Environmentally-friendly cereal impurity removing and drying integrated machine

An integrated machine and grain technology, applied in dryers, drying, drying of solid materials, etc., can solve the problems of no impurity removal function and single function of the drying device, and achieve faster drying rate, faster drying rate, The effect of increasing the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is further described in detail through specific implementation methods:

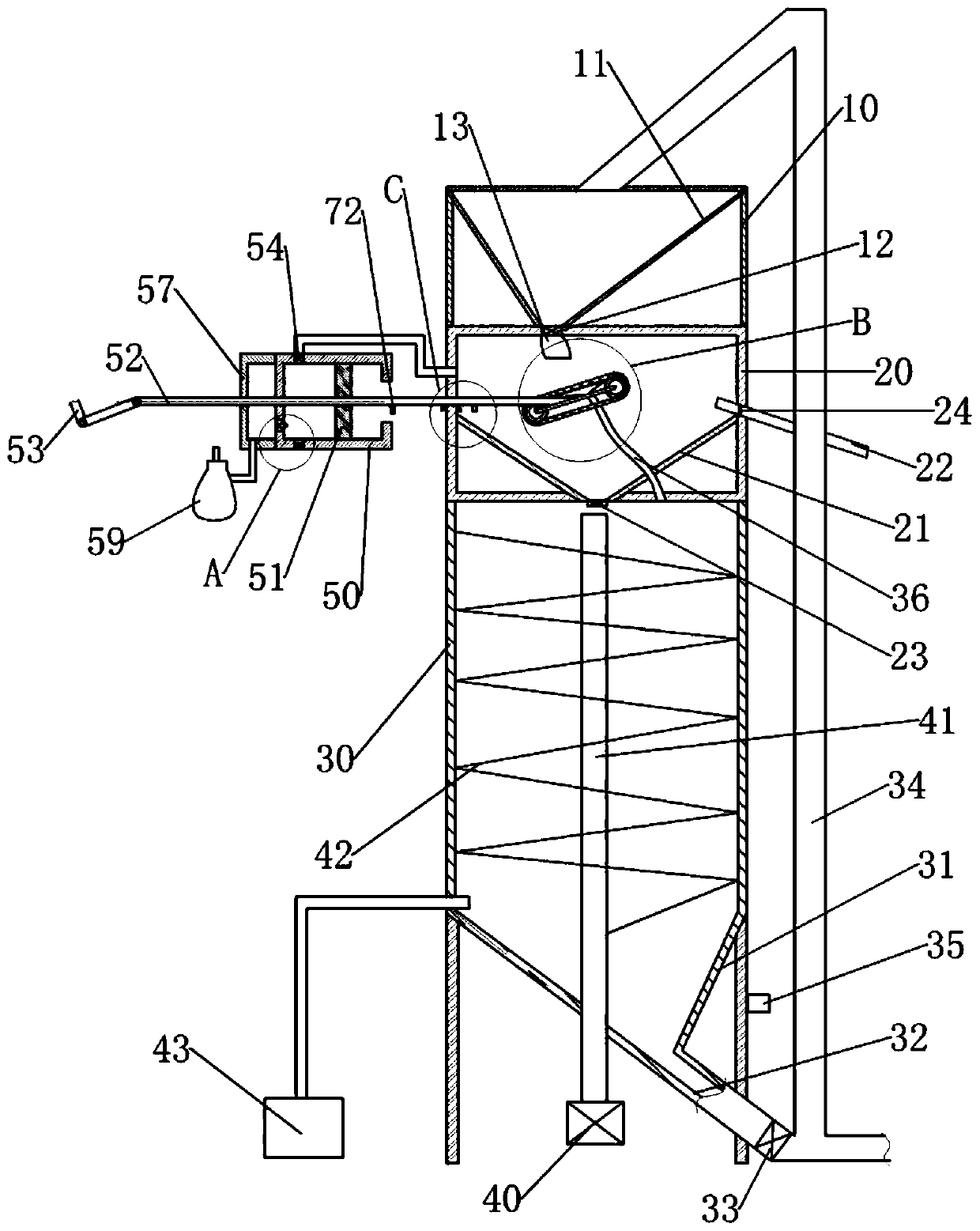

