Energy-saving method for denitrogenation of horizontal chained coal fired boiler

A technology for coal-fired boilers and boilers, applied in the field of coal-fired boilers, can solve the problems of complex equipment structure, difficulty in realization, and high cost of nitrogen removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

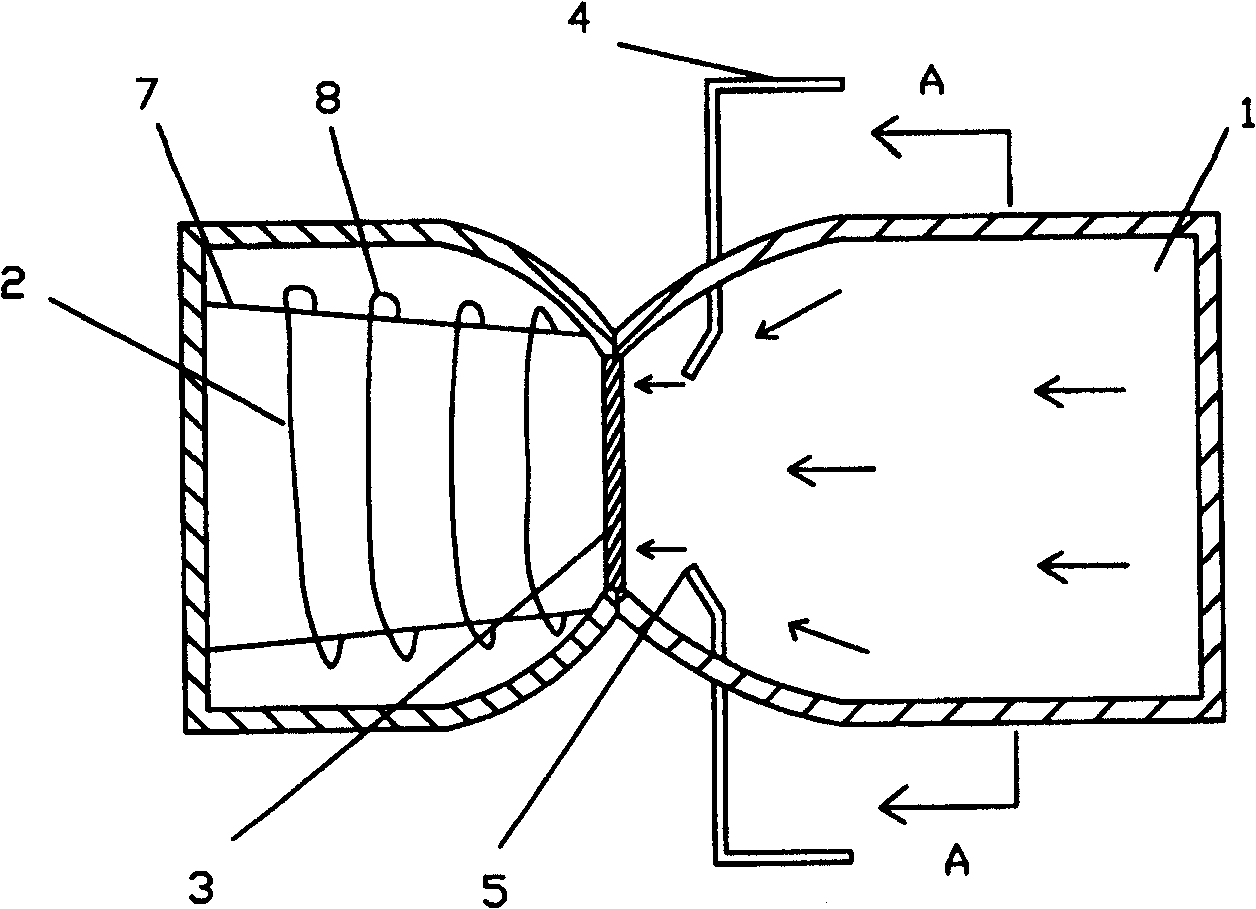

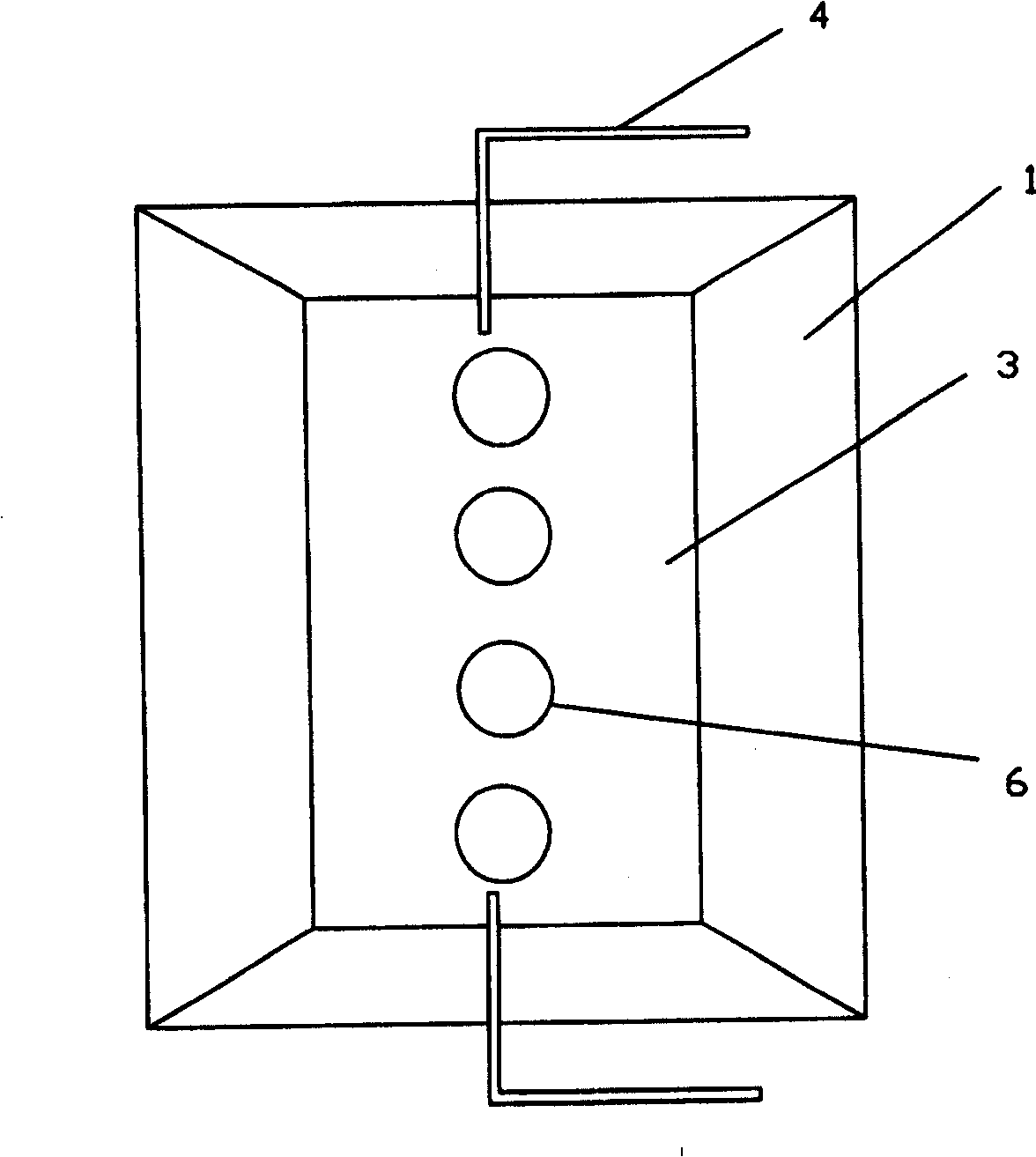

[0017] The horizontal chain coal-fired boiler uses the chain to send the coal into the furnace. Under the chain, the blower is used to provide the air required for coal combustion from the outside of the furnace to the main furnace. It is connected with the main furnace as a heat exchange chamber. The flue gas pipe and the water pipe on the flue gas pipe, the high-temperature flue gas output from the main furnace, transfers heat to the water in the water pipe through the flue gas pipe. The cross-sectional area of the main furnace facing the outlet of the heat exchange chamber will suddenly and gradually decrease. The outlet of the main furnace is trumpet-shaped to reduce the cross-section of the exhaust outlet of the main furnace, so as to accelerate the high-temperature flue gas entering the flue gas pipe in the heating chamber. flow rate. There is a smoke exhaust port on the heating chamber of the boiler, the outlet of the flue gas pipe is connected to the smoke exhaust po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com