Range hood with see-through shutter window

A technology of range hoods and transparent baffles, which can be applied to the removal of oil fumes, household stoves/stoves, heating methods, etc. It can solve the problems of wasting energy, affecting the operation of cooks, and not being able to finely cook and fine-tune, so as to achieve a good range fume effect , Easy to cook and do not block the line of sight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

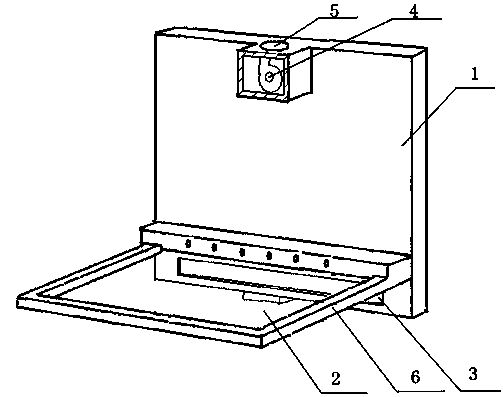

[0019] The device of the present invention is composed of a body 1, a transparent baffle 2 and an induced draft fan 4, the transparent baffle 2 is horizontally installed on the body 1, the inside of the body 1 is a cavity, and a horizontal bar is opened on the body 1 below the transparent baffle 2 Shaped smoke inlet hole 3, the body 1 at the far end of the smoke inlet hole 3 has a smoke exhaust hole 5, and the induced draft fan 4 is installed in the cavity of the body 1 near the smoke exhaust hole 5, and the body 1 is a flat rectangle. The cross section of the cavity of the body 1 is narrow and long, the length of the smoke inlet 3 is smaller than the width of the transparent baffle 2, the smoke exhaust hole 5 and the induced draft fan 4 are above the smoke inlet 3, and it is an upper exhaust type range hood , the transparent baffle 2 is made of high-temperature-resistant glass, and there is a frame 6 around the transparent baffle 2. Slideways are installed on both sides of the...

example 2

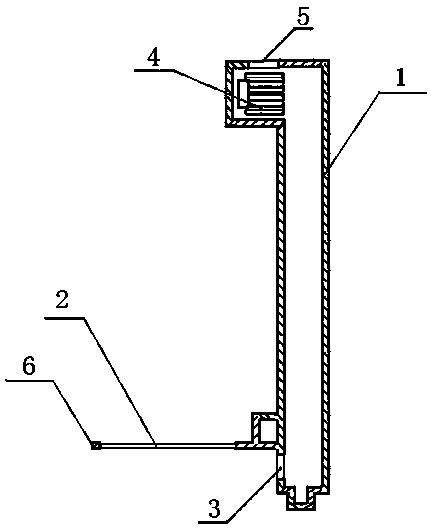

[0021] The device of the present invention is composed of a body 1, a transparent baffle 2 and an induced draft fan 4, the transparent baffle 2 is horizontally installed on the body 1, the inside of the body 1 is a cavity, and a horizontal bar is opened on the body 1 below the transparent baffle 2 Shaped smoke inlet hole 3, the body 1 at the far end of the smoke inlet hole 3 has a smoke exhaust hole 5, and the induced draft fan 4 is installed in the cavity of the body 1 near the smoke exhaust hole 5, and the body 1 is a flat rectangle. The cavity cross section of the body 1 is long and narrow, the length of the smoke inlet 3 is smaller than the width of the transparent baffle 2, and the smoke exhaust hole 5 and the induced draft fan 4 are below the smoke inlet 3, which is a bottom exhaust type range hood. The transparent baffle 2 is made of double-layer hollow glass, and a glass decorative painting is pasted on the body 1. There are frames 6 around the transparent baffle 2, sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com