Large stove and application method thereof

A stove and furnace body technology, applied in the field of large stoves, can solve the problems of low combustion efficiency, small size, and inability to directly use large stoves, etc., and achieve the effect of small stacking area and large furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

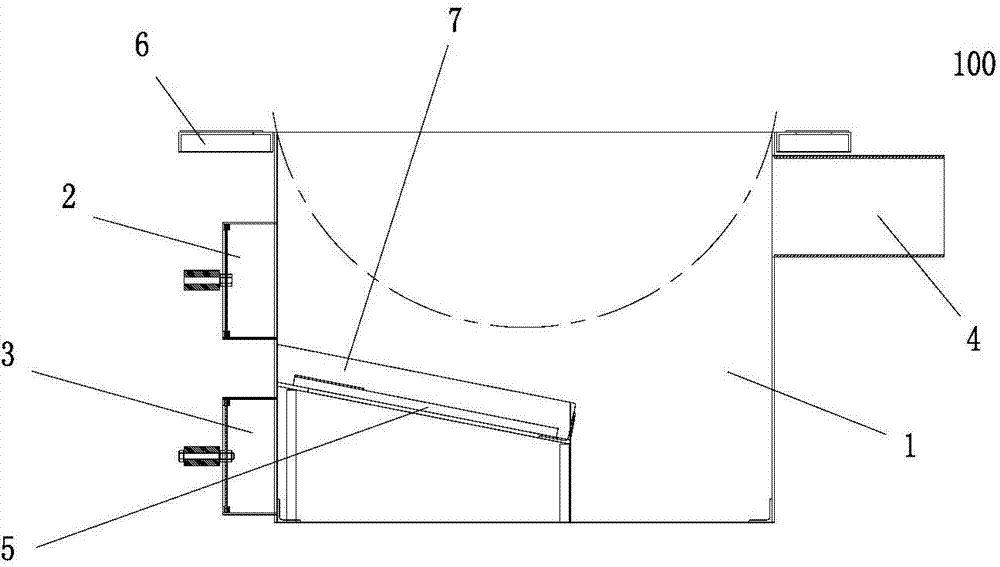

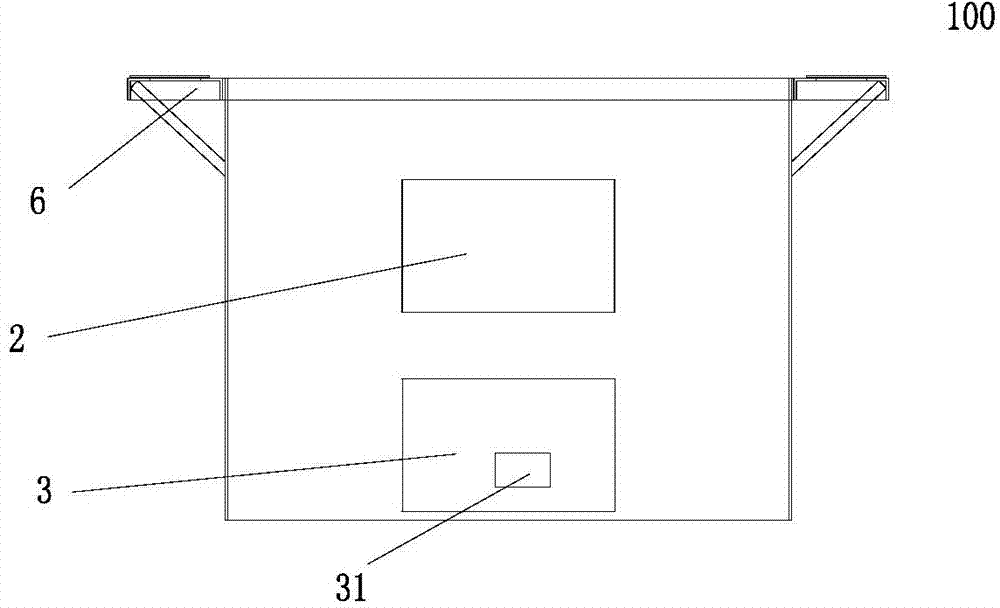

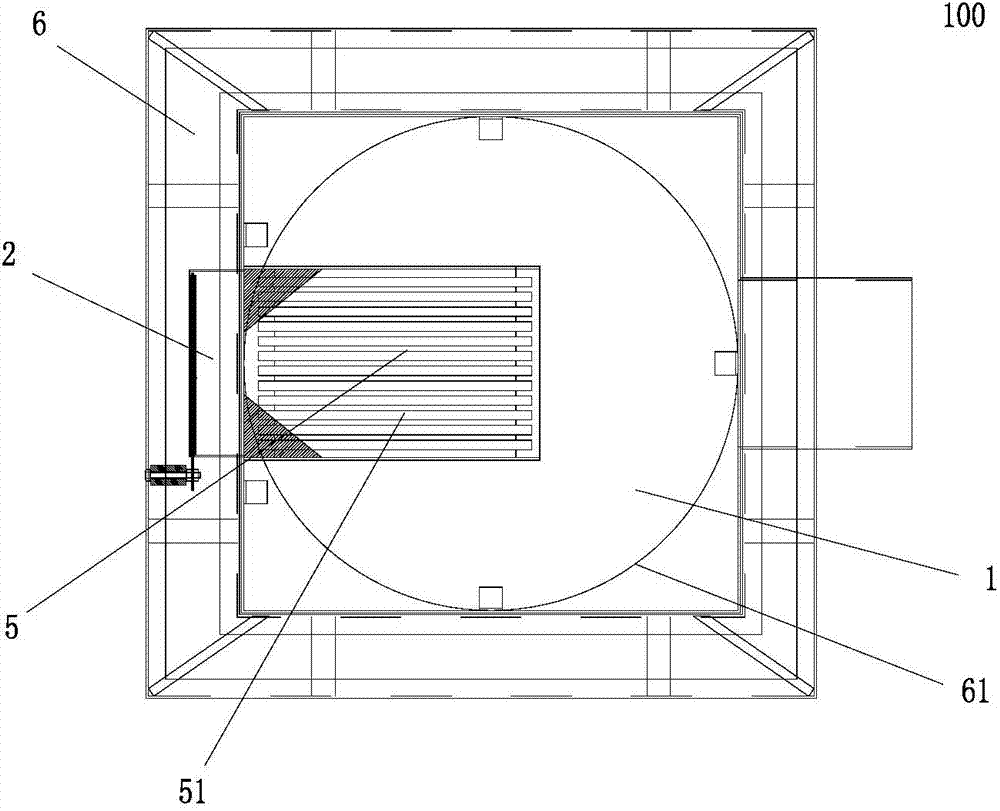

[0042] Such as Figure 1A , Figure 1B and Figure 1C As shown, the present embodiment proposes a large stove 100, which includes a furnace 1 surrounded by the side wall of the furnace body for fuel combustion. Enter the furnace mouth 61 at the bottom of the large firewood pot. Generally speaking, after the large firewood pot is arranged on the furnace mouth 61, the furnace hearth 1 of the large stove can be closed from the top. The side wall of the furnace body is provided with a flue outlet 4 for leading out combustion exhaust gas (the flue outlet 4 can be connected to the heated kang, and can also be directly connected to the chimney). The side wall of the furnace body is provided with a feeding port 2 and a soot cleaning port 3 leading to the furnace, and the feeding port 2 is higher than the soot cleaning port 3 . Corresponding to the feeding port 2, a furnace grate 5 is provided in the furnace, and a stockpiling area 51 for the centralized placement of biomass pellet ...

Embodiment 2

[0061] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that a heat exchange device is provided in the furnace, and the cold water in the heat exchange device is heated while cooking. Such as Figure 2A and Figure 2B As shown, in this embodiment, a water jacket 8 is provided in the furnace 1, and a cold water inlet pipeline and a hot water outlet pipeline are arranged on the water jacket 8, and the hot water outlet pipeline is connected to the hot water supply place to form a heat sink. water circulatory system. During the fuel combustion process, the water in the water jacket 8 can be heated at the same time, thereby providing necessary domestic hot water for people.

[0062] In this embodiment, a heat exchange device is provided in the furnace, and the heat in the furnace is used to heat the cold water in the heat exchange device while cooking to provide domestic hot water.

[0063] Another heat exchange dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com