Tail gas treatment device and tail gas treatment method in process of recycling waste printed circuit boards

A printed circuit board and exhaust gas treatment technology, which is applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve problems such as the inability to effectively remove organic gas and metal fume, and achieve the effects of low price, obvious effect and wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

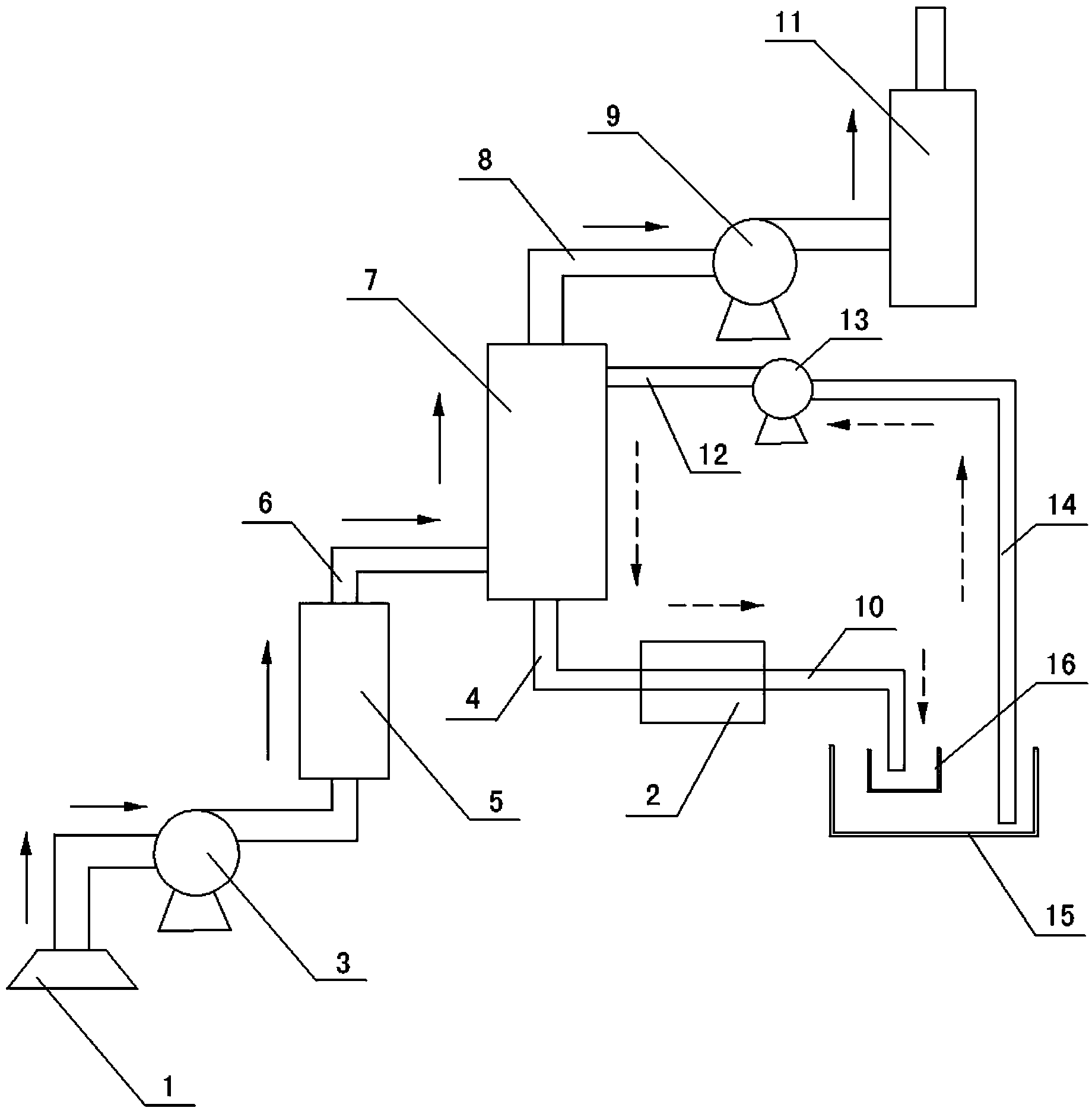

[0037] In the present embodiment, the tail gas treatment method in the waste printed circuit board recycling process is carried out as follows:

[0038] Step 1: The tail gas to be treated is firstly treated by activated carbon adsorption to filter out solid dust (such as glass fiber, calcium carbonate, etc.), heavy metal particles (such as metal particles containing lead, cadmium, mercury, chromium), and some inorganic non-toxic substances in the tail gas. Metal oxides (such as NO 2 , SO 2 etc.) and some organic gases (such as acetone, phenol, etc.), discharge the pretreatment tail gas;

[0039] In this embodiment, the exhaust gas collection cover 1 can be connected to the exhaust gas outlet of the waste printed circuit board recovery equipment, or directly placed on the tin melting equipment, so as to minimize the harmful exhaust gas escaping into the environment; then, by placing The tail gas induced fan 3 in front of the activated carbon adsorption device collects the tai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com