Underground coal mine fully mechanized mining face end mining and rapid withdrawing method

A technology of fully mechanized mining face and fully mechanized mining face, which is applied in the field of final mining and rapid withdrawal of fully mechanized mining face in underground coal mines. operation, realize environmental protection emission, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

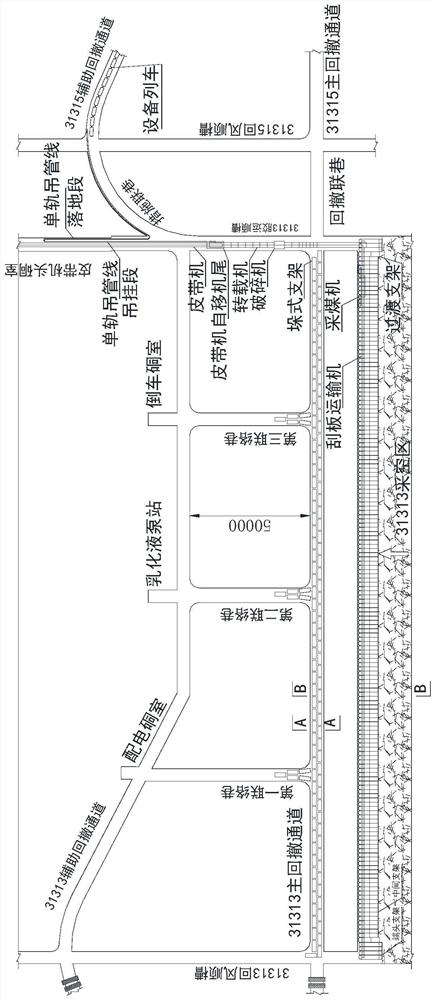

[0074] This embodiment takes the 31313 fully mechanized mining face of Chahasu Coal Mine as an example, and adopts the roadway design and withdrawal mode of the present invention to illustrate.

[0075] Chahasu Coal Mine 31313 fully mechanized mining face: the width of the face is 290 meters, and the average mining height is 5.2 meters. The face is equipped with a scraper conveyor (300 meters), a shearer, and 170 hydraulic supports; On the side of the connected rubber transport trough, there are reloaders and belt conveyors installed. There are monorail cranes (maximum length 150 meters, minimum length 75 meters) and equipment trains (including 38 carriages, 200 meters); the advancing length of 31313 fully mechanized mining face is 3009 meters.

[0076] 1. Retraction roadway design:

