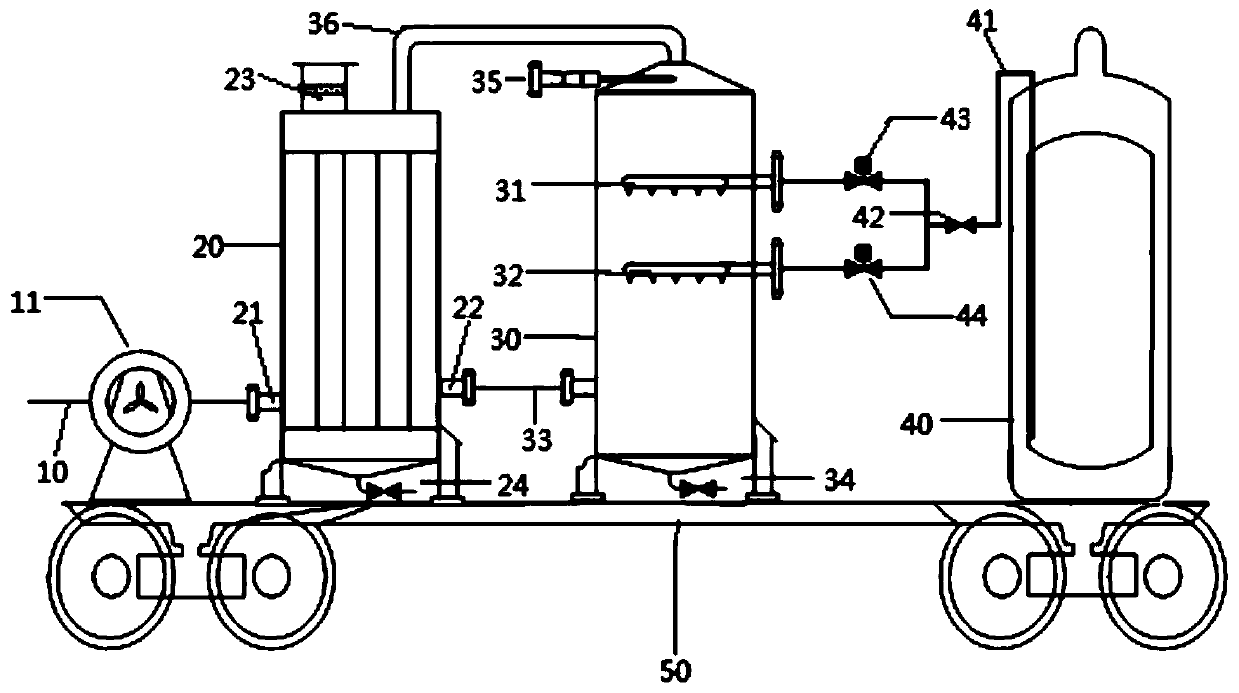

[0071] Such as figure 1 As shown, the exhaust gas treatment device includes a suction pipe 10 , a fan 11 , a first condensation tank 20 , a second condensation tank 30 and a liquid nitrogen storage tank 40 connected in sequence.

[0072] Wherein, the first condensing tank 20 is provided with a waste gas inlet 21 and a waste gas outlet 22, the waste gas inlet 21 and the waste gas outlet 22 are all arranged at the bottom of the first condensation tank 20, the waste gas inlet 21 is connected with the suction pipe 10, and the waste gas outlet 22 communicates with the inside of the second condensation tank 30 through the gas delivery pipe 33 connected to the bottom of the second condensation tank 30 . The inside of the first condensation tank 20 includes a condensing structure, the condensing structure is a cooler, the shell side inlet of the cooler is connected to the waste gas inlet 21, the shell side outlet is connected to the waste gas outlet 22, and the tube side inlet is conn...

Embodiment 2

[0080] The waste gas treatment device adopts the same structure as that of Example 1.

[0081] In addition, in the first condensation tank 20, the operating conditions of the cooler are as follows: the inlet temperature of the tube side is minus 70°C, the outlet temperature of the tube side is minus 35°C, and the pressure is 2kpa; the inlet temperature of the shell side is normal temperature, and the outlet temperature of the shell side is The temperature is minus 35°C and the pressure is 3kp. In the second condensation tank 30, the temperature inside the second condensation tank 30 is maintained at minus 90°C.

[0082] Based on the exhaust gas treatment device of the above preferred embodiment, and under the above operating conditions, when the VOCs exhaust gas concentration at the exhaust gas inlet 21 is 34% VOL, the VOCs exhaust gas concentration at the tube side outlet is 50% LEL, and the exhaust gas treatment efficiency is 98.93%.

Embodiment 3

[0084] The waste gas treatment device adopts the same structure as that of Example 1.

[0085] In addition, in the first condensation tank 20, the operating conditions of the cooler are as follows: the inlet temperature of the tube side is minus 80°C, the outlet temperature of the tube side is minus 40°C, and the pressure is 2kpa; the inlet temperature of the shell side is normal temperature, and the outlet temperature of the shell side is The temperature is minus 35°C and the pressure is 3kp. In the second condensation tank 30, the temperature inside the second condensation tank 30 is maintained at minus 90°C.

[0086] Based on the above exhaust gas treatment device and under the above operating conditions, when the VOCs exhaust gas concentration at the exhaust gas inlet 21 is 35% VOL, the VOCs exhaust gas concentration at the tube side outlet is 25% LEL, and the exhaust gas treatment efficiency is 99.14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com