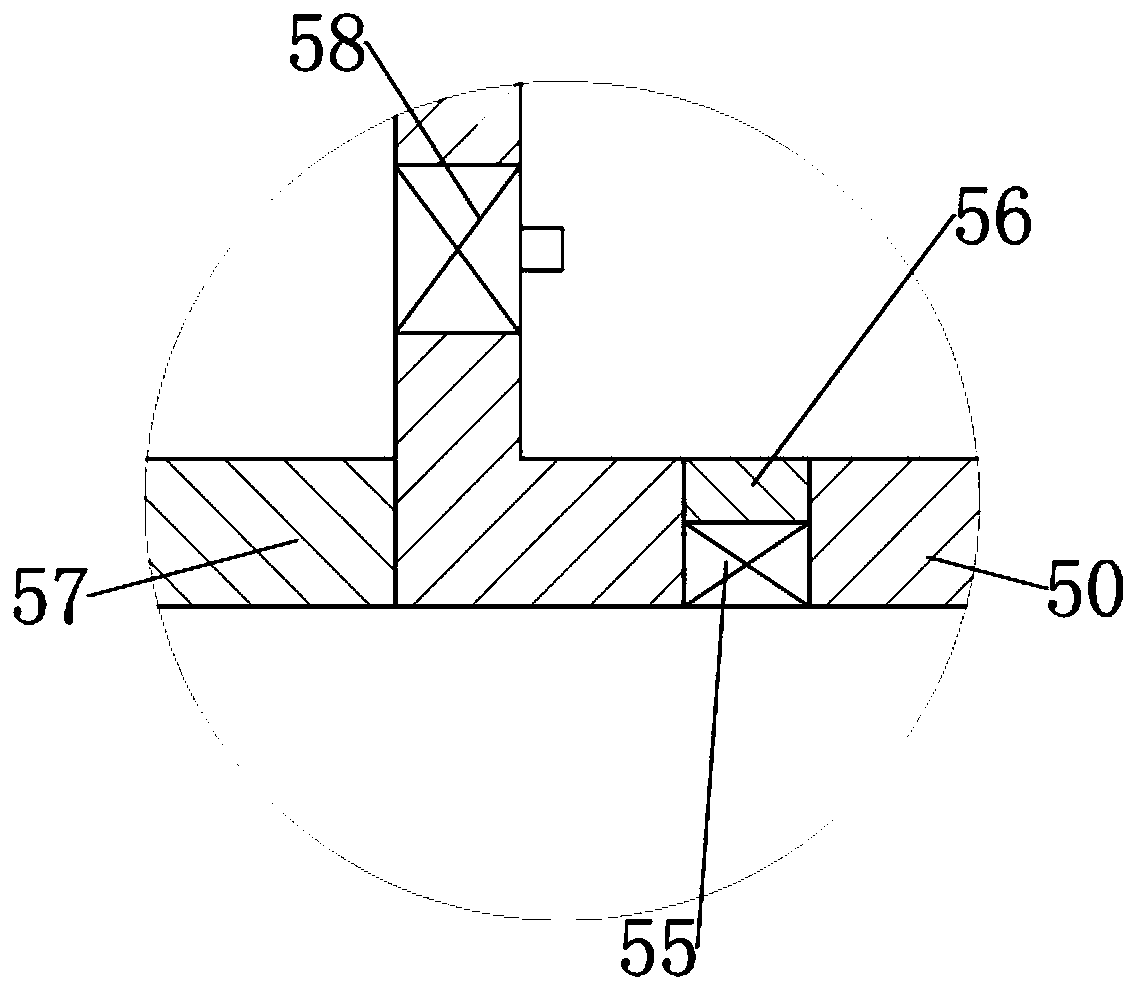

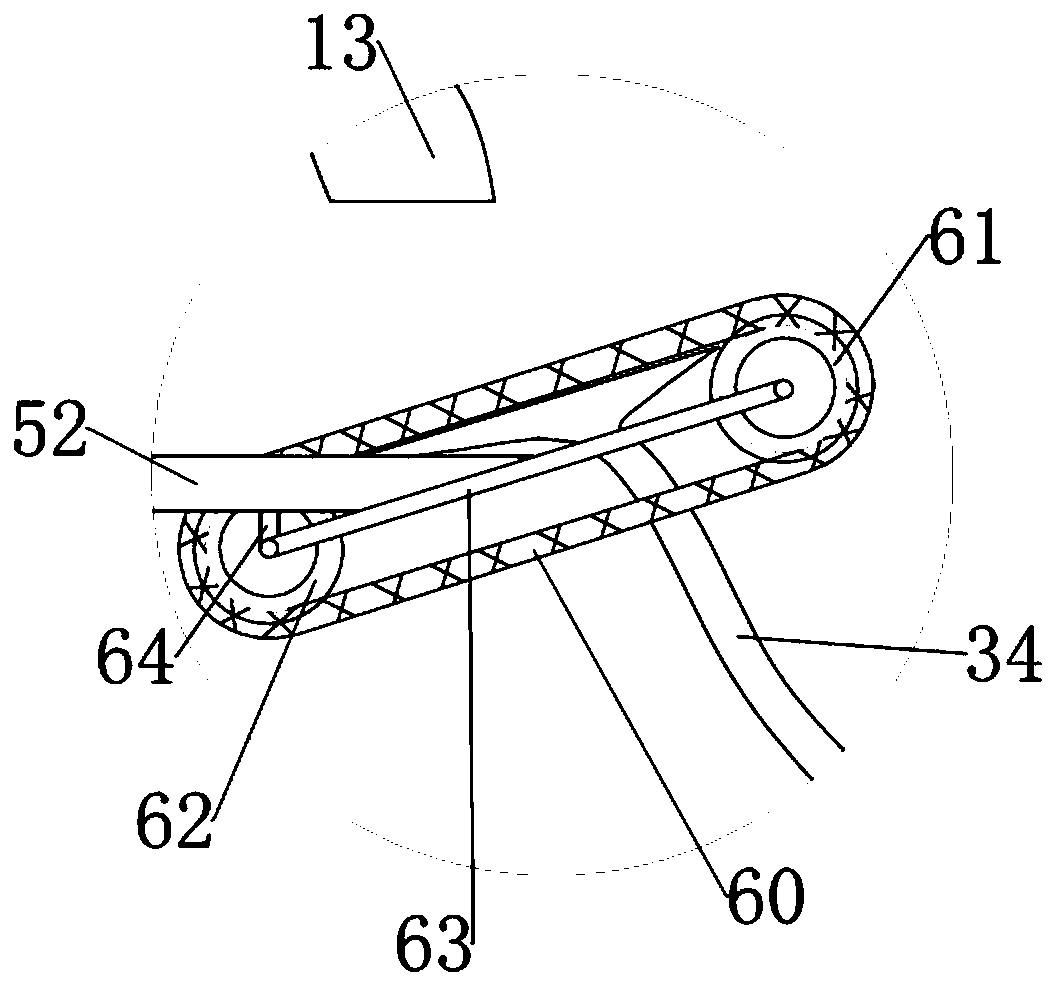

[0036] The reference signs in the accompanying drawings of the description include: feed box 10, feed hopper 11, first automatic valve 12, guide cylinder 13, miscellaneous removal box 20, lower hopper 21, chute 22, second automatic valve 23, plug Plate 24, drying box 30, discharge hopper 31, discharge pipe 32, third automatic valve 33, bucket elevator 34, third automatic valve switch 35, hose 36, first motor 40, rotating rod 41, screw screen Plate 42, hot blast stove 43, cylinder body 50, piston 51, piston rod 52, crank 53, one-way inlet valve 54, one-way air outlet valve 55, filter screen 56, dust collection chamber 57, press valve 58, cloth bag 59, Conveyor belt 60, first pulley 61, second pulley 62, inclined bar 63, vertical bar 64, first contact block 70, first automatic valve switch 71, second contact block 72, second automatic valve switch 73.

[0037] The embodiment is basica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com