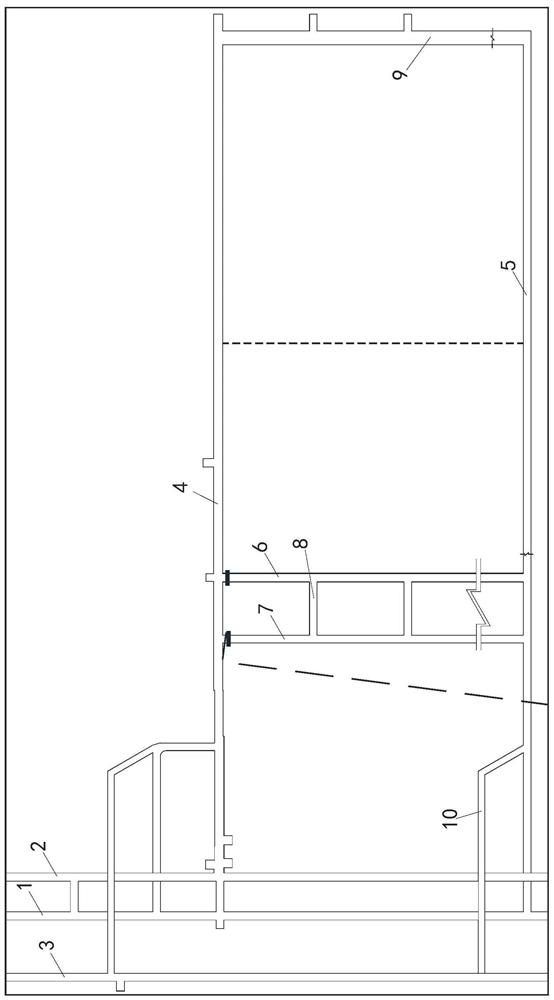

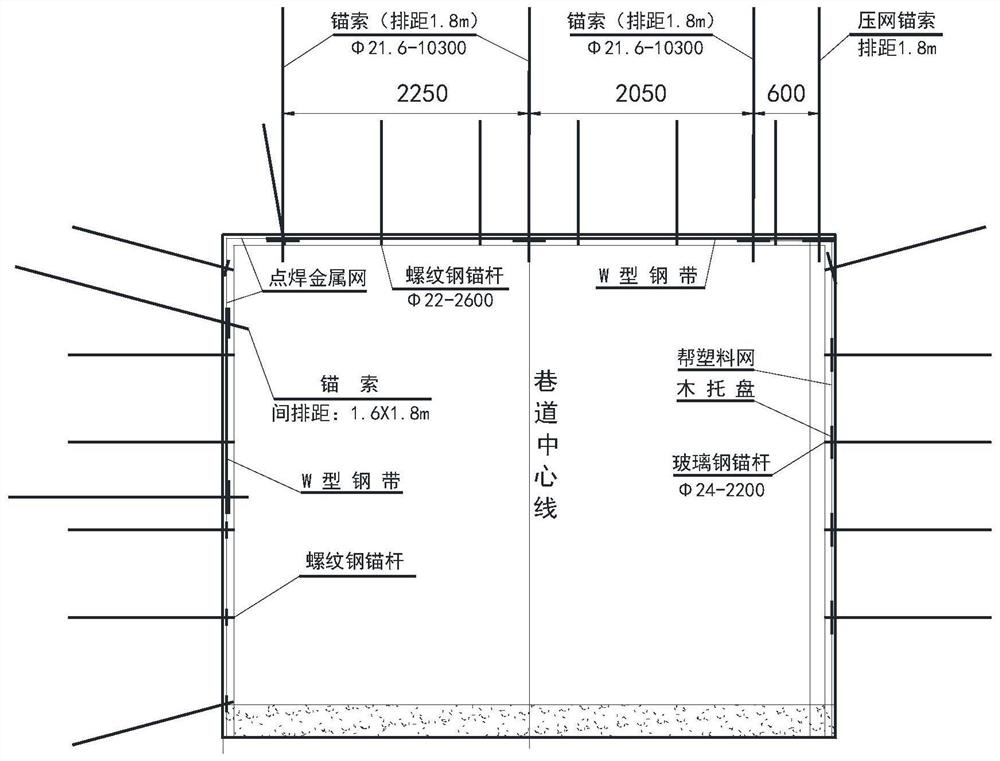

[0077] Such as figure 2 As shown, the final mining and withdrawal of the fully-mechanized mining face of the underground coal mine adopts the reserved double-channel multi-head retraction oper...

Embodiment 2

[0115] This embodiment takes the 31307 fully mechanized mining face of Chahasu Coal Mine as an example, and adopts traditional roadway design and retraction mode of operation for illustration.

[0116] Chahasu Coal Mine 31307 fully mechanized mining face: the width of the working face is 290 meters, the average mining height is 5.05 meters, the working face is equipped with a scraper conveyor (300 meters), a shearer, and 170 hydraulic supports; On the side of the connected rubber transport trough, there are reloaders and belt conveyors installed. There are monorail cranes (maximum length 150 meters, minimum length 75 meters) and equipment trains (including 38 carriages, 200 meters); the advancing length of 31309 fully mechanized mining face is 4150 meters.

[0117] 1. Retraction roadway design:

[0118] Such as Figure 12 As shown, the final mining and withdrawal of the fully-mechanized mining face of the underground coal mine adopts the reserved double-channel multi-head re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com